Class 11 Exam > Class 11 Questions > Bearing:Bearings are used to convert sliding...

Start Learning for Free

Bearing:

Bearings are used to convert sliding friction into rolling friction. Metal-upon-metal contact produces large amounts of friction. The friction adds to wear and tear of the metal, producing grinding that slowly degrades the metal. Bearings reduce friction by having the two surfaces roll over each other. They consist of a smooth metal ball or roller that rolls against a smooth inner and outer metal surface. The rollers or balls take the load, allowing by the device to spin. The two basic types of rolling element distinguish the two basic types of rolling bearing:

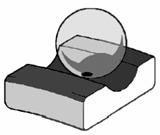

• ball → ball bearing

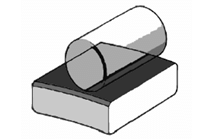

• roller → roller bearing

Balls make point contact with the ring raceways. With increasing load acting on the bearing, the contact point becomes an elliptical area. The small contact area provides low rolling friction, which enables ball bearings to accommodate high speeds but also limits their load-carrying capacity.

Rollers make line contact with the ring raceways. With increasing load acting on the bearing, the contact line becomes somewhat rectangular in shape. Because of the larger contact area and the consequently higher friction, a roller bearing can accommodate heavier loads, but lower speeds, than a same-sized ball bearing.

Bearing converts

- a)Rolling friction to sliding friction by reducing area of contact

- b)Sliding friction to rolling friction by increasing area of contact

- c)Rolling friction to sliding friction by increasing area of contact

- d)Sliding friction to rolling friction by decreasing area of contact

Correct answer is option 'D'. Can you explain this answer?

| FREE This question is part of | Download PDF Attempt this Test |

Verified Answer

Bearing:Bearings are used to convert sliding friction into rolling fr...

The reason of rolling friction being much less than sliding friction is that while rolling a small portion of the moving object comes in contact with the static object.

View all questions of this test

|

Explore Courses for Class 11 exam

|

|

Similar Class 11 Doubts

Bearing:Bearings are used to convert sliding friction into rolling friction. Metal-upon-metal contact produces large amounts of friction. The friction adds to wear and tear of the metal, producing grinding that slowly degrades the metal. Bearings reduce friction by having the two surfaces roll over each other. They consist of a smooth metal ball or roller that rolls against a smooth inner and outer metal surface. The rollers or balls take the load, allowing by the device to spin. The two basic types of rolling element distinguish the two basic types of rolling bearing:• ball → ball bearing• roller → roller bearingBalls make point contact with the ring raceways. With increasing load acting on the bearing, the contact point becomes an elliptical area. The small contact area provides low rolling friction, which enables ball bearings to accommodate high speeds but also limits their load-carrying capacity.Rollers make line contact with the ring raceways. With increasing load acting on the bearing, the contact line becomes somewhat rectangular in shape. Because of the larger contact area and the consequently higher friction, a roller bearing can accommodate heavier loads, but lower speeds, than a same-sized ball bearing.Bearing convertsa)Rolling friction to sliding friction by reducing area of contactb)Sliding friction to rolling friction by increasing area of contactc)Rolling friction to sliding friction by increasing area of contactd)Sliding friction to rolling friction by decreasing area of contactCorrect answer is option 'D'. Can you explain this answer?

