Metal Casting - 2 | Mechanical Engineering SSC JE (Technical) PDF Download

| Table of contents |

|

| Metal Casting |

|

| Die Casting |

|

| Types of Centrifugal Casting |

|

| Casting Defects |

|

| Melting of Cast Iron |

|

Metal Casting

Gating Ratio

- The gating system directs molten metal into the mold cavity and comprises the sprue, runner, and ingate. The gating ratio (Sprue:Runner:Ingate) varies based on the system type:

- Non-Pressurized System: Designed to minimise turbulence and gas entrapment; common ratios include 1:2:2, 1:3:3, or 1:1:3.

- Pressurised System: Controls flow via smaller ingates to maintain back pressure; typical ratios are 1:2:1 or 1:0.75:0.5.

Top Gate

In top gating, molten metal enters the mold cavity directly from the sprue's end.

Assumption

• The molten metal is entering into mould cavity directly from the end of the sprue at atmospheric pressure.

• Top gating system is used for ferrous material of large size casting.

As

Ag is the cross-sectional area and

Vg is the velocity of liquid metal.

ht = hs + hc

A and H are the cross-section of area and height of the mould cavity respectively.

tf1 is the total time to fill the mould.

Using Bernoulli's equation between 2 and 3

It means that at point (2) in the sprue, there will be a vacuum, and it will capture the atmosphere into the liquid metal through sand voids. This will produce a blow hole in the casted part.

This phenomenon is called the Aspiration effect, so to avoid this, area of the sprue is changed to have uniform atmospheric pressure throughout the sprue.

Bottom Gate:

Applying Bernoulli’s equation between (1) and (2),

V1 = can be neglected because the basin area >> gating system

P1 is atmospheric pressure:

Bernoulli's between (2) and (3)

410hP3 is the atmospheric pressure cross-section area of the casting is the same

Putting this in equation (4).

we know

Let us consider that in time dtf, the liquid metal comes out of the gate, increasing the level of metal in the cavity by dh.

Solidification Time Calculation:

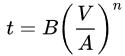

- Chvorinov's Rule is a mathematical relationship first expressed by Czech engineer Nicolas Chvorinov in 1940 that relates the solidification time for a simple casting to the volume and surface area of the casting.

- In simple terms, the rule establishes that under otherwise identical conditions, the casting with a large surface area and small volume will cool more rapidly than a casting with a small surface area and a large volume.

The relationship can be written as:

- V = Volume - It represents the amount of heat available.

A = Surface area – It represents the amount of heat dissipation. - Riser is provided to compensate liquid and solidification shrinkage during Casting.

- It is also used to show whether casting is full or not.

- So riser design should be such that it solidifies after casting, so that liquid metal is available to compensate for shrinkage.

- Riser should be designed in such a way that it has a minimum surface area.

- Riser volume can be taken three times the liquid shrinkage, but this design has to be checked to determine whether the riser will solidify before or after casting.

Purpose of Riser

Classification of Casting

1. Expendable moulds [Temporary moulds]

• Sand casting • Shall moulding

• Full moulding • CO2 moulding

• Investment Casting

Expendable-Pattern Casting(Lost Foam)

- The expendable pattern casting process uses a polystyrene pattern, which evaporates upon contact with molten metal to form a cavity for the casting.

- The process is also known as evaporative pattern or lost pattern, and under the trade name full mold process.

- It was formerly known as the “expanded polystyrene process” and has become one of the most important casting processes for ferrous and non-ferrous metals, particularly for the automotive industry.

- In this process, raw expendable polystyrene (EPS) beads, containing 5% to 8% pentane, are placed in a preheated die, which is usually made of aluminum.

- The polystyrene expands and takes the shape of the die cavity; additional heat is applied to fuse and bond the beads together.

- The die is then cooled and opened, and the polystyrene pattern is removed.

- In the expendable pattern casting process, also known as lost foam or evaporative casting, the patterns are coated with a water-based refractory slurry, derived and placed in a flask.

- The flask is then filled with loose fine and, which surrounds and supports the patterns and may be dried or mixed with bounding agents to give its additional strength and may be derived or mixed with bonding agents to give it additional strength.

