Class 11 Exam > Class 11 Questions > Attempt All sub parts from each question.Dam...

Start Learning for Free

Attempt All sub parts from each question.

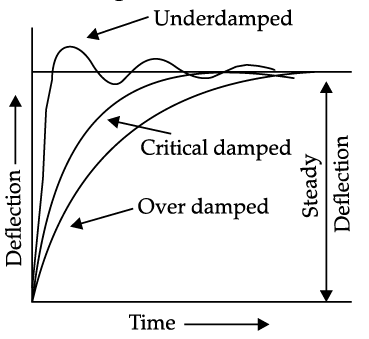

Damping: When an analog instrument is used to measure a physical parameter, a deflecting torque is applied to the moving system which is deflected from its initial position and should move steadily to the deflected position. But due to inertia, the moving system keeps on oscillating about equilibrium. To remove the oscillation of the moving system a damping torque is required. The damping torque should be of such that the pointer quickly comes to its final steady position, without overshooting. If the instrument is underdamped, the moving system will oscillate about the final steady position with a decreasing amplitude and will take some time before it comes to rest. When the moving system moves rapidly but smoothly to its final steady position, the instrument is said to be critically damped or deadbeat. If the damping torque is more than what is required for critical damping, the instrument is said to be overdamped. In an overdamped instrument, the moving system moves slowly to its final steady position in a lethargic fashion.

Methods of producing damping torque:

(i) Air friction damping

(ii) Fluid friction damping

(iii) Eddy current damping

Air Friction Damping: A light piston is attached to the moving system. This piston moves in an air chamber closed at one end. When there is an oscillation, the piston moves in and out of the chamber. When the piston moves into the chamber, the air inside is compressed and an air pressure is built up which opposes the motion of the piston and thus the moving system faces a damping torque which ultimately reduces the oscillation. Fluid Friction Damping: In this type of damping oil is used in place of air. Viscosity of the oil being greater, the damping torque is also more. A disc is attached to the moving system which is completely dipped into the oil. When the moving system oscillates, the disc moves in oil and a frictional drag is produced. This frictional drag opposes the oscillation. Eddy Current Damping: The moving system is connected to an aluminium disc which rotates in a magnetic field. Rotation in magnetic field induces an emf in it and if the path is closed, a current (known as eddy current) flows. This current interacts with the magnetic field to produce an electromagnetic torque which opposes the motion. This torque is proportional to the oscillation of the moving system. This electromagnetic torque ultimately reduces the oscillation. Air friction damping provides a very simple and cheap method of damping. The disadvantages of fluid friction damping are that it can be used only for instruments which are in vertical position. Eddy current damping is the most efficient form of damping.

Q. In Fluid Friction Damping the amount of damping torque

- a)Increases as viscosity decreases

- b)Increases as viscosity increases

- c)Is not related to the viscosity

- d)Increases as the conductivity increases

Correct answer is option 'B'. Can you explain this answer?

| FREE This question is part of | Download PDF Attempt this Test |

Verified Answer

Attempt All sub parts from each question.Damping: When an analog inst...

In fluid friction damping system, a disc is attached to the moving system which is completely dipped into the oil. As the viscosity of the oil increases, the damping torque also increases.

