Laminar Flow Through Pipes, Darcy-Weisbach Equation, Moody’s Diagram | Fluid Mechanics for Civil Engineering - Civil Engineering (CE) PDF Download

| Table of contents |

|

| Dimensional Analysis |

|

| Pipe flow energy loses |

|

| Friction Losses of Head in Pipes |

|

| Darcy’s formula for friction loss of head |

|

Dimensional Analysis

Pipe flow energy loses

Friction Losses of Head in Pipes

Various types of head losses occur in flowing liquids, including friction, inlet/outlet losses. The primary loss arises from frictional resistance within pipes, influenced by their internal roughness. Darcy's formula is commonly used to compute head loss caused by friction.

Darcy’s formula for friction loss of head

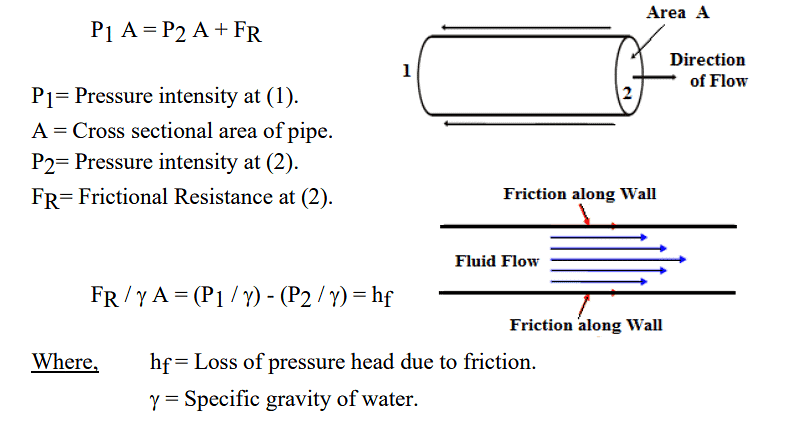

When water or any flowing liquid moves through a pipe, the horizontal forces acting on the water between two specific sections, denoted as (1) and (2), are as follows:

Through experimental observation, it has been determined that:

FR = Factor x Wetted Area x Velocity2

FR = (γ f / 2g) x (π d L) x v2

Where,

f = Friction coefficient

d = Diameter of pipe

L = Length of pipe.

It can be replaced with [v = Q / (π d2 /4)]. Substitute it into the final equation to determine the head loss given a known discharge.

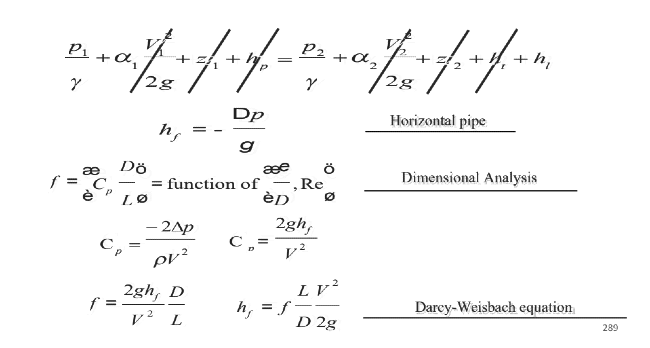

The Darcy-Weisbach equation establishes a connection between the loss of head or pressure caused by friction along a specific pipe length and the average velocity of fluid flow for an incompressible fluid.

The friction coefficient 'f' isn't constant; instead, it relies on pipe parameters and fluid velocity. However, it's reliably known with high accuracy within specific flow conditions.

For given conditions, it may be evaluated using various empirical or theoretical relations, or it may be obtained from published charts.

Re ( Reynold’s Number is a dimensionless number )

For pipes, Laminar Flow Re < 2000

Transitional Flow 2000<Re<4000

Turbulent Flow Re > 4000

For laminar flow, Poiseuille law, (f = 64/Re) where Re is the Reynolds number.

For turbulent flow

- Methods to determine the friction coefficient 'f' encompass using tools like the Moody chart or solving equations like the Colebrook-White equation.

- Additionally, there are empirical equations like the Hazen-Williams equation, applicable only to specific flow conditions, which are notably simpler for calculations.

- However, due to its versatility, the Darcy-Weisbach equation remains the favored choice despite its complexity.

The only difference of (hf ) between laminar and turbulent flows is the empirical value of (f).

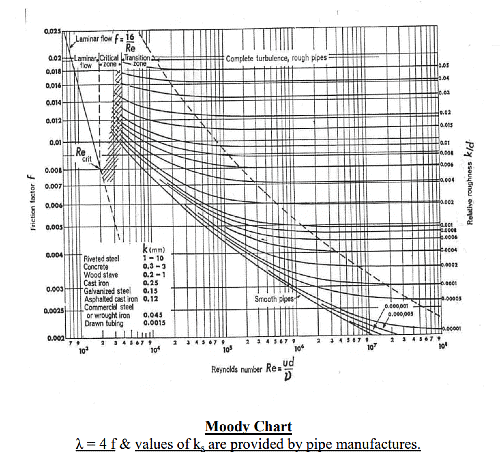

When we consider smooth and rough pipes, as illustrated in the Moody chart, we observe:

- For laminar flow, f = 64 / Re

- Transitional flow occurs when the flow within pipes doesn't fall within this specific area.

- As the Reynolds number decreases, in the case of smooth turbulent flow (which represents the boundary of turbulent flow), all relative roughness values (ks/d) gradually approach this line. Blasius equation: f = 0.079 / Re 0.25

- In the transitional turbulent phase, it's the area where the friction coefficient (f) changes based on both the relative roughness (ks/d) and the Reynolds number (Re). This region encompasses the majority of pipes in their operational conditions.

- In rough turbulent conditions, the friction coefficient (f) remains consistent for a specific relative roughness (ks/d) and doesn't rely on changes in the Reynolds number (Re).

|

54 videos|94 docs|110 tests

|

|

54 videos|94 docs|110 tests

|

|

Explore Courses for Civil Engineering (CE) exam

|

|