Study Notes on Welding | Manufacturing Engineering - Mechanical Engineering PDF Download

Joining

- The joining is the process used to assemble different parts to obtain the desired complex parts or geometry which is either too difficult or impossible to obtain by using only the manufacturing processes.

- The joining process is either temporary (Bolted joints) or permanent (Welding, riveting, coupling, etc.).

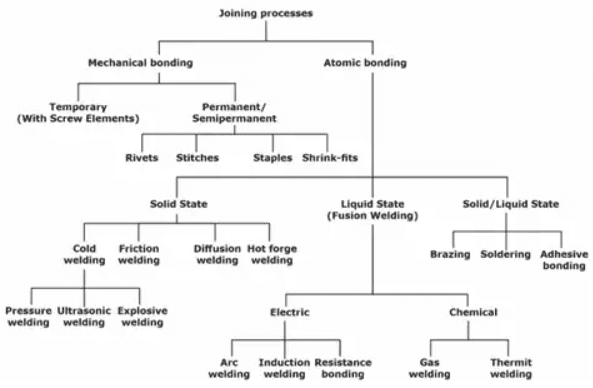

Different joining processes are classified below: Welding is the process of joining together two pieces of metal with or without the application of heat or pressure or both is applied and with or without addition of filler metal for formation of metallic bond.

Welding is the process of joining together two pieces of metal with or without the application of heat or pressure or both is applied and with or without addition of filler metal for formation of metallic bond.

Classification of the welding processes:

Welding process based on composition of filler material are as follows:

- Autogenous Welding: In this type, no filter material is required. All types of solid phase welding and resistance welding are the examples of this category.

- Homogenous: Here, the filler material provided to the joint is the same as the parent material. Arc, gas, and thermit welding are examples of this category.

- Heterogenous Welding: Here the filler material has different composition from the parent material. Soldering and brazing are two such joining processes. The insoluble materials, for example iron and silver, can be welded using the heterogeneous process.

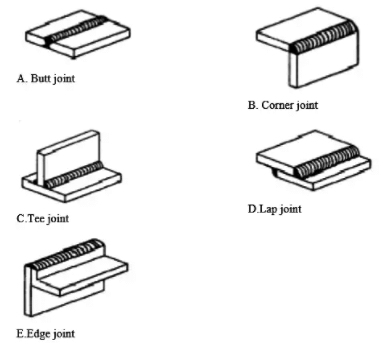

Types of joints

Different types of joints according to their configuration are butt, lap, corner, tee and edge joints. The contact area plays an important role in tensile strength of butt joints. In case of lap joint, the bonding area is taken as per the strength requirement but the main disadvantage is that the thickness of joint increases due to overlapping of the parts.

Welding Accessories

- Non consumable electrodes

- They are made of tungsten or carbon and do not melt during the welding thus called non-consumable electrodes.

- Generally non-consumable electrodes are used in TIG welding processes.

- Coated consumable electrodes

- With these type of electrodes, no additional filler metal and flux are required.

- These electrodes have core of mild steel and coating over them of flux material.

- Coating on the electrode performs many functions:

(a) It develops a reducing atmosphere and prevents oxidation

(b) It forms separable slag from metal impurities

(c) It establishes arc and provides necessary alloying elements to the weld pool.

Examples: Manganese oxide and potassium silicate are the alloying elements and stabilizers.

- Welding cables: These are needed to carry the current from the power source to different elements of Arc welding process equipment i.e. the arc, Electrode, the workpiece and finally return to the welding power source. These are insulated copper or aluminum cables.

- Hand screen: It protects the eyes during Arc welding process.

- Chipping hammer: It is used for removing the slag from the weld bead region by striking on it.

- Wire Brush: A wire brush is generally used to clean the surface before and after the welding process.

- Protective clothing: The clothing such as apron which is used to protect from the direct exposure of heat to the body. Example: Gloves is necessary before touching any item in the workshop.

- Filler Metal: Filler metal is provided separately to improve properties of weldment especially with non consumable electrodes. Filler metal is selected based on the metal to be welded. Common filler metals used are are discussed below.

- Coated filler metal: Rods of this type of filler metal consists the coating of flux material.

- Bare filler metal: No coating of flux is there, it is supplied additionally as per the requirement.

Examples: The alloy of chromium and vanadium are most commonly used for stainless steel and alloy steels. Phosphorous mixed copper is the main filler metal for the welding of the copper and its alloys.