View all questions of this test

|

Explore Courses for Class 11 exam

|

|

Similar Class 11 Doubts

Attempt All sub parts from each question.Damping: When an analog instrument is used to measure a physical parameter, a deflecting torque is applied to the moving system which is deflected from its initial position and should move steadily to the deflected position. But due to inertia, the moving system keeps on oscillating about equilibrium. To remove the oscillation of the moving system a damping torque is required. The damping torque should be of such that the pointer quickly comes to its final steady position, without overshooting. If the instrument is underdamped, the moving system will oscillate about the final steady position with a decreasing amplitude and will take some time before it comes to rest. When the moving system moves rapidly but smoothly to its final steady position, the instrument is said to be critically damped or deadbeat. If the damping torque is more than what is required for critical damping, the instrument is said to be overdamped. In an overdamped instrument, the moving system moves slowly to its final steady position in a lethargic fashion.Methods of producing damping torque:(i) Air friction damping(ii) Fluid friction damping(iii) Eddy current dampingAir Friction Damping: A light piston is attached to the moving system. This piston moves in an air chamber closed at one end. When there is an oscillation, the piston moves in and out of the chamber. When the piston moves into the chamber, the air inside is compressed and an air pressure is built up which opposes the motion of the piston and thus the moving system faces a damping torque which ultimately reduces the oscillation. Fluid Friction Damping: In this type of damping oil is used in place of air. Viscosity of the oil being greater, the damping torque is also more. A disc is attached to the moving system which is completely dipped into the oil. When the moving system oscillates, the disc moves in oil and a frictional drag is produced. This frictional drag opposes the oscillation. Eddy Current Damping: The moving system is connected to an aluminium disc which rotates in a magnetic field. Rotation in magnetic field induces an emf in it and if the path is closed, a current (known as eddy current) flows. This current interacts with the magnetic field to produce an electromagnetic torque which opposes the motion. This torque is proportional to the oscillation of the moving system. This electromagnetic torque ultimately reduces the oscillation. Air friction damping provides a very simple and cheap method of damping. The disadvantages of fluid friction damping are that it can be used only for instruments which are in vertical position. Eddy current damping is the most efficient form of damping.Q. In Fluid Friction Damping the amount of damping torquea)Increases as viscosity decreasesb)Increases as viscosity increasesc)Is not related to the viscosityd)Increases as the conductivity increasesCorrect answer is option 'B'. Can you explain this answer?

