Class 8 History Chapter 1 Question Answers - Our Pasts III (Part - I)

The Class 8 Social Studies chapter titled "Weavers, Iron Smelters, and Factory Owners" sheds light on India's crafts and industries during British rule, with a specific focus on textiles and iron and steel. These two industries played a pivotal role in driving the industrial revolution that transformed the modern world. Let's see the Short & Long Answer Questions of this chapter.

Very Short Answer Type Questions

Q1: What were two factors contributing to the global renown of Indian textiles?

Ans: Indian textiles gained worldwide recognition due to their exceptional quality and exquisite craftsmanship. These factors have cemented India's reputation in the global textile market.

Q2: What were the reasons behind the popularity of printed Indian cotton textiles in England?

Ans: Printed Indian cotton textiles gained popularity in England for several reasons:

- Intricate floral designs: The textiles featured detailed and artistic patterns that appealed to English tastes.

- Superior texture: The quality of the fabric was soft and comfortable, making it desirable for clothing.

- Affordability: These textiles were often less expensive than local alternatives, making them accessible to a wider audience.

Overall, the combination of aesthetic appeal, quality, and cost contributed to the success of Indian textiles in the English market.

Q3: During which era was patola weaving particularly renowned?

Ans: Patola weaving reached its peak of fame during the mid-19th century.

Patola WeaveQ4: What is the etymology of the term "calico"?

Patola WeaveQ4: What is the etymology of the term "calico"?

Ans: The term 'calico' originated from the city of Calicut, located in India. This fabric, traditionally made from cotton, became known for its vibrant patterns and colours, which were often associated with the region.

Q5: Which were the significant hubs for jamdani weaving?

Ans: The important centers for jamdani weaving were Dacca in Bengal and Lucknow in the United Provinces (U.P.).

Q6: Name two locations where Chintz production thrived in the mid-19th century.

Ans: The production of chintz flourished in Masulipatnam and Andhra Pradesh during the mid-19th century.

Q7: How did European trading companies purchase cotton and silk textiles in India?

Ans: European trading companies purchased cotton and silk textiles in India primarily by importing silver. This method allowed them to acquire these valuable goods efficiently, as silver was a highly sought-after commodity in trade.

Q8: Name the household spinning instrument.

Ans: The household spinning instruments are the Charkha and Takli.

Q9: What did Mahatma Gandhi urge people during the national movement?

Ans: During the national movement, Mahatma Gandhi urged people to boycott imported textiles and to use hand-spun and hand-woven cloth. This initiative aimed to promote self-reliance and support local artisans.

Q10: What became a symbol of nationalism?

Q10: What became a symbol of nationalism?

Ans: Khadi became a significant symbol of nationalism. This fabric, handspun from cotton, represented not only India's struggle for independence but also the promotion of self-reliance and indigenous industry. The use of Khadi was a statement against British colonial rule and an assertion of Indian identity.

Q11: How did the growth of cotton mills in the country prove to be a boon for the poor peasants, artisans, and agricultural laborers?

Ans: They got work in the mills.

Q12: How did Indian cotton factories prove to be helpful during the First World War?

Ans: During the First World War, Indian cotton factories proved essential by producing cloth for military supplies. This contribution supported the war effort significantly.

Q13: Why was Tipu’s sword so special?

Ans: Tipu’s sword was made from Wootz steel, a material renowned for its ability to produce a very sharp edge. This exceptional sharpness allowed the sword to easily cut through an opponent’s armour, making it highly effective in battle.

Tipu's Sultan SwordQ14: Why was the Wootz steel-making process completely lost by the mid-19th century?

Tipu's Sultan SwordQ14: Why was the Wootz steel-making process completely lost by the mid-19th century?

Ans: The decline of the Wootz steel-making process by the mid-19th century can be attributed to two primary factors:

- The sword and armour-making industry effectively ceased with the British conquest of India.

- Imports of iron and steel from England began to displace the products made by Indian craftsmen.

Q15: What were the furnaces made of?

