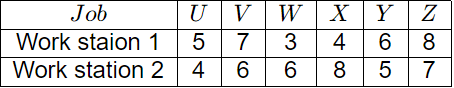

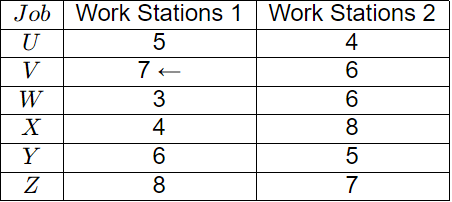

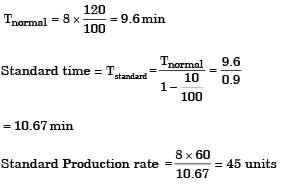

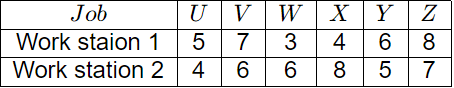

Q1: A set of jobs U, V, W, X, Y, Z arrive at time t = 0 to a production line consisting of two workstations in series. Each job must be processed by both workstations in sequence (i.e. the first followed by the second). The process times (in minutes) for each job on each workstation in the production line are given below.

The sequence in which the jobs must be processed by the production line if the total make span of production is to be minimized is [GATE ME 2024]

(a) W-X-Z-V-Y-U

(b) W-X-V-Z-Y-U

(c) W-U-Z-V-Y-X

(d) U-Y-V-Z-X-W

Ans: (a)

By J ohnson's rule of sequencing mark minimum time consuming operation for each process.

According to question, work on work station (1) is followed by work on workstation (2).

According to question, work on work station (1) is followed by work on workstation (2).

Perform that job in mark station which is minimum time consumption.

It is W-X during this Z on work station-2 will be performed.

So, W - X - Z

After W − X − Z, V, will be performed on workstation (1).

So, W − X − Z − V, in between Y-work on workstation will perform.

As minimum time in workstation is U, so will be performed at last.

So, W - X - Z - V - Y - U

Q1: A machine produces a defective component with a probability of 0.015. The number of defective components in a packed box containing 200 components produced by the machine follows a Poisson distribution. The mean and the variance of the distribution are [GATE ME 2023]

(a) 3 and 3, respectively

(b) √3 and √3 , respectively

(c) 0.015 and 0.015, respectively

(d) 3 and 9, respectively

Ans: (a)