Question Description

Attempt All sub parts from each question.Damping: When an analog instrument is used to measure a physical parameter, a deflecting torque is applied to the moving system which is deflected from its initial position and should move steadily to the deflected position. But due to inertia, the moving system keeps on oscillating about equilibrium. To remove the oscillation of the moving system a damping torque is required. The damping torque should be of such that the pointer quickly comes to its final steady position, without overshooting. If the instrument is underdamped, the moving system will oscillate about the final steady position with a decreasing amplitude and will take some time before it comes to rest. When the moving system moves rapidly but smoothly to its final steady position, the instrument is said to be critically damped or deadbeat. If the damping torque is more than what is required for critical damping, the instrument is said to be overdamped. In an overdamped instrument, the moving system moves slowly to its final steady position in a lethargic fashion.Methods of producing damping torque:(i) Air friction damping(ii) Fluid friction damping(iii) Eddy current dampingAir Friction Damping: A light piston is attached to the moving system. This piston moves in an air chamber closed at one end. When there is an oscillation, the piston moves in and out of the chamber. When the piston moves into the chamber, the air inside is compressed and an air pressure is built up which opposes the motion of the piston and thus the moving system faces a damping torque which ultimately reduces the oscillation. Fluid Friction Damping: In this type of damping oil is used in place of air. Viscosity of the oil being greater, the damping torque is also more. A disc is attached to the moving system which is completely dipped into the oil. When the moving system oscillates, the disc moves in oil and a frictional drag is produced. This frictional drag opposes the oscillation. Eddy Current Damping: The moving system is connected to an aluminium disc which rotates in a magnetic field. Rotation in magnetic field induces an emf in it and if the path is closed, a current (known as eddy current) flows. This current interacts with the magnetic field to produce an electromagnetic torque which opposes the motion. This torque is proportional to the oscillation of the moving system. This electromagnetic torque ultimately reduces the oscillation. Air friction damping provides a very simple and cheap method of damping. The disadvantages of fluid friction damping are that it can be used only for instruments which are in vertical position. Eddy current damping is the most efficient form of damping.Q. In Fluid Friction Damping the amount of damping torquea)Increases as viscosity decreasesb)Increases as viscosity increasesc)Is not related to the viscosityd)Increases as the conductivity increasesCorrect answer is option 'B'. Can you explain this answer? for Class 11 2024 is part of Class 11 preparation. The Question and answers have been prepared according to the Class 11 exam syllabus. Information about Attempt All sub parts from each question.Damping: When an analog instrument is used to measure a physical parameter, a deflecting torque is applied to the moving system which is deflected from its initial position and should move steadily to the deflected position. But due to inertia, the moving system keeps on oscillating about equilibrium. To remove the oscillation of the moving system a damping torque is required. The damping torque should be of such that the pointer quickly comes to its final steady position, without overshooting. If the instrument is underdamped, the moving system will oscillate about the final steady position with a decreasing amplitude and will take some time before it comes to rest. When the moving system moves rapidly but smoothly to its final steady position, the instrument is said to be critically damped or deadbeat. If the damping torque is more than what is required for critical damping, the instrument is said to be overdamped. In an overdamped instrument, the moving system moves slowly to its final steady position in a lethargic fashion.Methods of producing damping torque:(i) Air friction damping(ii) Fluid friction damping(iii) Eddy current dampingAir Friction Damping: A light piston is attached to the moving system. This piston moves in an air chamber closed at one end. When there is an oscillation, the piston moves in and out of the chamber. When the piston moves into the chamber, the air inside is compressed and an air pressure is built up which opposes the motion of the piston and thus the moving system faces a damping torque which ultimately reduces the oscillation. Fluid Friction Damping: In this type of damping oil is used in place of air. Viscosity of the oil being greater, the damping torque is also more. A disc is attached to the moving system which is completely dipped into the oil. When the moving system oscillates, the disc moves in oil and a frictional drag is produced. This frictional drag opposes the oscillation. Eddy Current Damping: The moving system is connected to an aluminium disc which rotates in a magnetic field. Rotation in magnetic field induces an emf in it and if the path is closed, a current (known as eddy current) flows. This current interacts with the magnetic field to produce an electromagnetic torque which opposes the motion. This torque is proportional to the oscillation of the moving system. This electromagnetic torque ultimately reduces the oscillation. Air friction damping provides a very simple and cheap method of damping. The disadvantages of fluid friction damping are that it can be used only for instruments which are in vertical position. Eddy current damping is the most efficient form of damping.Q. In Fluid Friction Damping the amount of damping torquea)Increases as viscosity decreasesb)Increases as viscosity increasesc)Is not related to the viscosityd)Increases as the conductivity increasesCorrect answer is option 'B'. Can you explain this answer? covers all topics & solutions for Class 11 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for Attempt All sub parts from each question.Damping: When an analog instrument is used to measure a physical parameter, a deflecting torque is applied to the moving system which is deflected from its initial position and should move steadily to the deflected position. But due to inertia, the moving system keeps on oscillating about equilibrium. To remove the oscillation of the moving system a damping torque is required. The damping torque should be of such that the pointer quickly comes to its final steady position, without overshooting. If the instrument is underdamped, the moving system will oscillate about the final steady position with a decreasing amplitude and will take some time before it comes to rest. When the moving system moves rapidly but smoothly to its final steady position, the instrument is said to be critically damped or deadbeat. If the damping torque is more than what is required for critical damping, the instrument is said to be overdamped. In an overdamped instrument, the moving system moves slowly to its final steady position in a lethargic fashion.Methods of producing damping torque:(i) Air friction damping(ii) Fluid friction damping(iii) Eddy current dampingAir Friction Damping: A light piston is attached to the moving system. This piston moves in an air chamber closed at one end. When there is an oscillation, the piston moves in and out of the chamber. When the piston moves into the chamber, the air inside is compressed and an air pressure is built up which opposes the motion of the piston and thus the moving system faces a damping torque which ultimately reduces the oscillation. Fluid Friction Damping: In this type of damping oil is used in place of air. Viscosity of the oil being greater, the damping torque is also more. A disc is attached to the moving system which is completely dipped into the oil. When the moving system oscillates, the disc moves in oil and a frictional drag is produced. This frictional drag opposes the oscillation. Eddy Current Damping: The moving system is connected to an aluminium disc which rotates in a magnetic field. Rotation in magnetic field induces an emf in it and if the path is closed, a current (known as eddy current) flows. This current interacts with the magnetic field to produce an electromagnetic torque which opposes the motion. This torque is proportional to the oscillation of the moving system. This electromagnetic torque ultimately reduces the oscillation. Air friction damping provides a very simple and cheap method of damping. The disadvantages of fluid friction damping are that it can be used only for instruments which are in vertical position. Eddy current damping is the most efficient form of damping.Q. In Fluid Friction Damping the amount of damping torquea)Increases as viscosity decreasesb)Increases as viscosity increasesc)Is not related to the viscosityd)Increases as the conductivity increasesCorrect answer is option 'B'. Can you explain this answer?.

