Non-Conventional Machining Processes | Manufacturing Engineering - Mechanical Engineering PDF Download

What is Non-Traditional Machining?

The term nontraditional machining refers to the group of material removal techniques that removes excess material involving mechanical, thermal, electrical, or chemical energy (or combinations of these energies) and without the use of a sharp cutting tool in the conventional sense.

The nontraditional processes are mostly classified as per the form of energy used to cause material removal. They are:

- Mechanical: The work material is eroded by a high-velocity stream of abrasives or fluid (or both). It is a typical form of mechanical action in these processes which enables the removal of excess material.

- Electrical: The use of electrochemical energy is done in these non-traditional processes to remove material; the mechanism is the reverse of electroplating.

- Thermal: The use of thermal energy is done to cut or shape the workpiece. The thermal energy is usually applied to a tiny portion of the work surface, which causes that portion to be removed by fusion and/or vaporization. Conversion of electrical energy takes place for the generation of thermal energy.

- Chemical: Most materials (particularly metals) are prone to chemical attack by certain acids or other etchants. Chemicals selectively remove material from areas of the workpiece in chemical machining, while other portions of the surface stay protected by a mask.

Mechanical Energy Processes

1. Ultrasonic Machining

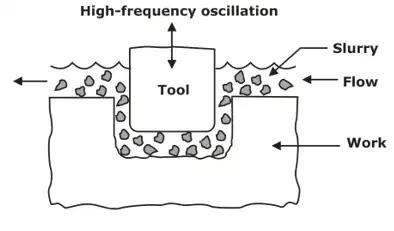

Ultrasonic machining (USM) is a nontraditional machining process where abrasives present in the slurry are driven at high velocity against the work by a tool vibrating at high frequency and low amplitude. The amplitudes are approximately around 0.075 mm, and the frequencies are approximately 20,000 Hz.

- The tool vibrates in the direction perpendicular to the work surface, and is fed slowly into the work, so that the tool's shape is formed in the part. The cutting is performed by the action of the abrasives, impacting against the work surface.

- Soft steel and stainless steel are the mostly used tool materials in USM. When the tool is made hollow, the internal contour should be parallel to the external one for ensuring uniform wear.

- Boron nitride, boron carbide, aluminum oxide, silicon carbide, and diamond are some of the abrasive materials used in USM. Grain size ranges between 100 and 2000.

- Abrasive concentration in water ranges from 20% to 60% in the mixture of abrasives and water, in the slurry used in USM.

- Material removal rate is an important performance variable in ultrasonic machining in addition to the surface finish.

2. Jet Machining

High-velocity stream of water (Water Jet Cutting) or water mixed with abrasive materials (Abrasive Water Jet Cutting) is directed to the workpiece to be cut in Jet Machining. When a mixture of gas and abrasive particles is used, process is known as Abrasive Jet Machining and it is used not for cutting the work but for finishing operations like deburring, cleaning, polishing.

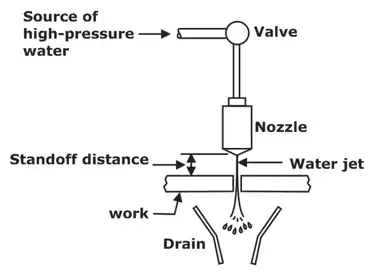

3. Water Jet Cutting (WJC) makes use of a fine, high-pressure, high velocity stream of water accelerated at the work surface for the purpose of cutting the work, as illustrated in the figure below.

- For the improvement of fluid characteristics additives such as alcohols, oil products and glycerol is added to water, which is the most common type of fluid.

- Pressurization of the fluid is done at 150-1000 MPa to generate jet velocities of 540-1400 m/s. The flow rate of fluid is usually from 0.5 to 2.5 l/min.

- Some of the work materials include soft metals, paper, cloth, wood, leather, rubber, plastics, and frozen food.

A narrow, focused, water jet mixed with abrasive particles is focused in Abrasive Water Jet Cutting (AWJC). This jet is sprayed with high pressures developing high velocities which cut through all materials.

- The abrasive particles which are present in the water jet induces cutting forces and enables cutting of thick and hard materials (steel plates over 80-mm thick can be cut).

- Velocity of the stream up to 90 m/s is attained, approximately 2.5 times the speed of sound.

- Abrasive Water Jet Cutting process was developed to cut materials that cannot bear high temperatures causing stress distortion or some other metallurgical reasons such as wood and composites, and other traditionally difficult-to-cut materials, e.g. ceramics, glass, stones, titanium alloys.

