Test: RCC- 1 - SSC JE MCQ

20 Questions MCQ Test - Test: RCC- 1

The critical section for determining the maximum bending moment for footing supporting a concrete column is located:

A doubly reinforced beam is considered less economical than a singly reinforced beam because:

The maximum permissible size of aggregates to be used in casting the ribs of a slab, is

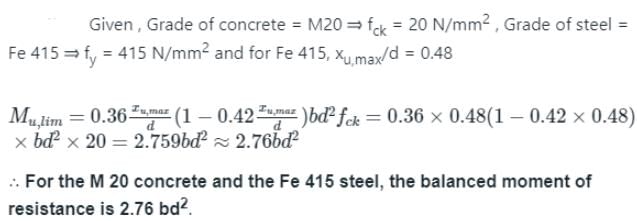

For the M 20 concrete and the Fe 415 steel, the balanced moment of resistance is:

For normal cases, stiffness of a simply supported beam is satisfied if the ratio of its span to its overall depth does not exceed

As stipulated in IS: 456 – 2000, some assumptions are considered in the computation of ultimate flexural strength of reinforce concrete section. Of the four options given below, the odd one is to be marked.

Which of the following statements is true?

A. Most of the loads applied to a building are environmental load.

B. Most of the loads are dead followed by live loads.

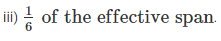

The effective span, of cantilever slab at the end of a continuous slab is:

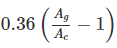

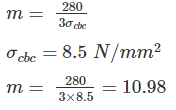

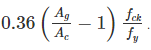

Which one of the following represents the ratio of volume of helical reinforcement to volume of core if  = 1, concrete is M 20 and steel is Fe 415.

= 1, concrete is M 20 and steel is Fe 415.

When a number of columns in a row are provided with a long and narrow combined footing, the footing is termed as

The highway bridges shall not be considered to be carrying any live load when the wind velocity at deck level exceeds:

So, ratio is 1 × 20/415 = 0.048

So, ratio is 1 × 20/415 = 0.048