2. Permanent Moulds [Metallic Moulds]:

(i) Centrifugal Casting

(ii) Die Casting

(iii) Gravity Die casting

(iv) Pressure Die casting: (a) Hot die casting (b) Cold die casting

- In the permanent mould casting process, also called hard mold casting, two halves of a mold are made from material such as cast iron, steel, bronze, graphite, or refractory metal alloys.

- The mould cavity and gating system are machined into the mold and thus become an integral part.

- To produce castings with internal cavities, cores made of metal or sand aggregate are placed in the mold prior to casting.

- This process is used mostly for aluminium, magnesium, copper alloys, and grey cast iron because of their generally lower melting points. Steels can also be cast using graphite or heat-resistant metal molds.

- This process produces at high production rates, casting with good surface finish, close dimensional tolerance, and uniform and good mechanical properties.

- Typical parts made are automobile pistons, cylinder heads, connecting rods, gear blanks, appliances, and kitchenware.

- Permanent mould casting is not economical for small production runs, and because of the difficulty in removing the casting from the mould, intricate shapes cannot be cast by this process. However, easily collapsed sand cores can be used and removed from the casting to leave intricate internal cavities.

- The process is then called Semi-permanent mould casting.

3. Continuous Moulding:

- Shell moulding:

A common method of making shell molds

- It is a process in which the sand mixed with a thermo-setting resin is allowed to come into contact with a heated metallic pattern plate so that a thin and strong shell of mould is formed around the pattern.

- It will produce a better surface finish and close tolerance, and an object with having small projection.

- The pattern is produced by metallic material, and it will be heated to 200°- 230° C.

- Moulding sand and material consists of fine-grain, silica phenolic resin under pressure of alcohol.

- Moulding sand will be made in contact with a heated metallic pattern. Due to the heat, of pattern resins will be activated and the moulding sand will stick to the surface of the pattern material, and it will form a shell.

- The thickness of the shell will depend on the contact time between the pattern material and the moulding sand, and this time period is known as DWELL TIME.

- After getting a sufficient thickness of shell, the pattern will be heated along with the shell up to 300°-330°C.

- Due to this, the strength of the shell will be increased.

Advantage

- Shell mould casting is generally more dimensionally accurate than sand casting.

- A smooth surface can be obtained

- Draft angles, which are lower than those of sand casting, are required in shell moulds.

- Permeability of the shell is high, and therefore, no gas inclusions occur.

- Automation is readily possible because of the simple processing involved in shell moulding.

Limitations

- The patterns are very expansive.

- The size of the casting obtained by shell moulding is limited.

- Highly complicated shapes cannot be obtained.

Application

- Small-sized mechanical parts that require a better surface finish and accuracy.

- Cylinder block of IC engine, rocker arm, small-size gate, etc.

Investment Casting

- The investment casting process, also called the lost wax process.

- The pattern is made of wax or plastic (such as polystyrene) by molding or rapid prototyping techniques.

- The sequences involved in investment casting are shown in the Figure below. The pattern is made by injecting molten wax or plastic into a metal die in the shape of the pattern.

- The pattern is then dipped into a slurry of refractory material, such as very fine silica and binders including water, ethyl silicate, and acids.

- After this initial coating has dried, the pattern is coated repeatedly to increase its thickness.

- The turn investment derives from the fact that the pattern is inverted, with the refractory material wax pattern requiring careful handling because they are not strong enough to withstand the forces involved during mold making.

- However, unlike plastic patterns, wax can be recovered and reused.

- Although the labour and material involved make the lost wax process costly, it is suitable for casting high melting point alloys with good surface finish and close dimensional tolerances.

- Therefore, few or no finishing operations, which would otherwise add significantly to the total cost of the casting, are required.

- Typical parts made are components for office equipment as well as mechanical components such as gears, cams, valves, and ratchets.

- In this, mould is prepared around an expendable pattern. It is used for making intricate shapes that are not symmetrical.

- Investment casting produces better tolerances. Compared to shell moulding.

- It is used for making jewelry, surgical equipment, blades for turbine bolts, and triggers for firearms.

- The pattern is made of either wax or mercury

Applications

- Complex shapes, which are difficult to produce by any other method, are possible since the pattern is withdrawn by melting it.

- Very fine details and thin sections can be produced by this process.

- Very close tolerances and surface finish can be produced.

- It can produce jet engine parts, turbine blades, dentures (surgical instruments,)gold ornaments, etc.