Ans: The furnaces were constructed using clay and sun-dried bricks.

Q16: Why were bellows used?

Ans: Bellows were used to maintain the burning of charcoal. By forcing air into the fire, bellows helped to increase the temperature and ensure that the charcoal continued to burn efficiently.

Q17: What were piece goods?

Ans: Piece goods refer to lengths of woven cloth, typically measuring 20 yards long and 1 yard wide. These textiles were often sold in specific lengths rather than as full rolls, making them accessible for various uses in tailoring and manufacturing.

Short Answer Type Questions

Q1: How were Indian textiles viewed in the world market?

Ans: Before the British conquest of Bengal around 1750, India was the largest producer of cotton textiles in the world. Renowned for their fine quality and exquisite craftsmanship, Indian textiles were extensively traded in regions such as Southeast Asia (including Java, Sumatra, and Penang) as well as West and Central Asia. From the 16th century onwards, European trading companies began purchasing Indian textiles for sale in Europe, further establishing their global significance.

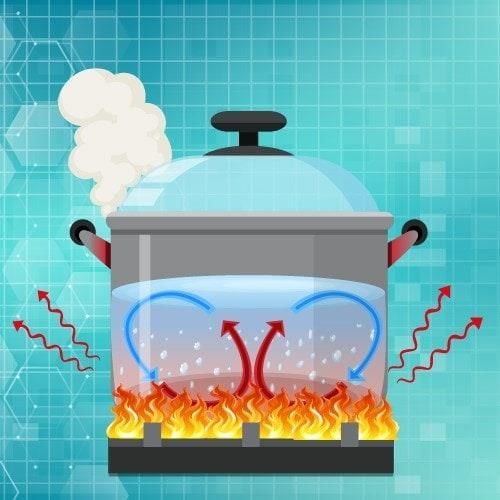

Q2: How did the inventions of the Spinning Jenny and Steam Engine revolutionize cotton textile weaving in England?

Ans: Textile industries had just emerged in England in the early 18th century.

So, it was difficult for the English producers to compete with Indian textiles. This competition with Indian textiles led to a search for technological innovation in England. In 1764, the Spinning Jenny was invented by John Kaye which increased the productivity of the traditional spindles.

Then came the steam engine. It was invented by Richard Arkwright in 1786. These two inventions revolutionized cotton textile weaving in England. Cloth could now be woven in immense quantities and cheaply too.

Spinning JennyQ3: Give a description of the four regions where textile production was concentrated in the early 19th century.

Spinning JennyQ3: Give a description of the four regions where textile production was concentrated in the early 19th century.

Ans: Textile production was concentrated in the following four regions in the early 19th century:

- Bengal was one of the most important centres for textile production. Located along the numerous rivers in the delta, the production centres in Bengal could easily transport goods to distant places.

- Dacca, in Eastern Bengal (present-day Bangladesh), was the foremost textile centre in the 18th century. It was renowned for its mulmul and jamdani weaving.

- Textile production was also concentrated along the Coromandel coast, stretching from Madras to northern Andhra Pradesh.

- On the western coast, there were significant weaving centres in Gujarat.

Q4: Who were the weavers? Name some communities famous for weaving.

Ans: Weavers often belonged to communities that specialised in weaving, with their skills being passed down from one generation to the next. Some communities famous for weaving include:

- Tanti weavers of Bengal.

- Julahas or Momin weavers of North India.

- Sale, Kaikollar, and Devangs of South India.

Q5: Describe the process of cloth making.

Ans: The process of cloth making consists of two main stages:

- The first stage of production is spinning, primarily carried out by women. Household spinning instruments such as the charkha and the takli were commonly used. The thread was spun on the charkha and wound onto the takli.

- Once the spinning was complete, the thread was woven into cloth by the weaver, a task usually performed by men in most communities. For coloured textiles, the thread was dyed by a specialist known as the rangrez. In the case of painted cloth, weavers required the assistance of expert block printers called chhipigars.

Q6: Handloom production did not completely die in India. Why?

