Welding - 1 | Mechanical Engineering SSC JE (Technical) PDF Download

Introduction

Welding is the process of joining similar or dissimilar metals with or without the application of heat and pressure Weldability of a material depends upon various factor.

If filler-material used is same of the base material then it is homogeneous welding] otherwise its hetrogeneous.

Metallurgy In Welding

The microstructure and grain size of the welded joint depend on the amount of heat applied and the consequent rise in temperature. Weld quality depends on many factors, among them the geometry of weld bead and the presence of cracks, residual stresses, inclusions and oxides films.

• Metal is heated over a range of temperature up to fusion and followed by cooling to ambient temperature.

• Because of differential heating, the material far away from the weld bead will be simply warmed out.

• But as the weld area is approached, progressively higher temperature are obtain resulting in a corresponding complex microstructure.

• The heating and cooling also results in setting in internal stresses and plastic strain in the weld.

• So at high temperature physical, chemical and metallurgical properties are liable to change.

The three distinct zones in a welding process are :

1. Base metal. 2. Heat affected zone. 3. Weld metal.

• A joint produced without filler metal is called autogenous and its weld zone is composed of unsolidified base metal.

• A joint made with a filler metal is called weld metal.

• After application of heat and the introduction of the filler metal into the weld area, the molten joint is allowed to cool to ambient temperature.

• Since central portion of the bead will be cooled slowly and in the outer ward direction grains will become finer and finer.

• So ductility and the toughness of bead metal at the centre will be higher.

• The weld metal when it is in the molten state has a good capacity to dissolve gases which come into contact with it like oxygen, nitrogen, and hydrogen.

• As metal start cooling, capacity of dissolving gases goes on decreasing thus causing additional volume of gases to be evolved.

• Due to the appearance of mushy zone during solidification, a potion of these gases may be trapped into the bead called porosity.

• This decreases the strength of weldment.

Heat Affected Zone

The heat affected zones (HAZ) is within the base metal itself. It has a microstructure different from that of :ne base metal prior to welding, because it has been subjected to elevated temperatures for a period of time during welding. The portion of the base metal that are far enough away from the heat source don’t undergo any structural changes during welding.

The properties of the HAZ depend on

(i) The rate of heat input and cooling

(ii) the temperature to which this zone was raised.

The strength and hardness of the heat affected zone depend partly on how the original strength and hardness of the base metal was developed prior to the welding. The heat applied during weld recrystallize, the elongated grains of the cold worked base metal. Grains close to the weld metal, on the other hand, have been subjected to elevated temperature for a longer period of time, consequently they will grow. This growth will cause their region to be softer and to have use strength. Such a joint will be weakest in its affected zone. The grain structure of such a weld that is exposed to corrosion by chemical reaction, the vertical center line is where the two pieces meet.

The effects of heat on the HAZ for joints made from dissimilar metal and for alloys strengthened by other method, are so complex as to beyond the scope of this text.

BEAD GEOMETRY

By the application of heat source we are depositing the liquid metal at the joint.

The depth, up to which the material is liqu fied is called penetration and there will be raised portion of the plane of parent metal called reinforcement. In ideal cases the dilution should be as close to be as 100%

Ap = Area of penetration ; AR = Area of Reinforcement

Type of welding

Transformer and its types

A transformer is a passive electrical device that transfers electrical energy from one electrical circuit to one or more circuits. A varying current in any one coil of the transformer produces a varying magnetic flux, which, in turn, induces a varying electromotive force across any other coils wound around the same core. Electrical energy can be transferred between the (possibly many) coils, without a metallic connection between the two circuits.

Constant current type transformer

• In manual arc welding since arc length can not be controlled, so arc current is controlled by transformer.

• A conventional arc welding power source is known as the constant current machine.

• The constant current curve shown in Figure that the welding power source produces max. Output voltage with no load and as load increases, the output voltage decreases.

Constant voltage transformer

• A constant voltage welding power source has essentially a flat volt ampere characteristic curve through usually with a slight drop.

• The curve may be shifted up or down to change the voltage.

• These characteristic are used only for continuous electrode wire welding such as gas welding semiautomatic and automatic welding process.

• If the load in the circuit changes, the power source automatically adjust its currents output to satisfy the requirements.

• And maintain essentially the same voltage across the output terminals.

