Highway Maintenance | Civil Engineering SSC JE (Technical) - Civil Engineering (CE) PDF Download

Introduction

Highway (road) maintenance is defined as preserving and keeping the serviceable conditions highway as normal as possible and practicable. The main objectives of road maintenance men are the allocation of available maintenance resources according to actual needs and priorities. If the maintenance works are not done at all or done faulty or the pavement structure inadequate for present-day and loading.

A highway (Road) surface level is deteriorating in its level of serviceability due to many causes, some of them are given below:

- Traffic factors: The traffic operating on the facility can cause different types of distress like rutting, corrugations, raveling, etc. The amount of deterioration depends upon the intensity of traffic, wheel load, and its repetitions.

- Environmental factors: The external influence of environmental factors like rainfall, temperature variations, snowfall, landslides, etc. also deteriorate the road pavement. Rainfall causes erosion of shoulders while snowfall cause ingress of water into the pavement structure. Similarly, temperature variation causes adversely affect the performance of the bituminous surface and cement concrete pavements.

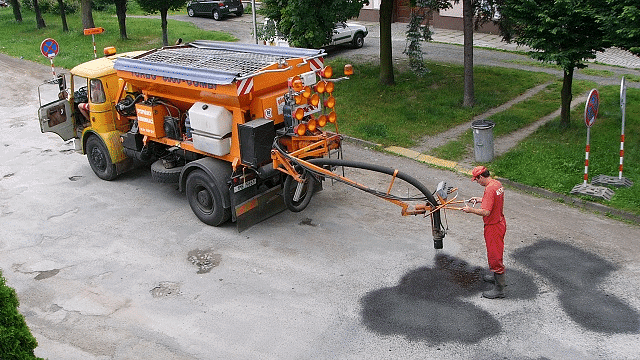

Repair of Road by Injection Pressure Surface Material

Repair of Road by Injection Pressure Surface Material

- Additionally, poor maintenance requires a large cost expenditure and is problematic for the location, design, and building of the highway. The cost of maintenance on poorly built roads could be larger than the initial cost.

- Road maintenance is a series of interdependent activities carried out for preserving and keeping road, roadside, highway furniture, structures and other facilities in the best possible condition provide satisfactory and safe transportation along the highway with the optimum cost”.

Need for Highway Maintenance

Road maintenance is one of the important components of the entire road system. The maintenance operations involve the assessment of road condition diagnosis of the problem and adopting the most appropriate maintenance steps.

General Causes of Pavement

Failures

Some of the general causes of pavement failures needing maintenance measures may be classified as given below:

- Defects in the quality of materials used.

- Defects in construction method and quality control during construction.

- Inadequate surface or subsurface drainage in the locality resulting in the stagnation of water in the subgrade or in any of the pavement layers.

- Increase in the magnitude of wheel loads and the number of load repetitions due to increase in traffic volume.

- Settlement of foundation of embankment of the material itself.

- Environment factors including heavy rainfall, soil erosion, high water table, snow fall, frost action, etc.