Question Description

Bearing:Bearings are used to convert sliding friction into rolling friction. Metal-upon-metal contact produces large amounts of friction. The friction adds to wear and tear of the metal, producing grinding that slowly degrades the metal. Bearings reduce friction by having the two surfaces roll over each other. They consist of a smooth metal ball or roller that rolls against a smooth inner and outer metal surface. The rollers or balls take the load, allowing by the device to spin. The two basic types of rolling element distinguish the two basic types of rolling bearing:• ball → ball bearing• roller → roller bearingBalls make point contact with the ring raceways. With increasing load acting on the bearing, the contact point becomes an elliptical area. The small contact area provides low rolling friction, which enables ball bearings to accommodate high speeds but also limits their load-carrying capacity.Rollers make line contact with the ring raceways. With increasing load acting on the bearing, the contact line becomes somewhat rectangular in shape. Because of the larger contact area and the consequently higher friction, a roller bearing can accommodate heavier loads, but lower speeds, than a same-sized ball bearing.Bearing convertsa)Rolling friction to sliding friction by reducing area of contactb)Sliding friction to rolling friction by increasing area of contactc)Rolling friction to sliding friction by increasing area of contactd)Sliding friction to rolling friction by decreasing area of contactCorrect answer is option 'D'. Can you explain this answer? for Class 11 2024 is part of Class 11 preparation. The Question and answers have been prepared according to the Class 11 exam syllabus. Information about Bearing:Bearings are used to convert sliding friction into rolling friction. Metal-upon-metal contact produces large amounts of friction. The friction adds to wear and tear of the metal, producing grinding that slowly degrades the metal. Bearings reduce friction by having the two surfaces roll over each other. They consist of a smooth metal ball or roller that rolls against a smooth inner and outer metal surface. The rollers or balls take the load, allowing by the device to spin. The two basic types of rolling element distinguish the two basic types of rolling bearing:• ball → ball bearing• roller → roller bearingBalls make point contact with the ring raceways. With increasing load acting on the bearing, the contact point becomes an elliptical area. The small contact area provides low rolling friction, which enables ball bearings to accommodate high speeds but also limits their load-carrying capacity.Rollers make line contact with the ring raceways. With increasing load acting on the bearing, the contact line becomes somewhat rectangular in shape. Because of the larger contact area and the consequently higher friction, a roller bearing can accommodate heavier loads, but lower speeds, than a same-sized ball bearing.Bearing convertsa)Rolling friction to sliding friction by reducing area of contactb)Sliding friction to rolling friction by increasing area of contactc)Rolling friction to sliding friction by increasing area of contactd)Sliding friction to rolling friction by decreasing area of contactCorrect answer is option 'D'. Can you explain this answer? covers all topics & solutions for Class 11 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for Bearing:Bearings are used to convert sliding friction into rolling friction. Metal-upon-metal contact produces large amounts of friction. The friction adds to wear and tear of the metal, producing grinding that slowly degrades the metal. Bearings reduce friction by having the two surfaces roll over each other. They consist of a smooth metal ball or roller that rolls against a smooth inner and outer metal surface. The rollers or balls take the load, allowing by the device to spin. The two basic types of rolling element distinguish the two basic types of rolling bearing:• ball → ball bearing• roller → roller bearingBalls make point contact with the ring raceways. With increasing load acting on the bearing, the contact point becomes an elliptical area. The small contact area provides low rolling friction, which enables ball bearings to accommodate high speeds but also limits their load-carrying capacity.Rollers make line contact with the ring raceways. With increasing load acting on the bearing, the contact line becomes somewhat rectangular in shape. Because of the larger contact area and the consequently higher friction, a roller bearing can accommodate heavier loads, but lower speeds, than a same-sized ball bearing.Bearing convertsa)Rolling friction to sliding friction by reducing area of contactb)Sliding friction to rolling friction by increasing area of contactc)Rolling friction to sliding friction by increasing area of contactd)Sliding friction to rolling friction by decreasing area of contactCorrect answer is option 'D'. Can you explain this answer?.

