Design and Construction of Gravity Dams | Civil Engineering Optional Notes for UPSC PDF Download

| Table of contents |

|

| What is the Design and Construction of Gravity Dams? |

|

| Classification of Dams |

|

| Structure of a Gravity Dam |

|

| Key Terminology in Dam Construction |

|

| Causes of Failure of a Gravity Dam |

|

What is the Design and Construction of Gravity Dams?

- Gravity dams are constructed using earthen material to impound water. Initially, earth material is excavated from the riverbed, allowing water to flow into the trench before the dam's construction begins to retain water on the upstream side.

- The design and construction of gravity dams prioritize safety against overturning and stability. Compliance with standard parameters set by government authorities and adherence to the IS code 6512 are crucial in designing these dams.

Classification of Dams

- Storage dams: These dams are primarily built to store water, especially during high flow periods like the rainy season. They serve various purposes such as water supply, hydroelectric power generation, irrigation, and flood control.

- Diversion dams: Constructed to redirect river water into canals or conduits, providing the necessary pressure for irrigation and other conveyance systems. They are typically of lower height and may have a small upstream reservoir.

- Detention dams: Designed for flood control, these dams slow down river flow during floods by temporarily storing excess water. This helps in reducing the impact of sudden floods downstream.

- Debris dams: Intended to retain debris like sand, gravel, and driftwood carried by flowing water, allowing clearer water to pass through after the debris settles.

- Coffer dams: Temporary enclosures built around construction sites to keep the area dry for construction activities. They are often used upstream of main dams to divert water during construction and ensure a safe working environment.

Structure of a Gravity Dam

The structure of a gravity dam comprises various components on its downstream and upstream sides, as depicted in the accompanying diagram.

Downstream Side

The downstream side of a gravity dam typically includes the following elements:

- Toe: The base of the dam that interfaces with the riverbed, bearing the weight of the structure.

- Heel: The back of the dam opposite the toe, counterbalancing the gravitational forces acting on the structure.

- Apron: A protective layer at the base of the dam that dissipates the energy of water flowing downstream.

Upstream Side

The upstream side of a gravity dam is characterized by the following components:

- Crest: The top of the dam that defines the maximum water level the structure can retain.

- Spillway: A mechanism for safely discharging excess water to prevent overtopping of the dam.

- Reservoir: The body of water impounded by the dam, serving various purposes like irrigation, water supply, and flood control.

Key Terminology in Dam Construction

- Toe: The part of the dam structure in contact with the ground or riverbed downstream.

- Abutment: Refers to the sides of the valley on which the dam structure rests.

- Galleries: Small rooms within the dam used for operational checks and activities.

- Spillways: Structures near the top of the dam that release excess water from the reservoir downstream.

- Sluiceway: An opening near the ground level of the dam to clear silt accumulation on the reservoir side.

- Crest: The highest point of the dam structure, sometimes used for walkways or roads.

- Parapet Walls: Low protective walls on the crest sides for safety.

- Heel: The part of the dam structure in contact with the ground or riverbed upstream.

- Spillway (again): Passage near the top of the dam to release surplus water from the reservoir.

- Abutments (again): Valley slopes on either side of the dam wall where the dam ends are fixed.

- Gallery: Passage within the dam used for various purposes like drainage, instrumentation, and maintenance.

- Freeboard: Space between the highest water level in the reservoir and the dam's top.

- Dead Storage Level: Permanent storage level beneath which water is not withdrawn.

- Diversion Tunnel: Tunnel constructed to redirect water flow during dam construction.

Examples and Further Explanation

For instance, the toe of a dam is crucial as it disperses the weight of the structure and ensures stability by distributing forces evenly. Similarly, the diversion tunnel serves a vital role in managing water flow during construction, preventing disruptions to the construction site.

