Plant Layout | Industrial Engineering - Mechanical Engineering PDF Download

| Table of contents |

|

| What is Plant Layout? |

|

| Types of Plant Layout |

|

| Product or Line Layout |

|

| Process or Functional Layout |

|

| Fixed or Position Layout |

|

| Combination Layout |

|

What is Plant Layout?

Plant layout refers to the strategic arrangement of all components involved in the production process to optimize space efficiency, reduce manufacturing costs, and ensure a smooth and continuous production cycle. This arrangement encompasses space for material movement, storage, indirect labor, and supporting activities or services. A well-designed plant layout serves as a master blueprint, maximizing the effective use of machinery, manpower, and materials, thereby coordinating all factory operations to enhance overall productivity.

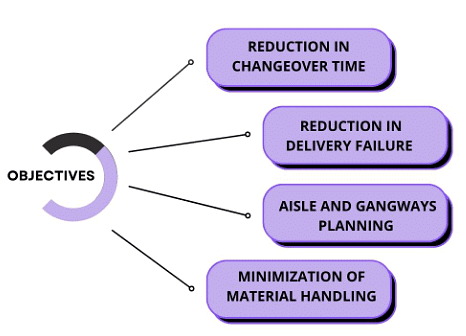

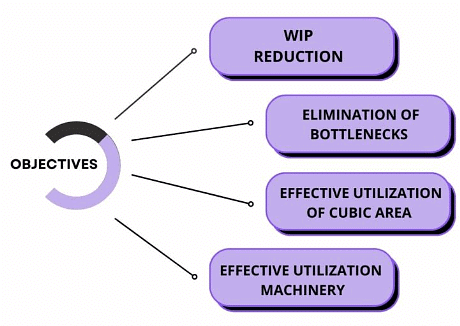

Objectives of Good Plant Layout:

- Effective utilization of installed machinery and manpower

- Minimization of material handling

- Elimination of bottlenecks through line balancing

- Reduction of physical efforts with low-cost automation

- High turnover with fewer delivery failures

- Reduction of work-in-progress (WIP) between processes

- Improved ergonomics and energy cost reduction through natural light, ventilation, and noise control

- Sufficient workspace for a better work environment

- Aisle and gangway planning for better accessibility and monitoring

- Stores designed for optimal flow, accessibility, storage capacity, and traceability of materials

- Reduction in changeover time through Single Minute Exchange of Die (SMED)

- Dust control based on clean room standards or ISO norms

- Reduced material and manpower travel distances

- Lower labor costs

- Shorter manufacturing times

- Increased flexibility

- Provision for future expansion

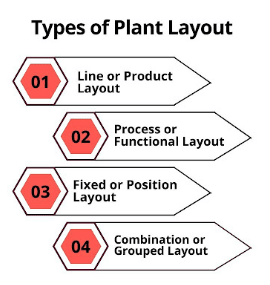

Types of Plant Layout

Plant layout involves the planned arrangement of machines, equipment, and other physical facilities. The layout design is influenced by various factors such as machinery, product, and materials. Based on these factors, there are four main types of plant layouts:

- Product or Line Layout

- Process or Functional Layout

- Fixed or Position Layout

- Combination Layout

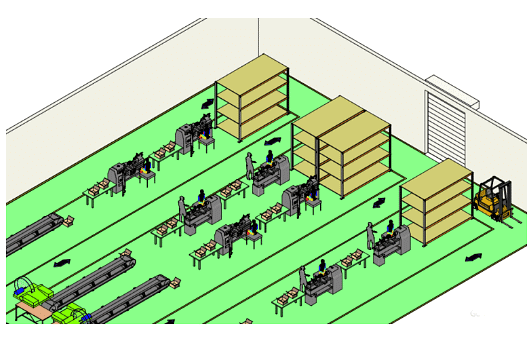

Product or Line Layout

In a product or line layout, machines are arranged in a sequential order according to the steps required to produce a product. Each machine in the sequence performs the next operation on the product, starting from raw material at one end and moving through various machines until completion. This setup is ideal for mass production and products with steady demand, as it ensures minimal work-in-process and efficient material handling.

