Stress & Strain | Mechanical Engineering SSC JE (Technical) PDF Download

Stress

- When a material is subjected to an external force, a resisting force is set up within the component.

- The internal resistance force per unit area acting on a material or intensity of the forces distributed over a given section is called the stress at a point.

- It uses the original cross section area of the specimen and is also known as engineering stress or conventional stress.

- Therefore, σ = P / A

Stress

Stress

- P is expressed in Newton (N) and A, original area, in square meters (m2), the stress σ will be expresses in N/m2. This unit is called Pascal (Pa).

- As Pascal is a small quantity, in practice, multiples of this unit is used.

1 kPa = 103 Pa = 103 N/ m2 (kPa = Kilo Pascal)

1 MPa = 106 Pa = 106N/ m2 = 1 N/mm2 (MPa = Mega Pascal)

1 GPa = 109 Pa = 109 N/ m2 (GPa = Giga Pascal)

- The resultant of the internal forces for an axially loaded member is normal to a section cut perpendicular to the member axis.

- The force intensity on the shown section is defined as the normal stress.

I

I

Tensile Stress

If σ> 0 the stress is tensile. i.e. The fibres of the component tend to elongate due to the external force. The beam is subjected to an external force tensile F and tensile stress distribution due to the force is shown in the figure.  Tensile Stress

Tensile Stress

Compressive Stress (σc)

- If σ < 0 the stress is compressive. i.e. The fibres of the component tend to shorten due to the external force.

- A member subjected to an external compressive force P and compressive stress distribution due to the force is shown in the given figure.

Shear Stress (τ)

- When forces are transmitted from one part of a body to other, the stresses developed in a plane parallel to the applied force are the shear stress.

- Shear stress acts parallel to plane of interest.

- Forces P is applied transversely to the member AB as shown.

- The corresponding internal forces act in the plane of section C and are called shearing forces.

- The corresponding average shear stress (T) = P/Area

Strain

- The displacement per unit length (dimensionless) is known as strain.

Tensile strain

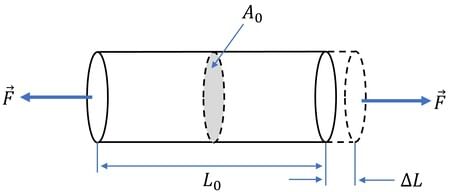

- The elongation per unit length as shown in the figure is known as tensile strain.

- εt = ΔL/L0

- It is engineering strain or conventional strain.

- Here we divide the elongation to original length not actual length (L0ΔL)

Tensile Strain

Tensile Strain

Compressive strain

If the applied force is compressive then the reduction of length per unit length is known as compressive strain. It is negative. Then εc = (-ΔL)/L0

Shear strain (γ)

When a force P is applied tangentially to the element shown. Its edge displaced to dotted line. Where E is the lateral displacement of the upper face of the element relative to the lower face and L is the distance between these faces.

Shear StrainThen the shear strain is :

Shear StrainThen the shear strain is :  formula

formula

True stress and True Strain

The true stress is defined as the ratio of the load to the cross section area at any instant.

True stress

True stress

Where σ and ε is the engineering stress and engineering strain respectively.

True strain

True strain

True strain

or engineering strain (ε) = eεt -1

The volume of the specimen is assumed to be constant during plastic deformation.

[ ∵ AoLo = AL ] It is valid till the neck formation.

Comparison of engineering and the true stress-strain curves shown below

stress vs strain

stress vs strain

- The true stress-strain curve is also known as the flow curve.

- True stress-strain curve gives a true indication of deformation characteristics because it is based on the instantaneous dimension of the specimen.

- In engineering stress-strain curve, stress drops down after necking since it is based on the original area.

- In true stress-strain curve, the stress however increases after necking since the cross-sectional area of the specimen decreases rapidly after necking.

- The flow curve of many metals in the region of uniform plastic deformation can be expressed by the simple power law.

σT = L(εT)n

Where K is the strength coefficient

n is the strain hardening exponent

n = 0 perfectly plastic solid

n = 1 elastic solid

For most metals, 0.1< n < 0.5

Relations

Relations

Hook’s law

The co-efficient E is called the modulus of elasticity i.e. its resistance to elastic strain. The co-efficient G is called the shear modulus of elasticity or modulus of rigidity.

