Test: Heat Exchanger Level - 3 - Chemical Engineering MCQ

10 Questions MCQ Test - Test: Heat Exchanger Level - 3

Dry saturated steam at 10 bars and 180oC enters a condenser (counter flow heat exchanger) at the rate of 15 kg/s and leaves at 300oC . The hot gas enters at 600oC with mass flow rate of 25 kg/s. If the condenser tubes are 30 mm in diameter and 3 m long, make calculations for the heat exchange area correct upto two decimal places. Neglect the resistance offered by the metallic tubes Take the following properties for steam and gas For steam

tsat = 180oC (at 10 bar)

cps = 2.7 kj/kg - K

hs = 600 W/m2 - oC

For gas

cpg = 1kj/kg -K

hg = 250 W/m2-oC

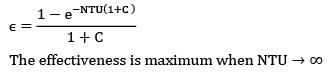

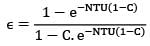

Hot water having specific heat 4200 j/kg-K flows through a heat exchanger at the rate of 4 kg/min with an inlet temperature of . The cold fluid having a specific heat 2400 j/kg-K flows at a rate of 8 kg/min with inlet temperature . Make calculations for the maximum possible effectiveness if the arrangement of fluid flow is parallel flow.

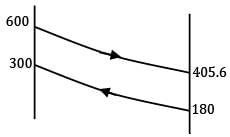

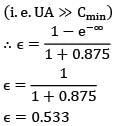

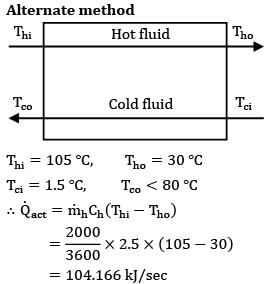

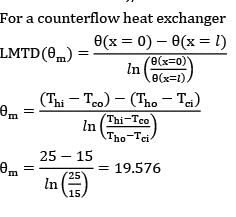

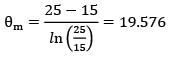

A counter flow heat exchanger is used to cool 2000 kg/hr of oil (cp = 2.5kj/kg-K) from 105oC to 30oC by use of water that

enters the heat exchanger with a temperature of 15oC. If the overall heat transfer coefficient is expected to be 1.5 kW/m2-.K , make calculations for the surface area required, presume that the exit temperature of the water is not to exceed 80oC.

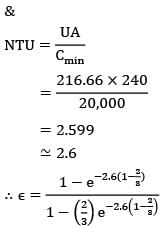

Water (sp. heat = 4kj/kg -K) enters a counter flow heat exchanger (both fluids unmixed) at

15oC and flows at the rate of 7.5 kg/s . It cools air (cp = 2kj/kg-K) flowing at the rate of 10 kg/s from an inlet temperature of 120oC. For an overall heat transfer coefficient 216.66 W/m2-K. and an exchanger surface area of 240 m2, determine the LMTD for the heat exchanger?

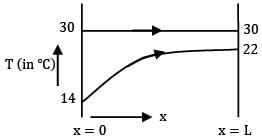

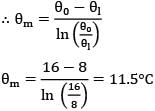

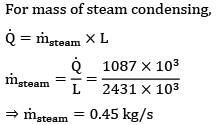

Steam in the condenser of a power plant is to be condensed at a temperature of 30oC with cooling water from a nearby lake, which enters the tubes of the condenser at 14oC and leaves at 22oC. The surface area of the tubes is 45m2 , and the overall heat transfer coefficient is 2100 W/m2-K. Determine the rate of condensation of the steam in the condenser. Take latent heat of vaporization of water as 2431 kJ/kg?