Bearing:Bearings are used to convert sliding friction into rolling friction. Metal-upon-metal contact produces large amounts of friction. The friction adds to wear and tear of the metal, producing grinding that slowly degrades the metal. Bearings reduce friction by having the two surfaces roll over each other. They consist of a smooth metal ball or roller that rolls against a smooth inner and outer metal surface. The rollers or balls take the load, allowing by the device to spin. The two basic types of rolling element distinguish the two basic types of rolling bearing:• ball → ball bearing• roller → roller bearingBalls make point contact with the ring raceways. With increasing load acting on the bearing, the contact point becomes an elliptical area. The small contact area provides low rolling friction, which enables ball bearings to accommodate high speeds but also limits their load-carrying capacity.Rollers make line contact with the ring raceways. With increasing load acting on the bearing, the contact line becomes somewhat rectangular in shape. Because of the larger contact area and the consequently higher friction, a roller bearing can accommodate heavier loads, but lower speeds, than a same-sized ball bearing.Bearing convertsa)Rolling friction to sliding friction by reducing area of contactb)Sliding friction to rolling friction by increasing area of contactc)Rolling friction to sliding friction by increasing area of contactd)Sliding friction to rolling friction by decreasing area of contactCorrect answer is option 'D'. Can you explain this answer? for Class 11 2024 is part of Class 11 preparation. The Question and answers have been prepared according to the Class 11 exam syllabus. Information about Bearing:Bearings are used to convert sliding friction into rolling friction. Metal-upon-metal contact produces large amounts of friction. The friction adds to wear and tear of the metal, producing grinding that slowly degrades the metal. Bearings reduce friction by having the two surfaces roll over each other. They consist of a smooth metal ball or roller that rolls against a smooth inner and outer metal surface. The rollers or balls take the load, allowing by the device to spin. The two basic types of rolling element distinguish the two basic types of rolling bearing:• ball → ball bearing• roller → roller bearingBalls make point contact with the ring raceways. With increasing load acting on the bearing, the contact point becomes an elliptical area. The small contact area provides low rolling friction, which enables ball bearings to accommodate high speeds but also limits their load-carrying capacity.Rollers make line contact with the ring raceways. With increasing load acting on the bearing, the contact line becomes somewhat rectangular in shape. Because of the larger contact area and the consequently higher friction, a roller bearing can accommodate heavier loads, but lower speeds, than a same-sized ball bearing.Bearing convertsa)Rolling friction to sliding friction by reducing area of contactb)Sliding friction to rolling friction by increasing area of contactc)Rolling friction to sliding friction by increasing area of contactd)Sliding friction to rolling friction by decreasing area of contactCorrect answer is option 'D'. Can you explain this answer? covers all topics & solutions for Class 11 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for Bearing:Bearings are used to convert sliding friction into rolling friction. Metal-upon-metal contact produces large amounts of friction. The friction adds to wear and tear of the metal, producing grinding that slowly degrades the metal. Bearings reduce friction by having the two surfaces roll over each other. They consist of a smooth metal ball or roller that rolls against a smooth inner and outer metal surface. The rollers or balls take the load, allowing by the device to spin. The two basic types of rolling element distinguish the two basic types of rolling bearing:• ball → ball bearing• roller → roller bearingBalls make point contact with the ring raceways. With increasing load acting on the bearing, the contact point becomes an elliptical area. The small contact area provides low rolling friction, which enables ball bearings to accommodate high speeds but also limits their load-carrying capacity.Rollers make line contact with the ring raceways. With increasing load acting on the bearing, the contact line becomes somewhat rectangular in shape. Because of the larger contact area and the consequently higher friction, a roller bearing can accommodate heavier loads, but lower speeds, than a same-sized ball bearing.Bearing convertsa)Rolling friction to sliding friction by reducing area of contactb)Sliding friction to rolling friction by increasing area of contactc)Rolling friction to sliding friction by increasing area of contactd)Sliding friction to rolling friction by decreasing area of contactCorrect answer is option 'D'. Can you explain this answer?.

