Cement | Civil Engineering SSC JE (Technical) - Civil Engineering (CE) PDF Download

Cement:

A Cement is a binder, a substance used in construction that sets, hardens and adheres to other materials, binding them together. Cement is seldom used solely, but is used to bind sand and gravel (aggregate) together. Cement is used with fine aggregates to produce mortar for masonry, or with sand and gravel aggregates to produce concrete.

Storage of Cement:

Cement, being highly hygroscopic in nature (which readily absorbs moisture not only from free water but from air), has to be protected from dampness during packing, transportation, and storage. Strength of concrete prepared with cement stored for longer periods gets affected adversely. With 3 months long-stored cement, there is a 20% reduction in strength of concrete, whereas when cement is stored for two years, the 28 day concrete strength reduces by 50%. Hence, cement which has deteriorated during storage for longer periods should be tested in a laboratory before use.

Composition of Cement:

Lime (CaO) 60 % - 65 %

Silica (SiO2) 20% - 25%

Alumina (Al2O3) 4% - 8%

Iron Oxide (Fe2O3) 2% - 4%

Magnesium Oxide (MgO) 1% - 3%

Sulphurtrioxide (SO3) 1% - 8%

Alkalies 0.3 % - 1%

Functions of Ingredients:

1. Lime:

Lime is the important ingredient of cement and its proportion is to be maintained carefully. Lime in excess makes the cement unsound and causes the cement to expand and disintegrate. On the other hand, if lime is in deficiency the strength of the cement is decreased and it causes cement to set quickly.

2. Silica:

This also an important ingredient of cement and it gives or imparts quick setting property to imparts strength to cement.

3. Alumina:

This ingredient imparts quick setting properly to cement. Excess alumina weakens the cement.

4. Calcium Sulphate:

This ingredient is in the form of gypsum and its function is to increase the initial setting time of cement.

5. Magnesia:

The small amount of this ingredient imparts hardness and colour to cement.

6. Sulphur:

A very small amount of sulphur is useful in making sound cement. If it is in excess, it causes the cement to become unsound.

7. Alkalies:

Most of the alkalies present in raw material are carried away by the flue gases during heating and only small quantity will be left. If they are in excess in cement, efflorescence is caused.

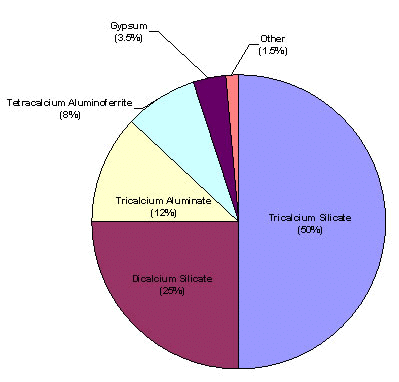

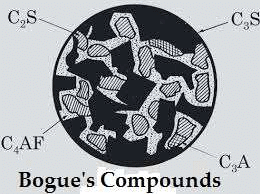

Bogue's Compound:

When water is added in the cement, it reacts with it chemically and leads to the formation of complex compound termed as Bogue's compounds which different properties to the cement.

| Compound | Chemical Formula | Abbreviated Designation | % by Mass |

| Tricalciumsilicate | 3CaOSiO2 | C3S | 25 - 50 |

| Dicalciumsilicate | 2CaOSiO2 | C3S | 20 - 45 |

| Tricalciumaluminate | 3CaOAl2O3 | C3A | 5 - 12 |

| Tetracalciumaluminoferrite | 4CaOAl2O3 Fe2 O3 | C3A | 5 - 12 |

1. Lime. silica, and iron oxide contribute towards strength.

2. Whereas alumina imparts quick setting property.

3. Magnesium oxide, when present in small amounts, adds hardness and colour to cement.

4. A very small amount of sulphur is useful in producing sound cement.

5. Both magnesia and sulphur are harmful if present in excess. Similarly, excess alkalies cause efflorescence.

Formation of these compounds in cement is not simultaneous:

1. Tri-calcium Aluminate [3CaO. Al2O3] [4-14%] C3A

It is formed within 24 hrs of add of water in the cement and is responsible for maximum development of heat of hydration.

2. Tetra Calcium Aluminoferrite [4CaO, Al2O3. Fe2O3] [C4AF] [10-18%]

It is also formed within 24 hrs of the add of water in the cement and is responsible for heat of hydration in the early ages of the cement which subsequently goes on decreasing with time.

