Fish Processing, Crop Process Engineering | Crop Process Engineering Notes - Agricultural Engg - Agricultural Engineering PDF Download

Introduction

Fish is found abundantly in all natural waters and is a valuable source of food. Out of about 25,000 species of fish, 250 species of fish are used for edible purpose. Edible fishes are classified into two major categories as fishes having vertebrae with fin appendages are termed as finfish and fishes without skeleton but covered with hard shell are termed as shellfish. Edible shellfishes are mainly salt water fishes.

The fish and shellfish processing industry include marketing of fish, shellfish and marine plant and animals as well as byproducts such as fish meal and oil. Fish oils are richest sources of vitamin A and D. Fish is good source of proteins and minerals. It is used as a live stock feed and the oil is used in margarine and paints also. Exports of canned fish and fish meal are increasing due to the diminishing supply in other countries. About 30 per cent fish processed for human consumption is marketed as fresh; the remainder is frozen fish and fillets in ready-to-eat meals and other convenience products. As the fish and sea food is perishable, it is very essential to process and thereby it can be stored for longer period.

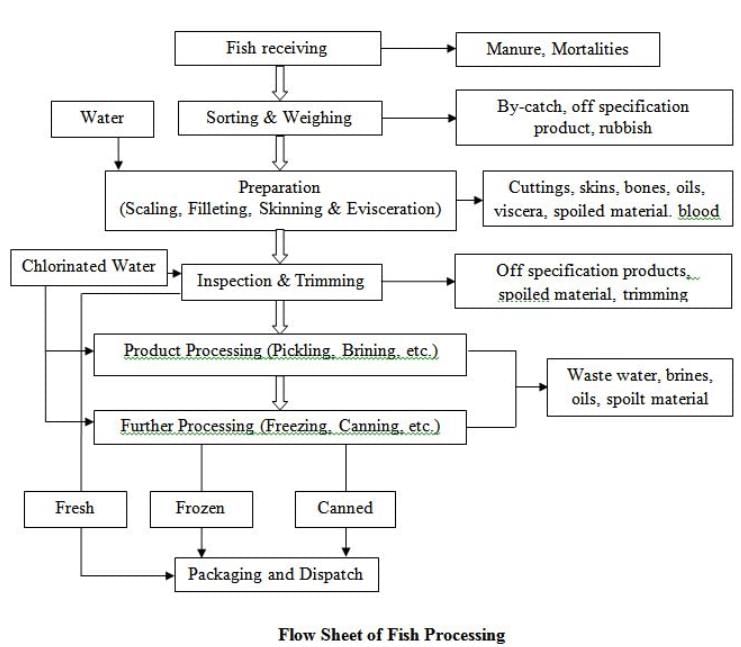

1. Primary Processing of Fish and Sea Food

Pretreatment: Fish are kept on ice in boxes before delivery to the processing plant. At the time of arrival, the fish may be re-iced and placed in cold storage until required for further processing. Pretreatment involves ice removal, washing, grading according to size and de-heading. Large fish may also be scaled before additional processing. Some fish are skinned by immersing in to a warm caustic bath. The effluent from this process has a high organic load and has to be neutralized before discharge.

Filleting: The filleting areas are generally separated from the pretreatment department to prevent workers and materials from non sterile pretreatment from contaminating the sterile filleting area. Filleting is performed by machines with mechanical knives that cut the fillets from the backbone and remove the collarbone. Some fillets may be skinned at this step in this process.

Trimming and Inspection: In the trimming section, pin bones are removed and operators inspect the fillets. Any defects and any inferior parts found are removed. Off cuts are collected and minced. Depending upon the final products, the fillets can be cut in to portions according to weight or final product requirements.

Storage/Packaging (Fresh): Fresh products are packaged in boxes with ice which is separated from the product by a layer of plastic. Fillets or pieces can be individually frozen and wrapped in plastic. The blocks are typically frozen and kept in cold storage.

2. Preservation Methods of Fish

Fish is a perishable commodity. It can not be store in normal condition for longer period. There are some in practice to preserve fish which is explained hereunder.

2.1 Canning of Fish

Canning is performed by two methods: precooking and raw pack. Precooking begins with thawing of the fish which are then eviscerated, washed and cooked. Canning retains the natural flavor of the fish usually oily fish are most suitable for canning. Cooking occurs with steam, oil, hot air or smoke for up to 10 hours, depending upon the fish size. The cooked fish are then cooled. After cooling, the head, fins, bones, and undesirable meats are removed and remainder is chopped / cut and placed in cans. Additional fish or vegetable oil, brine, and/or water are added to the cans which are sealed and pressure-cooked before shipment.

The raw pack method begins with thawing and weighing of the fish. Fish are then washed and brined as well as “nobbed,” which is the removal of the head, viscera and tails. The fish are placed in cans, then cooked, drained and dried. After drying, liquid (brine, oil, sauce, water) is added to the cans. Finally, the cans are sealed and sterilized with hot water or steam and then stored.