Failures in Flexible Pavements

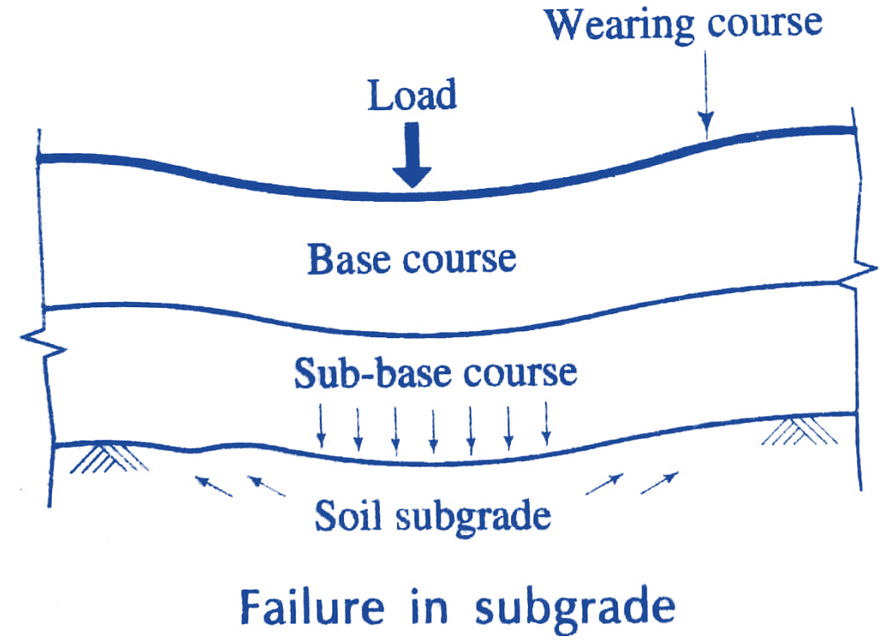

(a) Failure in Subgrades

- One of the prime cause of flexible pavement failure is excessive deformation in subgrade soil. This can be noticed in the form of excessive undulations or waves and corrugations in the pavement surface.

- The lateral shoving of pavement near the edge along the wheel path of vehicles is due to insufficient bearing capacity or a shear failure in subgrade soil.

- The failure of subgrade may be attributed due to inadequate stability and excessive stress application.

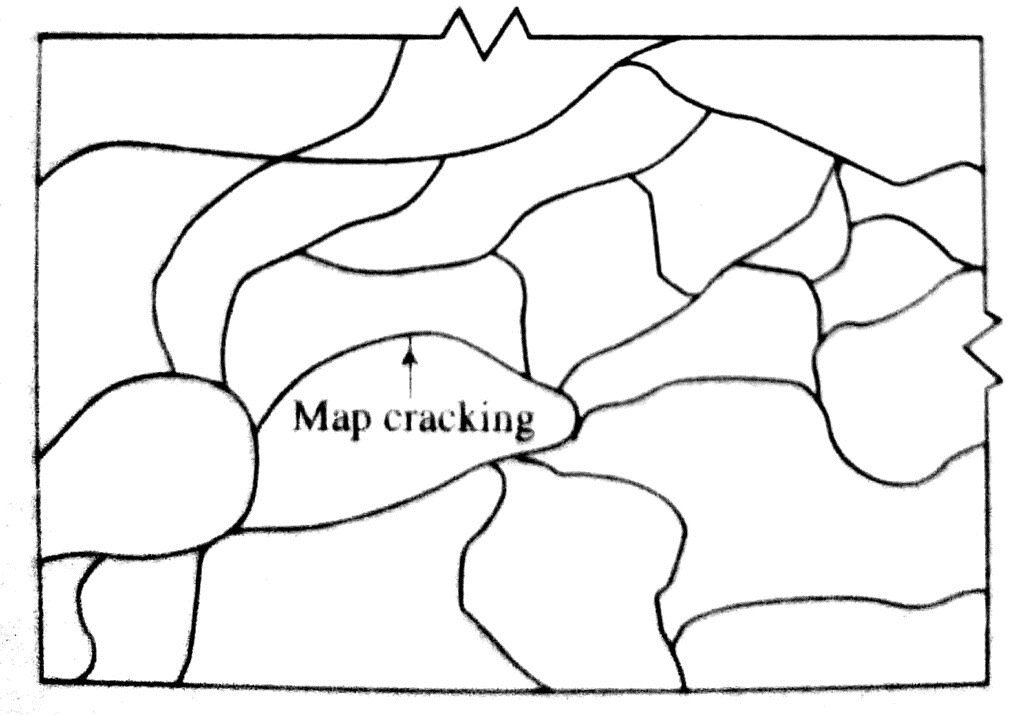

(b) Failures in Sub-base or Base Courses

Following are the chief types of sub-base or base course failures:

- Inadequate stability or strength

- Loss of binding action

- Loss of base course materials

- Inadequate wearing course

- Use of interior materials and crushing of base course materials.

- Lack of lateral confinement for the granular base course.

Failure in Base Course

Failure in Base Course

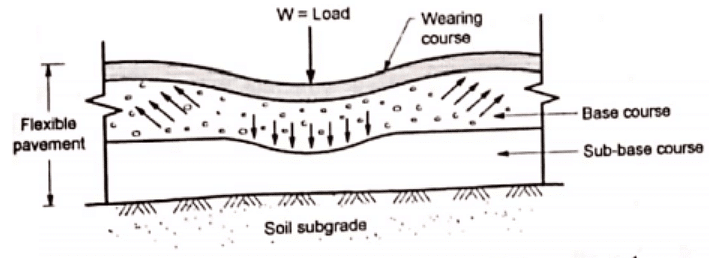

(c) Type of Flexible Pavement Failures Alligator (Map) Cracking

- This is the most common type of failure and occurs due to relative movement of pavement layer materials.