Attempt All sub parts from each question.Damping: When an analog instrument is used to measure a physical parameter, a deflecting torque is applied to the moving system which is deflected from its initial position and should move steadily to the deflected position. But due to inertia, the moving system keeps on oscillating about equilibrium. To remove the oscillation of the moving system a damping torque is required. The damping torque should be of such that the pointer quickly comes to its final steady position, without overshooting. If the instrument is underdamped, the moving system will oscillate about the final steady position with a decreasing amplitude and will take some time before it comes to rest. When the moving system moves rapidly but smoothly to its final steady position, the instrument is said to be critically damped or deadbeat. If the damping torque is more than what is required for critical damping, the instrument is said to be overdamped. In an overdamped instrument, the moving system moves slowly to its final steady position in a lethargic fashion.Methods of producing damping torque:(i) Air friction damping(ii) Fluid friction damping(iii) Eddy current dampingAir Friction Damping: A light piston is attached to the moving system. This piston moves in an air chamber closed at one end. When there is an oscillation, the piston moves in and out of the chamber. When the piston moves into the chamber, the air inside is compressed and an air pressure is built up which opposes the motion of the piston and thus the moving system faces a damping torque which ultimately reduces the oscillation. Fluid Friction Damping: In this type of damping oil is used in place of air. Viscosity of the oil being greater, the damping torque is also more. A disc is attached to the moving system which is completely dipped into the oil. When the moving system oscillates, the disc moves in oil and a frictional drag is produced. This frictional drag opposes the oscillation. Eddy Current Damping: The moving system is connected to an aluminium disc which rotates in a magnetic field. Rotation in magnetic field induces an emf in it and if the path is closed, a current (known as eddy current) flows. This current interacts with the magnetic field to produce an electromagnetic torque which opposes the motion. This torque is proportional to the oscillation of the moving system. This electromagnetic torque ultimately reduces the oscillation. Air friction damping provides a very simple and cheap method of damping. The disadvantages of fluid friction damping are that it can be used only for instruments which are in vertical position. Eddy current damping is the most efficient form of damping.Q. In Fluid Friction Damping the amount of damping torquea)Increases as viscosity decreasesb)Increases as viscosity increasesc)Is not related to the viscosityd)Increases as the conductivity increasesCorrect answer is option 'B'. Can you explain this answer? for Class 11 2024 is part of Class 11 preparation. The Question and answers have been prepared according to the Class 11 exam syllabus. Information about Attempt All sub parts from each question.Damping: When an analog instrument is used to measure a physical parameter, a deflecting torque is applied to the moving system which is deflected from its initial position and should move steadily to the deflected position. But due to inertia, the moving system keeps on oscillating about equilibrium. To remove the oscillation of the moving system a damping torque is required. The damping torque should be of such that the pointer quickly comes to its final steady position, without overshooting. If the instrument is underdamped, the moving system will oscillate about the final steady position with a decreasing amplitude and will take some time before it comes to rest. When the moving system moves rapidly but smoothly to its final steady position, the instrument is said to be critically damped or deadbeat. If the damping torque is more than what is required for critical damping, the instrument is said to be overdamped. In an overdamped instrument, the moving system moves slowly to its final steady position in a lethargic fashion.Methods of producing damping torque:(i) Air friction damping(ii) Fluid friction damping(iii) Eddy current dampingAir Friction Damping: A light piston is attached to the moving system. This piston moves in an air chamber closed at one end. When there is an oscillation, the piston moves in and out of the chamber. When the piston moves into the chamber, the air inside is compressed and an air pressure is built up which opposes the motion of the piston and thus the moving system faces a damping torque which ultimately reduces the oscillation. Fluid Friction Damping: In this type of damping oil is used in place of air. Viscosity of the oil being greater, the damping torque is also more. A disc is attached to the moving system which is completely dipped into the oil. When the moving system oscillates, the disc moves in oil and a frictional drag is produced. This frictional drag opposes the oscillation. Eddy Current Damping: The moving system is connected to an aluminium disc which rotates in a magnetic field. Rotation in magnetic field induces an emf in it and if the path is closed, a current (known as eddy current) flows. This current interacts with the magnetic field to produce an electromagnetic torque which opposes the motion. This torque is proportional to the oscillation of the moving system. This electromagnetic torque ultimately reduces the oscillation. Air friction damping provides a very simple and cheap method of damping. The disadvantages of fluid friction damping are that it can be used only for instruments which are in vertical position. Eddy current damping is the most efficient form of damping.Q. In Fluid Friction Damping the amount of damping torquea)Increases as viscosity decreasesb)Increases as viscosity increasesc)Is not related to the viscosityd)Increases as the conductivity increasesCorrect answer is option 'B'. Can you explain this answer? covers all topics & solutions for Class 11 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for Attempt All sub parts from each question.Damping: When an analog instrument is used to measure a physical parameter, a deflecting torque is applied to the moving system which is deflected from its initial position and should move steadily to the deflected position. But due to inertia, the moving system keeps on oscillating about equilibrium. To remove the oscillation of the moving system a damping torque is required. The damping torque should be of such that the pointer quickly comes to its final steady position, without overshooting. If the instrument is underdamped, the moving system will oscillate about the final steady position with a decreasing amplitude and will take some time before it comes to rest. When the moving system moves rapidly but smoothly to its final steady position, the instrument is said to be critically damped or deadbeat. If the damping torque is more than what is required for critical damping, the instrument is said to be overdamped. In an overdamped instrument, the moving system moves slowly to its final steady position in a lethargic fashion.Methods of producing damping torque:(i) Air friction damping(ii) Fluid friction damping(iii) Eddy current dampingAir Friction Damping: A light piston is attached to the moving system. This piston moves in an air chamber closed at one end. When there is an oscillation, the piston moves in and out of the chamber. When the piston moves into the chamber, the air inside is compressed and an air pressure is built up which opposes the motion of the piston and thus the moving system faces a damping torque which ultimately reduces the oscillation. Fluid Friction Damping: In this type of damping oil is used in place of air. Viscosity of the oil being greater, the damping torque is also more. A disc is attached to the moving system which is completely dipped into the oil. When the moving system oscillates, the disc moves in oil and a frictional drag is produced. This frictional drag opposes the oscillation. Eddy Current Damping: The moving system is connected to an aluminium disc which rotates in a magnetic field. Rotation in magnetic field induces an emf in it and if the path is closed, a current (known as eddy current) flows. This current interacts with the magnetic field to produce an electromagnetic torque which opposes the motion. This torque is proportional to the oscillation of the moving system. This electromagnetic torque ultimately reduces the oscillation. Air friction damping provides a very simple and cheap method of damping. The disadvantages of fluid friction damping are that it can be used only for instruments which are in vertical position. Eddy current damping is the most efficient form of damping.Q. In Fluid Friction Damping the amount of damping torquea)Increases as viscosity decreasesb)Increases as viscosity increasesc)Is not related to the viscosityd)Increases as the conductivity increasesCorrect answer is option 'B'. Can you explain this answer?.

