GATE Past Year Questions: Brakes, Clutches & Ropes | Design of Machine Elements - Mechanical Engineering PDF Download

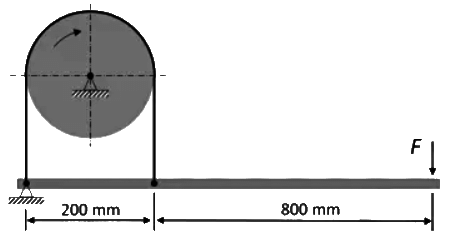

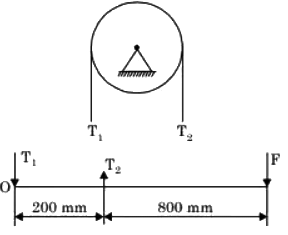

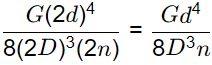

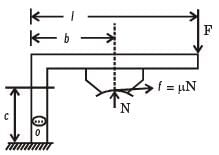

Q1: A band brake shown in the figure has a coefficient of friction of 0.3 . The band can take a maximum force of 1.5kN. The maximum braking force (F) that can be safely applied is _____ N. (rounded off the nearest integer). [GATE ME 2024] Ans: 115 to 119

Ans: 115 to 119

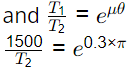

Data given, μ = 0.3

F = 1.5kN = 1500 N

θ = 180º = π

F.B.D. of system is ∑M0 = 0

∑M0 = 0

F × 1000 − T2 × 200 = 0

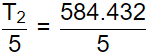

F = T2/5

T2 = 584.492 N

So, F =

= 116.9 N ≈ 117 N

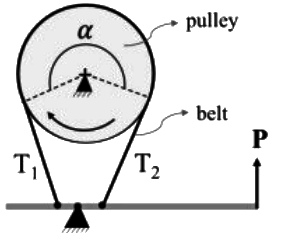

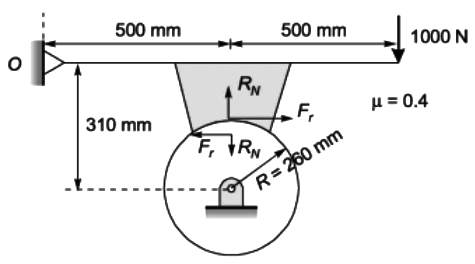

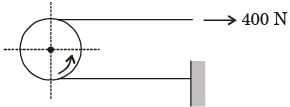

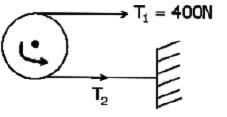

Q1: The braking system shown in the figure uses a belt to slow down a pulley rotating in the clockwise direction by the application of a force P. The belt wraps around the pulley over an angle α = 270 degrees. The coefficient of friction between the belt and the pulley is 0.3. The influence of centrifugal forces on the belt is negligible.

During braking, the ratio of the tensions T1 to T2 in the belt is equal to __________. (Rounded off to two decimal places)

Take π = 3.14. [GATE ME 2023] Ans: 4.05 to 4.15

Ans: 4.05 to 4.15

μ = 0.3

α = 270º = 3π/2

T1/T2 = eμα

So,

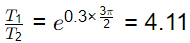

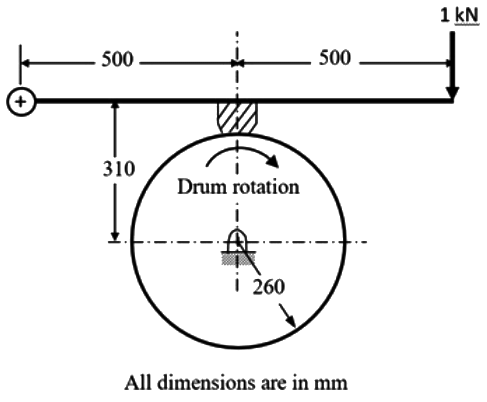

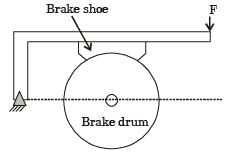

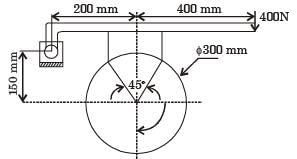

Q1: A short shoe drum (radius 260 mm) brake is shown in the figure. A force of 1 kN is applied to the lever. The coefficient of friction is 0.4. The magnitude of the torque applied by the brake is ________N.m (round off to one decimal place). [GATE ME 2021 SET-1]

The magnitude of the torque applied by the brake is ________N.m (round off to one decimal place). [GATE ME 2021 SET-1]

Ans: 199 to 201 Taking moment about 'O'

Taking moment about 'O'

RN(500) + Fγ[310 − 260] - 1000 x 1000 = 0

RN(500) + 0.4(RN)(50) - 1000 x 1000 = 0

RN = 1923.076 N

Fr = µRN = 769.23 N

Tf = Fr x R = 200 N - m

Q1: A helical spring has spring constant k. If the wire diameter, spring diameter and the number of coils are all doubled then the spring constant of the new spring becomes [GATE ME 2020 SET-2]

(a) k/2

(b) k

(c) 8k

(d) 16k

Ans: (b)

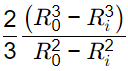

k(sping ) = Gd4/8D3n

knew =

Hence knew = k

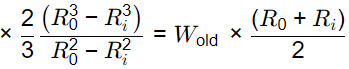

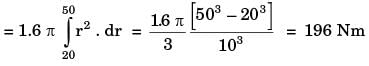

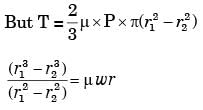

Q2: In a disc-type axial clutch, the frictional contact takes place within an annular region with outer and inner diameters 250 mm and 50 mm, respectively. An axial force F1 is needed to transmit a torque by a new clutch. However, to transmit the same torque, one needs an axial force F2 when the clutch wears out. If contact pressure remains uniform during operation of a new clutch while the wear is assumed to be uniform for an old clutch and the coefficient of friction does not change, then the ratio F1/F2 is_________ (round off to 2 decimal places). [GATE ME 2020 SET-1]

Ans: 0.85 to 0.89

T = μW × Rm

Tnew = μ × W × Rnew

Tnew = μ × Wnew x

Todd = μ × W × Rold

Tnew = Tdd

Wnew

= 0.871

= 0.871

[2003]

[2008]

[2006]

[1987]

[2016,Set-2]

[2012]

[2010]

[2007]

[2003]

|

51 videos|102 docs|77 tests

|

FAQs on GATE Past Year Questions: Brakes, Clutches & Ropes - Design of Machine Elements - Mechanical Engineering

| 1. What are the main types of brakes used in mechanical systems? |  |

| 2. How do clutches function in mechanical systems? |  |

| 3. What are the key factors to consider when designing a brake system? |  |

| 4. What is the importance of friction in clutches and brakes? |  |

| 5. How do ropes transmit force in mechanical applications? |  |

= 23.87 Nm

= 23.87 Nm

0.125

0.125