- Quartz sand, silicon carbide, and corundum (Al2O3) are some of the common type of abrasive materials. The grit size ranges from 60 and 120.

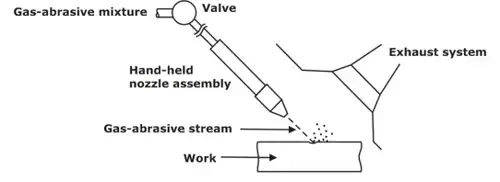

In Abrasive Jet Machining (AJM) tiny abrasive particles (typically ~0.025mm) are directed and accelerated in a gas stream (usually air) towards the surface that has to be machined.

- As the particles make an impact in the work surface, small fractures are generated, and the gas stream carries both the abrasive and the fractured (wear) particles away.

- The jet velocity ranges from 150-300 m/s and pressure is from 2-10 times of atmospheric pressure.

- Aluminum oxide (corundum) and silicon carbide of small grit sizes are the preferred abrasive materials. Sharp edges should be there in the grain and they should not be reused as the sharp edges could be worn down and smaller particles can clog the nozzle.

- Deburring, etching, and cleaning of hard and brittle metals, alloys, and nonmetallic materials (e.g., germanium, silicon, glass, ceramics, and mica) are some of the applications of Abrasive Jet Machining.

4. Electrochemical Machining

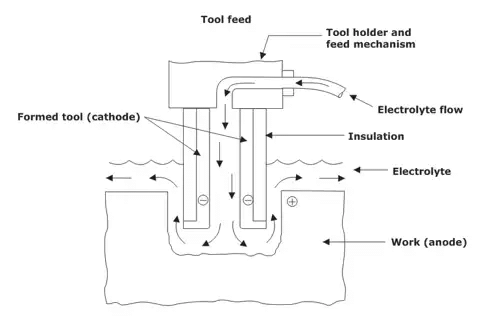

ECM uses principle of electrolysis to remove metal from the work piece. Electrolysis is based on faradays laws of electrolysis which is stated as "weight of substance produced during electrolysis is proportional to current passing, length of time the process used and the deposition of equivalent weight of material ".

- Reverse of electroplating (anode loses metal to cathode) is ECM. So, in ECM work is made anode and tool is made cathode. So, work loses metal, but before depositing it on to tool, it is carried away be electrolyte.

- In ECM constant feed motion is provided to the tool and pumping of electrolyte occurs at a high pressure through the tool and the small gap between tool and work piece.

- The current of the order of few thousand amperes is used and voltage of 8-20 volts and gap is of the order of 0.2mm. Practically no tool wears in ECM.

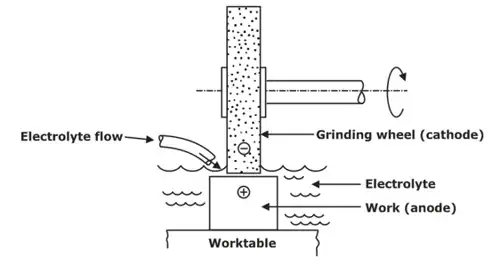

5. Electrochemical Grinding (ECG)

In this process, a rotating grinding wheel having a conductive bond material is used to cause the anodic dissolution of the metal work part surface, as illustrated in Figure. This process is called electrochemical grinding (ECG), which is a special form of ECM.

- Aluminum oxide and diamond are the abrasives used in ECG. For having an electrically conductive bond, the bond is usually metallic or resin bond impregnated by metal powders for the sake of making it conductive.

- Sharpening of cemented carbide tools and grinding of surgical needles, other thin wall tubes, and fragile parts are some of the applications of ECG.

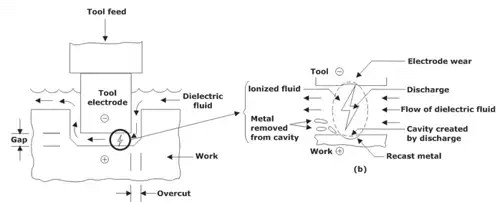

6. Electric Discharge Machining

In electric discharge processes, The work material is removal of work material by a series of sparks causing localized melting and evaporation of the material on the work surface takes place in electric discharge machining. Electrically conducting work materials are the only materials upon which these processes could be used.

- Final shape of the finished work is developed by a formed electrode tool. The sparks take place across a small gap between work surface and tool.

- Dielectric fluid must be present for EDM to take place as it creates a path for each discharge as the fluid becomes ionized in the gap. Eg a kerosene based oil.

- Typical electrode materials include Copper, tungsten, and graphite are some of the materials which are used as electrodes. Machining of these materials are relatively easy and therefore complex shapes can be given to them.