• The constant voltage welding power system has its greatest advantage when current density of the electrode wire is high

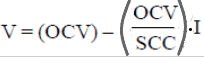

OCV= Open circuit voltage.

SCC= Short circuit current.

Short Circuit Current

It is that current which flow when we touch work piece by electrode. This is the current required during arc iteration. It is that current which flow when we maintain a gap between work piece and electrode

V = A + BI

V = Voltage

L = Arc length

A, B = Constant

Open Circuit Voltage

• Its the amount of voltage required to generate the arc under no load condition.

• Generally open circuit voltage is around 80 volt

Duty Cycle

• It is the amount of time during which the transformer will be used for welding under normal loading conditions.

• It is the time span in successive 10 min interval during which current can be drawn from the transformer, after that there should be a compulsory break otherwise the temperature of its essential components will increase. Usually 60% duty cycle is the standard industrial rating. A power source with such a rating can supply its rated output for 6 minutes in every ten minute interval of its operation.

where,

I2D = Constant

D = Duty cycle, and

I = Current

NOTE : After every interval there should be compulsory break otherwise the temperature of its essential components will increase.

Arc Blow

• Due to fixed polarity magnetic lines forms in the work piece material.

• Upon welding at the centre of the work magnetic lines will be equally distributed on both sides. So arc will be straight.

• But while welding near the edges, since the magnetic lines will be concentrated in the material arc it will be deflected towards work piece.

• This phenomenon is called Are Blow which result in severe spatter and improper bead geometry

• To avoid this phenomenon metal plates arc kept at the entry and at the exist called Tab in and Tab out.

• Reduce the current intensity so strength of magnetic field can be reduced.

• Change the welding current from DC to AC because continuous change in polarity, the effect of magnetic field is mollified.

Classification of Welding Process

(1) Arc Welding (2) Resistance Welding

(3) Solid state Welding (4) Radiant Energy Welding

(5) Thermite Welding (6) Allied Welding

(7) Gas Welding

Arc Welding

Principle of Arc

• An arc is generated between two conductor of electricity, cathode and anode (considering direct current, DC); when they are touched to establish the flow of current and then separated by a small distance.

• An arc is a sustained electric discharge through the ionized gas column, called plasma, between the two electrodes. In order to produce the arc, potential difference between the two electrodes (voltage) should be sufficient to allow them to move across the air gap.

• The larger air gap requires higher potential difference. If air gap becomes too large the arc may be extinguished. Duty cycle is the amount of time during which transformer, will be used for welding under normal loading conditions.

While welding near the edges, since most of the magnetic lines will be concentrated in the material, arc will be deflected towards the workpiece. This phenomenon is called arc blow which result in spatter.

• Melting Efficiency = (h)

• Heat require to melt the joint = Volume melted × Rate of melting.

• Volume melted = Area of joint × Welding speed.

• Net heat supply =

I = Current

V = Voltage

hHT = Heat transfer efficiency.

Shielded Metal Arc Welding (SMAW)

Shielded metal arc welding (SMAW) is one of the oldest, simplest and most versatile joining processes (as shown in Figure ). About 50% of all industrial and maintenance welding is currently performed by this process. The electric arc is generated by touching the tip of a coated electrode against the workpiece and then withdrawing it quickly to a distance sufficient to maintain the arc. The electrode are in the shape of a thin long stick so this process is also known as stick welding.

The heat generated melts a portion of the tip of the electrode, of its coating and of the base metal in the immediate area of the arc. A weld forms after the molten metal, a mixture of the base metal, the electrode metal and substances from the coating on the electrode, solidifies in the weld area. The electrode coating deoxidizes the weld area and provides a shielding gas to protect is from oxygen in the environment.

A bare section at the end of the electrode is clamped to one terminal of the power source. While the other terminal is connected to the workpiece being welded. The current usually ranges between 50A and 300A. Power source requirements are generally less than 10 kW. The current may be DC or AC. For sheet metal welding, DC is preferred because of the steady arc it produces.

The polarity of the DC current that is, the direction of current flow, can be important its selection depends on such factor as type of electrode, the metals to be welded and the depth of the heated zone. In straight polarity, the workpiece is positive and the electrode negative, it is preferred for sheet metals, because it produces shallow penetration and for joint wide gaps. In reverse polarity, the electrode is positive, and deeper weld penetration is possible, in the AC method, the arc pulsates rapidly this method is suitable for welding thick sections and for using large diameter electrode at maximum currents.