P = 0.015

n = 200

mean = λ = np = 200 × 0.015 = 3

variance = σ2 = λ = 3

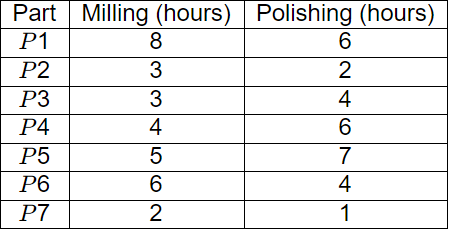

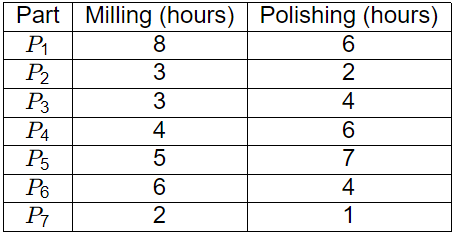

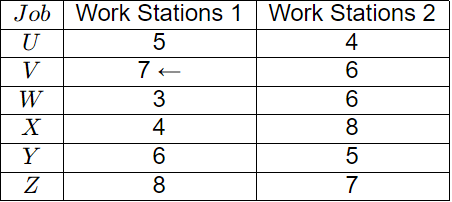

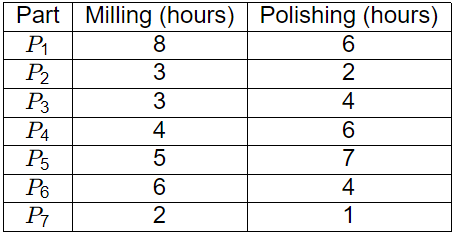

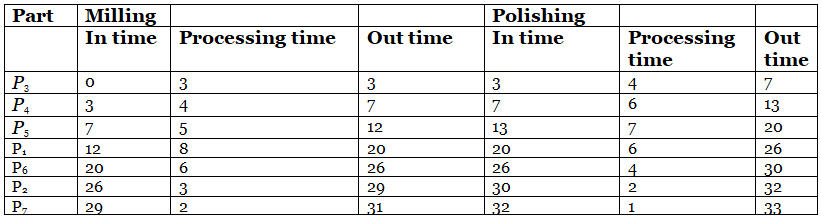

Q1: Parts P1-P7 are machined first on a milling machine and then polished at a separate machine. Using the information in the following table, the minimum total completion time required for carrying out both the operations for all 7 parts is __________ hours. [GATE ME 2022 SET-2]

(a) 31

(a) 31

(b) 33

(c) 30

(d) 32

Ans: (b)

Sequencing model :

Optimum job sequence (According to Johnson's algorithm)

Optimum job sequence (According to Johnson's algorithm)

P3, P4, P5, P1, P6, P2, P7

Optimum Make-span (Minimum total completion time)

Minimum total completion time of all parts = 33 hours

Minimum total completion time of all parts = 33 hours

Q2: An electric car manufacturer underestimated the January sales of car by 20 units, while the actual sales was 120 units. If the manufacturer uses exponential smoothing method with a smoothing constant of α = 0.2, then the sales forecast for the month of February of the same year is _______units (in integer). [GATE ME 2022 SET-2]

Ans: 104 to 104

Actual sales in Jan (DJan) = 120 units

Under estimate in Jan = DJan − FJan = 20

DJan = 100 units

Smoothing constant (α = 0.2)

Forecast for Feb (DJan) = ?

FFeb = FJan + α(DJan − FJan) = 100 + 0.2(120 − 100) = 104 units

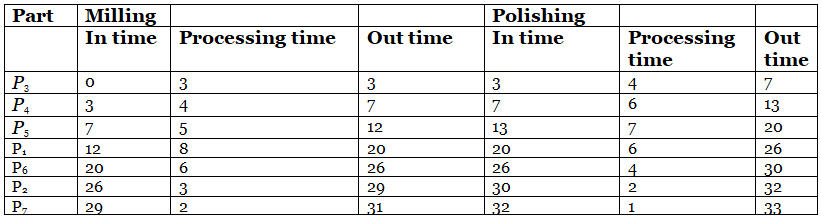

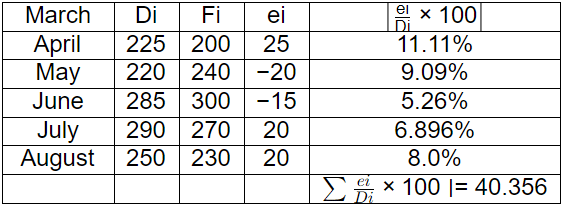

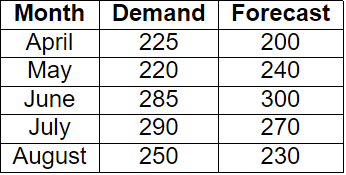

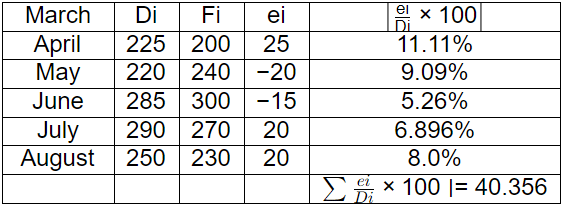

Q1: The demand and forecast of an item for five months are given in the table.

The Mean Absolute Percent Error (MAPE) in the forecast is _______% (round off to two decimal places) [GATE ME 2021 SET-2]

Ans: 6 to 10

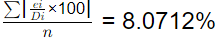

MAPE =

MAPE =

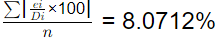

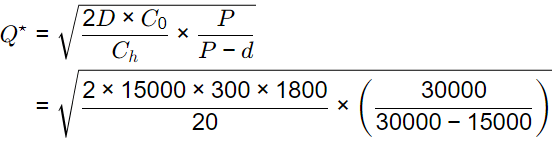

Q2: Daily production capacity of a bearing manufacturing company is 30000 bearings. The daily demand of the bearing is 15000. The holding cost per year of keeping a bearing in the inventory is Rs. 20. The setup cost for the production of a batch is Rs. 1800. Assuming 300 working days in a year, the economic batch quantity in number of bearings is ______ (in integer). [GATE ME 2021 SET-2]