- This may be cuased by the repeated application of heavy wheel loads resulting in fatigue failure or due to the moisture variations resulting in swelling and shrinkage of subgrade and other pavement materials.

- Localized weakness in the underlying base course would also cause cracking of the surface course in this pattern.

Map Cracking

Map Cracking

(d) Consolidation of Pavement Layers

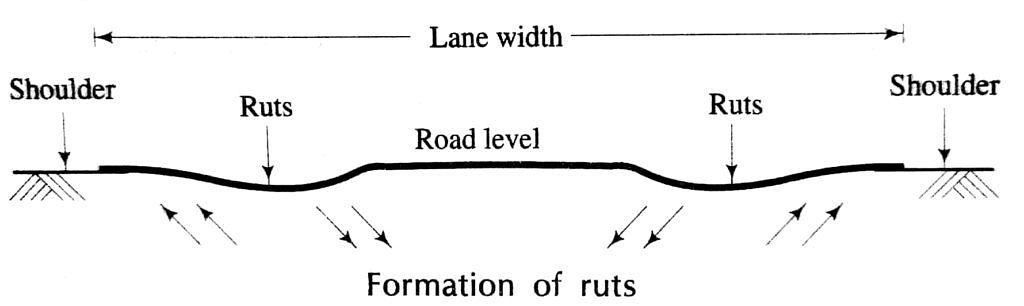

- Formation of ruts are mainly attributed to the consolidation of one or more layers of pavement

- The repeated application of loads along the same wheel path cause cumulative deformation resulting in consolidation deformation longitudinal ruts.

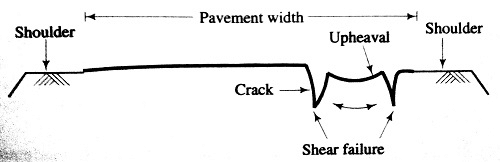

(e) Shear Failure and Cracking

- Shear failures are associated with the inherent weakness of the pavement mixtures, the shearing resistance being low due to inadequate stability or excessively heavy loading.

Shear failure & Cracking

Shear failure & Cracking

(f) Longitudinal Cracking

- Due to frost action and differential volume changes in subgrade longitudinal cracking is caused in pavement traversing through the full pavement thickness.

- Settlement of fill and sliding of side slopes also would cause this type of failure.

Longitudinal Cracking

Longitudinal Cracking

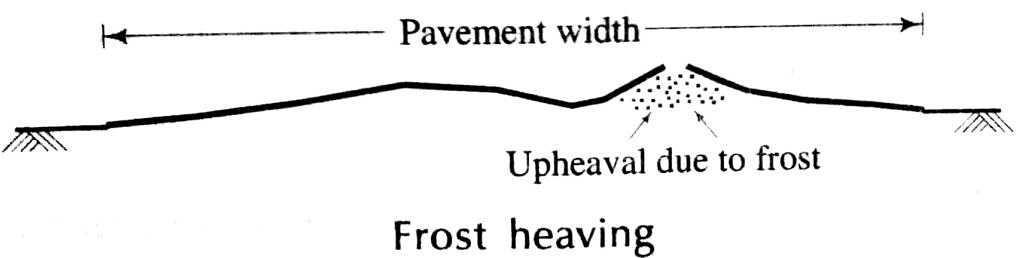

(g) Frost Heaving

- In shear failure, the upheaval of portion of pavement is followed with a depression.

- In the case of frost heaving, there is mostly a localized heaving-up pavement portion depending upon the ground water and climatic conditions.

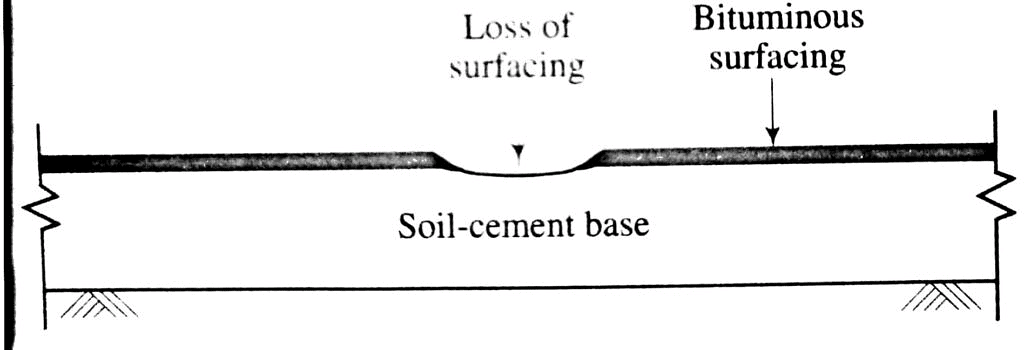

(h) Lack of Binding with Lower Layer

- Slipping occurs when the surface course is not keyed/bound with the underlying base. This results in opening up and loss of pavement materials forming patches or pot holes.