Die Casting

Hot chamber die casting

- The hot chamber process involves the use of a piston, which traps a certain volume of molten metal and forces it into the die gravity through a gooseneck and nozzle.

- The pressure ranges up to 35 MPa, with an average of about 15 MPa.

- The metal is held under pressure until it solidifies in the die.

- To improve die life and to aid in rapid cooling, dies are usually cooled by circulating water or oil through various passageways in the die block.

- Low melting point alloys such as zinc, magnesium, tin, and lead are commonly cast using this process

Die casting involves the preparation of components by injecting molten metal at high pressure into a metallic die. - In this process, the mould is made up of some permanent material like cast iron, die steel, copper, and aluminium.

- Two halves can either be placed horizontally or vertically, and when liquid metal is poured under gravity, it is called gravity die casting.

- When liquid metal is injected into this permanent mould, it is called pressure die casting.

Advantages

- The same mould can be used again and again, which increases the production rate

- Dimensional tolerance of the order of 0.01 to 0.03 inch.

- Rapid cooling produces high strength.

- Better section sensitivity, but after some amount of use.

- It is very economical for large-scale production.

Limitations

- The maximum size of casting is limited to a certain size

- This is not suitable for all materials because of the limitation on the die material.

- Normally, zinc, aluminium, magnesium, and copper alloys are die-cast.

- The air in the die cavity gets trapped inside the casting and is therefore a problem often with die castings.

- It is used for producing crank casting, fuel injection pumps, valve bodies, small-size connecting rods, and carburetors.

Cold chamber die casting

- In the cold chamber process, molten metal is processed into the injection cylinder (short chamber). The shot chamber is not heated, hence the term cold chamber.

- The metal is forced into the die cavity at a pressure usually ranging from 20 MPa to 70 MPa.

- The machines may be horizontal or vertical, in which case the shot chamber is vertical and the machine is similar to a vertical press.

- High melting point alloys of magnesium and copper are normally cast using this method, although other metals can also be cast in this manner.

- The main difference between these two is that in the hot chamber die casting, the heating furnace for the liquid metal is integral with the die casting machine.

Whereas in the cold chamber machine, the metal is melted in a separate furnace and then poured into the die casting machine with a ladle for each casting cycle, which is also called a shot.

Slush Casting

- Hollow casting with a thin wall can be made by a process called slush casting.

- The molten metal is poured into the metal mold; after the desired thickness of solidified skin is obtained, the mold is inverted or swung, and the remaining liquid metal flows out.

- The mould halves are then opened, and the casting is removed.

- Such casting is important for small production runs and. is generally used for making ornamental and decorative objects such as camp bases and stems and toys from lower melting point metal such as zinc, tin, and lead alloys.

NOTE:

• Very thin sections, gold jewelry, lamp bases, statues, and other brass items are made up by this process.

• Toys, decorative items, and camp shades are made by this process.

Blow Moulding

• Glass and plastic bottles, bulbs, etc., are moulded by this process.

• Glass or plastic in the semi-viscous form (called gob) is placed in the die, and air is blown into the die.

• As a result of the material takes the shape of a die.

Centrifugal Casting

• This is a process where the mould is rotated rapidly about its axis (central axis) as the metal is poured into it.

• Because of the centrifugal force, a continuous pressure will be acting on the metal as it solidifies.

• The slag oxides and other inclusions, being lighter, get separated from the metal and segregate towards the centres.

Types of Centrifugal Casting

True Centrifugal Casting

• In this process, a metallic mould (in two parts with a flange) is rotated at 3000

rpm using a rotating device.

• Liquid metal is then poured into it.

• The mould is slightly inclined from the horizontal position so that the liquid metal covers the entire work length of the mould.

• Percentage yield in casting is defined as the ratio of useful material to the total liquid material poured into the cavity, which is nearly 95%-98%.

• Cause grains settle down at the outside surface due to higher centrifugal force. The gains towards the centre will be finer and finer. Such surfaces are called “Jagged Surfaces”

Limitations of true centrifugal casting

• Only certain shapes, which are axis symmetric and have concentric hours, are suitable for true centrifugal casting.

• The equipment is expensive and thus is suitable only for large-scale production.

Applications

• The mechanical properties of centrifugally cast jobs are better compared to other processes, because the inclusions, such as slag and oxides, segregate towards the centre and can be easily removed by machining.

• After the pressure acting on the metal throughout the solidification, the porosity gets eliminated, giving rise to dense metal.

