Mechanical Engineering Exam > Mechanical Engineering Questions > Misrun is a casting defect which occur due to...

Start Learning for Free

Misrun is a casting defect which occur due to

- a)very high pouring temperature of the metal

- b)insufficient fluidity of molten metal

- c)absorption of gases by the liquid metal

- d)improper alignment of moulds flasks

Correct answer is option 'B'. Can you explain this answer?

Verified Answer

Misrun is a casting defect which occur due toa)very high pouring tempe...

Misrun is a casting defect caused due to insufficient fluidity of molten metal.

Most Upvoted Answer

Misrun is a casting defect which occur due toa)very high pouring tempe...

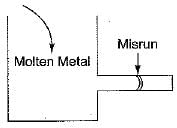

Misrun Casting Defect

Misrun is a casting defect that occurs when the molten metal does not completely fill the mold cavity during the casting process. This defect can have a significant impact on the quality and integrity of the final cast product. There are several factors that can contribute to the occurrence of misrun defects, but one of the primary causes is the insufficient fluidity of the molten metal.

Insufficient Fluidity of Molten Metal

The fluidity of molten metal refers to its ability to flow and fill the mold cavity properly. If the molten metal has low fluidity, it may not be able to reach all the corners and intricacies of the mold cavity, resulting in incomplete filling and the formation of misrun defects.

Causes of Insufficient Fluidity

There are several factors that can lead to insufficient fluidity of the molten metal:

1. Low Pouring Temperature: If the pouring temperature of the metal is too low, it can cause the molten metal to solidify before it completely fills the mold cavity. This can result in misrun defects.

2. High Viscosity: The viscosity of the molten metal is directly related to its fluidity. If the metal has a high viscosity, it will have poor flowability and may not be able to fill the mold cavity properly.

3. Improper Alloy Composition: The composition of the metal alloy can also affect its fluidity. Some alloy compositions may have inherently low fluidity, making them more prone to misrun defects.

4. Inadequate Pouring Technique: The pouring technique used during the casting process can also impact the fluidity of the molten metal. If the metal is poured too slowly or with insufficient force, it may not be able to flow properly and fill the mold cavity completely.

Prevention of Misrun Defects

To prevent misrun defects, it is important to address the factors that contribute to the insufficient fluidity of the molten metal. Some measures that can be taken to prevent misrun defects include:

- Ensuring the pouring temperature of the metal is appropriate for the specific alloy and casting process.

- Optimizing the alloy composition to improve fluidity.

- Using proper pouring techniques, such as pouring with sufficient force and at the right speed.

- Designing the mold cavity and gating system to facilitate proper flow and filling of the molten metal.

- Properly maintaining and preparing the mold surfaces to minimize any obstructions to the flow of the molten metal.

By addressing these factors and implementing preventive measures, the occurrence of misrun defects can be minimized, resulting in higher quality castings.

Misrun is a casting defect that occurs when the molten metal does not completely fill the mold cavity during the casting process. This defect can have a significant impact on the quality and integrity of the final cast product. There are several factors that can contribute to the occurrence of misrun defects, but one of the primary causes is the insufficient fluidity of the molten metal.

Insufficient Fluidity of Molten Metal

The fluidity of molten metal refers to its ability to flow and fill the mold cavity properly. If the molten metal has low fluidity, it may not be able to reach all the corners and intricacies of the mold cavity, resulting in incomplete filling and the formation of misrun defects.

Causes of Insufficient Fluidity

There are several factors that can lead to insufficient fluidity of the molten metal:

1. Low Pouring Temperature: If the pouring temperature of the metal is too low, it can cause the molten metal to solidify before it completely fills the mold cavity. This can result in misrun defects.

2. High Viscosity: The viscosity of the molten metal is directly related to its fluidity. If the metal has a high viscosity, it will have poor flowability and may not be able to fill the mold cavity properly.

3. Improper Alloy Composition: The composition of the metal alloy can also affect its fluidity. Some alloy compositions may have inherently low fluidity, making them more prone to misrun defects.

4. Inadequate Pouring Technique: The pouring technique used during the casting process can also impact the fluidity of the molten metal. If the metal is poured too slowly or with insufficient force, it may not be able to flow properly and fill the mold cavity completely.