• This is also called as stick electrode welding or coated electrode welding or manual arc welding.

• If uses coated electrodes of 2.5 to 6.35 mm diameter and 300 to 450 mm length held in an electrode with work piece.

• Then a gap is maintained between electrode and the work piece with in the gap between electrode and work piece, free electrons and holes will be formed in gas.

NOTE:

The rate at which electrode wire is getting consumed with the same rate the electrode has to be fed towards the molter pool.

It is because arc length decides the arc voltage and arc current.

If lower is the current settings, the temperature of molten pool will be lower as a result of that the liquid flux trying to come out of material will be solidified and slag will be trapped with in the bead.

This defect is called slag inclusion.

Movement of electrode along the longitudinal direction of bead.

SHAW (Shielded Metal Arc Welding) can be performed both on AC and DC source with dropping characteristics.

The temperature in the core of the arc ranges between 6000 - 7000° C.

GAS Tungsten Arc Welding (GTAW) or Tungsten Inert Gas Welding (TIG)

• In this technique non consumable tungsten electrode will be used to generate the arc. This was primarily invented to weld alloys of aluminium and magnesium.

• Aluminium material is very difficult to weld because as soon as it is exposed to atmosphere it forms a layer over it.

• To increase thermal resistance of Tungsten alloying elements like thorium and Beryllium are added. The gas nozzle of a tungsten inert gas welding force is

its weak test part and it festered to the torch body by threaded connection.

• Molten weld pool is protected by inert gas atmosphere (Helium, Ne, Ar N2 and C02 etc) N2 is preferred for welding copper.

• The power supply will be AC to DC depending on the work piece material.

• For all other material except Al, Mg alloy Direct Current Straight Polarity (DCSP) will be used.

• So that heat concentration will be more on work piece side and depth of penetration is more.

• For Al and Mg alloys if we use straight polarity due to high temperature oxide formation is severe and this will not alloy electrons from the electrode.

• To overcome this direct current reverse polarity is used (DCRP).

• The melting rate of the electrode is more when compared to melting of the work piece due to this depth of penetration is reduced.

• To overcome this AC welding will be used for welding AI and Mg alloys.

Applications

GTAW process is used for a wide variety of metal and applications, Particularly aluminium, magnesium, titanium and the refractory metals. It is used especially for thin sheets of metals. The lost of the insert Gas makes this process more expensive than SMAW but provides welds with very high quality and surface finish. It is used in a variety of critical applications with a wide range of workpiece thickness and shapes.

The equipment is portable.

• Welding of Al and Mg alloys in Aerospace industries and automobiles industries.

• This process is used to weld in all Position because weld bead thickness is less.

NOTE:

• It is difficult to weld high thickness material by TIG because if we use filler material movement of the filler material with respect to electrode is difficult.

• For stable arc in constant voltage transformer = Varc = Vtransformer

• For stable arc in constant current transformer = Iarc = Itransformer

Power in welding is given by-

P = VI

P = Power

V = Voltage

I = Current

• During welding if the movement of electrode with respect to the workpiece will be controlled automatically, than these welding machines are called automatic welding machine.

• If the movement of the electrode is controlled by automatic machine and the relative movement of electrode manually than this type of welding is known as semiautomatic machines.

Metal Inert Gas Welding (MIG) or Gas Metal Inert Gas Welding (GMIG)

Metal gas arc welding (MIG) is also known as gas metal arc welding, the weld area is shielded effectively by inserting atmosphere of argon helium, carbon dioxide, or various other gas mixture. The consumable bare wire is feed automatically through a nozzle into the weld arc.

As an addition to the use of inert shielding gases, deoxidizers are usually present in the electrode metal itself, in order to prevent oxidation of the molten weld paddle multiple weld layers can be deposited at the joint.1Metal can be transferred by three methods in GMAW processes these are the spray, the globular and the short circuiting. In spray transfer, small droplets of molten metal from the electrode are transferred to the weld area at a rate of several hundred developed per second. The transfer is spatter free and way stable. In globular transfer, carbon dioxide rich gases are utilized and globules propelled by the forces of the electric arc transfer the metal,: with considerable splatter. High welding currents are used; they make possible greater weld

penetration and welding speed than arc achieved in spray transfer. Heavier sections are commonly joined by this method.