Volumetric Strain

A relationship similar to that for length changes holds for three-dimensional (volume) change. For volumetric strain(εv)

the relationship is (εv) = (V-V0)/V0 or (εv) = ΔV/V0 = P/K

- Where V is the final volume, V0 is the original volume, and ΔV is the volume change.

- Volumetric strain is a ratio of values with the same units, so it also is a dimensionless quantity.

- ΔV/V= volumetric strain = εx + εy + εz= ε1 + ε2 + ε3

- Dilation: The hydrostatic component of the total stress contributes to deformation by changing the area (or volume, in three dimensions) of an object. Area or volume change is called dilation and is positive or negative, as the volume increases or decreases, respectively. e = P/K ; Where P is pressure.

modulus

modulus

- For a linearly elastic, isotropic and homogeneous material, the number of elastic constants required to relate stress and strain is two. i.e. any two of the four must be known.

- If the material is non-isotropic (i.e. anisotropic), then the elastic modulii will vary with additional stresses appearing since there is a coupling between shear stresses and normal stresses for an anisotropic material.

Poisson’s Ratio

Poisson's ratio

Poisson's ratio

(Under unidirectional stress in x-direction)

- The theory of isotropic elasticity allows Poisson's ratios in the range from -1 to 1/2.

- Poisson's ratio in various materials

Ratios of various material

Ratios of various material

- We use cork in a bottle as the cork easily inserted and removed, yet it also withstand the pressure from within the bottle. Cork with a Poisson's ratio of nearly zero, is ideal in this application.

For bi-axial stretching of sheet

Ratio

Ratio

Elongation

A prismatic bar loaded in tension

Elongation for a bar

Elongation for a bar

Elongation of composite body

Elongation of a composite body

Elongation of a composite body

Elongation of a tapered body

Elongation of a tapered body

Elongation of a tapered body

Elongation of a body due to its self weight

Elongation due to self weight

Elongation due to self weight

Structural members or machines must be designed such that the working stresses are less than the ultimate strength of the material.

Working stress

Working stress

Factor of Safety

(n) = σy or σp or σult / σw

Thermal or Temperature stress and strain

- When a material undergoes a change in temperature, it either elongates or contracts depending upon whether temperature is increased or decreased of the material.

- If the elongation or contraction is not restricted, i. e. free then the material does not experience any stress despite the fact that it undergoes a strain.

- The strain due to temperature change is called thermal strain and is expressed as,

ε = α(ΔT)

- Where α is co-efficient of thermal expansion, a material property, and ΔT is the change in temperature.

- The free expansion or contraction of materials, when restrained induces stress in the material and it is referred to as thermal stress.

σt = αE(ΔT)

where, E = Modulus of elasticity

- Thermal stress produces the same effect in the material similar to that of mechanical stress. A compressive stress will produce in the material with increase in temperature and the stress developed is tensile stress with decrease in temperature.

[Intext Question]

Thermal stress on Brass and Mild steel combination

A brass rod placed within a steel tube of exactly same length. The assembly is making in such a way that elongation of the combination will be same. To calculate the stress induced in the brass rod, steel tube when the combination is raised by tοC then the following analogy have to do.

Where, δ = Expansion of the compound bar = AD in the above figure.

δst= Free expansion of the steel tube due to temperature rise tοC = αsLt = AB in the above figure.

δsf = Expansion of the steel tube due to internal force developed by the unequal expansion = BD in the above figure.

δbt = Free expansion of the brass rod due to temperature rise tοC = αbLt = AC in the above figure.

δbt= Compression of the brass rod due to internal force developed by the unequal expansion. = BD in the above figure.

And in the equilibrium equation

Tensile force in the steel tube = Compressive force in the brass rod

Where, σs= Tensile stress developed in the steel tube.

σb= Compressive stress developed in the brass rod.

As= Cross section area of the steel tube.

Ab= Cross section area of the brass rod.

Maximum stress and elongation due to rotation

|

5 videos|103 docs|59 tests

|

FAQs on Stress & Strain - Mechanical Engineering SSC JE (Technical)

| 1. What is the difference between tensile stress and compressive stress? |  |

| 2. How is strain defined in materials science? |  |

| 3. What is Hook's Law and how does it relate to stress and strain? |  |

| 4. What is Poisson's Ratio and why is it important in material science? |  |

| 5. What are true stress and true strain, and how do they differ from engineering stress and strain? |  |

|

5 videos|103 docs|59 tests

|

|

Explore Courses for Mechanical Engineering exam

|

|