Prevention of Misrun Defects

To prevent misrun defects, it is important to address the factors that contribute to the insufficient fluidity of the molten metal. Some measures that can be taken to prevent misrun defects include:

- Ensuring the pouring temperature of the metal is appropriate for the specific alloy and casting process.

- Optimizing the alloy composition to improve fluidity.

- Using proper pouring techniques, such as pouring with sufficient force and at the right speed.

- Designing the mold cavity and gating system to facilitate proper flow and filling of the molten metal.

- Properly maintaining and preparing the mold surfaces to minimize any obstructions to the flow of the molten metal.

By addressing these factors and implementing preventive measures, the occurrence of misrun defects can be minimized, resulting in higher quality castings.

|

Explore Courses for Mechanical Engineering exam

|

|

Question Description

Misrun is a casting defect which occur due toa)very high pouring temperature of the metalb)insufficient fluidity of molten metalc)absorption of gases by the liquid metald)improper alignment of moulds flasksCorrect answer is option 'B'. Can you explain this answer? for Mechanical Engineering 2025 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about Misrun is a casting defect which occur due toa)very high pouring temperature of the metalb)insufficient fluidity of molten metalc)absorption of gases by the liquid metald)improper alignment of moulds flasksCorrect answer is option 'B'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2025 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for Misrun is a casting defect which occur due toa)very high pouring temperature of the metalb)insufficient fluidity of molten metalc)absorption of gases by the liquid metald)improper alignment of moulds flasksCorrect answer is option 'B'. Can you explain this answer?.

Misrun is a casting defect which occur due toa)very high pouring temperature of the metalb)insufficient fluidity of molten metalc)absorption of gases by the liquid metald)improper alignment of moulds flasksCorrect answer is option 'B'. Can you explain this answer? for Mechanical Engineering 2025 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about Misrun is a casting defect which occur due toa)very high pouring temperature of the metalb)insufficient fluidity of molten metalc)absorption of gases by the liquid metald)improper alignment of moulds flasksCorrect answer is option 'B'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2025 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for Misrun is a casting defect which occur due toa)very high pouring temperature of the metalb)insufficient fluidity of molten metalc)absorption of gases by the liquid metald)improper alignment of moulds flasksCorrect answer is option 'B'. Can you explain this answer?.

Solutions for Misrun is a casting defect which occur due toa)very high pouring temperature of the metalb)insufficient fluidity of molten metalc)absorption of gases by the liquid metald)improper alignment of moulds flasksCorrect answer is option 'B'. Can you explain this answer? in English & in Hindi are available as part of our courses for Mechanical Engineering.

Download more important topics, notes, lectures and mock test series for Mechanical Engineering Exam by signing up for free.

Here you can find the meaning of Misrun is a casting defect which occur due toa)very high pouring temperature of the metalb)insufficient fluidity of molten metalc)absorption of gases by the liquid metald)improper alignment of moulds flasksCorrect answer is option 'B'. Can you explain this answer? defined & explained in the simplest way possible. Besides giving the explanation of

Misrun is a casting defect which occur due toa)very high pouring temperature of the metalb)insufficient fluidity of molten metalc)absorption of gases by the liquid metald)improper alignment of moulds flasksCorrect answer is option 'B'. Can you explain this answer?, a detailed solution for Misrun is a casting defect which occur due toa)very high pouring temperature of the metalb)insufficient fluidity of molten metalc)absorption of gases by the liquid metald)improper alignment of moulds flasksCorrect answer is option 'B'. Can you explain this answer? has been provided alongside types of Misrun is a casting defect which occur due toa)very high pouring temperature of the metalb)insufficient fluidity of molten metalc)absorption of gases by the liquid metald)improper alignment of moulds flasksCorrect answer is option 'B'. Can you explain this answer? theory, EduRev gives you an

ample number of questions to practice Misrun is a casting defect which occur due toa)very high pouring temperature of the metalb)insufficient fluidity of molten metalc)absorption of gases by the liquid metald)improper alignment of moulds flasksCorrect answer is option 'B'. Can you explain this answer? tests, examples and also practice Mechanical Engineering tests.

|

Explore Courses for Mechanical Engineering exam

|

|

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.