Solutions for Attempt All sub parts from each question.Damping: When an analog instrument is used to measure a physical parameter, a deflecting torque is applied to the moving system which is deflected from its initial position and should move steadily to the deflected position. But due to inertia, the moving system keeps on oscillating about equilibrium. To remove the oscillation of the moving system a damping torque is required. The damping torque should be of such that the pointer quickly comes to its final steady position, without overshooting. If the instrument is underdamped, the moving system will oscillate about the final steady position with a decreasing amplitude and will take some time before it comes to rest. When the moving system moves rapidly but smoothly to its final steady position, the instrument is said to be critically damped or deadbeat. If the damping torque is more than what is required for critical damping, the instrument is said to be overdamped. In an overdamped instrument, the moving system moves slowly to its final steady position in a lethargic fashion.Methods of producing damping torque:(i) Air friction damping(ii) Fluid friction damping(iii) Eddy current dampingAir Friction Damping: A light piston is attached to the moving system. This piston moves in an air chamber closed at one end. When there is an oscillation, the piston moves in and out of the chamber. When the piston moves into the chamber, the air inside is compressed and an air pressure is built up which opposes the motion of the piston and thus the moving system faces a damping torque which ultimately reduces the oscillation. Fluid Friction Damping: In this type of damping oil is used in place of air. Viscosity of the oil being greater, the damping torque is also more. A disc is attached to the moving system which is completely dipped into the oil. When the moving system oscillates, the disc moves in oil and a frictional drag is produced. This frictional drag opposes the oscillation. Eddy Current Damping: The moving system is connected to an aluminium disc which rotates in a magnetic field. Rotation in magnetic field induces an emf in it and if the path is closed, a current (known as eddy current) flows. This current interacts with the magnetic field to produce an electromagnetic torque which opposes the motion. This torque is proportional to the oscillation of the moving system. This electromagnetic torque ultimately reduces the oscillation. Air friction damping provides a very simple and cheap method of damping. The disadvantages of fluid friction damping are that it can be used only for instruments which are in vertical position. Eddy current damping is the most efficient form of damping.Q. In Fluid Friction Damping the amount of damping torquea)Increases as viscosity decreasesb)Increases as viscosity increasesc)Is not related to the viscosityd)Increases as the conductivity increasesCorrect answer is option 'B'. Can you explain this answer? in English & in Hindi are available as part of our courses for Class 11.

