Mechanical Engineering Exam > Mechanical Engineering Questions > What is the main advantage of hydrodynamic be...

Start Learning for Free

What is the main advantage of hydrodynamic bearing over roller bearing

- a)easy to assemble

- b)relatively low price

- c)superior load carrying capacity at higher speeds

- d)less frictional resistance

Correct answer is option 'C'. Can you explain this answer?

| FREE This question is part of | Download PDF Attempt this Test |

Verified Answer

What is the main advantage of hydrodynamic bearing over roller bearing...

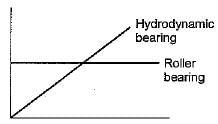

As the speed increases, load carrying capacity of hydrodynamic bearing increases.

Most Upvoted Answer

What is the main advantage of hydrodynamic bearing over roller bearing...

Advantage of Hydrodynamic Bearing over Roller Bearing: Superior Load Carrying Capacity at Higher Speeds

Introduction:

Hydrodynamic bearings and roller bearings are two commonly used types of bearings in mechanical systems. While both types have their own advantages and disadvantages, hydrodynamic bearings offer superior load carrying capacity at higher speeds compared to roller bearings. This advantage makes hydrodynamic bearings suitable for high-speed applications where heavy loads are involved.

Explanation:

1. Load Carrying Capacity:

- Hydrodynamic bearings have a higher load carrying capacity at higher speeds compared to roller bearings. This is because hydrodynamic bearings rely on a thin film of lubricant to separate the rotating surfaces, allowing them to support higher loads.

- The hydrodynamic lubrication mechanism creates a pressure gradient within the bearing, which generates a hydrodynamic lift force that counteracts the applied load. This allows hydrodynamic bearings to carry heavier loads without excessive wear or friction.

- In contrast, roller bearings have limited load carrying capacity, especially at high speeds. The contact between the rollers and the raceways can result in higher friction and wear, limiting their ability to support heavy loads.

2. Speed:

- Hydrodynamic bearings excel at high-speed applications due to their ability to maintain a stable lubricating film between the rotating surfaces.

- At higher speeds, the hydrodynamic lift force generated by the lubricant film becomes more significant, providing better load support and reducing the risk of metal-to-metal contact.

- Roller bearings, on the other hand, may experience higher friction and wear at higher speeds due to the rolling contact between the rollers and raceways. This can limit their speed capabilities and lead to premature failure.

3. Friction and Heat:

- Hydrodynamic bearings generate less friction and heat compared to roller bearings, thanks to the continuous flow of lubricant in the bearing interface.

- The lubricant film in hydrodynamic bearings reduces the direct contact between the rotating surfaces, minimizing friction and heat generation.

- In roller bearings, the rolling contact between the rollers and raceways can result in higher friction, leading to increased heat generation. This can cause premature wear and failure of the bearing.

Conclusion:

The main advantage of hydrodynamic bearings over roller bearings is their superior load carrying capacity at higher speeds. Hydrodynamic bearings can support heavier loads without excessive wear or friction, making them suitable for high-speed applications. Additionally, hydrodynamic bearings generate less friction and heat compared to roller bearings, further enhancing their performance and longevity.

Introduction:

Hydrodynamic bearings and roller bearings are two commonly used types of bearings in mechanical systems. While both types have their own advantages and disadvantages, hydrodynamic bearings offer superior load carrying capacity at higher speeds compared to roller bearings. This advantage makes hydrodynamic bearings suitable for high-speed applications where heavy loads are involved.

Explanation:

1. Load Carrying Capacity:

- Hydrodynamic bearings have a higher load carrying capacity at higher speeds compared to roller bearings. This is because hydrodynamic bearings rely on a thin film of lubricant to separate the rotating surfaces, allowing them to support higher loads.

- The hydrodynamic lubrication mechanism creates a pressure gradient within the bearing, which generates a hydrodynamic lift force that counteracts the applied load. This allows hydrodynamic bearings to carry heavier loads without excessive wear or friction.

- In contrast, roller bearings have limited load carrying capacity, especially at high speeds. The contact between the rollers and the raceways can result in higher friction and wear, limiting their ability to support heavy loads.

2. Speed:

- Hydrodynamic bearings excel at high-speed applications due to their ability to maintain a stable lubricating film between the rotating surfaces.

- At higher speeds, the hydrodynamic lift force generated by the lubricant film becomes more significant, providing better load support and reducing the risk of metal-to-metal contact.

- Roller bearings, on the other hand, may experience higher friction and wear at higher speeds due to the rolling contact between the rollers and raceways. This can limit their speed capabilities and lead to premature failure.