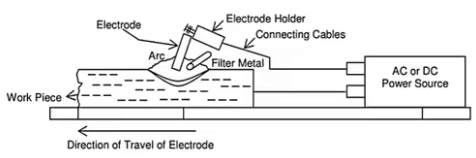

Arc welding

It is the liquid state joining process in which coalescence of the metal is achieved with the application of the heat from an electric arc generated between an electrode and workpiece.

- Electric arc is generated when electrode is brought into contact with the work and is then quickly separated by a short distance approximately 2 mm.

- The circuit operates at low voltage and high current, so arc is established in the gap due to thermionic emission from electrode (Cathode) to workpiece (Anode).

- The arc is sustained due to continuous presence of a thermally ionized column of gas. This arc produces at temperature of the order of 5500°C or higher.

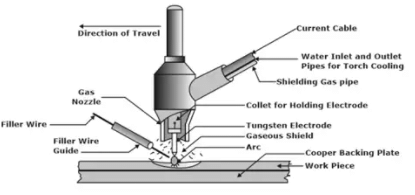

TIG Welding

- A non consumable is used in TIG welding process and its objective is only to create an arc.

- A separate metal rod is supplied as filler material during welding.

- TIG welding is mainly used to weld Aluminium and Magnesium allloys. Aluminium is very difficult to weld because as soon as it is exposed to atmosphere it forms a layer over it. Thus, work piece is given negative polarity and electrode positive polarity to avoid this problem. With such polarity, electrons flow from workpiece to electrode and peels of oxide layer and fresh Aluminum comes in contact with the arc. This phenomenon of self cleaning is known as cathodic cleaning.

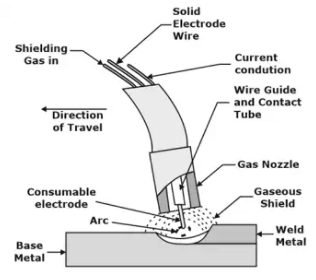

MIG Welding

- MIG works on same principle of TIG or arc welding.

- It utilizes the heat generated due to electric arc for the welding process. The heat generated is used to melt consumable electrode and parent metal workpieces which make a strong joint together on the solidification.

- The shielded gases are used to protect the weld zone from other reactive gases. This welding results in good surface finish of the welded parts and a stronger joint.

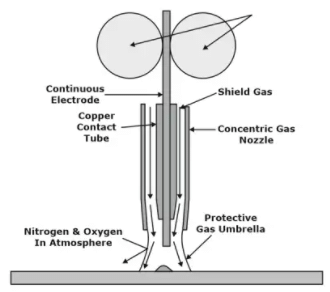

Submerged Arc Welding (SAW)

- This is semi-automatic version of SMAW process which can produce long weld runs.

- The electrode used is in the form of spool of having copper coating (to increase the conductivity of wire) and granular flux.

- The powdered flux is poured in to the welding area not only helps in maintaining the arc but also minimizes the Spatter of liquid metal and suppresses the intensity ultraviolet radiation.

- Flux is fed on weld zone by gravity through flow nozzle, a long continuous weld can be performed.

- This process is mainly suitable for down hand welding position.

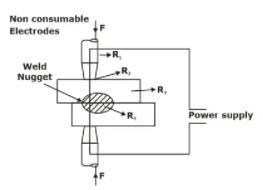

Resistance Welding

- Resistance welding is a fusion welding process that also utilizes pressure in welding operation.

- In Resistance welding whatever the heat required for melting and joining of plates is obtained due to electrical resistance circuit, so the name given as resistance welding operation.

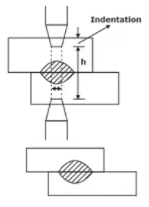

Resistance Spot Welding

It is a resistance welding process in which contacting metal surface are joint at different points by the heat obtained from resistance to electric current.

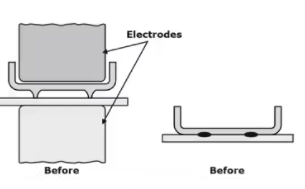

Seam welding

- It is resistance welding process where continuous series of spots is obtained to join the metal with the application of heat from resistance and pressure by electrodes.

- Here disc electrodes are continuously rotated and the workpiece is advanced underneath them while at the same time the pressure on the joints is maintained. The electrodes pressure is relieved after solidification of molten metal.

- This process is used for air tight joints.

Projection welding

- The method of joining a projected component on a flat component by using resistance welding is called resistance projection welding.

- In projection welding, the shape of the electrode remains same as the shape of components to be joined.