• Up to certain dimensions and thickness of the object, proper directional solidification can be obtained.

• No core is required for making concentric holes in the case of true centrifugal casting.

• There is no need for gates and runners, which increases the casting yield, reaching almost 100%.

• The axis of rotation can be either horizontal, vertical, or any angle in between.

• Components having fine grain size and high density can also be produced by true centrifugal casting.

Semicentrifugal Casting

• In this process, the mould is placed on the horizontal plane, and it is rotated along the vertical axis.

• The outer portion of the mould will be filled by purely centrifugal action, and as the liquid metal approaches towards centre, the centrifugal component decreases and the gravity component increases.

• The central portion is purely filled by gravity.

• The speed of rotation and percentage yield are lower than true centrifugal casting.

• It is used for making wheels, pulleys, spoke wheels, and alloyed wheels.

Centrifugal Casting

• As shown in the figure that some castings are placed on the periphery of a drum and are connected to the central sprue through individual gates.

• After solidification, the gating system is disconnected to get the casted part.

• The percentage yield in this case is only 5%-10%, and the speed of rotation is much lower.

• The casting need not be axis symmetric, and the process is primarily used in making patterns for investment casting.

• The centrifugal process is used to obtain higher metal pressure during solidification.

• When casting shapes are not axis symmetrical, this is suitable only for small jobs of any shape.

• It is used for making patterns used in investment casting.

Casting Defects

Drop

Irregular projection on the top of casting caused by dropping of sand from cope.

Buckle

V-shaded depression occurring on flat casting due to expansions of ^d at the mould face before liquid metal solidifies.

Scab

The protruding surface of the casting on the roof. (Figure ) .

Swell

Liquid metal displaces the sand at the wall regions due to hydrostatic pressure.

Mould Shift

Due to misalignment between the two halves.

Remedies

• Heat the molten liquid metal in the furnace up to pouring temperature only.

• Convert green sand mould into dry sand mould before allowing the liquid metal into the mould cavity.

• Select the moulding sand such that it has better permeability.

Discontinuties

- Discontinuities such as cracks, cold hot tearing, and cold shuts.

- If the solidifying metal is constrained from shrinking freely, cracking and tearing can occur.

- Although many factors are involved, such as tearing, coarse grain size, and the presence of low melting point segregates along the grain boundaries, these increase the tendency for hot tearing.

- A cold sheet is an interface in a casting that lacks complete fusion because of the meeting of two streams of liquid metal from different gates.

Incomplete Casting

- Such as misrun (due to premature solidification), insufficient volume of the metal poured, and runout (due to loss of metal from a mold after processing).

- Incomplete casting can result from the molten metal being at too low a temperature or from pouring the metal too slowly.

Inclusions

- Generally non-metallic form is used during melting, solidification, and molding. They are regarded as harmful because they act as stress raisers and reduce the strength of the casting.

- Inclusion may form during melting when molten metal reacts with the environment or with the crucible or mold material.

- Chemical reactions among components in the molten metal may produce inclusion slag, and other foreign material entrapped in the molten metal also becomes inclusions.

Cupola

- This is the commonly used melting furnace used in foundries.

- Cupolas are refractory-lined vertical steel vessels lined with attenuating layers of metal, like flux.

- Although they require major investments and are being replaced by induction furnaces, cupolas operate continuously, have high melting rates, and produce large amounts of molten metal.

Melting of Cast Iron

Widespread use of the cupola for gray-iron melting rests upon its unique advantage.1. Continuous melting: Foundry production is initiated since a cable of molten iron may be tapped from the furnace at regular intervals. The flow of molten iron metal and moulds for pouring may be synchronized for quality production as required by the automotive, agricultural equipment.

2. Low Cost of Melting: Raw material and operating costs are lower than any other type of melting furnace producing equivalent product.

3. Chemical composition control is possible by proper furnace operation with continuous melting.

4. Adequate temperature control for fluidity in pouring casting can be obtained.

|

5 videos|103 docs|59 tests

|

FAQs on Metal Casting - 2 - Mechanical Engineering SSC JE (Technical)

| 1. What is metal casting? |  |

| 2. What are the advantages of metal casting? |  |

| 3. What types of molds are used in metal casting? |  |

| 4. What is the process of metal casting? |  |

| 5. What are some common applications of metal casting? |  |