Download more important topics, notes, lectures and mock test series for Class 11 Exam by signing up for free.

Here you can find the meaning of Attempt All sub parts from each question.Damping: When an analog instrument is used to measure a physical parameter, a deflecting torque is applied to the moving system which is deflected from its initial position and should move steadily to the deflected position. But due to inertia, the moving system keeps on oscillating about equilibrium. To remove the oscillation of the moving system a damping torque is required. The damping torque should be of such that the pointer quickly comes to its final steady position, without overshooting. If the instrument is underdamped, the moving system will oscillate about the final steady position with a decreasing amplitude and will take some time before it comes to rest. When the moving system moves rapidly but smoothly to its final steady position, the instrument is said to be critically damped or deadbeat. If the damping torque is more than what is required for critical damping, the instrument is said to be overdamped. In an overdamped instrument, the moving system moves slowly to its final steady position in a lethargic fashion.Methods of producing damping torque:(i) Air friction damping(ii) Fluid friction damping(iii) Eddy current dampingAir Friction Damping: A light piston is attached to the moving system. This piston moves in an air chamber closed at one end. When there is an oscillation, the piston moves in and out of the chamber. When the piston moves into the chamber, the air inside is compressed and an air pressure is built up which opposes the motion of the piston and thus the moving system faces a damping torque which ultimately reduces the oscillation. Fluid Friction Damping: In this type of damping oil is used in place of air. Viscosity of the oil being greater, the damping torque is also more. A disc is attached to the moving system which is completely dipped into the oil. When the moving system oscillates, the disc moves in oil and a frictional drag is produced. This frictional drag opposes the oscillation. Eddy Current Damping: The moving system is connected to an aluminium disc which rotates in a magnetic field. Rotation in magnetic field induces an emf in it and if the path is closed, a current (known as eddy current) flows. This current interacts with the magnetic field to produce an electromagnetic torque which opposes the motion. This torque is proportional to the oscillation of the moving system. This electromagnetic torque ultimately reduces the oscillation. Air friction damping provides a very simple and cheap method of damping. The disadvantages of fluid friction damping are that it can be used only for instruments which are in vertical position. Eddy current damping is the most efficient form of damping.Q. In Fluid Friction Damping the amount of damping torquea)Increases as viscosity decreasesb)Increases as viscosity increasesc)Is not related to the viscosityd)Increases as the conductivity increasesCorrect answer is option 'B'. Can you explain this answer? defined & explained in the simplest way possible. Besides giving the explanation of