Ans: 40200 to 40300

= 40249.2 ≃ 40250 units

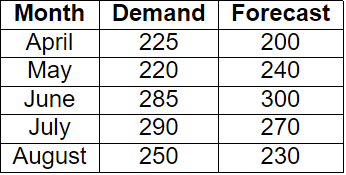

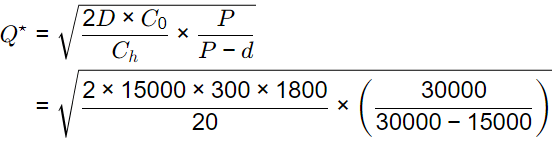

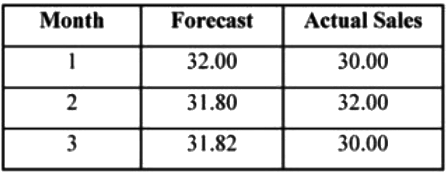

Q1: The forecast for the monthly demand of a product is given in the table below.

The forecast is made by using the exponential smoothing method. The exponential smoothing coefficient used in forecasting the demand is [GATE ME 2020 SET-2]

The forecast is made by using the exponential smoothing method. The exponential smoothing coefficient used in forecasting the demand is [GATE ME 2020 SET-2]

(a) 0.1

(b) 0.4

(c) 0.5

(d) 1

Ans: (a)

Ft = Ft−1 + α(Dt−1 − Ft−1)

For 2nd month Ft = 31.8, for 1st month

Ft−1 = 32 and Dt−1 = 30

31.8 = 32 + α(30 - 32)

2α = 32 - 31.8

α = 0.1

Q2: In Materials Requirement Planning, if the inventory holding cost is very high and the setup cost is zero, which one of the following lot sizing approaches should be used? [GATE ME 2020 SET-2]

(a) Economic Order Quantity

(b) Lot-for-Lot

(c) Base Stock Level

(d) Fixed Period Quantity, for 2 periods

Ans: (b)

In Lot-for-lot, holding cost is high and ordering cost is less.

Question for GATE Past Year Questions: Production Planning

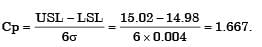

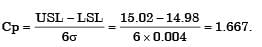

Try yourself:Cylindrical pins of diameter 15±0.020 mm are being produced on a machine. Statistical quality control tests show a mean of 14.995 mm and standard deviation of 0.004 mm. The process capability index Cp is

[2017]

Explanation

Diameter of cylindrical Pin = 15 ±.020 Upper Specification limit = 15 + 0.02 = 15.02 mm

Lower Specification limit = 15 – 0.02 = 14.98 mm

Standard deviation (��) = 0.004 mm Process capability Index.

Report a problem

Question for GATE Past Year Questions: Production Planning

Try yourself:During the development of a product, an entirely new process plan is made based on design logic, examination of geometry and tolerance information. This type of process planning is known as

[2015]

Question for GATE Past Year Questions: Production Planning

Try yourself:Which one of the following is NOT a decision taken during the aggregate production planning stage?

[2012]

Question for GATE Past Year Questions: Production Planning

Try yourself:The word kanban is most appropriately associated with

[2011 : 1 Mark]

Question for GATE Past Year Questions: Production Planning

Try yourself:Vehicle manufacturing assembly line is an example of

[2010]

Question for GATE Past Year Questions: Production Planning

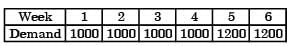

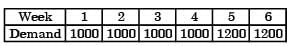

Try yourself:The Product structure of an assembly P is shown in the figure.Estimated demand for end product P is as follows:Ignore lead times for assembly and subassembly. Production capacity (per week) for component R is the bottleneck operation.Starting with zero inventory, the smallest capacity that will ensure a feasible production plan up to week 6 is

[2008]

Explanation

The M .R.P. f or R is given by

If 6P – 12800 ≥ 0 then the capacity is f easible \ Minimization ,

6P = 12800⇒

P ≌ 2200

Report a problem

Question for GATE Past Year Questions: Production Planning

Try yourself:Capacities of production of an item over 3 consecutive months in regular time are 100,100 and 80 and in overtime are 20, 20 and 40. The demands over those 3 months are 90, 130 and 110. The cost of production in regular time and overtime are respectively Rs. 20 per item and Rs. 24 per item. Inventory carrying cost is Rs. 2 per item month. The levels of starting and final inventory are nil. Backorder is not permitted. For minimum cost of plan, the level of planned production in overtime in the third month is

[2007]

Explanation

For minimum total cost the entire regular time production capacity has to be used.

