Water Bound Macadam | Civil Engineering Optional Notes for UPSC PDF Download

Water Bound Macadam (WBM)

Water Bound Macadam (WBM) is a type of road construction where the wearing course consists of clean, crushed aggregates that are mechanically interlocked through rolling and bound together with a filler material and water. This mixture is laid on a well-compacted base course. The strength of the WBM road comes from the mechanical interlocking of the aggregate particles and the cohesion between them, created by a cementitious film of soil moisture binder.Characteristics of Water Bound Macadam:

- Aggregate Interlocking: The primary strength of WBM roads is derived from the mechanical interlocking of crushed stone aggregates.

- Binder: The filler material, typically a mix of sand, clay, or other cementing materials, combined with water, binds the aggregates together.

- Compaction: Proper compaction of the base course and the aggregate layers is essential for the road's durability.

- Surface Treatment: Periodic application of water and sometimes road oil or calcium chloride helps to minimize dust and maintain the road's surface integrity.

Uses of Water Bound Macadam:

- Finished Pavement Surface: Suitable for minor roads with slower-moving traffic.

- Base Course: Provides a good base for more durable pavement surfaces that handle heavy traffic.

Limitations of Water Bound Macadam:

- Dust Production: WBM roads produce dust, requiring periodic water sprinkling or other treatments to settle the dust.

- Unsuitable for Fast Traffic: The binding effect of the sand and clay can be compromised by fast-moving vehicles, leading to the disintegration of the road surface. Thus, WBM roads are not ideal for areas with fast-moving pneumatic wheel vehicles but are more suited for slower-moving iron-wheeled vehicles like bullock carts.

Maintenance:

To ensure the longevity and serviceability of WBM roads, regular maintenance practices such as sprinkling water, applying road oil, and spreading calcium chloride are necessary to reduce dust and prevent surface deterioration.

Water Bound Macadam (WBM) Road

A Water Bound Macadam (WBM) road is constructed using multiple layers of crushed stone aggregates compacted and bound together with water. This method provides a cost-effective and durable solution for low-traffic roads, known for its good drainage and load-bearing capacity. The interlocking nature of the aggregates ensures stability and resistance against deformation.Key Features of WBM Roads:

- Cost-Effective: Suitable for rural and low-traffic areas due to its relatively low construction cost.

- Durability: Offers good durability when maintained properly, capable of handling moderate traffic loads.

- Drainage: The construction allows for effective drainage, reducing water logging issues.

- Load-Bearing Capacity: The interlocking aggregates provide a robust structure capable of bearing significant loads.

Materials Required for Water Bound Macadam Road Construction:

Coarse Aggregates:

- Crushed Stone: Typically, hard and durable crushed stones are used. The size and gradation of the stones are crucial for ensuring proper interlocking and stability.

- Gradation: Properly graded aggregates ensure a dense and stable layer, enhancing load distribution and road strength.

Filler Materials:

- Stone Dust: Used to fill the voids between the coarse aggregates.

- Sand and Clay: These materials help in binding the aggregates together when mixed with water.

Binder:

- Water: Essential for compacting the layers and binding the filler materials with the coarse aggregates. The water also helps in creating a cementitious film around the aggregates, providing additional cohesion.

Construction Process:

- Preparation of Subgrade: The base or subgrade is prepared and compacted to provide a stable foundation.

- Laying of Aggregates: Layers of crushed stone aggregates are spread and compacted. Typically, multiple layers are used, each with a specific thickness.

- Addition of Filler and Binder: Filler materials like stone dust, sand, or clay are added to fill the gaps between aggregates. Water is applied to assist in binding and compaction.

- Compaction: Rolling and compacting are done to achieve the desired density and stability. This step ensures the interlocking of aggregates and the cohesion of the filler materials.

- Surface Treatment: To minimize dust and enhance durability, treatments like sprinkling water, applying road oil, or spreading calcium chloride may be used.

Maintenance:

- Periodic Watering: To control dust and maintain the binding effect.

- Surface Treatments: Application of road oil or calcium chloride to reduce dust and improve surface integrity.

- Repairs: Regular inspections and repairs to address any surface disintegration or potholes.