- Since the process is based on melting temperature, not hardness, therefore some extremely hard materials can be machined this way

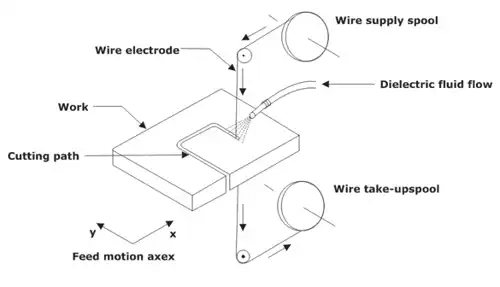

7. Electric Discharge Wire Machining

Wire Electric Discharge Machining (Wire EDM) is a special form of EDM process which makes use of a small diameter wire as the electrode to cut a narrow work. Wire EDM is illustrated in the figure.

- Continuous feeding of the work piece is done slowly past the wire for achieving the desired cutting path. For controlling the work-part motions during cutting, numerical control is used.

- The wire is continuously advanced between a supply spool and a take-up spool to present a fresh electrode of constant diameter to the work during the cutting duration.

- Presence of dielectric is must in wire EDM as well just like usual EDM.

- Materials used for the wire include brass, copper, tungsten, and molybdenum are the materials used for the wires and the diameter of wire ranges from 0.08 mm to 0.3 mm.

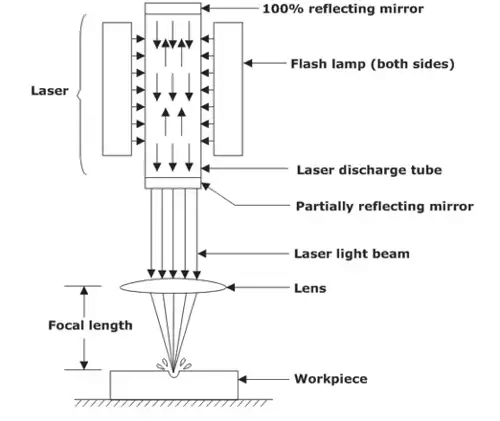

8. Laser Beam Machining (LBM)

Using of light energy from a laser to remove material by vaporization takes place in Laser Beam Machining (LBM). An illustration of LBM setup is shown below:

- Carbon dioxide (CO2) gas lasers are mostly used in LBM. Production of monochromatic light with constant wavelength occurs by LASER.

- The a normal white light has significantly more power than LASER, but LASER can be highly focused, thus delivering a significantly higher light intensity and temperature in a very localized area.

- Heat treatment, welding, and measurement, number of cutting operations such as drilling, slitting, slotting, and marking operations are few applications of LASER.

9. Electron Beam Machining (EBM)

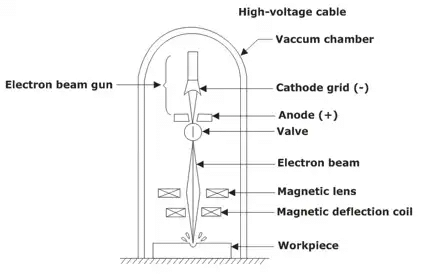

High-velocity stream of electrons focused on the workpiece surface to remove material by melting and vaporization takes place in EBM. A schematic of the setup of an EBM equipment is shown below:

- A continuous stream of electrons focused through an electromagnetic lens on the work surface is done by an electron beam gun. Acceleration voltages of of approximately 150,000 V are used to generate a velocity of over 200,000 km/s.

- A reduction of the area of the beam to a diameter as small as 0.025 mm is possible by the lens. Upon impingement to the surface, the kinetic energy of the electrons is converted into thermal energy of high density, which causes vaporization of the material in a very localized area.

- A vacuum chamber must be used to eliminate the collision of the electrons with gas molecules.

- Thin parts in the range of 0.2 to 6 mm thick are used in EBM.

- Extremely small diameter holes, down to 0.05 mm diameter can be drilled, holes with very high depth-to-diameter ratios can also be drilled, more than 100:1, and cutting of slots that are only about 0.025 mm are few of the applications of EBM.

|

52 videos|86 docs|29 tests

|

FAQs on Non-Conventional Machining Processes - Manufacturing Engineering - Mechanical Engineering

| 1. What are non-conventional machining processes in mechanical engineering? |  |

| 2. What are some examples of non-conventional machining processes? |  |

| 3. What are the advantages of non-conventional machining processes? |  |

| 4. Are non-conventional machining processes more expensive than conventional machining processes? |  |

| 5. What are the limitations of non-conventional machining processes? |  |