Hence, total over time capacity required = (90 + 130 + 110) – (100+ 100 + 80) = 50

20 Overtime units will be used up in first 2 weeks. Hence 30 overtime units are needed to fulfill the 3rd month demand.

Report a problem

Question for GATE Past Year Questions: Production Planning

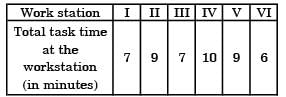

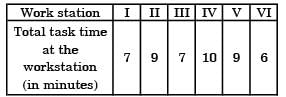

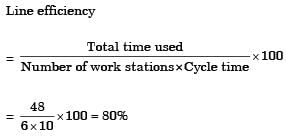

Try yourself:The table gives details of an assembly line.What is the line efficiency of the assembly line?

[2006]

Explanation

Report a problem

Question for GATE Past Year Questions: Production Planning

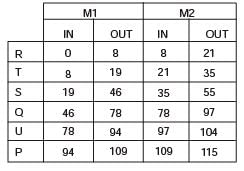

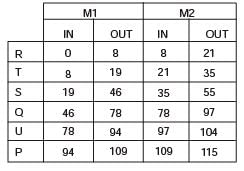

Try yourself:A manufacturing shop processes sheet metal jobs, wherein each job must pass through two machines (M1 and M2, in that order). The processing time (in hours) for these jobs isThe optimal make-span (in hours) of the shop is

[2006]

Explanation

Using Johnson’s algorithm

Report a problem

Question for GATE Past Year Questions: Production Planning

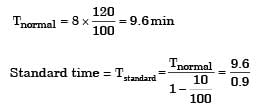

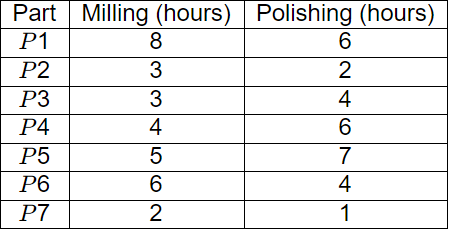

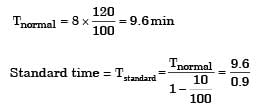

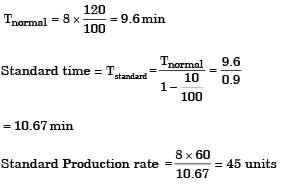

Try yourself:A welding operation is time-studied during which an operator was pace-rated as 120%. The operator took, on an average, 8 minutes for producing the weld-joint. If a total of 10% allowances are at lowed for this operation. The expected standard production rate of the weldjoint (in units per 8 hour day) is

[2005]

Explanation

Normal time = Actual Time × Rating factor.

Standard Production rate =

Standard Production rate =

Report a problem

Question for GATE Past Year Questions: Production Planning

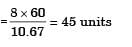

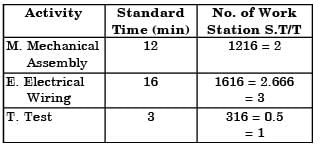

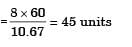

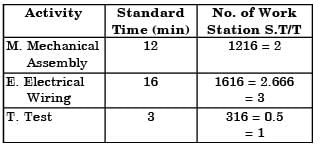

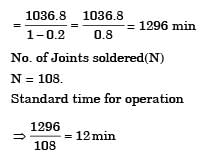

Try yourself:An electronic equipment manufacturer has decided to add a component subassembly operation that can produce 80 units during a regular 8-hour shift.This operation consists of three activities as belowFor line balancing the number of work stations required for the activities M, E and T would respectively be

[2004]

Explanation

Number of units produce in a day = so units working hour in a day = 8 hours

T = 6 min

T = 6 min

Number of work station are the whole number more the function.