In short circuiting the metal is transferred in individual droplets more than 50 per second as the electrode tip touches the molten weld metal and short circuits. Low currents and voltages are utilized, with carbon dioxide rich gases and with electrodes made up of small diameter wire.

• In MIG consumable electrode is used in the form of spool wire.

• Direct current reverse polarity will be used for welding all materials because it increase the weld deposition rate.

• Here high thickness material can also be welded by increasing the current supply, the depth of penetration increase

• Movement of electrode and feeding of the electrode is done automatically so the power source used must have constant voltage.

• in MIG metal transformed in the form of molten drop.

Application

The GMAW process is suitable for welding a variety of ferrous and nonferrous metal and is used extensively in the metal fabrication industry. Because of the relatively simple nature of the process, the training of operations is easy. The process is versatile, rapid and economical and welding productivity is double that of the SMAW process.

The GMAW process can easily be automated and lends itself readily to robotics and to flexible manufacturing system.

It is used for welding of stainless steels, Aluminium, Mg, Cu, and Ni alloys in aircraft and automobiles industries. Initial cost is very high.

Submerged Arc Welding (SAW)

In submerged arc welding (SAW) (as shown in Figure ) the weld arc is, shield by a granulor flux, : consisting of silica, maganese oxide, calcium fluoride and other compounds. The flux is fed into the weld zone by gravity flow through a nozzle. The thick layer of flux completely covers the molten metal it prevents spatters and suppress

the intense ultraviolet radiation and flame characteristics of the SMAW process. The flux acts as a thermal insulator, promoting penetration of heat into the workpiece. The consumable electrode is a coil of bare round will 1.5 mm -10 mm in diameter; it is fed automatically through a tube (welding Gun). Electric currents typically range between 300 A and 2000 A. The power supplies are usually connected to standard single or three phase power lines with a primary rating up to 440 V.

Process Capabilities of SAW

Because the flux is fed by gravity, the SAW process is largely limited to weld in a flat or horizontal position and having a backup piece. Circularly welds can be made on pipes, provided that they are rotated During welding the infused flux can be recovered treated and reused

The SAW process can be automated for greater economy. It is used to weld a variety of carbon and alloy steel and stainless sheet or plate, often at a speed as 5 m/ min. The quality of the weld is very high, with good toughness, ductility and uniformity of properties.

The typical applications include thick plate welding for shipbuilding and for pressure vessels.

(a) and (b) Welding using SAW process

Applications

• It is extensively used in joints in thick plates in pressure vessel, ships, bridges, structural work, welded pipes and nuclear reactors.

• It is also used for making LPG cylinders.

NOTE:

• This is semi automatic version of shielded metal arc welding.

• In this type of welding electrode is in the form of spool of copper wire and granular flux is used.

• It is used for long run weld.

• Powder flux is supplied into the welding area and arc is maintained within the pool of flux.

• This minimizes the spatter of liquid metal and suppress the intense violet radiation.

• Flux also act as a thermal insulator by deep penetration of heat into the work piece.

• It is mainly used in the down hand welding position in a semiautomatic welding process.

• Feeding of electrode towards the weld pool is controlled by machine.

• In SAW flux is used in the form of Granules and flux material contain CaO and Caf2.

• The weld obtain by this process is stronger than the base metal.

• It can only be used for welding flat position and heat effected zone is high.

Plasma Arc Welding

• Plasma is the pool of ionized gas. Initially the arc is being created between tungsten electrode and | the work piece, by taking energy from the spark converter into plasma

• The temperature of plasma is around 50000° C but for welding process it is

restricted to 20000° C.

• This high temperature arc when impinges upon the work piece, resulting in reuniting of electrons and ions to form atomic and molecular gas. Releasing heat in the process which thus utilized for welding.

• Due to increase source of heat penetration will through and without spreading the heat affected zone it is called keyhole phenomenon.

• This phenomenon will insure 100% penetration

• When plasma torch is used for cutting it called metal melting process.

• Plasma arc is also concentrated because it feed through small nozzle.

