Test: Machining Processes - 1 - Mechanical Engineering MCQ

10 Questions MCQ Test Topicwise Question Bank for Mechanical Engineering - Test: Machining Processes - 1

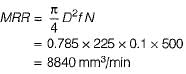

A hole is being drilled in a block of magnesium alloy with a 15 mm drill at a feed of 0.1 mm/rev. The spindle is running at 500 rpm. What is the MW? (in mm3/min)?

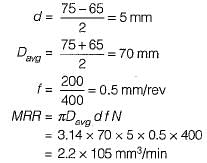

A 150 mm-long, 75 mm-diameter titanium-alloy rod is being reduced in diameter to 65 mm by turning on a lathe in one pass. The spindle rotates at 400 rpm and the tool is traveling at an axial velocity of 200 mm/min. Calculate the MRR.

The regulating wheel of a centreless grinder is rotating at a surface speed of 127 mm/s and is inclined at an angle of 5°, Calculate the feed rate of material past the grinding wheel. [sin5° = 0.087, cos5° = 0.996]

Consider the following statements:

Flutes are made in the drill:

1. To curl the chip lightly for easier removal

2. To allow the coolant and lubricant to get down to the cutting edge

3. To form the channels through which chips can escape from the hole

Which of these statements are correct?

What does 36 denote in the following marking of the grinding wheel?

5 1 A 36 L 5 V 2 3

Which one of the following gear manufacturing processes is not based on generation principle?

In a shaping operation, the average cutting speed Is (stroke length S, number of strokes per minute N, quick return ration R)

Stroke of a shaping machine is 250 mm. It makes 30 double strokes per minute. Overall average speed of operation is

|

45 videos|314 tests

|