Orientation (Part - 1) | Chemical Technology - Chemical Engineering PDF Download

Orientation

1.1 Why a chemical engineer needs expertise in process technology ?

A process engineer at operation in chemical plant shall have a deeper understanding of the technology on which the process plant is built to produce the profit making chemicals. A chemical engineer with sound knowledge in process technology has the following distinct advantages:

a) Ability to clearly distinguish the functional role and importance of various processes and operations in the process plan

b) Technical knowledge with respect to the selection of important parameters such as Temperature, Pressure and underlying physical principles of a process.

c) Ability to distinguish various process streams and their conditions of operation (Temperature, pressure and phases)

d) Basic knowledge for process troubleshooting and necessary safety precautions associated to a process/operation.

1.2 How to master fundamentals of process technology?

To master chemical process technology five crucial steps are involved namely:

a) Raw-Materials and reactions: A chosen process route to manufacture desired chemicals with appropriate purities will eventually lead to preparing a list of raw-materials and utilities. Thereby, prominent reactions can be also known

b) Conceptual process flow-sheet: A conceptual process flow-sheet where a chemical engineer has an abstract representation of the actual process flow-sheet will enable quicker learning. A conceptual process flow-sheet typically constitute the following attributes:

- Raw-material purification (Solid-fluid operations such as cyclone separators, ...bag filters etc.)

- Raw-material processing (Heat exchange operations such as furnace ...heating, cooling etc.)

- Raw-material to product transformation (Reaction operations using CSTR, ...PFR, PBR and Batch reactors)

- Product purification (In separation processes such as flash, distillation, ...absorption and extraction)

- Product processing (heat exchangers, phase change units)

- Recycle of un-reacted raw-materials as recycle streams to the reaction ...operations.

- Technological know-how of each unit operation/process to eventually identify its functional role in the process flow-sheet

- Temperature, pressure and composition of streams entering the unit ...process/operation

- Temperature, pressure and composition of streams leaving the unit ...process/operation

- Phases of various streams entering and leaving the unit process/operation

- Associated waste and environmental hazardous products generation

c) Process intensification in the form of heat-integration, stream utilization and waste reduction and multiple recycle streams: These options are in fact optional and they enrich the energy enhancement and waste reduction efficiency of a process plant. Originally, chemical plants developed without such process intensification policies have been subjected to rigorous research and case study investigations to identify opportunities for cost reduction and better energy/waste management.

d) Additional critical issues related to various unit operations/processes

- Cost reduction approaches/process economics: How the operating variables (such as temperature, pressure, flow-rates, reflux rates, heating rate etc.) affect the cost of the unit operation/process

- Safety issues: What safety issues are most relevant and need frequent ...monitoring

e) Alternate technologies: For a desired function of a process unit, can thereby alternate technologies that could reduce the cost and even then provide the same functional role and desired flow rates and compositions of the emanating streams.

1.3 How much to memorize for a chosen technology ?

To a large extent, University education expects a chemical engineering undergraduate student to remember and draw at least a conceptual flow-sheet. However, when a systematic approach is not adopted in the learning process, it is rather difficult to remember all flow-sheets and relate to the logic behind their role in the process topology. Therefore, a well-trained student in process technology remembers process flow-sheets with logical sequence of unit processes/operations and not by strict memory.

1.4 Advantages of suggested learning approach for mastering process technology

a) Trains student to be more analytical/concept-oriented rather than with memorized knowledge that is bereft of logical reasoning

b) Systematic approach enables the growth of students’ interest in the subject.

c) Additional concepts further reveal to the student how to gradually complicate process technologies for maximum efficiency.

d) Inculcate strong interest in the student towards technology research and innovation by enabling a learning environment that fundamentally targets the technological know-how.

1.5 Prominent unit-operations and unit-processes in chemical industry

A detailed summary of various prominent unit operations/processes and their functional role in the chemical plant are summarized in Table 0.1 along with suitable figures.

Category | Unit operations/processes | Functional role |

fluid operations | a) Centrifugal pump | a) To pressurize liquids and gases. |

solid operations | a) Crusher | a) To reduce the size of solids |

Solid-fluid separators | a) Cyclone separator | a) To separate solid particles from solid-liquid/gas mixtures |

Heat exchangers | a) Shell & Tube heat exchangers | a) To either remove or add heat to process streams so as to meet desired conditions in other units. |

Mass transfer units | a) Phase separation | a) To separate a feed into products with different compositions. |

Reactor units | a) Completely stirred tank reactor (CSTR) | a) To carry out reactions in homogenous fluids (gases/liquids). |

Table 0.1: Important unit operations/unit processes and their functional role in chemical process technology.