Solutions for Bearing:Bearings are used to convert sliding friction into rolling friction. Metal-upon-metal contact produces large amounts of friction. The friction adds to wear and tear of the metal, producing grinding that slowly degrades the metal. Bearings reduce friction by having the two surfaces roll over each other. They consist of a smooth metal ball or roller that rolls against a smooth inner and outer metal surface. The rollers or balls take the load, allowing by the device to spin. The two basic types of rolling element distinguish the two basic types of rolling bearing:• ball → ball bearing• roller → roller bearingBalls make point contact with the ring raceways. With increasing load acting on the bearing, the contact point becomes an elliptical area. The small contact area provides low rolling friction, which enables ball bearings to accommodate high speeds but also limits their load-carrying capacity.Rollers make line contact with the ring raceways. With increasing load acting on the bearing, the contact line becomes somewhat rectangular in shape. Because of the larger contact area and the consequently higher friction, a roller bearing can accommodate heavier loads, but lower speeds, than a same-sized ball bearing.Bearing convertsa)Rolling friction to sliding friction by reducing area of contactb)Sliding friction to rolling friction by increasing area of contactc)Rolling friction to sliding friction by increasing area of contactd)Sliding friction to rolling friction by decreasing area of contactCorrect answer is option 'D'. Can you explain this answer? in English & in Hindi are available as part of our courses for Class 11.

Download more important topics, notes, lectures and mock test series for Class 11 Exam by signing up for free.

Here you can find the meaning of Bearing:Bearings are used to convert sliding friction into rolling friction. Metal-upon-metal contact produces large amounts of friction. The friction adds to wear and tear of the metal, producing grinding that slowly degrades the metal. Bearings reduce friction by having the two surfaces roll over each other. They consist of a smooth metal ball or roller that rolls against a smooth inner and outer metal surface. The rollers or balls take the load, allowing by the device to spin. The two basic types of rolling element distinguish the two basic types of rolling bearing:• ball → ball bearing• roller → roller bearingBalls make point contact with the ring raceways. With increasing load acting on the bearing, the contact point becomes an elliptical area. The small contact area provides low rolling friction, which enables ball bearings to accommodate high speeds but also limits their load-carrying capacity.Rollers make line contact with the ring raceways. With increasing load acting on the bearing, the contact line becomes somewhat rectangular in shape. Because of the larger contact area and the consequently higher friction, a roller bearing can accommodate heavier loads, but lower speeds, than a same-sized ball bearing.Bearing convertsa)Rolling friction to sliding friction by reducing area of contactb)Sliding friction to rolling friction by increasing area of contactc)Rolling friction to sliding friction by increasing area of contactd)Sliding friction to rolling friction by decreasing area of contactCorrect answer is option 'D'. Can you explain this answer? defined & explained in the simplest way possible. Besides giving the explanation of