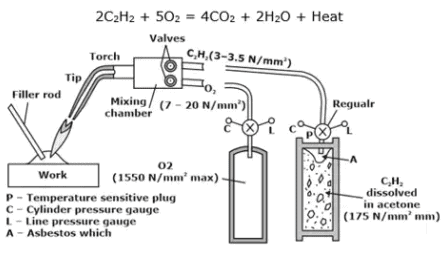

Oxyacetylene welding (Gas welding)

- It can used for welding of wide range of metals and alloys.

- In this welding, Acetylene and oxygen mixture are burnt under a controlled environment which releases a large amount of heat resulting in high temperature rise.

- Carbon dioxide is also produced which prevents the oxidation of metals being welded.

- Highest temperature obtained in this welding is 3200°C.

The chemical reaction involved in burning of acetylene is:

- Oxygen cylinder valves are made of Brass and Acetylene cylinder valves are made by Steel. Brass valve does not corrode so easily and that is why brass valves are used in oxygen cylinder.

- Acetylene is a very dangerous gas because it can explode under its own weight. So, calcium silicate is filled in the cylinder and then acetone is poured. Acetylene is absorbed in acetone.

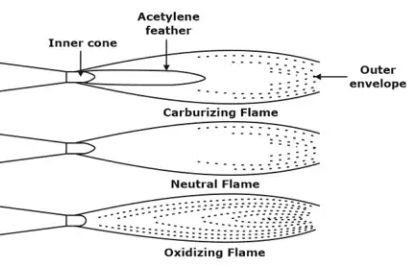

Flame Formation and its Types

Based on the proportion of acetylene and oxygen, flames are divided into three categories named neutral flame, carburizing flame and oxidizing flame. These are explained below:

- Neutral flame

- It consists of 1 : 1 ratio of acetylene and oxygen by volume. It has two parts namely the inner cone and the outer envelope.

- It produces hissing sound on burning and is used for welding low Carbon steels & Aluminum.

- The temperature of neutral flame is 3200°C.

- Carburizing flame

- In this flame, there is excess of volume of acetylene over oxygen and thus it is white in color due to excess acetylene.

- Its temperature generation range is 3100 °C to 3300 °C.

- It is used for the welding of metals where risk of oxidation at elevated temperature is more like aluminum, its alloys and lead and its alloys.

- Oxidizing Flame

- This flame has an excess volume of the oxygen over the acetylene. It is the hottest flames and produces roaring sound.

- It consists of a very short pointed white inner cone and a shorter outer envelope. The reduction of length of the inner cone is a measure of excess oxygen.

- These flames are used to weld alloys of Copper and Zinc. In welding these metals, the oxidizing flame produces a base metal oxide layer to protect the evaporation of low point alloying elements.

- The temperature of these flames is around 3480°C.

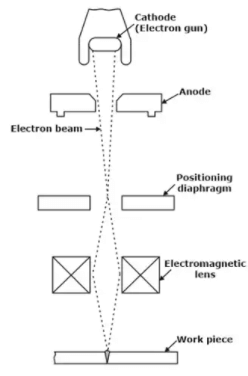

Electron Beam Welding

- Electron Beam Welding (EBW) is a fusion welding in which coalescence is produced by heating the work piece due to impingement of the concentrated electron beam of high kinetic energy on the work piece.

- Electron beam welding process is done under the vacuum condition.

- Molten metal fills into the gap between parts to be joined and subsequently it gets solidified and forms the weld joint.

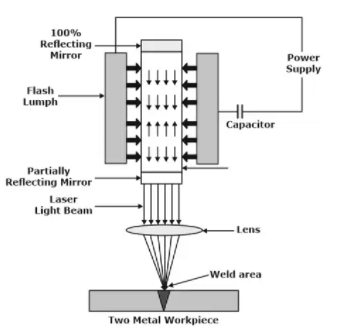

Laser Beam Welding

- In the LBM process, the laser beam is directed by flat optical elements, such as mirrors and then focused to a small spot (for high power density) at the workpiece using either reflective focusing elements or lenses.

- Inert gas shielding is generally employed to prevent oxidation of the molten puddle and filler metals may be occasionally used.

- The Lasers which are predominantly being used for industrial material processing and welding tasks are the Nd-YAG laser and 1.06 µm wavelength CO2 laser, with the active elements most commonly employed in these two varieties of lasers being the neodymium (Nd) ion and the CO2 molecules respectively.