Ans: Handloom production did not completely die in India for several reasons. Firstly, certain types of clothing, such as saris with intricate borders and garments featuring traditional woven patterns, could not be produced by machines. These items had a significant demand not only among the wealthy but also within the middle classes.

Furthermore, textile manufacturers in Britain were unable to create the very coarse cloths that were essential for the poorer segments of Indian society. In the late 19th century, Sholapur and Madurai emerged as important new centres of weaving. During the national movement, Gandhiji encouraged people to use hand-spun and handwoven cloth known as Khadi, which gradually became a symbol of nationalism.

Q7: Give a brief description of the growth of cotton mills in India.

Ans: The first cotton mill in India was established as a spinning mill in Bombay in 1854. By 1900, over 84 mills were operating in Bombay. Additional mills were also set up in other cities. The first mill in Ahmedabad was initiated in 1861, followed by another mill in Kanpur, located in the United Provinces, a year later. The growth of cotton mills significantly increased the demand for labour. Consequently, thousands of poor peasants, artisans, and agricultural labourers migrated to cities to work in these mills.

Cotton MillsQ8: Who are the Agarias? Why did they leave their village?

Cotton MillsQ8: Who are the Agarias? Why did they leave their village?

Ans: The Agarias are a community of iron smelters. They are specialized in the craft of iron smelting.

In the late 19th century a series of famines devastated the dry tracts of India. In central India, many of the Agaria iron smelters stopped work, deserted their villages, and migrated, looking for some other work to survive the hard times. A large number of them never worked their furnaces again.

Long Answer Type Questions

Q1: Write a few lines on each of the following:

(a) Patola weave

(b) Jamdani weave

(c) Chintz

Ans: (a) Patola weave- It came into existence in the mid-19th century. It was woven in Surat, Ahmedabad, and Patan. It was highly valued in Indonesia. It became a part of the local weaving tradition there.

(b) Jamdani weave- It grew in the early 20th century. Jamdani is a fine muslin on which decorative motifs are woven on the loom, typically in grey and white. Often a mixture of cotton and gold thread was used. The most important centers of jamdani weaving were Dacca in Bengal and Lucknow in the United Provinces.

(c) Chintz- The term chintz is derived from the Hindi word chhint, a cloth with small and colorful flowery designs. It was produced in Masulipatnam and Andhra Pradesh in the mid-19th century. It was in great demand in England and Europe.

Q2: How did Iron and Steel factories come up in India?

Ans: Jamsetji Tata decided to invest a significant portion of his fortune to establish a large iron and steel industry in India. However, this was contingent upon identifying sources of high-quality iron ore. To achieve this, his son, Dorabji Tata, in collaboration with Charles Weld, an American geologist, began exploring Chhattisgarh in search of iron ore deposits in the year 1904. After several hours of traversing the forests, Weld and Dorabji encountered a small village where they met the Agarias, who were transporting basket loads of iron ore. When inquired about the source of their iron ore, the Agarias indicated a hill in the distance. Weld and Dorabji rushed to the hill, and upon examination, the geologist declared that they had finally found what they were seeking. Unfortunately, the region was arid, prompting the Tatas to look for a more suitable location to establish their factory. A few years later, a large area of forest was cleared along the banks of the Subarnarekha River to build the factory and an industrial township named Jamshedpur. This site was advantageous as it provided access to both water and iron ore deposits. The Tata Iron and Steel Company, commonly known as TISCO, commenced steel production in 1912.

|

69 videos|426 docs|46 tests

|

FAQs on Class 8 History Chapter 1 Question Answers - Our Pasts III (Part - I)

| 1. What were the major challenges faced by weavers during the industrialization period? |  |

| 2. How did iron smelting evolve during the industrial revolution? |  |

| 3. What role did factory owners play in the lives of workers during the industrial era? |  |

| 4. How did the relationship between weavers and factory owners change over time? |  |

| 5. What were the social impacts of the transition from handloom weaving to factory production? |  |