GATE Syllabus for Mechanical Engineering 2026

- Candidates are advised to refer to the Mechanical Engg. syllabus while preparing for GATE. The GATE 2026 Mechanical Engineering syllabus will help the candidates boost their preparation since they are made familiar with the topics asked in the exam.

- The GATE 2026 examination will be conducted by the Indian Institute of Technology, ROORKEE. Along with the GATE syllabus for mechanical engineering, the candidates are also advised to check the exam pattern of GATE 2026 for preparation purposes.

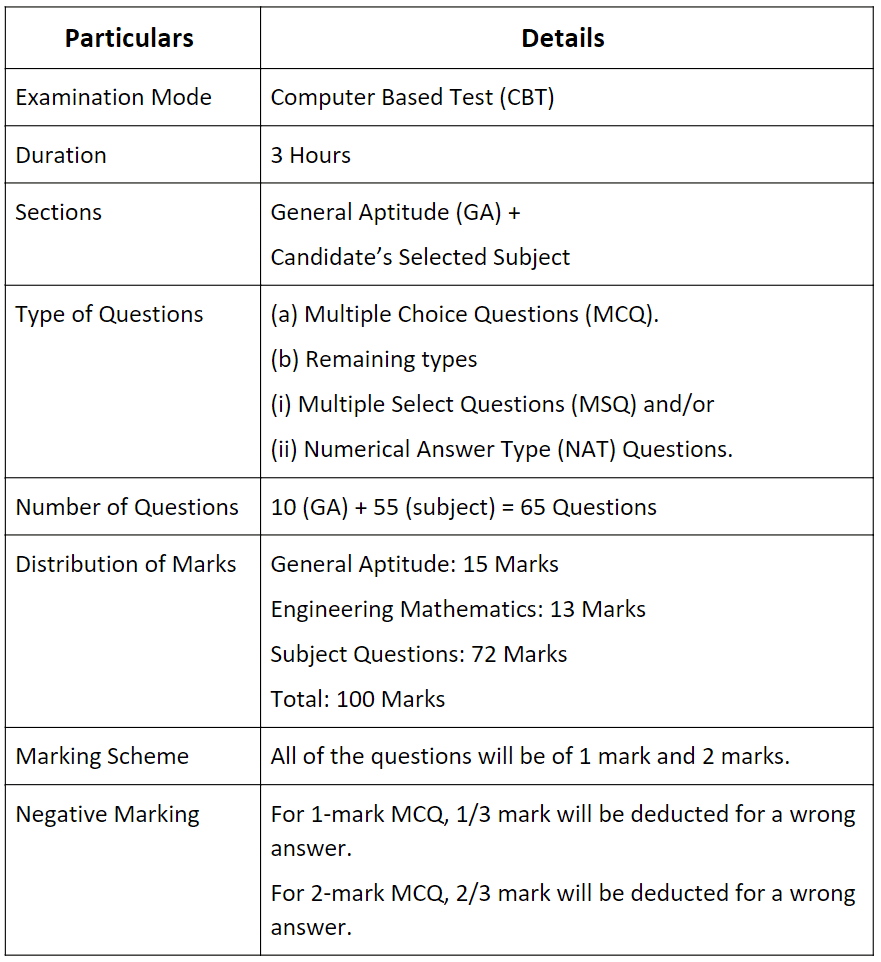

Table: The overview of the GATE 2026 exam pattern for Mechanical Engineering.

Here is the list of topics and sub-topics for each subject that needs to be covered for the GATE 2026 Mechanical Engineering Exam. Make sure the you should get to know the following parts in which syllabus is divided:

- General Aptitude

- Section 1: Engineering Mathematics

- Section 2: Applied Mechanics and Design

- Section 3: Fluid Mechanics and Thermal Sciences

- Section 4: Materials, Manufacturing and Industrial Engineering

Syllabus for General Aptitude (GA) (Common to all Papers)

1. Verbal Aptitude

- Basic English grammar: tenses, articles, adjectives, prepositions, conjunctions, verb-noun agreement, and other parts of speech.

- Basic vocabulary: words, idioms, and phrases in context.

- Reading Comprehension

- Narrative Sequencing

2. Quantitative Aptitude

- Data interpretation: data graphs (bar graphs, pie charts, and other graphs representing data), 2- and 3-dimensional plots, maps, and tables.

- Numerical computation and estimation: ratios, percentages, powers, exponents and logarithms, permutations and combinations, and series.

- Mensuration and Geometry

- Elementary Statistics and Probability

3. Analytical Aptitude

4. Spatial Aptitude

(a) Transformation of shapes:

- Translation

- Rotation

- Scaling

- Mirroring

- Assembling

- Grouping

(b) Paper folding

(c) Cutting

(d) Patterns in 2 and 3 dimensions.

Mechanical Engineering

Section 1: Engineering Mathematics

Linear Algebra

Matrix algebra, systems of linear equations, eigenvalues, and eigenvectors.

Calculus

Functions of a single variable, limit, continuity and differentiability, mean value theorems, indeterminate forms; evaluation of definite and improper integrals; double and triple integrals; partial 64 derivatives, total derivative, Taylor series (in one and two variables), maxima, and minima, Fourier series; gradient, divergence and curl, vector identities, directional derivatives, line, surface and volume integrals, applications of Gauss, Stokes and Green’s theorems.

Differential equations

First-order equations (linear and nonlinear); higher-order linear differential equations with constant coefficients; Euler-Cauchy equation; initial and boundary value problems; Laplace transforms; solutions of heat, wave, and Laplace's equations.