Gas Cutting

For thicker plates and contour, oxy-fuel cutting is used. The difference in oxyacetylene gas cutting and acetylene welding is a torch tip which is used for preheating the plate as well as providing oxygen jet.

- The tip has a central hole for oxygen jet and surrounded holes for preheating flames.

- When high-pressure oxygen jet with a pressure of order 300 kPa is directed against a heated steel plate, the oxygen jet burn the metal and blows it away causing the kerf(cut).

- Larger the size of the orifice, wider is the kerf width and larger is the volume of the oxygen consumed.

|

Download the notes

Study Notes on Welding

|

Download as PDF |

Arc Cutting

- In arc cutting, the metal is melted with the application of heat of arc and then blown away using any gases such as air or shielding gases.

- The torch holds the electrode and supply high pressure gas where needed. There are different types of arc cutting based on heat source:

- Carbon arc cutting: The process carries a carbon electrode to obtain the required arc. The metal that is cut is blown away by arc force and gravity.

- Air carbon arc cutting: Here, Arc is generated between copper coated graphite or carbon electrode and the work piece with molten metal being forced out by means of a compressed air at pressure of 550 to 690kPa.

- Oxygen arc cutting: It carries a hollow tubular electrode to obtain the arc. Compressed oxygen is forced through a hollow portion so that metal is oxidized and blown in a similar manner as oxy fuel gas cutting (OFC).

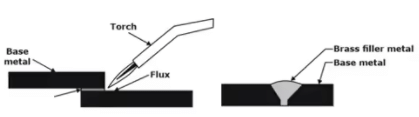

Brazing

- In this welding, the coalescence of a joint is obtained using the filler metal whose liquidus temperature is above 450°C and is below the solidus temperature of the base metal.

- In brazing, the base metal is not melted. Dissimilar metals can be joined by brazing. Except for aluminum and magnesium, brazing can join almost all metals.

- Here the filler metal in the joint, is filled by capillary action. Thus, it is necessary to control the clearance between two parts.

- Since too much clearance doesn’t allow the capillary force to draw the filler metal into the joint and also insufficient clearance may be too small to allow the filler metal to give rise to an effective strength.

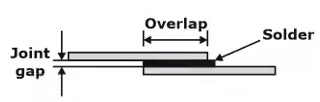

Soldering

- It is used tp join similar or dissimilar metals by means of a filler metal whose liquidus temperature is below 450°C.

- The joint design used for soldering is similar to that of brazing as in both cases filler metals enter the joint by capillary action.

- Like brazing, soldering also needs solvent cleaning, acid pickling and mechanical cleaning of the joint surface. In order to remove the oxides from the joint surface for avoiding filler metal from oxidizing, fluxes are generally used in soldering.

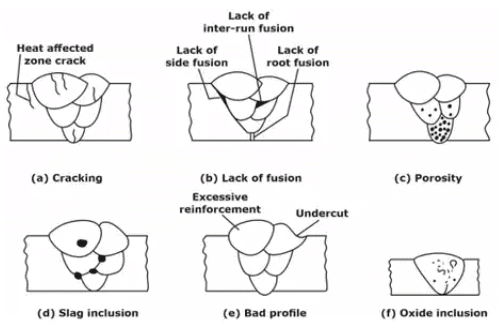

Weld Defects and Testing

The ideal weld should be such that adequate fusion exists between the filler metal and edge preparation together with good penetration. The major discontinuities are

- In welding, the defects often found infusing due to lack of fusion, lack of penetration, the inclusion of slag or oxide, presence of cracks, porosity and uncut and excessive penetration.

- These are the defects generally shown in butt welds.

- The defects like cracking, lack of fusion, porosity, slag inclusion, bad profile, and oxide inclusion alter the static strength of the welded joint under ductile conditions but have serious consequences if the joint is subjected to fatigue loading.

- The presence of crack enhances the probability of brittle fracture. Similarly, a lack of fusion causes a lack of discontinuity and hence diminishes the fatigue strength.

|

52 videos|54 docs|29 tests

|

FAQs on Study Notes on Welding - Manufacturing Engineering - Mechanical Engineering

| 1. What are the different types of welding techniques used in mechanical engineering? |  |

| 2. What are the advantages of welding in mechanical engineering? |  |

| 3. What are the potential challenges in welding mechanical engineering? |  |

| 4. What are the common applications of welding in mechanical engineering? |  |

| 5. What are the factors to consider for selecting the appropriate welding technique in mechanical engineering? |  |