In summary, a WBM road is a practical and efficient choice for low-traffic areas, offering a balance between cost and performance. Proper material selection, construction techniques, and maintenance practices are key to the longevity and effectiveness of WBM roads.

Construction Procedure of WBM Road

W.B.M Cross sectionPreparation of Foundation for WBM Road

W.B.M Cross sectionPreparation of Foundation for WBM Road

- The base, subbase, and wear course are supported by the subgrade layer, which acts as the road's foundation layer. To achieve the requisite R.L. of ground, the necessary filling and cutting are completed.

- Cleaning off the dust and other loose items before preparing this subgrade layer for the grade and camber.

- The holes, depressions, and uneven surfaces are filled with modified subgrade materials if necessary, and the materials are then rolled and compacted.

- The foundation's level must be extremely uniform, have the necessary cross-section and elevation, and be in a well-drained state.

Provision for Lateral Confinement

- Prior to placing the various layers of Water Bound Macadam materials, the lateral reinforcement or confinement is built.

- The shoulders have a thickness comparable to the WBM road's well compacted layers before the aggregates are laid. It should be built with high-quality soil or mortar.

- Nonetheless, the retaining wall can be built as lateral confinement if the soil is unstable and the road is at a higher elevation or needs to be filled.

- The major goal of lateral confinement is to retain the road surface that will be built between them and make it simpler to lay coarse materials.

Spreading of Coarse Aggregates

- To spread the coarse aggregates throughout the subgrade's surface, a lumped mass of coarse aggregates is stacked along the needed length of the road at predetermined intervals.

- The coarse aggregates are then uniformly distributed on a subgrade base with the use of various pieces of equipment, such as a backhoe or dozer.

- The specifics of the pavement design will determine the aggregate thickness and overall number of layers. Every layer should be thick enough to provide a 7.5 cm layer upon compaction.

- In general, a single compacted layer should be 75 mm thick and is adequate for minor or standard roads. Two layers of 150 mm each in compacted thickness may be given for large or special roads.

- After that, templates are positioned every 6 m along the route to inspect the road profile. The road's camber and gradient are periodically tested to make sure they are correct.

Rolling Operation

- For the straight stretch of the road, rolling is first done along the margins before moving to the middle. Rolling is completed for superelevated curves from the lower end, then moved to the high edge.

- The vibratory rollers or three-footed power rollers weighing 6 tonnes to 11 tonnes are used to roll Water Bound Macadam Roads.

- Driving the roller requires the use of skilled operators since poor rolling operations can result in the production of corrugations, an uneven finish on the road surface, or the wearing down of the road after only a few months of construction.

- The primary goal of this rolling is to thoroughly fix the coarse aggregate over one another.

Application of Screenings

- The distribution of the screening material comes next. Rolling is followed by the use of screening material to fill any gaps that were left between the aggregates following compaction.

- Around 50% of the total voids are typically filled with screening, while the remaining 50% are filled with filler materials.

- Spreading, booming, and rolling are done simultaneously for each layer up to the coarse aggregate surface that seems firm and thoroughly compacted with no voids.

- The screening is applied in three layers or perhaps more, depending on the specific circumstances.

- To get rid of the uncompacted screening material, each layer needs to be blasted after compaction.

Sprinkling of Water and Grouting

- After wet rolling with screening materials is complete, the layer is water sprinkled on and then rolled once more to allow the water to shred the surface even more finely and penetrate into the interior cavities.

- A wave of grout flushed ahead of the roller as the water spritzing and rolling procedure continued to fill in all the gaps.

- The size and kind of the aggregate, the desired surface type, and other considerations all influence how much water should be sprinkled.

- A second layer of screens can be put and properly compacted if the voids can still be seen.

Application of Binding Material

- The application of binding materials follows the same steps as the application of screens. After that, water is sprinkled on each layer and a rolling operation is performed.

- To remove binding material that adheres to the rollers' wheels during rolling operations, the roller's wheel should be continuously moistened.

- Depending on the suitability and requirements of the WBM road, the binding material is often applied in two or more successive thin layers and is either stone dust or lime dust.