3. Tricalcium silicate [3CaO. SiO2] [C3S] [45- 65%]

It is formed within a week after the add of water in the cement and is responsible for strength to cement in its early ages.

4. Dicalcium silicate [C2S] [15-35%]

This compound forms very slowly and takes about a year or so for its formation after the addition of water in the cement and is responsible for progressive strength of the cement in the later stages.

Note:

C3S (Tricalcium silicate)

(i) This is used for initials strength and have good cementing properties.

(ii) This is used in cooled weather, concreted emergency repair work precast concrete

C2S ( Dicalcium silicate)

(i) This is used for ultimate strength and it contain low heat.

(ii) It is used for heavy structures like dam and bridge.

| 3 Days 90 Days |

| C3A 212 310 I 24 hrs C4AF 69 98 II 24 hrs C3 S 58 105 III 1 weak C2 S 12 42 IV 1 year |

Heat hydration of cement: The heat of hydration is the heat generated when water and portland cement react. Heat of hydration is most influenced by the proportion of C3S and C3A in the cement, but is also influenced by water-cement ratio, fineness and curing temperature. As each one of these factors is increased, heat of hydration increases.

Note:

Bogues compounds generates heats in the order

C3A > C3S > C4AF > C2S

Heat of hydration of cement doing 7 days varies between 89-90 calories per gram and doing 28 days varies b/w 90 - 100 calores/gm.

On an average, 23% or water by weight of cement is required for complete hydration to take place.

Approximately, 15% of water added to the cement is entrap with the voids of the cement and does not carries out the hydration Hence, total quantity of water to be added for complete hydration to take is 38%.

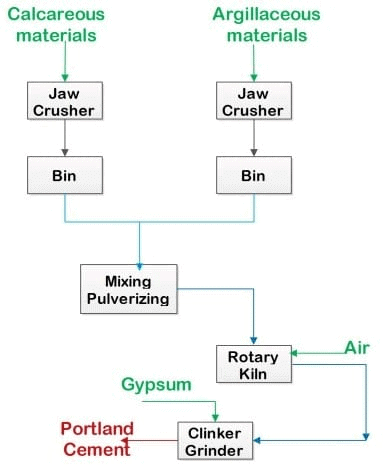

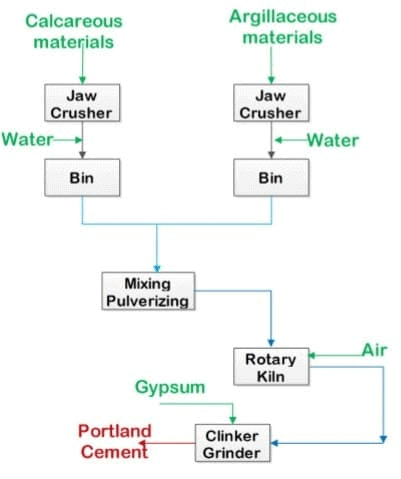

Manufacturing of cement:

There are two methods of manufacturing of cement:

(i) Dry process

(ii) Wet process

Dry Process (New Method):

The both calcareous and argillaceous raw materials are firstly crushed in the gyratory crushers to get 2-5cm size pieces separately. The crushed materials are again grinded to get fine particles into ball or tube mill.

Each finely grinded material is stored in hopper after screening. Now these powdered minerals are mixed in required proportion to get dry raw mix which is then stored in silos and kept ready to be sent into rotary kiln. Now the raw materials are mixed in specific proportions so that the average composition of the final product is maintained properly.

Wet Process (Old Method):

The raw materials are firstly crushed and made into powdered form and stored in silos. The clay is then washed in washing mills to remove adhering organic matters found in clay.

The powdered limestone and water washed clay are sent to flow in the channels and transfer to grinding mills where they are completely mixed and the paste is formed, i.e., known as slurry.

The grinding process can be done in ball or tube mill or even both. Then the slurry is led into collecting basin where composition can be adjusted. The slurry contains around 38-40% water that is stored in storage tanks and kept ready for the rotary kiln.