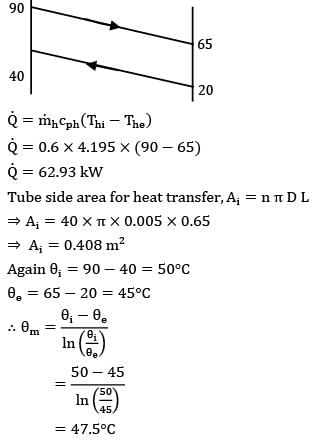

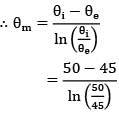

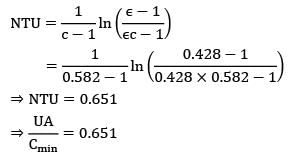

A test is conducted to determine the overall heat transfer coefficient in an automotive radiator that is a water-to-air heat exchanger with both fluids (air and water) unmixed. The radiator has 40 tubes of internal diameter 0.5 cm and length 65 cm in a closely spaced platefinned matrix. Hot water enters the tubes at 90oC at a rate of 0.6 kg/s and leaves at 60oC. Air flows across the radiator through the inter-fin spaces and is heated from 20oC to 40oC. Determine the overall heat transfer coefficient (in kW/m2-K) of this radiator based on the inner surface area of the tubes. Take specific heat of water as 4.195 kJ/kg-K? Consider the heat exchanges to be counter flow.

A counter flow double pipe heat exchanger is to heat water from 20oC to 80oC at a rate of 1.2kg/s. The heating is to be accomplished by geo-thermal water available at 160oC at a mass flow rate of 2 kg/s. The inner tube is thin-walled and has a diameter of 1.5 cm. The overall heat transfer coefficient of the heat exchanger is 620 W/m2-K . Determine the length of the heat exchanger required to achieve the desired heating. Given

NTU =  specific heat of water is 4.18 Kj/kg-K and for geothermal water is 4.31 Kj/kg-K.

specific heat of water is 4.18 Kj/kg-K and for geothermal water is 4.31 Kj/kg-K.

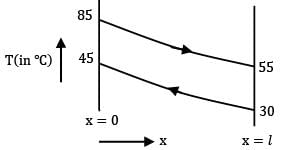

A double pipe counter flow heat exchanger is to be designed to cool 12000 kg/hr of an oil of specific heat 1.95 Kj/Kg-K . from 85oC to 55oC by water entering the heat exchanger at 30oC and leaving at 45oC . If the overall heat transfer coefficient of heat exchanger is 400 W/m2-. K Calculate the surface area of the heat exchanger.

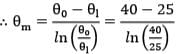

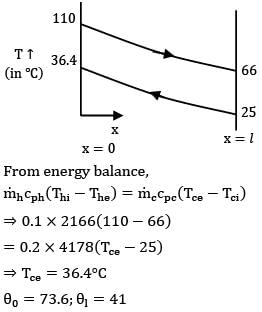

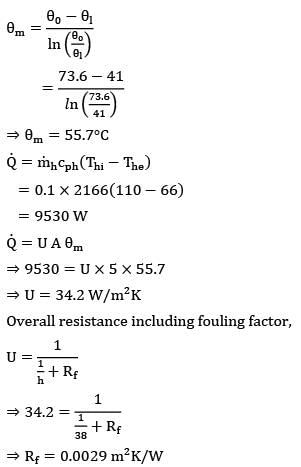

A counter flow, concentric tube heat exchanger used for engine cooling has been in service for an extended period of time. The heat transfer surface area of the exchanger is , 5 m2 and the design value of the overall convection coefficient is 38 W/m2. During a test run, engine oil flowing at 0.1 kg/s. is cooled from 110oC 66oC by water supplied at a temperature of 25oC and a flow rate of 0.2kg/s. Calculate the fouling factor,

Rf”(m2 - K/W).

Given for engine oil c = 2166j/kg-K;

& for water c = 4178 j/kg-K

The condenser of a large steam power plant is a shell-and-tube heat exchanger having a single shell and 30,000 tubes, with each tube making two passes. The tubes are thin-walled with 25 mm diameter and steam condenses on the outside of the tube with ho= 11kW.m2-K. The cooling water flowing through the tubes at a rate of 30,000 kg/s and the heat transfer rate is 2 GW. Water enters at 20oC while steam condenses at 50oC. Find the length of the tubes in one pass, properties of water at are

cp = 4.18 kj/kg-K, μ = 855 x 10-6 N-s/m2

K = 0.613 W/m-K and Pr = 5.83.

Given that for laminar flow through pipes corresponding Nusselt number is 4.0 and for turbulent flow,

it is Nu = 0.023  Pr0.4.

Pr0.4.

(B) 4.55

= 21oC

= 21oC