A pictorial representation of various unit processes and operations that are often encountered in chemical process flowsheets is presented in Table 0.2. Along with these figures, their function role in the process technology is also presented.

| Process Technology | Functional Role |

| Reactors a) CSTR b) Batch-Reactor c) PFR d) Packed bed reactor e) Trickle bed reactor f) Fluidized bed reactor | - Central and most important process technology in process flow - Carry out desired reactive transformations |

a) CSTR | - Well mixed reaction system - Homogenous liquid/gas phase reaction - Most easy configuration - Temperature control through Jacket - Reactant instantaneously reaches lowest concentration -Mostinexpensive to design and operate |

b) Batch Reactor | - Has a simple design, with the requirement of very little - Ideal for small scale experimental studies on reactor kinetics - Can be used industrially for treatment of very small quantities |

c) PFR | - Homogenous liquid/gas phase reaction - Reactant gradually reaches low concentrations - Good control over temperature - Temperature control through jacket (not shown) |

d) Packed Bed Reactor (PBR) | - Hetero------geneous reaction - Packing to act as catalyst - Packing packed in tubes - Shell fed with cooling/heating fluid (optional) - Most common in process flow sheets |

e) Trickle Bed Reactor | - Multi-phase reaction - If the reaction is not catalytic, packing serves to enhance interfacial area - If the reaction is catalytic, packing acts as a catalyst as well - Complicated design |

f) Fluidized bed reactor | - Provides highest mass, heat and hence reaction rates for solid-fluid reactions - Very commonly deployed in petroleum refineries (catalytic cracking) - Complicated accessories (shown) and control system required - The accessories are for catalyst re-generation and transport |

| Process Technology | Functional Role |

| Separators: a) Batch distillation b) Continuous distillation c) Absorption d) Stripping e) Liquid-liquid extraction f) Leaching g) Crystallization h) Drying i) Flash separator j) Membrane separator k) Packed bed contactor | - Most important process technology - Provides desired separation between phases and streams - Located next to the reactor as 100 % conversions are very rare in industrial practice |

a) Batch distillation column | - Used to separate a liquid mixture based on relative volatility (differences in boiling points) - Operated in batch mode |

b) Continuous distillation (Fractionator) | - The most important separation technology in process flow sheets - Provides very pure products - Differences in boiling points is the working principle - Energy intensive operation - Usually multi-component distillation is apparent in industrial practice |

c) Absorption column | - Used to absorb components from gaseous stream - Solvent is used - Usually followed with stripper to re-generate the fresh solvent - Operated at low temperature and moderate/high pressure |

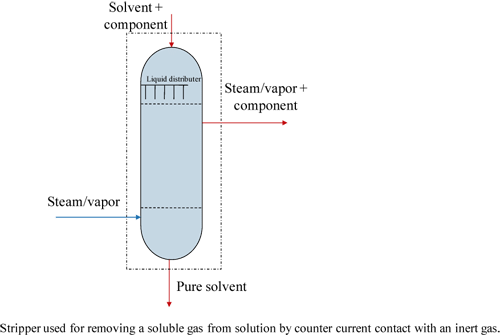

d) Stripper

| - Steam/Hot gas is used to strip the gas - Regenerated solvent used for absorption |

e) Liquid Liquid extraction | - Used to separate components from a liquid with a liquid solvent - Consists of a series of mixers and separators - Produces extract (rich with solvent and components extracted) and raffinate (product with lean extractants) |

f) Leaching | - A liquid solvent extracts components from a solid - High interfacial area between solid/liquid is required to enhance extraction capability |

g) Crystallization | - Used to crystallize solids from a slurry/super-saturated solution - Fine crystals added to serve as nucleating agent |

h) Spray drier | - Liquid slurry is sprayed in the form of droplets - Hot gas (air) dries the solid - Enables very good control over the product particle size |

i) Rotary drier | - Through rotation, an agitated liquid film is dried to obtain the dried solid |

j) Flash separator | - Very common technology to separate liquid streams at high pressure and lower temperatures. - Upon pressure reduction/heating, low boiling components separate as vapor phase and yield a liquid phase. - Complete separation only possible for fewer components |

k) Membrane separation | - A semi-permeable barrier (membrane) is used to separate feed streams based on concentration difference/pressure difference. - Various types of processes available - New technology in process industries. |

l) Packed bed contactor | - Used for absorption/stripping operations

|

|

69 videos|121 docs

|

FAQs on Orientation (Part - 1) - Chemical Technology - Chemical Engineering

| 1. What is the scope of chemical engineering? |  |

| 2. What are the career prospects for chemical engineers? |  |

| 3. What skills are required to excel in chemical engineering? |  |

| 4. How does chemical engineering contribute to sustainable development? |  |

| 5. What are the challenges faced by chemical engineers in the industry? |  |