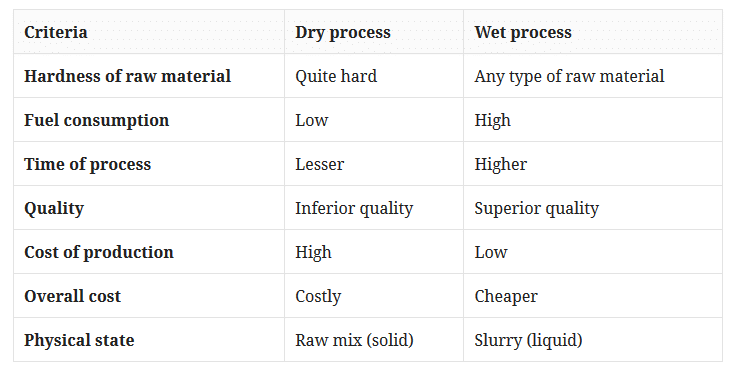

Comparison of dry process and wet process of Cement Manufacture: Testing

Testing

of Cement: Testing of Cement is done in both field and laboratory in order to analyse its quality characteristics:

I. Field Test:

(a) Colour:

The colour of the cement should be uniform and grey.

(b) Physical test:

This test is performed to analyse the physical properties of cement that includes the following;

(i) the cement should feel smooth when rubbed b/w finger.

(ii) if a small quantity of cement is thrown in bucket of water, it should sink and does not float over the surface.

(iii) cement should be free from presence of any lumps which are formed due to absorption of moisture by the cement from the atmosphere leading to its hydration

(c) Strength Test: Prepare 25×25×200 mm block from given sample of cement and immense in water for curing for 7 days.

Remove the block from water and place it over the supports that are 150 mm apart and subject if to but load of 340 N at the centre the block should not show any sign of failure under application of this load.

II. Laboratory Test:

(a) Fineness Test:

Fineness of the cement is tested to check the grinding of the cement which plays the direct role in influencing the rate of hydration, rate of development of strength and rate of evolution of heat. Fineness of the cement is tested either by sieve test or air permeability test.

Sieve test:

(i) Take 100 gms of cement to be tested and place it over standard IS sieves No. 9 (90μ).

(ii) Break the air set lumps in the cement if any by fingers.

(iii) Perform the sieving for at least 15 min and weight the residue left over the sieve which for OPC should not exceed 10% of its original weight.

(iv) Sieve test is rarely performed practically in today's time Air permeability Test:

This method of test overs the procedure for determining the fineness of the cement i.e. expressed as specific area (Surface area/weight) and represented in terms of total surface area in cm2/gm.

Generally, Blanes Air Permeability apparatus is used to perform on the test. This principle of this test is based upon relationship b/w the flow of air to the bed of cement particles and size of cement particles surface area of cement particles forming the cement bed Specific surface area for OPC should not be less than 2250 cm2/gm.

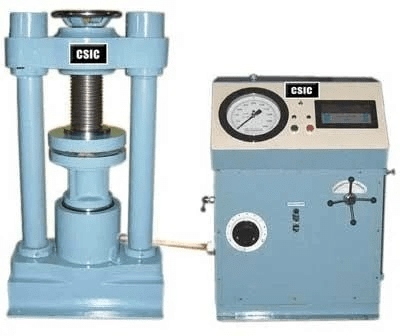

(b) Strength Test:

Compressive Strength:

In order to find the compressive strength of cement, prepare the motor of cement and standard sand (Ennore sand) in the proportion of 1 ; 3 (weight of standard sand is kept to be 550 gm for preparation of mortar). Having w/c ratio of 0.4 Place the mortar in the moulds of 75 mm and subject it to crowing for sufficient duration The compressive strength of cube are further tested in UTM.

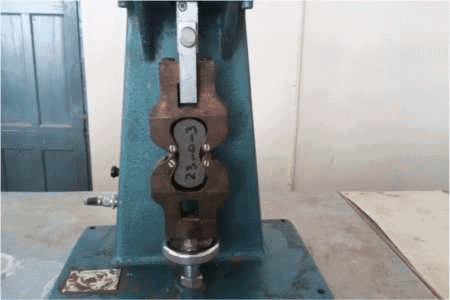

Tensile Strength:

Tensile Strength:

Tensile strength of cement or concrete cannot be tested directly (as they are brittle material). Tensile of strength of cement is computed by preparing the mortar as in above test which is further placed in standard in briquettes

Tensile strength =failing load / 6.45

Tensile strength =failing load / 6.45

(c) Standard Consistency Test:

In order to find initial setting time, final setting times, soundness and strength a parameter termed as standard consistency is find.

