Energy from Waste resources - People, Development and Environment Notes

1. Fuel Cells

The basic principle involved in the working of the fuel cell is based on the conversion of stored chemical energy into electrical and heat energy, without going through the combustion. A fuel cell is an electro-chemical device, which consists of an electrolyte sandwiched between two electrodes. Oxygen passes over one electrode and hydrogen over the other, and they react electrochemically to generate electricity, water and heat.

Now, we list out the comparison of the Internal combustion engine vehicles vs Fuel cell-powered vehicles:

- Compared to vehicles powered by the internal combustion engine, fuel cell-powered vehicles have very high energy conversion efficiency, and near-zero pollution, carbon dioxide and water vapour being the only emission.

- Fuel-cell powered electric vehicles score over battery-operated electric vehicles in terms of increased efficiency and easier and faster refuelling.

- In India, diesel-run buses are major means of transport and these emit significant of SPM and Sox. Thus, fuel-cell-powered buses and electric vehicles could be introduced with relative ease to dramatically reduce urban air pollution and to make a positive impact on urban air quality.

- Fuel cell systems are excellent candidates for small-scale decentralized power generation as compared with conventional large scale power plant that uses non-renewable fuels; imposing adverse ecological and environmental impacts.

- Fuel cell, on the other hand, does not impose environmental threat and is comparatively cleaner and environmentally friendly.

- A fuel cell can supply combined heat and power to commercial building, hospital, airports and military installation at remote locations.

- With an efficiency of 55%, as compared with 35% efficiency of conventional power plants, fuel cell have significantly lower CO2 and water vapour making it more environmentally friendly.

- In Fuel cells, additional capacity can be added whenever required with relative ease, that makes the system modular and can be set up wherever power is required.

- The only disadvantage is the high initial cost that is the only biggest hurdle in the widespread commercialization of fuel cells.

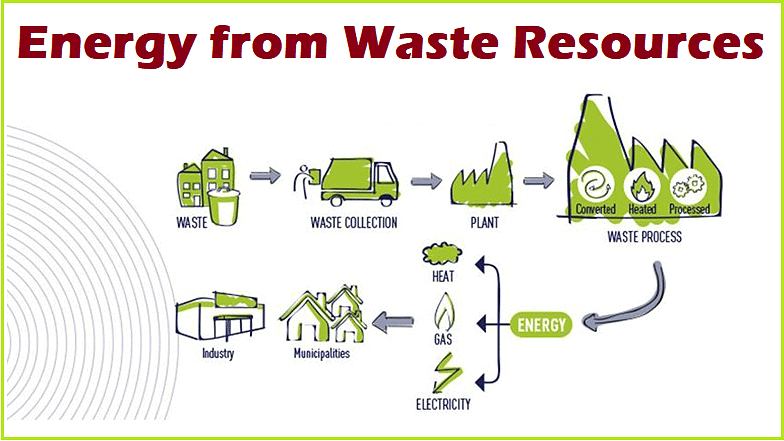

2. Energy from waste

In today’s era, there are increasing quantities of waste due to urbanization, industrialization and changes in life patterns which are harmful to the environment. In the recent past, the development of technology has helped to reduce the amount of waste for its safe disposal and to generate electricity from it. Waste-to-energy has the potential to divert waste from landfills and generate clean power without the emission of harmful greenhouse gas. Pyrolysis and gasification are emerging technologies apart from the common incineration and bio-methanation.Some important facts related to Energy Generation from Waste:

- There is an estimated potential of about 1460 MW from Municipal Solid Waste (MSW). The total installed capacity of grid-interactive power from Waste to energy is 99.08 MW of grid power and about 115.07 MW of off-grid.

Major constraints faced by Indian Waste to Energy Sectors are as follows:

- Choice of Technology: Waste-to-energy is still a new concept in India. Most of the proven and commercial technology with respect to urban wastes are required to be imported.

- High Cost: The costs of projects especially based on bio methanation technology are high as critical equipment for the project is required.

- Improper Segregation: India lacks a source-separated waste stream, owing to the low level of compliance of Municipal Solid Waste Rules 2000 by the Municipal Corporation/Urban Local Bodies. The organic waste is mixed with other types of waste. Hence, the operations of waste to energy technique lack of smoothness that ultimately causes it to be short-lived.

3. Biomass

Biomass is renewable energy resource derived from the carbonaceous waste including the byproducts from the timber industry, agricultural crops, residue from agricultural or forestry, oil-rich algae, and the organic components from municipal and industrial wastes.- Biomass is a good substitute for conventional fossil fuel for heating and energy generation purposes. When biomass is burnt it releases about the same amount of CO2 as fossil fuel does, without adding CO2 to the atmosphere. Fossil fuels release carbon dioxide that is accumulated through photosynthesis during its formation under the surface of the earth. On the other hand, the carbon dioxide released by biomass is balanced by the carbon dioxide captured during its growth.

- The chemical process like gasification, combustion and pyrolysis convert biomass to useful products, combustion being the most common of them. Each of the technology mentioned produces a major calorific end product and a mixture of by-products. The processing method is selected on the basis of nature and origin of feedstock, their physiochemical state and application spectrum of fuel product derived from it.

(a) Aerobic Digestion/Biomethanation: Biomethanation or methanogenesis is a scientific process in which anaerobic microorganism decompose biodegradable matter producing methane-rich biogas and effluent. The three functions that take place are hydrolysis, acidogenesis and methanogenesis.

(b) Combustion/Incineration: In this process, waste is directly burned in the presence of air (oxygen) at high temperature, liberating heat energy, inert gas and ash. This heat energy is then utilized in steam generation and further in moving the steam turbines for power generation.

(c) Pyrolysis/gasification: Pyrolysis is a process of chemical decomposition of organic matter when heated in the absence of air. During this process, molecular breakdown takes place to form a gas called syngas. Gasification due to partial combustion of organic matter in the presence of a restricted quantity of air or oxygen, producing the gas known as producer gas (carbon monoxide - 25%, hydrogen and hydrocarbon - 15 % and carbon dioxide and nitrogen 60%). After cleaning of syngas and producer gas, they are then burned in an internal combustion engine (IC engine) generator sets or turbines for electricity production.

Biomass energy is one of the most important sources of energy forming 32% of the total primary energy usage in the country with more than 70% of the Indian population dependant on its energy needs. The current availability of biomass is estimated at about 450-500 million tonnes annually translating to the potential of around 18000 MW. In addition, about 5000 MW additional power could be generated using bagasse based cogeneration in the country’s 550 sugar mills. The government plans to meet 20% of the countries diesel requirement by 2020 using biodiesel. Potential sources of biodiesel production have been identified in wild plants such as jatropha curcas, neem, mahua, karanj etc. Central Finance Assistance (CFA) is provided by the Ministry of New and Renewable Energy (MNRE) in the form of capital subsidy and financial incentives to biomass energy projects in India.

|

25 videos|43 docs|10 tests

|