Test: Cold Working, Recrystallisation, Rolling & Forging - 2 - Mechanical Engineering MCQ

30 Questions MCQ Test GATE Mechanical (ME) Mock Test Series 2025 - Test: Cold Working, Recrystallisation, Rolling & Forging - 2

For mild steel, the hot forging temperature range is

Assertion (A): Hot working does not produce strain hardening.

Reason (R): Hot working is done above the re-crystallization temperature.

Reason (R): Hot working is done above the re-crystallization temperature.

| 1 Crore+ students have signed up on EduRev. Have you? Download the App |

A strip is to be rolled from a thickness of 30 mm to 15 mm using a two-high mill having rolls ofdiameter 300 mm. The coefficient of friction for unaided bite should nearly be

Assertion (A): In a two high rolling mill there is a limit to the possible reduction in thickness in one pass.

Reason (R): The reduction possible in the second pass is less than that in the first pass.

Which one of the following is an advantage of forging?

Consider the following statements related to forging:

1. Flash is excess material added to stock which flows around parting line.

2. Flash helps in filling of thin ribs and bosses in upper die.

3. Amount of flash depends upon forging force.

Q.

Which of the above statements are correct?

Hot rolling of mild steel is carried out

Assertion (A): There is good grain refinement in hot working.

Reason (R): In hot working physical properties are generally improved.

Assertion (A): Plastic deformation in metals and alloys is a permanent deformation under load. This property is useful in obtaining products by cold rolling.

Reason (R): Plastic or permanent deformation in metal or alloy is caused by movement or dislocations.

The blank diameter used in thread rolling will be

Assertion (A): Rolling requires high friction which increases forces and power consumption.

Reason (R): To prevent damage to the surface of the rolled products, lubricants should be used.

Match List I (Different systems) with List II (Associated terminology) and select the correct answer using the codes given below the Lists:

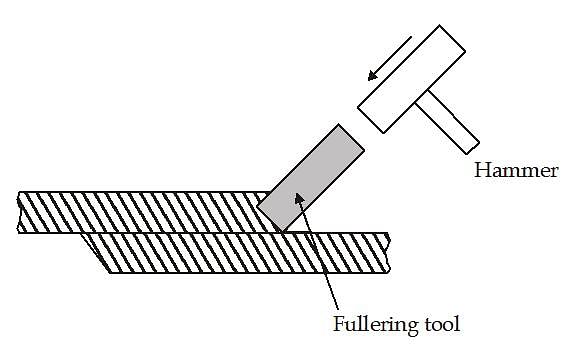

Consider the following steps involved in hammer forging a connecting rod from bar stock:

1. Blocking 2 . Trimming 3. Finishing 4. Fullering 5. Edging

Q.

Which of the following is the correct sequence of operations?

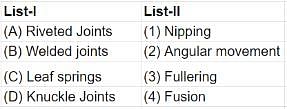

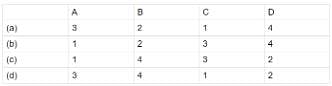

Match List I (Forging operations) with List II (Descriptions) and select the correct answer using the codes given below the Lists:

Codes: A B C D A B C D

(a) 3 2 1 4 (b) 4 1 2 3

(b) 3 1 2 4 (d) 4 2 1 3

In a rolling process, sheet of 25 mm thickness is rolled to 20 mm thickness. Roll is of diameter 600 mm and it rotates at 100 rpm. The roll strip contact length will be

In a single pass rolling operation, a 20 mm thick plate with plate width of 100 mm, is reduced to 18 mm. The roller radius is 250 mm and rotational speed is 10 rpm. The average flow stress for the plate material is 300 MPa. The power required for the rolling operation in kWis closest to

An imaginary circle which by pure rolling action, gives the same motion as the actual gear,and is called

Consider the following operations involved in forging a hexagonal bolt from a round bar stock, whose diameter is equal to the bolt diameter:

1. Flattening 2. Upsetting 3. Swaging 4. Cambering

Q.

The correct sequence of these operations is

Match List I (Type of Forging) with List II (Operation) and select the correct answer using the code given below the Lists:

Code:

A B C D A B C D

(a) 4 1 2 3 (b) 3 2 1 4

(c) 4 2 1 3 (d) 3 1 2 4

Assertion (A): In drop forging besides the provision for flash, provision is also to be made in the forging die for additional space called gutter.

Reason (R): The gutter helps to restrict the outward flow of metal thereby helping to fill thin ribs and bases in the upper die.

Consider the following characteristics of rolling process:

1. Shows work hardening effect

2. Surface finish is not good

3. Heavy reduction in areas can be obtained

Q.

Which of these characteristics are associated with hot rolling?

Rolling very thin strips of mild steel requires

A strip with a cross-section 150 mm x 4.5 mm is being rolled with 20% reduction of areausing 450 mm diameter rolls. The angle subtended by the deformation zone at the roll centre is(in radian)

Match List - I (products) with List - II (processes) and select the correct answer using the

codes given below the lists:

Codes: A B C D A B C D

(a) 1 2 3 4 (b) 4 3 2 1

(b) 1 2 4 3 (d) 4 3 1 2

The bending force required for V-bending, U-bending and Edge-bending will be in the ratio of

Which one of the following processes is most commonly used for the forging of bolt heads of hexagonal shape?

A steel wheel of 600 mm diameter rolls on a horizontal steel rail. It carries a load of 500 N.The coefficient of rolling resistance is 0.3 mm. The force in N, necessary to roll the wheel along the rail is

In one setting of rolls in a 3-high rolling mill, one gets

The forging defect due to hindrance to smooth flow of metal in the component called 'Lap'occurs because

Match List I (Different systems) with List II (Associated terminology) and select the correct

answer using the codes given below the Lists:

|

29 docs|220 tests

|

|

29 docs|220 tests

|