3. Friction and Heat:

- Hydrodynamic bearings generate less friction and heat compared to roller bearings, thanks to the continuous flow of lubricant in the bearing interface.

- The lubricant film in hydrodynamic bearings reduces the direct contact between the rotating surfaces, minimizing friction and heat generation.

- In roller bearings, the rolling contact between the rollers and raceways can result in higher friction, leading to increased heat generation. This can cause premature wear and failure of the bearing.

Conclusion:

The main advantage of hydrodynamic bearings over roller bearings is their superior load carrying capacity at higher speeds. Hydrodynamic bearings can support heavier loads without excessive wear or friction, making them suitable for high-speed applications. Additionally, hydrodynamic bearings generate less friction and heat compared to roller bearings, further enhancing their performance and longevity.

Attention Mechanical Engineering Students!

To make sure you are not studying endlessly, EduRev has designed Mechanical Engineering study material, with Structured Courses, Videos, & Test Series. Plus get personalized analysis, doubt solving and improvement plans to achieve a great score in Mechanical Engineering.

|

Explore Courses for Mechanical Engineering exam

|

|

Similar Mechanical Engineering Doubts

What is the main advantage of hydrodynamic bearing over roller bearinga)easy to assembleb)relatively low pricec)superior load carrying capacity at higher speedsd)less frictional resistanceCorrect answer is option 'C'. Can you explain this answer?

Question Description

What is the main advantage of hydrodynamic bearing over roller bearinga)easy to assembleb)relatively low pricec)superior load carrying capacity at higher speedsd)less frictional resistanceCorrect answer is option 'C'. Can you explain this answer? for Mechanical Engineering 2024 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about What is the main advantage of hydrodynamic bearing over roller bearinga)easy to assembleb)relatively low pricec)superior load carrying capacity at higher speedsd)less frictional resistanceCorrect answer is option 'C'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for What is the main advantage of hydrodynamic bearing over roller bearinga)easy to assembleb)relatively low pricec)superior load carrying capacity at higher speedsd)less frictional resistanceCorrect answer is option 'C'. Can you explain this answer?.

What is the main advantage of hydrodynamic bearing over roller bearinga)easy to assembleb)relatively low pricec)superior load carrying capacity at higher speedsd)less frictional resistanceCorrect answer is option 'C'. Can you explain this answer? for Mechanical Engineering 2024 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about What is the main advantage of hydrodynamic bearing over roller bearinga)easy to assembleb)relatively low pricec)superior load carrying capacity at higher speedsd)less frictional resistanceCorrect answer is option 'C'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for What is the main advantage of hydrodynamic bearing over roller bearinga)easy to assembleb)relatively low pricec)superior load carrying capacity at higher speedsd)less frictional resistanceCorrect answer is option 'C'. Can you explain this answer?.

Solutions for What is the main advantage of hydrodynamic bearing over roller bearinga)easy to assembleb)relatively low pricec)superior load carrying capacity at higher speedsd)less frictional resistanceCorrect answer is option 'C'. Can you explain this answer? in English & in Hindi are available as part of our courses for Mechanical Engineering.

Download more important topics, notes, lectures and mock test series for Mechanical Engineering Exam by signing up for free.

Here you can find the meaning of What is the main advantage of hydrodynamic bearing over roller bearinga)easy to assembleb)relatively low pricec)superior load carrying capacity at higher speedsd)less frictional resistanceCorrect answer is option 'C'. Can you explain this answer? defined & explained in the simplest way possible. Besides giving the explanation of

What is the main advantage of hydrodynamic bearing over roller bearinga)easy to assembleb)relatively low pricec)superior load carrying capacity at higher speedsd)less frictional resistanceCorrect answer is option 'C'. Can you explain this answer?, a detailed solution for What is the main advantage of hydrodynamic bearing over roller bearinga)easy to assembleb)relatively low pricec)superior load carrying capacity at higher speedsd)less frictional resistanceCorrect answer is option 'C'. Can you explain this answer? has been provided alongside types of What is the main advantage of hydrodynamic bearing over roller bearinga)easy to assembleb)relatively low pricec)superior load carrying capacity at higher speedsd)less frictional resistanceCorrect answer is option 'C'. Can you explain this answer? theory, EduRev gives you an

ample number of questions to practice What is the main advantage of hydrodynamic bearing over roller bearinga)easy to assembleb)relatively low pricec)superior load carrying capacity at higher speedsd)less frictional resistanceCorrect answer is option 'C'. Can you explain this answer? tests, examples and also practice Mechanical Engineering tests.

|

Explore Courses for Mechanical Engineering exam

|

|

Suggested Free Tests

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.