Force Acting on a Dam Structure

When designing a dam, the initial crucial step involves identifying and understanding the different forces that impact the structure. The dam is typically subjected to several forces, including:- Water pressure

- Earthquake forces

- Silt pressure

- Wave pressure

- Ice pressure

- Self-weight of the dam

These forces are considered to act per unit length of the dam. To achieve a precise and robust design, it is imperative to thoroughly investigate the effects of all these forces. Among these forces, water pressure and the self-weight of the dam are the most common and significant.

Water Pressure

Water pressure can be categorized into the following two groups:

- External Water Pressure

- Internal Water Pressure

External Water Pressure: This refers to the pressure of water on the upstream face of the dam. There are two scenarios to consider:

If the upstream face of the dam is vertical, and there is no water on the downstream side:

- The total pressure, acting on the upstream face at a height H/3 from the bottom, is in the horizontal direction. The pressure diagram is triangular, and the total pressure is calculated as P1 = wh^2 / 2, where w is the specific weight of water (usually taken as unity) and H is the height of water stored in meters.

- If the upstream face has a batter, and there is no water on the downstream side:

In addition to the horizontal water pressure (P1 as in the previous case), there is a vertical pressure due to the water column resting on the upstream sloping side. The vertical pressure P2 acts on a length portion of the base. This vertical pressure is determined by specific calculation

Water Pressure Below the Base of the Dam or Uplift Pressure

Definition

When water is stored upstream of a dam, it exerts pressure that can create uplift below the dam.

Mechanism

Water seeps into pores and fissures of the foundation and dam, causing an upward pressure known as uplift.

Consequences

Uplift reduces the effective weight of the structure, requiring methods to mitigate its impact.

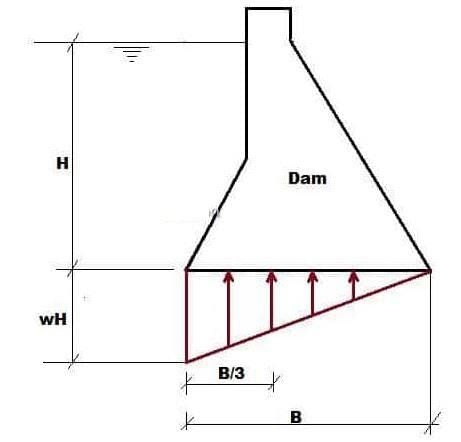

Illustration

Refer to the figure for a visual representation of uplift pressure.

1. Uplift Pressure in Dams

- Uplift Pressure (Pu): Calculated as (wH x B)/2, where B is the base width of the dam, and H is the height of water stored.

- Uplift Location: The total uplift force acts at B/3 from the heel or upstream end of the dam.

- Uplift Mitigation: Uplift is often reduced by incorporating drainage pipes or holes in the dam section.

- Stabilizing Force: The self-weight of the dam is the primary force stabilizing the structure.

- Material Density: Construction materials are selected with a density around 2.045 grams per cubic meter for optimal stability.

2. Earthquake Forces

- Earthquake Impact: Earthquake effects are akin to accelerating the dam's foundation in the wave's direction.

- Seismic Considerations: Earthquake waves are resolved into vertical and horizontal forces for design, with values typically ranging from 0.1g to 0.3g in seismic regions.

- Vertical Acceleration: Reduces the unit weight of dam material and water, factoring in earthquake forces.

- Horizontal Acceleration: Causes a momentary increase in water pressure and results in hydrodynamic pressure due to the reservoir's movement resistance.

Key Concepts

- When silt settles, it exerts pressure according to the Rankine formula, represented as Psilt = 0.5γsh2ka, acting at h/3 from the base.

- ka, the Coefficient of active earth pressure of silt, is calculated using the formula [1 - sinϕ] / [1 + sinϕ], where ϕ is the angle of internal friction of the soil with no cohesion, γs is the submerged unit weight of silt material, and h is the height of silt deposited.