Complex variables

Analytic functions; Cauchy-Riemann equations; Cauchy’s integral theorem and integral formula; Taylor and Laurent series.

Probability and Statistics

Definitions of probability, sampling theorems, conditional probability; mean, median, mode, and standard deviation; random variables, binomial, Poisson, and normal distributions.

Numerical Methods

Numerical solutions of linear and non-linear algebraic equations; integration by trapezoidal and Simpson’s rules; single and multi-step methods for differential equations.

Section 2: Applied Mechanics and Design

Free-body diagrams and equilibrium; trusses and frames; virtual work; kinematics and dynamics of particles and of rigid bodies in plane motion; impulse and momentum (linear and angular) and energy formulations, collisions.

Stress and strain, elastic constants, Poisson's ratio; Mohr’s circle for plane stress and plane strain; thin cylinders; shear force and bending moment diagrams; bending and shear stresses; deflection of beams; torsion of circular shafts; Euler’s theory of columns; energy methods; thermal stresses; strain gauges and rosettes; testing of materials with the universal testing machine; testing of hardness and impact strength.

Displacement, velocity, and acceleration analysis of plane mechanisms; dynamic analysis of linkages; cams; gears and gear trains; flywheels and governors; balancing of reciprocating and rotating masses; gyroscope.

Vibrations

Free and forced vibration of single degree of freedom systems, the effect of damping; vibration isolation; resonance; critical speeds of shafts.

Design for static and dynamic loading; failure theories; fatigue strength and the S-N diagram; principles of the design of machine elements such as bolted, riveted, and welded joints; shafts, gears, rolling, and sliding contact bearings, brakes and clutches, springs.

Section 3: Fluid Mechanics and Thermal Sciences

Fluid properties; fluid statics, manometry, buoyancy, forces on submerged bodies, the stability of floating bodies; control-volume analysis of mass, momentum, and energy; fluid acceleration; differential equations of continuity and momentum; Bernoulli’s equation; dimensional analysis; the viscous flow of incompressible fluids, boundary layer, elementary turbulent flow, flow through pipes, head losses in pipes, bends, and fittings.

Modes of heat transfer; one-dimensional heat conduction, resistance concept and electrical analogy, heat transfer through fins; unsteady heat conduction, lumped parameter system, Heisler's charts; thermal boundary layer, dimensionless parameters in free and forced convective heat transfer, heat transfer correlations for flow over flat plates and through pipes, the effect of turbulence; heat exchanger performance, LMTD and NTU methods; radiative heat transfer, Stefan- Boltzmann law, Wien's displacement law, black and grey surfaces, view factors, radiation network analysis.

Thermodynamic systems and processes; properties of pure substances, the behavior of ideal and real gases; zeroth and first laws of thermodynamics, calculation of work and heat in various processes; second law of thermodynamics; thermodynamic property charts and tables, availability and irreversibility; thermodynamic relations.

Applications of Thermodynamics

Power Engineering: Air and gas compressors; vapour and gas power cycles, concepts of regeneration and reheat. I.C. Engines: Air-standard Otto, Diesel, and dual cycles. Refrigeration and air conditioning: Vapour and gas refrigeration and heat pump cycles; properties of moist air, psychrometric 65 chart, basic psychrometric processes. Turbomachinery: Impulse and reaction principles, velocity diagrams, Pelton-wheel, Francis, and Kaplan turbines.

Section 4: Materials, Manufacturing and Industrial Engineering

Structure and properties of engineering materials, phase diagrams, heat treatment, stress-strain diagrams for engineering materials.

Casting, Forming, and Joining Processes

Different types of castings, design of patterns, moulds, and cores; solidification and cooling; riser and gating design. Plastic deformation and yield criteria; fundamentals of hot and cold working processes; load estimation for bulk (forging, rolling, extrusion, drawing) and sheet (shearing, deep drawing, bending) metal forming processes; principles of powder metallurgy. Principles of welding, brazing, soldering, and adhesive bonding.

Machining and Machine Tool Operations

Mechanics of machining; basic machine tools; single and multipoint cutting tools, tool geometry and materials, tool life and wear; economics of machining; principles of non-traditional machining processes; principles of work holding, design of jigs and fixtures.

Metrology and Inspection

Limits, fits, and tolerances; linear and angular measurements; comparators; gauge design; interferometry; form and finish measurement; alignment and testing methods; tolerance analysis in manufacturing and assembly.

Computer Integrated Manufacturing

Basic concepts of CAD/CAM and their integration tools.

Production Planning and Control

Forecasting models, aggregate production planning, scheduling, materials requirement planning.

Inventory Control

Deterministic models; safety stock inventory control systems.

Operations Research

Linear programming, simplex method, transportation, assignment, network flow models, simple queuing models, PERT, and CPM.

|

30 docs|220 tests

|

FAQs on GATE Syllabus for Mechanical Engineering 2026

| 1. What are the important topics to cover in the General Aptitude section for the GATE Mechanical Engineering exam? |  |

| 2. How can I improve my score in the General Aptitude section of the GATE Mechanical Engineering exam? |  |

| 3. Is the General Aptitude section equally important as the technical section in the GATE Mechanical Engineering exam? |  |

| 4. Are there any specific books or study materials recommended for preparing for the General Aptitude section of the GATE Mechanical Engineering exam? |  |

| 5. How can I manage my time effectively while preparing for both the technical and General Aptitude sections of the GATE Mechanical Engineering exam? |  |