Mechanical Engineering Exam > Mechanical Engineering Notes > Engineering Materials > GATE Past Year Questions: Heat Treatment

GATE Past Year Questions: Heat Treatment | Engineering Materials - Mechanical Engineering PDF Download

Question for GATE Past Year Questions: Heat Treatment

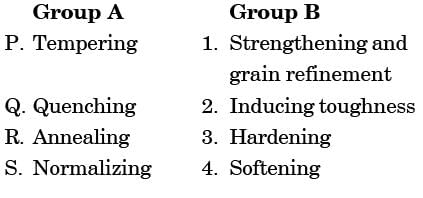

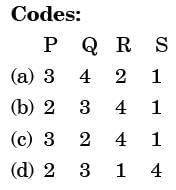

Try yourself:Match the heat treatment processes (Group A) and their associated effects on properties (Group B) of medium carbon steel

[ME 2014, Set-4]

View Solution

Question for GATE Past Year Questions: Heat Treatment

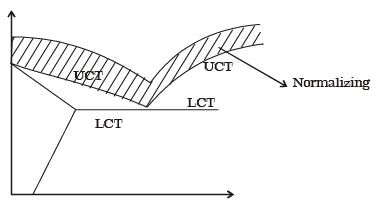

Try yourself:During normalizing process of steel, the specimen is heated

[ME 2012]

View Solution

Question for GATE Past Year Questions: Heat Treatment

Try yourself:From the lists given below, choose the most appropriate set of heat treatment process and the corresponding process characteristies

Process

P. Tempering

Q. Austempering

R. Martempering

Characteristics

1. Austenite is converted into bainite

2. Austenite is converted into martensite

3. Cementite is converted into globular structure

4. Both hardness and brittleness are reduced

5. Carbon is absorbed into the metal

[ME 2004]

View Solution

Question for GATE Past Year Questions: Heat Treatment

Try yourself:Cold working of steel is defined as working

[ME 2003]

View Solution

Question for GATE Past Year Questions: Heat Treatment

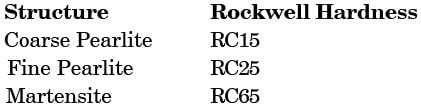

Try yourself:During heat treatment of steel, the hardness of various structures in increasing order is

[ME 2003]

View Solution

The document GATE Past Year Questions: Heat Treatment | Engineering Materials - Mechanical Engineering is a part of the Mechanical Engineering Course Engineering Materials.

All you need of Mechanical Engineering at this link: Mechanical Engineering

|

15 videos|35 docs|13 tests

|

FAQs on GATE Past Year Questions: Heat Treatment - Engineering Materials - Mechanical Engineering

| 1. What is heat treatment in mechanical engineering? |  |

Ans. Heat treatment in mechanical engineering refers to the process of heating and cooling a material in a controlled manner to alter its physical and mechanical properties. It is commonly used to improve the hardness, strength, toughness, and ductility of materials.

| 2. What are the common techniques used in heat treatment? |  |

Ans. There are several common techniques used in heat treatment, including annealing, tempering, quenching, hardening, and case hardening. Annealing involves heating the material to a specific temperature and then slowly cooling it to make it softer and more ductile. Tempering is a process of reheating a hardened material to a lower temperature to reduce its brittleness. Quenching refers to rapidly cooling a material to increase its hardness. Hardening involves heating a material to a high temperature and then cooling it rapidly to achieve maximum hardness. Case hardening is a process of hardening only the surface layer of a material.

| 3. What are the advantages of heat treatment in mechanical engineering? |  |

Ans. Heat treatment offers several advantages in mechanical engineering. It can improve the mechanical properties of materials, such as increasing their hardness, strength, and toughness. Heat treatment can also enhance the wear resistance and corrosion resistance of materials, making them more durable and long-lasting. Additionally, it can modify the microstructure of materials, resulting in improved machinability and dimensional stability.

| 4. What factors should be considered when selecting a heat treatment technique? |  |

Ans. When selecting a heat treatment technique, several factors should be considered. These include the type of material being treated, the desired mechanical properties, the required dimensional stability, the available equipment and resources, and the cost and time constraints. It is important to choose a heat treatment technique that is suitable for the specific material and application to achieve the desired results.

| 5. What are the limitations of heat treatment in mechanical engineering? |  |

Ans. While heat treatment offers numerous benefits, it also has some limitations. One limitation is that it is not suitable for all types of materials. For example, some materials may have compositions that make them difficult to heat treat effectively. Another limitation is that heat treatment can induce residual stresses in the material, which may cause distortion or warping. Additionally, improper heat treatment can lead to undesirable changes in the material's properties or even failure. Therefore, careful planning and execution are essential to ensure successful heat treatment in mechanical engineering.

Related Searches