So no of work station required for the activities, M, E & T would be 2, 3, 4, 1 9. Normal time = Actual Time × Rating factor.

Report a problem

Question for GATE Past Year Questions: Production Planning

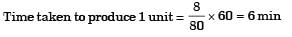

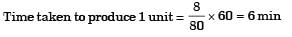

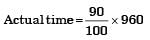

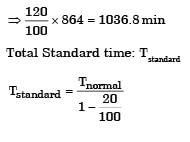

Try yourself:A soldering operation was work-sampled over two days (16 hours) during which an employee soldered 108 joints, actual working time was 90% of the total time and the performance rating was estimated to be 120 percent. If the contract provides allowance of 20 percent of the total time available, the standard time for the operation would be

[2004]

Explanation

Report a problem

Question for GATE Past Year Questions: Production Planning

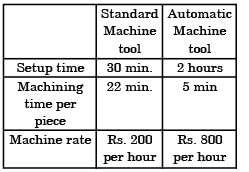

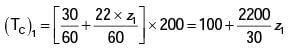

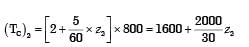

Try yourself:A standard machine tool and an automatic machine tool are being compared for the production of a component. Following data refers to the two machines.The breakeven production batch size above which the automatic machine tool will be economical to use, will be

[2004]

Explanation

Report a problem

Question for GATE Past Year Questions: Production Planning

Try yourself:Two machines of the same production rate are available for use. On machine 1, the fixed cost is Rs. 100 and the variable cost is Rs. 2 per piece produced. The corresponding numbers for the machine are Rs. 200 and Rs. 1 respectively.For certain strategic reasons both the machines are to be used concurrently. The sale price of the first 800 units is Rs. 3.50 per unit & and subsequently it is only Rs. 3.00. The breakeven production rate for each machine is

[2003]

Explanation

For Machine M1: Fixed cost = Rs 100 Variable cost = Rs 2 per piece For Machine M2: Fixed cost = Rs 200 Variable cost = 1 Rs per piece Total cost = Fixed cost + Variable cost × Number of units.

100 + 2n + 200 + n = 300 + 2n For the first 300 units, selling price is 3.50 Rs per unit.

So the break even point

300 + 3n = 3.50 (n+n)

300 + 3n = 3.50 (2 n)

7n = 300 + 3n = n = 75.

Report a problem

Question for GATE Past Year Questions: Production Planning

Try yourself:Production flow analysis (PFA) is a method of identifying part families that uses data from

[2001]

Explanation

Production flow analysis ( P F A ) i s a comprehensive method for material analysis part family formations, design of manufacturing cell & facility layout design.These operation are taken from the Route sheet.

Report a problem

Question for GATE Past Year Questions: Production Planning

Try yourself:The manufacturing area of a plant is divided into four quadrants. Four machines have to located one in each quadrant. The total number of possible layouts is

[1995]

According to question, work on work station (1) is followed by work on workstation (2).

According to question, work on work station (1) is followed by work on workstation (2). (a) 31

(a) 31 Optimum job sequence (According to Johnson's algorithm)

Optimum job sequence (According to Johnson's algorithm) Minimum total completion time of all parts = 33 hours

Minimum total completion time of all parts = 33 hours

MAPE =

MAPE =

The forecast is made by using the exponential smoothing method. The exponential smoothing coefficient used in forecasting the demand is [GATE ME 2020 SET-2]

The forecast is made by using the exponential smoothing method. The exponential smoothing coefficient used in forecasting the demand is [GATE ME 2020 SET-2]

Standard Production rate =

Standard Production rate =

T = 6 min

T = 6 min

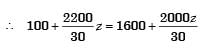

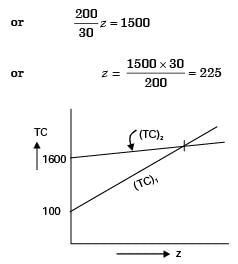

Total cost of z2 component by using Automatic Machine tool,

Total cost of z2 component by using Automatic Machine tool, Let break even point be z number of components

Let break even point be z number of components