Bearing:Bearings are used to convert sliding friction into rolling friction. Metal-upon-metal contact produces large amounts of friction. The friction adds to wear and tear of the metal, producing grinding that slowly degrades the metal. Bearings reduce friction by having the two surfaces roll over each other. They consist of a smooth metal ball or roller that rolls against a smooth inner and outer metal surface. The rollers or balls take the load, allowing by the device to spin. The two basic types of rolling element distinguish the two basic types of rolling bearing:• ball → ball bearing• roller → roller bearingBalls make point contact with the ring raceways. With increasing load acting on the bearing, the contact point becomes an elliptical area. The small contact area provides low rolling friction, which enables ball bearings to accommodate high speeds but also limits their load-carrying capacity.Rollers make line contact with the ring raceways. With increasing load acting on the bearing, the contact line becomes somewhat rectangular in shape. Because of the larger contact area and the consequently higher friction, a roller bearing can accommodate heavier loads, but lower speeds, than a same-sized ball bearing.Bearing convertsa)Rolling friction to sliding friction by reducing area of contactb)Sliding friction to rolling friction by increasing area of contactc)Rolling friction to sliding friction by increasing area of contactd)Sliding friction to rolling friction by decreasing area of contactCorrect answer is option 'D'. Can you explain this answer?, a detailed solution for Bearing:Bearings are used to convert sliding friction into rolling friction. Metal-upon-metal contact produces large amounts of friction. The friction adds to wear and tear of the metal, producing grinding that slowly degrades the metal. Bearings reduce friction by having the two surfaces roll over each other. They consist of a smooth metal ball or roller that rolls against a smooth inner and outer metal surface. The rollers or balls take the load, allowing by the device to spin. The two basic types of rolling element distinguish the two basic types of rolling bearing:• ball → ball bearing• roller → roller bearingBalls make point contact with the ring raceways. With increasing load acting on the bearing, the contact point becomes an elliptical area. The small contact area provides low rolling friction, which enables ball bearings to accommodate high speeds but also limits their load-carrying capacity.Rollers make line contact with the ring raceways. With increasing load acting on the bearing, the contact line becomes somewhat rectangular in shape. Because of the larger contact area and the consequently higher friction, a roller bearing can accommodate heavier loads, but lower speeds, than a same-sized ball bearing.Bearing convertsa)Rolling friction to sliding friction by reducing area of contactb)Sliding friction to rolling friction by increasing area of contactc)Rolling friction to sliding friction by increasing area of contactd)Sliding friction to rolling friction by decreasing area of contactCorrect answer is option 'D'. Can you explain this answer? has been provided alongside types of Bearing:Bearings are used to convert sliding friction into rolling friction. Metal-upon-metal contact produces large amounts of friction. The friction adds to wear and tear of the metal, producing grinding that slowly degrades the metal. Bearings reduce friction by having the two surfaces roll over each other. They consist of a smooth metal ball or roller that rolls against a smooth inner and outer metal surface. The rollers or balls take the load, allowing by the device to spin. The two basic types of rolling element distinguish the two basic types of rolling bearing:• ball → ball bearing• roller → roller bearingBalls make point contact with the ring raceways. With increasing load acting on the bearing, the contact point becomes an elliptical area. The small contact area provides low rolling friction, which enables ball bearings to accommodate high speeds but also limits their load-carrying capacity.Rollers make line contact with the ring raceways. With increasing load acting on the bearing, the contact line becomes somewhat rectangular in shape. Because of the larger contact area and the consequently higher friction, a roller bearing can accommodate heavier loads, but lower speeds, than a same-sized ball bearing.Bearing convertsa)Rolling friction to sliding friction by reducing area of contactb)Sliding friction to rolling friction by increasing area of contactc)Rolling friction to sliding friction by increasing area of contactd)Sliding friction to rolling friction by decreasing area of contactCorrect answer is option 'D'. Can you explain this answer? theory, EduRev gives you an

ample number of questions to practice Bearing:Bearings are used to convert sliding friction into rolling friction. Metal-upon-metal contact produces large amounts of friction. The friction adds to wear and tear of the metal, producing grinding that slowly degrades the metal. Bearings reduce friction by having the two surfaces roll over each other. They consist of a smooth metal ball or roller that rolls against a smooth inner and outer metal surface. The rollers or balls take the load, allowing by the device to spin. The two basic types of rolling element distinguish the two basic types of rolling bearing:• ball → ball bearing• roller → roller bearingBalls make point contact with the ring raceways. With increasing load acting on the bearing, the contact point becomes an elliptical area. The small contact area provides low rolling friction, which enables ball bearings to accommodate high speeds but also limits their load-carrying capacity.Rollers make line contact with the ring raceways. With increasing load acting on the bearing, the contact line becomes somewhat rectangular in shape. Because of the larger contact area and the consequently higher friction, a roller bearing can accommodate heavier loads, but lower speeds, than a same-sized ball bearing.Bearing convertsa)Rolling friction to sliding friction by reducing area of contactb)Sliding friction to rolling friction by increasing area of contactc)Rolling friction to sliding friction by increasing area of contactd)Sliding friction to rolling friction by decreasing area of contactCorrect answer is option 'D'. Can you explain this answer? tests, examples and also practice Class 11 tests.

|

Explore Courses for Class 11 exam

|

|

Suggested Free Tests

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.