Standard consistency is consistency of the cement which permits the penetration of Vicat's Plunger of diametre 10 mm and height 50 mm into the moulds of the given sample of amount upto the depth of 33 to 35 mm from the top and 5mm to 7 mm from bottom

This test hence deals with finding the water content at which the cement paste of standard consistency is prepared. In order to perform this test take 500 gms cement and add 24% of water by weight in first trial of form the mould. Remove the air voids if any found during the preparation of mould. However the plunger gently upto the top surface of the mould and release it quickly. Repeat this test up tell the penetration of 33-35 mm is observed from the top The percentage of water at which standard consistency is observed is denoted by 'p' this test is performed at 24 ±2ºC and at the relative humidity of 90%.

(e) Setting Time Test:

This test is used to detect the deterioration of cement due to storage. The setting time of the cement is generally analysed in terms of initial and final setting time.

Initial setting time: is defined as the time measured from the instant water is added into the time up to the times it starts loosing its plasticity In order to find the initial setting time 500 gm of cement sample is gauged with 0.85p% water required to prepare the cement past of standard consistency) added in this test and is tilled in the mould.

However the square needle gently up to the top surface of the mould and release it quickly Note the time taker by the needle to penetrate up to the depth of 33-35 mm from the this time is regarded as initial setting time and 5mm to 7mm from bottom For OPC, initial setting times is approximately 30 min. Final setting times is taken as the elapsed between the moment water is added in the cement upto the time completely looses its plasticity and attains sufficient firmness and is capable of resisting definite pressure.

In order to find the final setting time, needle with annular collar is lowered into the mould Final setting time is taken as the time at which needle is able to make an impression over the mould but annular collar fail to do so. For OPC, Final setting times is taken as 10 hrs.

(f) Soundness Test:

It is important that cement after setting does not shows any appreciable change in volume as it seriously affect the durability of structure (cracking) when cement is used in its construction.

The soundness of cement is due to presence of lime magnesia and sulphur which can be tested by any of the following method:

(i) Soundness due to lime:

Soundness due to lime is measured by lime chatlier's apparatus that consists of small split cylinder of spring brass of dia 30 mm and of height 30 mm An indicator arms of length 165mm is placed on either side of the split. In order to perform this test the sample of the cement is gauged with 0.78p and is placed in the cylindrical mould i.e. further covered with glass plate on top and bottom the entire assembly is immersed in the water having the temperature of 27 – 32°C for 24 hours which after removing is further tested for the displacement of split with the help of indicator is The entire assembly is again immersed in the water is boiled upto temperature of 100°C for 3 hrs.

The displacement of the split is again measured after removing the mould from the water. The difference of the reading during the both part of the test must not exceed 10 mm for OPC.

(ii) Soundness due to time and Magnesia. Soundness due to lime and magnesia is found using Autoclave test which is sensitive to both. In order to perform this test, mould of neat cement of size 25 mm is prepared and is placed in the autoclave in which pressure of steam is raised upto 21 kg/cm2 and is maintained for 3 hours. Change in size of the mould after removing it from autoclave should not exceed 0.8% or 2mm the original side.

(g) Chemical composition test:

• The ratio of percentage of Alumina to iron oxide should not be less than 0.66.

• The ratio of percentage of line to silica, alumina and iron oxide (termed to lime saturation factor) 0.66.

Lime saturation factor = 0.66 Ca O – 0.75 O3 1.02

• Total sulphur content 2.75%.

• Weight of insoluble residue 1.5%.

• Total loss on ignition 4%.

• Weight of magnesia 5%.

Different Types of cement:

1. Rapid Hardening cement:

• It is the cement which shows the higher rate of development of strength and must not be confused with quick setting cement which only sets quickly.

• This cement attains the strength at the age of 3 days which is equivalent to strength of OPC at 7 days.

This cement find its application in:

(a) prefabricated concrete construction,

(b) cold weather concreting,

(c) emergency repair work,

(d) where formwork is to be removed early to be reuse else where.

2. Extra Rapid Hardening cement:

• This cement is manufactured by inter-grinding rapid hardening clinkers with calcium chloride percentage of which should not exceed 2% by weigh of cement.

• This cement should be used within 20 minute of its formation.

• This cement attains 25% higher strength than rapid hardening cement at and age of 1-2 days and 10-20 higher strength at the age of 10 days.

• This gain of strength of the cement is reduced with age and at the age of 90 days, strength of the cement is found to be approximately same as that of OPC.