Attempt All sub parts from each question.Damping: When an analog instrument is used to measure a physical parameter, a deflecting torque is applied to the moving system which is deflected from its initial position and should move steadily to the deflected position. But due to inertia, the moving system keeps on oscillating about equilibrium. To remove the oscillation of the moving system a damping torque is required. The damping torque should be of such that the pointer quickly comes to its final steady position, without overshooting. If the instrument is underdamped, the moving system will oscillate about the final steady position with a decreasing amplitude and will take some time before it comes to rest. When the moving system moves rapidly but smoothly to its final steady position, the instrument is said to be critically damped or deadbeat. If the damping torque is more than what is required for critical damping, the instrument is said to be overdamped. In an overdamped instrument, the moving system moves slowly to its final steady position in a lethargic fashion.Methods of producing damping torque:(i) Air friction damping(ii) Fluid friction damping(iii) Eddy current dampingAir Friction Damping: A light piston is attached to the moving system. This piston moves in an air chamber closed at one end. When there is an oscillation, the piston moves in and out of the chamber. When the piston moves into the chamber, the air inside is compressed and an air pressure is built up which opposes the motion of the piston and thus the moving system faces a damping torque which ultimately reduces the oscillation. Fluid Friction Damping: In this type of damping oil is used in place of air. Viscosity of the oil being greater, the damping torque is also more. A disc is attached to the moving system which is completely dipped into the oil. When the moving system oscillates, the disc moves in oil and a frictional drag is produced. This frictional drag opposes the oscillation. Eddy Current Damping: The moving system is connected to an aluminium disc which rotates in a magnetic field. Rotation in magnetic field induces an emf in it and if the path is closed, a current (known as eddy current) flows. This current interacts with the magnetic field to produce an electromagnetic torque which opposes the motion. This torque is proportional to the oscillation of the moving system. This electromagnetic torque ultimately reduces the oscillation. Air friction damping provides a very simple and cheap method of damping. The disadvantages of fluid friction damping are that it can be used only for instruments which are in vertical position. Eddy current damping is the most efficient form of damping.Q. In Fluid Friction Damping the amount of damping torquea)Increases as viscosity decreasesb)Increases as viscosity increasesc)Is not related to the viscosityd)Increases as the conductivity increasesCorrect answer is option 'B'. Can you explain this answer?, a detailed solution for Attempt All sub parts from each question.Damping: When an analog instrument is used to measure a physical parameter, a deflecting torque is applied to the moving system which is deflected from its initial position and should move steadily to the deflected position. But due to inertia, the moving system keeps on oscillating about equilibrium. To remove the oscillation of the moving system a damping torque is required. The damping torque should be of such that the pointer quickly comes to its final steady position, without overshooting. If the instrument is underdamped, the moving system will oscillate about the final steady position with a decreasing amplitude and will take some time before it comes to rest. When the moving system moves rapidly but smoothly to its final steady position, the instrument is said to be critically damped or deadbeat. If the damping torque is more than what is required for critical damping, the instrument is said to be overdamped. In an overdamped instrument, the moving system moves slowly to its final steady position in a lethargic fashion.Methods of producing damping torque:(i) Air friction damping(ii) Fluid friction damping(iii) Eddy current dampingAir Friction Damping: A light piston is attached to the moving system. This piston moves in an air chamber closed at one end. When there is an oscillation, the piston moves in and out of the chamber. When the piston moves into the chamber, the air inside is compressed and an air pressure is built up which opposes the motion of the piston and thus the moving system faces a damping torque which ultimately reduces the oscillation. Fluid Friction Damping: In this type of damping oil is used in place of air. Viscosity of the oil being greater, the damping torque is also more. A disc is attached to the moving system which is completely dipped into the oil. When the moving system oscillates, the disc moves in oil and a frictional drag is produced. This frictional drag opposes the oscillation. Eddy Current Damping: The moving system is connected to an aluminium disc which rotates in a magnetic field. Rotation in magnetic field induces an emf in it and if the path is closed, a current (known as eddy current) flows. This current interacts with the magnetic field to produce an electromagnetic torque which opposes the motion. This torque is proportional to the oscillation of the moving system. This electromagnetic torque ultimately reduces the oscillation. Air friction damping provides a very simple and cheap method of damping. The disadvantages of fluid friction damping are that it can be used only for instruments which are in vertical position. Eddy current damping is the most efficient form of damping.Q. In Fluid Friction Damping the amount of damping torquea)Increases as viscosity decreasesb)Increases as viscosity increasesc)Is not related to the viscosityd)Increases as the conductivity increasesCorrect answer is option 'B'. Can you explain this answer? has been provided alongside types of Attempt All sub parts from each question.Damping: When an analog instrument is used to measure a physical parameter, a deflecting torque is applied to the moving system which is deflected from its initial position and should move steadily to the deflected position. But due to inertia, the moving system keeps on oscillating about equilibrium. To remove the oscillation of the moving system a damping torque is required. The damping torque should be of such that the pointer quickly comes to its final steady position, without overshooting. If the instrument is underdamped, the moving system will oscillate about the final steady position with a decreasing amplitude and will take some time before it comes to rest. When the moving system moves rapidly but smoothly to its final steady position, the instrument is said to be critically damped or deadbeat. If the damping torque is more than what is required for critical damping, the instrument is said to be overdamped. In an overdamped instrument, the moving system moves slowly to its final steady position in a lethargic fashion.Methods of producing damping torque:(i) Air friction damping(ii) Fluid friction damping(iii) Eddy current dampingAir Friction Damping: A light piston is attached to the moving system. This piston moves in an air chamber closed at one end. When there is an oscillation, the piston moves in and out of the chamber. When the piston moves into the chamber, the air inside is compressed and an air pressure is built up which opposes the motion of the piston and thus the moving system faces a damping torque which ultimately reduces the oscillation. Fluid Friction Damping: In this type of damping oil is used in place of air. Viscosity of the oil being greater, the damping torque is also more. A disc is attached to the moving system which is completely dipped into the oil. When the moving system oscillates, the disc moves in oil and a frictional drag is produced. This frictional drag opposes the oscillation. Eddy Current Damping: The moving system is connected to an aluminium disc which rotates in a magnetic field. Rotation in magnetic field induces an emf in it and if the path is closed, a current (known as eddy current) flows. This current interacts with the magnetic field to produce an electromagnetic torque which opposes the motion. This torque is proportional to the oscillation of the moving system. This electromagnetic torque ultimately reduces the oscillation. Air friction damping provides a very simple and cheap method of damping. The disadvantages of fluid friction damping are that it can be used only for instruments which are in vertical position. Eddy current damping is the most efficient form of damping.Q. In Fluid Friction Damping the amount of damping torquea)Increases as viscosity decreasesb)Increases as viscosity increasesc)Is not related to the viscosityd)Increases as the conductivity increasesCorrect answer is option 'B'. Can you explain this answer? theory, EduRev gives you an

