Tape Corrections - Errors in Chain Surveying, Surveying and Levelling | Surveying and Levelling Notes- Agricultural Engg - Agricultural Engineering PDF Download

Tape Corrections: Precise measurements of distance is made by means of a steel tape 30 m or 50 m in length. Before use it is desirable to ascertain its actual length (absolute length) by comparing it with the standard of known length, which can be done for a small fee by the Survey and Standards department. It is well to note here the distinction between the nominal or designated length and absolute length of a tape. By the former is meant it’s designated length, e.g. 30 m, or 100 m, while by the latter is meant it’s actual length under specified conditions. The tape may be standardized when supported horizontally throughout its full length or in catenary. The expression that “a tape is standard at a certain temperature and under a certain pull” means that under these conditions the actual length of the tape is exactly equal to its nominal length. Since the tape is not used in the field under standard conditions it is necessary to apply the following corrections to the measured length of a line in order to obtain its true length:

Correction for absolute length, (ii) Correction for temperature, (iii) Correction for tension or pull, (iv) Correction for sag, and (v) Correction for slope or vertical alignment.

A correction is said to be plus or positive when the uncorrected length is to be increased, and minus or negative when it is to be decreased in order to obtain true length.

Correction for Absolute Length: It is the usual practice to express the absolute length of a tape as its nominal or designated length plus or minus a correction. The correction for the measured length is given by the formula,

Ca = Lc / l ------------------- (1)

Where Ca = the correction for absolute length.

L = the measured length of a line.

l = the nominal length of a tape.

C= the correction to a tape.

The sign of the correction (Ca) will be the same as that of C. it may be noted that L and l must be expressed in the same units and the unit of Ca is the same as that of C.

Correction for Temperature: It is necessary to apply this correction, since the length of a tape is increased as its temperature is raised, and consequently, the measured distance is too small. It is given by the formula,

Ct = a (Tm – To)L-----------(2)

in which Ct = the correction for temperature, in m.

a = the coefficient of thermal expansion.

Tm = the mean temperature during measurement.

To = the temperature at which the tape is standardized.

L = the measure length in m.

The sign of the correction is plus or minus according as Tm is greater or less than To. The coefficient of expansion for steel varies from 10.6 x 10-6 to 12.2 x 10-6 per degree entigrade and that for invar from 5.4 x 10-7 to 7.2 x 10-7. If the coefficient of expansion of a tape is not known, an average value of 11.4 x 10-6 for steel and 6.3 x 10-7 for invar may be assumed. For very precise work, the coefficient of expansion for the tape in question must be carefully determined.

Correction for Pull (or Tension): The correction is necessary when the pull used during measurement is different from that at which the tape is standardized. It is given by the formula,

Cp = (P-Po)L / AE ----------(3)

Where Cp = the correction for pull in metres.

P = the pull applied during measurement, in newtons (N).

Po= the pull under which the tape is standardized in newtons (N).

L = the measured length in metres.

A = the cross-sectional area of the tape, in sq.cm.

E = the modulus of elasticity of steel.

The value of E for steel may be taken as 19.3 to 20.7 x 1010 N/m2 and that for invar 13.8 to 15.2 x 1010 N/m2. For every precise work its value must be ascertained. The sign of the correction is plus, as the effect of the pull is to increase the length of the tape and consequently, to decrease the measured length of the line.

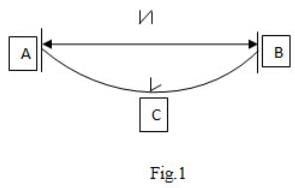

Correction for Sag: (Fig.1). When a tape is stretched over points of support, it takes the form of a catenary. In actual practice, however, the catenary curve is assumed to be a parabola. The correction for sag (or sag correction) is the difference in length between the arc and the subtending chord (i.e., the difference between the horizontal distance between supports and the length measured along the curve). It is required only when the tape is suspended during measurement. Since the effect of the set on the tapes is to make the measured length too great this correction is always subtractive. It is given by the formula,

Cs = l1 (mgl1)2 / 24P2 = l1(Mg)2 / 24P2 ………………(4)

in which Cs = the sag correction for a single span, in metres.

l1 = the distance between supports in metres.

m = the mass of the tape, in kilograms per metre.

M = Total mass of the tape in kilograms.

P = the applied pull, in newtons (N).

If there are n equal spans per tape length, the sag corrections per tape length is given, by Cs = nl1(mgl1)2 / 24P2 = l(mgl1)2 / 24P2 = l(mgl)2 / 24n2P2 ………….(4a)

in which l = the length of the tape = nl1, and l1= l/n.

Normal Tension: The normal tension is a tension at which the effects of pull and sag are neutralized, i.e. the elongation due to increase in tension is balanced by the shortening due to sag. It may be obtained by equating the corrections for pull and sag. Thus we have,

(Pn-Po)l1 / AE = l1(mgl1)2 / 24Pn2 or (Pn-Po) Pn2 = W2AE / 24

~ Pn = 0.204 W √AE / √(Pn-Po) …………………………………………..(5)

in which Pn = the normal tension in newtons (N).

W = the weight of the length of tape between supports in newtons (N).

The value of Pn may be determined by trial

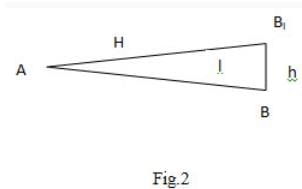

Correction for Slope or Vertical Alignment: (Fig 2) This correction is required when the points of support are not exactly at the same level.

Let l1 l2, etc. = the lengths of successive uniform slopes.

Let l1 l2, etc. = the lengths of successive uniform slopes.

lt1, lt2 etc. = the differences in height between the extremities of each of these slopes.

Cs = the total correction for slope.

If l is the length of any one slope, and h the difference in height between the ends of the slope,

the slope correction = l - √ l2-h2

= l – l (1 – h2 / 2l2 – h4 / 3l4 – etc..)

=(h2 / 2l + h4 / 3l3 + etc.) = h2 / 2l ------------------------(6)

hence, Cs = (h12 / 2l1 + h22 / 2l2 + ….. + hn2 / 2ln) -------------------------------(6a)

When the slopes are of uniform length l we have

Cs = l / 2l (h12 + h22 + ……… + hn2) = ∑h2 / 2l -------------------------(6b)

This correction is always subtractive from the measured length. If the slopes are given in terms of vertical angles (plus or minus angles), the following formula may be used:

The correction for the slope = l – l cos 0 = 2l sin2 0 / 2

= l versin 0 (-ve) --------------------------(7)

in which l = the length of the slope : 0 = the angle of the slope.

FAQs on Tape Corrections - Errors in Chain Surveying, Surveying and Levelling - Surveying and Levelling Notes- Agricultural Engg - Agricultural Engineering

| 1. What are some common errors that can occur in chain surveying? |  |

| 2. How can incorrect chaining affect the accuracy of a survey? |  |

| 3. What is the impact of incorrect ranging in chain surveying? |  |

| 4. How does sagging or stretching of the tape affect levelling in surveying? |  |

| 5. What precautions can be taken to minimize errors in tape measurements during agricultural engineering surveys? |  |

|

Explore Courses for Agricultural Engineering exam

|

|