3. Sulphate Resisting Cement:

• OPC is highly susceptible to the attack of sulphate especially to that of MgSO4 which reacts with both Ca(OH)2 to form CaSO4 and calcium aluminate to form calcium - sulphur aluminate volume of which is approximately 227% than the original volume of the constituent.

The cement is manufactured by reducing the:

% of C3A and C4AF. [C2A 5% and C4AF + 2C3A 25%].

The cement find its application in:

(a) marine structure,

(b) sewage treatment works,

(c) foundation works,

(d) construction of pipe to be laid in marshy area.

4. Super-sulphated cement:

This cement is manufactured by inter grinding 80% granulates blast furnace slag with 15% hard burned gypsum and 5% cement clinkers.

5. Portland slag cement:

• This cement is produced by intergrinding cement clinkers with gypsum and granulated blast furnace slag in definite proportion.

• It is low heat cement.

• This cements offers higher resistance to sulphate and fluoride.

• It offers higher water tightness due to its lower permeability i.e. attained by the refinement of bored structure.

6. Quick setting cement:

• This cement is produced by adding small percentage of aluminium sulphate and reducing gypsum content and increasing fineness of the cement.

• This cement find its application in grouting works and concreting in static or running water.

7. Low Heat cement:

• This cement is produced by reducing the proportion of C3A and C3S and increasing proportion of C2S [C3A – 5%, C3S – 46%, C2S – 56%].

• The cement develops the strength at very slow rate and is generally used in mass concreting.

• Heat of hydration of cement of the age of 7 days is not greater than 65 calories/gm and at the age of 28 days, is not greater than 75 calories/gm.

8. Portland Pozzolana cement:

Portland pozzolana cement is prepared by grinding pozzolanic clinker with Portland cement. It is also produced by adding pozzolana with the addition of gypsum or calcium sulfate or by intimately and uniformly blending portland cement and fine pozzolana.

This cement has high resistance to various chemical attacks on concrete compared with ordinary portland cement and thus it is widely used. It is used in marine structures, sewage works, sewage works and for laying concrete under water such as bridges, piers, dams and mass concrete works etc.

• This cement possess:

(a) higher tensile strength.

(b) attains compressive strength with age.

(c) is more plastic and workable.

(d) offer higher resistance to attack of sulfur and chlorine.

(e) after higher resistance against explosion.

(f) low heat cement.

(g) after higher resistance to penetration of water.

(h) is more economical.

9. High Alumina Cement:

• This cement is manufactured by intergrinding the clinker obtained from calcination of bauxite and lime.

• In this type of cement percentage of alumina should not be less than 32% and ratio of alumina to lime should be in the range of 0.85 to 1.3.

This cement after initial setting time of more than 3.5 hour and final setting time for of 5 hours hence provide more time for placing & finishing.

• This cement can with stand high temperature and action of acids.

• This cements attains higher earlier strength such that 20% of ultimate strength is attained in one day and substantial strength is attained within 6-8 hours.

Important Points:

• Flour area occupied by 1 bag of cement = 0.3 m2 upto height 0.18 m.

• 1 bag = 34.5 liter.

• Volume = 0.0345 m3.

• Voids in Cement = 40%.

• During hand mixing 10% extra cement added.

• Water required for hydration - 20 - 30 Liter.

• Sugar increases 4% strength of cement.

• In the compressive strength Test at least 3 samples should be taken of size 70.67 mm (50 cm2).

• Compressive Test:

(i) 1 : 3 (Cement 185 gm : Ennore sand 555 gm).

(ii) Water required =  %.

%.

where - P is consistency.

• Tensile Strength Test:

(i) Tensile Strength of cement is determined with the help of briquette are used.

(ii) Water required =  %.

%.

Note: Compressive test is done in room Temperature (27 + 2ºC) and at 90% humidity.

|

2 videos|122 docs|55 tests

|

FAQs on Cement - Civil Engineering SSC JE (Technical) - Civil Engineering (CE)

| 1. What is Cement SSC Exam? |  |

| 2. What are the eligibility criteria for Cement SSC Exam? |  |

| 3. What is the syllabus for Cement SSC Exam? |  |

| 4. How can I prepare for Cement SSC Exam? |  |

| 5. What is the selection process for Cement SSC Exam? |  |

|

2 videos|122 docs|55 tests

|

|

Explore Courses for Civil Engineering (CE) exam

|

|