Setting and Drying of Surface

- The WBM is given a day to cure after the last rolling operation, and if any depressions or undulations are still present the next day, then enough screens and binding materials can be spread and compacted.

- The WBM road can be altered by mixing bituminous material into the top courses as well, preventing the surface from easily decaying and disintegrating.

Preparation of Shoulders

As the road is being cured, shoulders are built adjacently while maintaining the proper slope with earth filling activity. They are adequately compressed.

Open for Traffic

The road is then prepared for traffic after adequate drying and without any depressions.

During a few days, the traffic should be severely disrupted along the entire width of the road by erecting barriers such as drums, barricades, etc. lengthwise.

Maintenance of WBM Roads

- If any type of potholes or rugs are found on the newly constructed Water Bound Macadam Road within a short period of time, the responsible authority should repair it by filling it with the required material and properly placing the material on potholes.

- To prevent aggregate from becoming loose from the road's surface course, a thin layer of moist soil should be spread over the surface on a regular basis, especially after the rainy season.

- Dragging is required to remove the unevenness that occurred on the constructed road. It may worsen the situation for the newly built roads.

- Any broken materials on the road should be replaced with new materials.

- The surface of the constructed road must be renewed every 2 to 5 years after construction, depending on traffic volume.

- After the road is open to traffic, the loose mixture on the road surface must be removed. The levelled road surface should be added along with the new binding material, and it should be properly compacted and watered.

- A surface dressing of bituminous materials can effectively eliminate the dust problem.

Advantages of WBM Roads

Some of its main advantages are:

- It is cost-effective because the cost of building a Water Bound Macadam road is relatively low.

- There is no need for skilled labourers in the construction of the WBM road.

- Water Bound Macadam roads are built with locally and easily accessible materials.

- If WBM roads are properly maintained on a regular basis, they can withstand heavy traffic and up to 900 tonnes per day.

Disadvantages of WBM Roads

The disadvantages are discussed below.

- The cost of maintaining a Water Bound Macadam road is higher than that of a bitumen base course.

- Water Bound Macadam road has a shorter overall lifespan than bitumen road.

- If these roads are not properly maintained on a regular basis, there is a high risk of traffic accidents and inconvenience.

- Because these roads absorb rainwater, they cause yielding and softening of the subsoil.

- When a fast-moving vehicle passes over a WBM road, the stone fragment is disturbed, and the road surface eventually disintegrates.

Other Road Construction Methods

Other construction methods include;

- Macadam Construction

- Tresaguet Construction

- Metcalf Construction

- Telford Construction

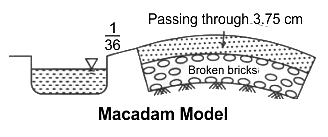

Macadam Construction

This was the first method of scientific construction where the top layer was provided with higher strength compared to the bottom. A curved surface for the pavement with a slope of 1 in 36, along with side drains, was recommended.

Tresaguet Construction

He has proposed a sloped shoulder with a linear slope followed by side chains. The maximum thickness of this road was limited to 30 cm. The surface of such a road was provided with very fine materials.

Telford Construction

Although he had not recommended any drains alongside the pavement, he was first to advise the provision of slope in the pavement surface. The thickness varies from 17 cm at the end to 22 cm at the centre for foundation stress. The wearing course in his design was provided with very fine material of about 4 cm thickness.

Metcalf Construction

John Metcalf (1717-1810 AD) was engaged in road construction in England when Tresaguet worked in France. Robert Phillips recommended the design. Metcalf constructed 290 km of road in northern England. This road was quite similar to Tresaguet Road.

|

350 videos|464 docs|2 tests

|

FAQs on Water Bound Macadam - Civil Engineering Optional Notes for UPSC

| 1. What is Water Bound Macadam (WBM) road construction? |  |

| 2. What is the procedure for constructing a Water Bound Macadam (WBM) road? |  |

| 3. What is the significance of Water Bound Macadam (WBM) roads? |  |

| 4. How is Water Bound Macadam (WBM) road construction different from other road construction methods? |  |

| 5. What are the common challenges faced during the construction of Water Bound Macadam (WBM) roads? |  |

|

350 videos|464 docs|2 tests

|

|

Explore Courses for UPSC exam

|

|