• In the non transferred type the arc occurs between the electrode and the nozzle and heat is carried out to the work piece by plasma gas.

• The major application of the process is in welding stainless steel, titanium, metal having high melting point.

• Commercially it is used in aeronautical industry, precision instrument industry and jet engine manufacturing.

• The major draw back is that intense arc will produce extensive ultra violet and inferred radiation which is harmful for skin.

Applications

Compared to other arc welding process, plasma arc welding has higher energy concentration (and so permits deeper and narrower welds), better arc stability use thermal distortion and higher welding speeds, from 120 to 1000 mm/min. A variety of metals can be welded, with part thicknesses generally less than 6 mm.

The high heat concentration can penetrate completely through the joint, with thicknesses as much as 20 mm for some titanium and aluminium alloys. In the keyhole technique, the force of the plasma arc displaces the molten metal and produces a hole at the leading edge of the weld pool. Plasma arc welding, rather than the GTAW process is often used for butt and lap joints, because of its higher energy concentration, better arc stability and higher welding speeds. Proper training and skill are essential for operators who use this equipment. Safety consideration includes protection against glare, spatter and noise from the plasma arc.

Electro Slag Welding or Electro Gas Welding

• Welding is started by generating electric arc and completed by resistance heating effect of slag material. (As shown in Figure)

• Welding progresses in the vertical direction and due to this temperature of the molten pool keeps on increasing.

• A pair of water cooled Cu shoes is being provided on the sides to avoid any spillage of liquid metal to the sides.

• Once the temperature of the molten pool reaches a particular value arc is switched off and the molten pool is so hot that it starts consuming the wire without any arc.

• If heat effected zone increases it may cause distortion of the plate.

• Both AC and DC can be used with a rating of 1000 amperes.

Applications

Electro slag welding is capable of welding plates with thickness ranging from 50 mm to more than 900 mm. Welding is done in one pass. The current required is about 600 A at 40 V - 50V, although higher currents are used for thick plates. Travel speed of the weld is in the range of 12 to 36 mm /min. Weld quality is good and the process is used for heavy structural steel sections such as heavy machinery and nuclear reactor vessel. The cost of the typical ESW system is high and higher for multiple electrode units.

• The process is used to join two thick plates along the edges

• The major application is in ship building

• It can be used for welding plates of thickness 20 mm - 40 mm.

NOTE : It can only be used in welding in vertical position.

Electrodes

Electrodes for the consumable arc welding processes described arc classified according to the strength of the deposited weld metal, the current (AC or DC) and the type of coating. Electrodes arc identified by numbers and letters or by colour code.

Electrode Coating

Electrodes are coated with clay like materials that includes silicate binders and powdered materials such as oxides, carbonates, fluorides metal alloys and cellucose.

This is because

(i) to stabilize the arc

(ii) to generates core to act as a shield against the surrounding atmosphere the gases produced arc carbon dioxide and water vapor.

(iii) to control the rate as which the electrode melts.

(iv) to act as a flux (a) protect the weld against formation of oxides, nitrides and other inclusions and (b) with the resulting slag protect the molten weld pool.

(v) to add alloying elements to the weld zone to enhance the properties of the join-among them, deoxidizers to prevent the weld from becoming brittle.

The deposited electrode coating or slag must be removed after each-pass in order to ensure a good weld.

Gas Cutting

Gas cutting is similar to oxyfuel welding but the heat source is now used to remove a narrow zone from plate or sheet. This process is particularly suitable for steels.

The basic reactions with steels arc

Fe + O --> FeO + heat

3Fe + 2O2 --> Fe2O3 + heat

and

4Fe + 3O2 --> 2Fe2O3 + heat

The greatest heat is generated by the second reactions and it can produces a temperature rise to about 870ºC. However, this temperature is not sufficiently high to cut steels, so the workpiece is preheated with fuel gas and Oxygen is introduced later.

|

6 videos|104 docs|59 tests

|

FAQs on Welding - 1 - Mechanical Engineering SSC JE (Technical)

| 1. What are the different types of welding processes? |  |

| 2. What safety precautions should be followed when welding? |  |

| 3. What factors should be considered when selecting a welding technique? |  |

| 4. How can one ensure a strong weld joint? |  |

| 5. What are common defects in welding and how can they be prevented? |  |