Silt Pressure Example

If a reservoir has silt settling with a height of 6 meters, and the submerged unit weight of the silt material (γs) is 15 kN/m3, while the angle of internal friction (ϕ) is 30 degrees, calculate the active earth pressure coefficient (ka) and the total pressure exerted by the silt.

- ka = [1 - sin(30)] / [1 + sin(30)] = (1 - 0.5) / (1 + 0.5) = 0.5 / 1.5 = 0.33

- Psilt = 0.5 * 15 * 6^2 * 0.33 = 29.7 kN/m^2

Wave Pressure

Wave pressure is caused by wind-generated waves on a reservoir's surface, exerting pressure on the downstream side.

The maximum pressure intensity due to wave action is given by Pw = 2.4γwhw, acting at hw/2 meters above the still water surface.

The pressure distribution is assumed to be triangular with a height of 5hw/3.

Wave Pressure Example

Suppose a reservoir experiences waves with a wave height (hw) of 4 meters, and the submerged unit weight of water (γw) is 10 kN/m^3. Calculate the total force due to wave action at a certain point.

Ice Pressure

- The ice that forms on the surface of reservoirs in colder regions may undergo melting and expansion, exerting pressure on the dam face.

- This force acts uniformly along the dam's length at the reservoir level, ranging from 250 to 1500 kN/sq.m based on temperature fluctuations.

- Typically, a standard value of 500 kN/sq.m is assumed under normal conditions.

Weight of Dam

- The total weight of the dam and its foundation serves as a significant counterforce against external pressures.

- In a two-dimensional dam analysis, the weight is calculated per unit length.

Causes of Failure of a Gravity Dam

- Overturning of a dam about the toe

- Sliding-shear failure of gravity dam

- Compression - by crushing the gravity dam

- Tension - by the development of tensile forces, which results in the crack in the gravity dam

Overturning Failure of Gravity Dam

The overturning failure of a gravity dam happens when horizontal forces like water pressure, wave pressure, and silt pressure act against the dam, creating overturning moments. The self-weight of the dam generates resisting moments to counter this. If all forces acting on a dam section align to pass through the toe, the dam will rotate and overturn about the toe. This situation is known as overturning failure. However, in reality, dams often fail earlier due to compression rather than through this mechanism.

The safety factor against overturning is a crucial measure in structural engineering, defined as the ratio of resisting moments to overturning moments specifically around the toe of a structure. Typically falling between 2 and 3, this factor is calculated by dividing the sum of overturning moments by the sum of resisting moments. For instance:

- The factor of safety against overturning, denoted as FOS, is represented as:

- FOS = sum of overturning moments / sum of resisting moments

Sliding Failure of Gravity Dam

Gravity dams are susceptible to sliding failure when the net horizontal forces at the dam base surpass the frictional resistance between the dam body and its foundation. This issue is particularly critical in taller dams, where considerations of shear strength alongside friction are essential for a robust design. Factors influencing the safety against sliding include:

- Frictional resistance

- Frictional resistance and shear strength of the dam

Gravity Dam Failure due to Tension Cracks

Gravity dams constructed with materials like masonry and concrete are prone to tension-related issues due to their weakness in this regard. To prevent tension-induced failure, design strategies aim to eliminate tension development within the structure. Tension cracks, if developed, can compromise the integrity of the dam by reducing the effective base width, leading to increased pressure at the toe. It's important to note that while tension cracks themselves don't directly cause failure, they can initiate structural collapse by generating excessive compressive stresses.

Gravity Dam Failure Due to Compression

- High gravity dams allow for some tension under severe loading conditions to enhance design efficiency. This allowance is based on the understanding that extreme loading scenarios are typically short-lived rather than frequent.

Gravity Dam Failure Due to Compression

- The failure of a gravity dam can stem from the exceeding of permissible compressive stresses, resulting in the material of the dam being crushed.

|

350 videos|464 docs|2 tests

|

|

350 videos|464 docs|2 tests

|

|

Explore Courses for UPSC exam

|

|