Product or Line Layout

Product or Line Layout

Advantages:

- Low material handling costs

- Reduced work-in-process (WIP)

- Optimal utilization of machinery and manpower

- Shorter production times

- Reduced space requirements

- Lower manufacturing costs

Disadvantages:

- Lack of flexibility

- A breakdown in one machine can halt the entire production line

- Difficulty in scaling production beyond the current line capacity

- Overall production rate decreases if one machine is slower than others

Process or Functional Layout

In a process or functional layout, similar machines are grouped together based on the nature of their operations. This arrangement is useful for industries requiring low production volumes, batch production, and non-repetitive manufacturing and maintenance activities.

Process or Functional Layout

Process or Functional Layout

Advantages:

- No need for layout changes for different products

- Machine breakdowns can be managed by transferring work to another machine

- High flexibility in assigning work to workers and equipment

- Better machine utilization

- Improved product quality due to specialized supervision and workers

- Production is not affected by a single machine breakdown

- Easy load distribution control

Disadvantages:

- High material handling costs

- Large space requirements

- High inventory investment

- Expensive supervision

- Longer production times

- Bottlenecks due to queued work

- More floor space needed

- Complex scheduling as work does not follow a fixed path

Fixed or Position Layout

In a fixed or position layout, the main material stays in a fixed location, and all tools, machinery, and accessories are brought to this location. This layout is suitable for manufacturing large items in small quantities and when the cost of moving the main material is high, such as in the production of boilers and turbines.

Advantages:

- Reduced material and worker movement

- Lower capital investment

- High flexibility for various products

- Continuity in production

- Lower production costs

Disadvantages:

- Complicated fixtures required

- Highly skilled manpower needed

- Time-consuming machine movement

- Underutilization of machines

- Limited to large items only

Combination Layout

Combination or group layout integrates the benefits of the above layouts. This approach is common in modern manufacturing industries, providing a compromise that balances economy and flexibility.

Advantages:

- Reduced material handling and machine setup costs

- Elimination of excess work-in-process inventory

- Simplified production planning

- Smooth workflow

Disadvantages:

- Costly and time-consuming changes to existing layouts

- Thorough analysis required for incorporating new components

- Complexity in usage

Determining the Optimum Layout for Your Factory

Selecting an optimal plant layout is a critical investment, as changes post-construction are often costly. Factors to consider include:

- Factory Building Structure: The size and nature of the building determine available space, influencing layout decisions.

- Nature of Product: Light, small products may suit a process layout, while large products might require a fixed layout. Sequential production favors a line layout.

- Nature of Material: Material properties like durability and heat resistance affect layout choices due to potential processing challenges.

- Production Volume: Large-scale production may benefit from a line layout, while varied products might be better suited to a process layout.

- Machinery: Machine space, speed, maintenance, and material handling needs are critical considerations.

- Factory Location: Climate, sunlight, noise, and ventilation impact safety and layout efficiency.

Lean Layouting Case Study of a Leading Furniture Manufacturing Company

Layout issues are common across industries. Lean Layouting, which focuses on eliminating waste, has proven to deliver impressive results. In this case study, a leading furniture manufacturing company improved its layout through Lean Layouting by addressing the 8 types of waste, enhancing overall efficiency.

Pain Area of the Leading Furniture Manufacturing Company

The Leading Furniture Manufacturing Company wants Lean Layout for effective utilisation of resources and area for additional facilities in existing plant and wants to decrease distance travelled by material and manpower also wants better monitoring and supervision of the process.

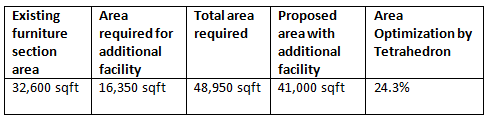

- Existing furniture section area of the company was 32,600 sqft.

- Area required for the additional facility(5-year projection) was 16,350 sqft.

- They required total area = Existing area + Area for new facilities

- Total area they required= 48,950 sqft

- The Proposed area by us with the new facility was 41,000 sqft.