ample number of questions to practice Attempt All sub parts from each question.Damping: When an analog instrument is used to measure a physical parameter, a deflecting torque is applied to the moving system which is deflected from its initial position and should move steadily to the deflected position. But due to inertia, the moving system keeps on oscillating about equilibrium. To remove the oscillation of the moving system a damping torque is required. The damping torque should be of such that the pointer quickly comes to its final steady position, without overshooting. If the instrument is underdamped, the moving system will oscillate about the final steady position with a decreasing amplitude and will take some time before it comes to rest. When the moving system moves rapidly but smoothly to its final steady position, the instrument is said to be critically damped or deadbeat. If the damping torque is more than what is required for critical damping, the instrument is said to be overdamped. In an overdamped instrument, the moving system moves slowly to its final steady position in a lethargic fashion.Methods of producing damping torque:(i) Air friction damping(ii) Fluid friction damping(iii) Eddy current dampingAir Friction Damping: A light piston is attached to the moving system. This piston moves in an air chamber closed at one end. When there is an oscillation, the piston moves in and out of the chamber. When the piston moves into the chamber, the air inside is compressed and an air pressure is built up which opposes the motion of the piston and thus the moving system faces a damping torque which ultimately reduces the oscillation. Fluid Friction Damping: In this type of damping oil is used in place of air. Viscosity of the oil being greater, the damping torque is also more. A disc is attached to the moving system which is completely dipped into the oil. When the moving system oscillates, the disc moves in oil and a frictional drag is produced. This frictional drag opposes the oscillation. Eddy Current Damping: The moving system is connected to an aluminium disc which rotates in a magnetic field. Rotation in magnetic field induces an emf in it and if the path is closed, a current (known as eddy current) flows. This current interacts with the magnetic field to produce an electromagnetic torque which opposes the motion. This torque is proportional to the oscillation of the moving system. This electromagnetic torque ultimately reduces the oscillation. Air friction damping provides a very simple and cheap method of damping. The disadvantages of fluid friction damping are that it can be used only for instruments which are in vertical position. Eddy current damping is the most efficient form of damping.Q. In Fluid Friction Damping the amount of damping torquea)Increases as viscosity decreasesb)Increases as viscosity increasesc)Is not related to the viscosityd)Increases as the conductivity increasesCorrect answer is option 'B'. Can you explain this answer? tests, examples and also practice Class 11 tests.

|

Explore Courses for Class 11 exam

|

|

Suggested Free Tests

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.