- Such conditions are more frequent in case when the bituminous surfacing is provided over the existing cement concrete base course or soil cement base course.

Failure due to Lack of Binding

Failure due to Lack of Binding

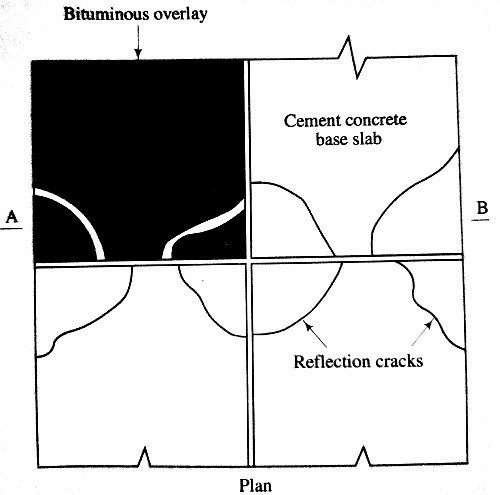

(i) Reflection Cracking

- This type of cracking is observed in bituminous overlays provided over existing cement concrete pavements.

- The crack pattern as existing in cement concrete pavements are mostly reflected on bituminous surfacing in the same pattern.

- Structural action of the total pavement section is not much influenced by the presence of reflection cracks but since the cracks appear at the surface, these allow surface water to seep through and cause damage to the soil subgrade or result in mud pumping.

Reflection Cracking

Reflection Cracking

(j) Failure in Cement Concrete Pavements

- Failure of cement concrete pavements are recognized mainly by the formation of structural cracking.

- The failures are mainly due to two factors:

1. Deficiency of pavement materials

2. Structural inadequacy of the pavement system

Deficiency of Pavement Materials

Following are the chief causes which would give rise to the different defects or failures of cement concrete pavement:

1. Soft aggregates

2. Poor workmanship in joint construction

3. Poor joint filler and sealer material

4. Poor surface finish

5. Improper and insufficient curing

The various defects that creep in due to the above are:

1. Disintegration of cement concrete

2. Formation of cracking

3. Spalling of joints

4. Poor riding surface

5. Slippery surface

6. Formation of shrinkage cracks

7. Ingress of surface water and further progressive failures.

Structural Inadequacy of Pavement System

Inadequate subgrade support pavement thickness would be a major cause of developing structural cracking in pavements.

Following are the cause and types of failure which develop:

1. Inadequate pavement thickness

2. Inadequate subgrade support and poor subgrade soil

3. Incorrect spacings of joints.

Above would give rise to the failures of the following types:

1. Cracking of slab corners

2. Cracking of pavements longitudinally.

3. Settlement of slabs

4. Widening of joints

5. Mud pumping

Typical Rigid Pavement Failures

(a) Scaling of Cement Concrete

- Scaling is observed in cement concrete pavement showing overall deterioration of the concrete.

- The scaling is mainly attributed due to the deficiency in the mix or presence of some chemical impurities which damage the mix.

- Due to excessive viration given to mix, the cement mortar comes to the top during construction and thus with use, the cement mortar gets abraded exposing the aggregate of the mix. This makes the pavement surface rough and shabby in appearance.

(b) Shrinkage Cracks

- During the curing operation of cement concrete pavements immediately after the construction, the shrinkage cracks normally develop.

(c) Warping Cracks

- If the joints are not well designed to accommodate the warping of slabs at edges, this results in development of excessive stresses due to warping and the slab develops cracking at the edges in an irregular pattern.

- Hinge joints are generally provided for relieving the slabs of warping stresses.

(d) Mud Pumping

- Mud pumping is recognized when the soil slurry ejects out through the joints and cracks of cement concrete pavement caused during the downward movement of slab under the heavy wheel loads.

