Test: Machining Processes - 3 - Mechanical Engineering MCQ

30 Questions MCQ Test Topicwise Question Bank for Mechanical Engineering - Test: Machining Processes - 3

Gear shaping is a process of manufacturing gears. Which one of the following principles is employed by it?

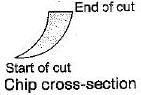

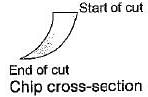

Which of the following is an example of orthogonal cutting?

The cutting tool that performs orthogonal cutting is

For cutting of brass with single-point cutting tool on a lathe, tool should have

Which among the following is slowest speed operation in lathe?

Which of the following uses a single point cutting tool?

Lip angle of a single point tool is generally in the range.

In planetary milling machine, the work and cutter respectively.

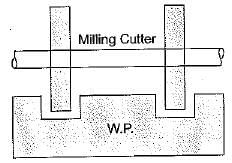

Milling operation which produces flat vertical surfaces on both side of a work piece is known as

In milling machine, the cutting tool is held in position by

In which of the following milling machine, the table can be tilted in a vertical plane by providing a swivel arrangement at the knee

In case of straddle milling the number of side milling cutters mounted on arbor is/are

In which of the following milling operation cutter is rotated in the same direction of travel of work piece

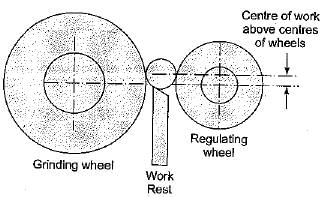

Soft materials can not be economically grinded due to

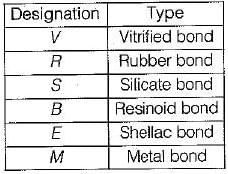

In the Grinding wheel of A 60 Gr7 B 23, B stand for

Which one of the following grinding wheels (with grade, grit and bond) is suitable for cutter grinding?

Force on individual grain of a grinding wheel is proportional to the

Which one of the following materials is used as a bonding materials for grinding wheels?

In grinding operation for faster and bulk material removal

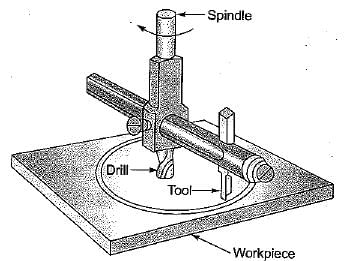

The broaching operation in which the work moves past the stationary tool is called

The broaching operation in which either the work or tool moves across the other, is known as

|

45 videos|314 tests

|