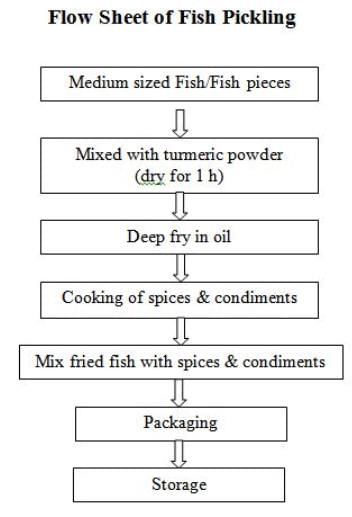

2.2 Pickling (Salting) of Fish

The dry salting or wet salting method of pickling is widely used for fish processing in India. In dry salting method, first fishes are rubbed with salt powder and then packed in tubs with dry salt powder sprinkled in between layers of fishes. After 15-20 hours, the fishes are removed from tubs, washed in brine and then followed by sun drying for 2-3 days.

In wet salting cleaned fishes with longitudinal silts (cut) are packed in large container which containing concentrated salt solutions and stirred daily till properly pickled. Generally, up to 8-10 days after pickling, salty water is allowed to drain off. Wet salted (pickled) fish is sold into market without drying. During salting ethylene oxide and sodium benzoate may be added to avoid some of the common defects like color changes, mold growth, attacks by insects, case hardening, rancidity development etc.

2.3 Freezing of Fish

Freezing, greatly extend the period of storage. In freezing, if the fish is gutted and frozen down to -28 to -300C within two hours of its catch gives effective keeping quality as similar to that of fresh fish. Large fish are frozen by sharp freezing, while small fishes are usually frozen as fillets (lengthwise cuts), steaks (crosscut section) or sticks (lengthwise or crosswise cut from fillet or steaks) are quick frozen. During freezing some undesirable changes may occur, if proper care is not taken. Slow freezing can result in protein de-naturation due to increases in salt concentration in muscle tissue during freezing and also making it tough and rubbery. Frozen fish undergo oxidative changes and fatty fish become rancid more quickly so oxidation can be prevented by properly protecting or covering of fish with suitable packaging materials (wrappers) before freezing.

2.4 Drying of Fish

Sun drying is the most widely used method for drying. Drying removes moisture from tissues and arrests the bacterial and enzymatic growth. This method is not hygienic and also there is appreciable percentage of loss due to spoilage and putrefaction. Dried fish develops a peculiar odor. The fish can be dried in the covered solar dryer with natural draft or forced draft.

3. Manufacturing of Fish Products

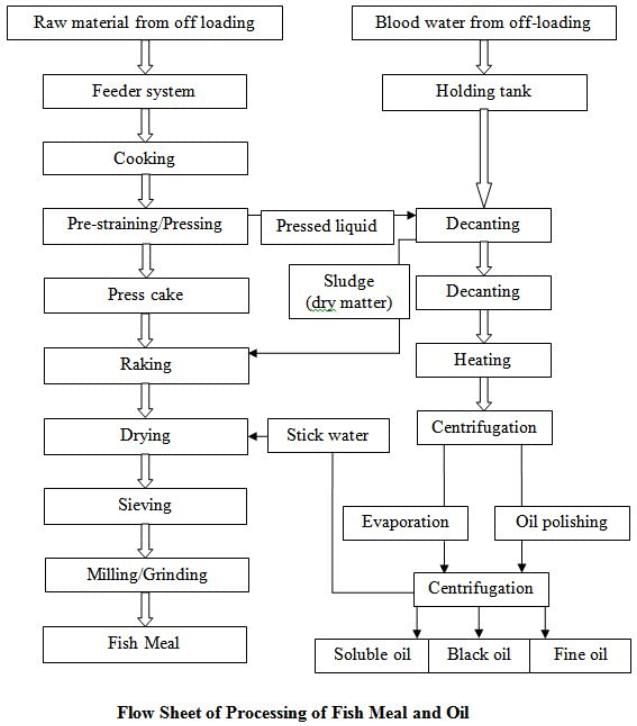

3.1 Fish Meal and Fish Oil Production

Fish meal is delivered from the dry components of the fish and the oil from oily component. The water that makes up the remainder of the fish matter is evaporated during the process. The fish by-products are cooked in a process that coagulates the protein and releases the water and oil. The mixture is screened and the liquid from the mixture is squeezed out through a perforated casing. The pressed cake is shredded and dried with steam or direct flame dryers. The meal passes through a vibrating screen and to a hammer mill where it is ground to the desired size. The meal is used in animal and pet feed due to its high protein content.

The oil is further processed by passing through a decanter to remove sludge which is then fed back in to the meal dryer. Oil is separated from the liquid by centrifuge and is polished by using hot water washes and additional centrifuging. The removed water is evaporated to concentrate the solids and the remaining oil is refined to remove any impurities.

3.2 Fish Flour (Fish Protein Concentrate)

Fish flour contains 85 to 90 per cent of high quality protein. The extraction of oils and fatty substances from ground fish tissue by solvent extraction till no fishy odor or flavor remains. The fat extracted tissue is dried after evaporation of solvent by dehydration process using dryer. After dehydration, milling gives a bland highly nutritious powder rich in high quality protein and minerals. This product, when processed under sanitary conditions is good for use as human consumption.

|

Explore Courses for Agricultural Engineering exam

|

|