Following are the factors which cause the mud pumping :

1. Extent of slab deflection

2. Type of subgrade soil

3. Amount of free water - Pumping is noticed just after the rains in cement concrete pavements that are placed on clayey soil subgrade.

- Due to the applications of repeated loads, initial spaces are developed underneath the pavement slabs and water infiltrates into these spaces through joints, cracks and edges of the pavements.

- Since the soil is also of fine-grained type, it holds water and forms the soil slurry or soil suspension in water or the mud.

Maintenance of Water Bound Macadam Road

- WBM roads are damaged rapidly due to the heavy mixed traffic and adverse climatic conditions.

- In dry weather dust is formed and during rains mud is formed. The steel tyred bullock carts cause severe wear and tear to the WBM surface.

- Dust nuisance can be effectively prevented by providing bituminous surface dressing course over WBM pavement. However temporary measures include spraying of dust palliatives.

- Pot holes and ruts formed should be patched up. The patch repair work is carried out by first cutting out a rectangular shape of the defective area to remove the stone up to the affected depth.

Maintenance of Bituminous Surfaces

- Patch works is normally done on affected localized areas or sections using a cold premix.

- Generally, cutback or emulsion is used as binder for patching.

- Bituminous emulsions could be used even when the pavement surface and the aggregates are wet during monsoons.

Pavement Evaluation

- There are two approaches of pavement evaluations:

(i) Structural evaluation of pavements.

(ii) Evaluation of pavement surface condition. - Structural evaluation of both flexible and rigid pavement may be carried out by plate bearing test.

- The performance of a flexible pavement is related to be elastic deflection under loads or its rebound deflect ion. Benkelman beam is used for measurement of transient deflection.

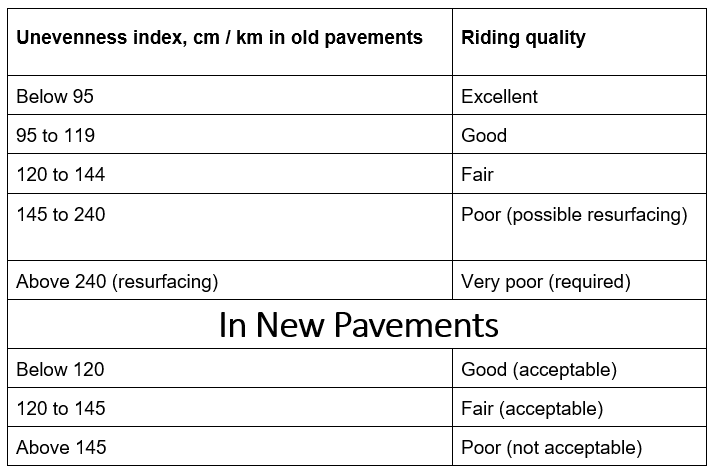

- The pavement unevenness may be measured using unevenness indicator, profilograph profilometer or roughometer. Unevenness index of the surface in cm/km length of road may be called bump integrator or unevenness integrator.

- The pavement serviceability concept was introdu ced at the AASHO Road Test for comparing relative performance of various test sections during periods.

- The present serviceability rating (PSR) is the mean opinion of the members of the rating panel and this is correlated with the physical measurements such as longitudinal and transverse profile of the pavement degree of cracking and patching etc., affecting pavement serviceability.

Flexible Overlay Over Flexible Pavement by Conventional Design Method

- The total pavement thickness required is designed for the design traffic and the existing conditions of subgrade.

- The existing thickness of the pavement is found from test pits dug along the wheel path on the pavement.

- The overlay thickness required h0 = hd – he

where, hd = total design thickness required; cm he = total thickness of the existing pavement, cm

Overlay design by Benkelmann Beam Deflection Studies

- Benkelmann Beam is a device which can be conveniently used to measure the rebound deflection of a pavement due to a dual wheel load assembly or the design wheel load.

- The equipment consists of a slender beam of length 3.66 m which is pivoted to a datum frame at a distance 2.44 m from the probe end.

|

2 videos|133 docs|55 tests

|

FAQs on Highway Maintenance - Civil Engineering SSC JE (Technical) - Civil Engineering (CE)

| 1. What is the need for highway maintenance? |  |

| 2. What are the deficiencies of pavement materials? |  |

| 3. What are the typical failures observed in rigid pavements? |  |

| 4. How is water bound macadam road maintained? |  |

| 5. What is the importance of pavement evaluation in highway maintenance? |  |