- Total area saved = 7,950 sqft

- Area/Space Optimization by Tetrahedron was 24.3%

Area optimization by Lean Layouting

Area optimization by Lean Layouting

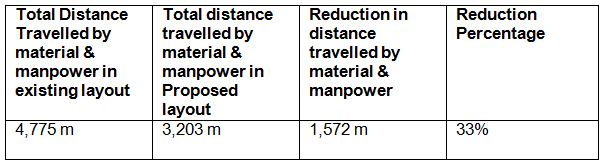

And the company also wants to reduce distance travelled by material and manpower.Total distance travelled by material and manpower of the company was 4,775 m. We proposed a layout with material and manpower distance travelled reduction of 1,572 m Reduction in distance travelled by material & manpower

Reduction in distance travelled by material & manpower

Step by Step Lean Plant Layout By Tetrahedron

Company is a furniture manufacturing company.They want to add some more facilities for which they supposed that they need 16,350 sq ft new area with existing area of 32,600 sqft. We helped them to optimise their area and proposed overall 41,000 sq ft area with new facilities and saved 7950 sqft area with 24.7% optimization of area.

Company also wants to reduce distance travelled by material & manpower. Total distance travelled by material & manpower in the existing layout was 4,775 m, Tetrahedron reduced distance travelled by 33%.

Following are the steps how Tetrahedron did this job:

Understanding clients’ needs:

- It all starts with understanding clients’ needs. First we understand the Pain area and Objective and growth of clients then we discuss with management and make specific strategies with 5-Year Business Growth Projection.

- In this case we received a clear request for area optimization and reduction in distance travelled by material & manpower.

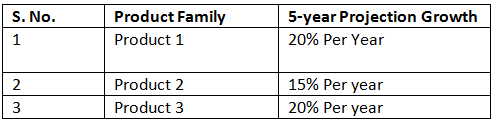

- We take 5-year projection growth data from client to understand their growth forecasting for making a lean layout which can be applicable for a minimum of 5 years. Data of 5-year projection growth of this company is given below.

5-Year Business Growth Projection

5-Year Business Growth Projection - The Objective and Scope of New layout was Designed and implementation of the flow focused and lean layout for Plant.

- We also focus on company products and demand calculation.For better understanding we provide some data of this company.

Data Collection Process:

- Before making any plan we need some data and information about the operation to be explored.

- We collect Data for Product analysis, Raw material analysis, Machine analysis, Process analysis to select the best strategy.

- Then we discuss it With management and share Best Practices of Other Industry and set Criteria for Effective Layout.

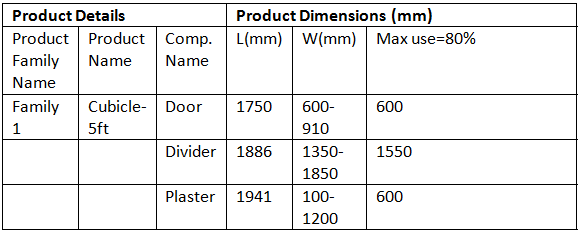

- In this case first we do Product analysis based on Quantity, Shape, Size and weight. For example-

- To begin, we gather details for all the products within the three families. We then conduct a raw material analysis considering factors such as quantity, shape, size, lead time, and a five-year projection.

- Following the raw material analysis, we perform a machine analysis focusing on dimensions, weight, tools, and CTM. Tetrahedron physically verifies all machine details and dimensions on-site for each process. Machines are arranged according to process requirements using lean-focused tools, with designated spaces for tools alongside the machines.

- Next, we undertake a process analysis based on flow, cycle time, manpower, and CTQ/CTB. This analysis covers both the current and proposed layouts. Value stream mapping is plotted for the products, and cycle time work balancing graphs are developed. Manpower requirements are assessed, aiming for manpower reduction across the plant. CTQ/CTB considerations are integrated into the proposed layout design.

Flow Design:

- We design the flow to ensure smooth operations, creating a layout in a static 3D model that can be adjusted as needed. This involves planning manual accessibility paths, aisles, gangways, safety equipment, and exits to minimize material travel distance. Tetrahedron designs the aisles and gangways for material and manpower movements, incorporates manual accessibility paths, and integrates safety equipment and exit locations based on process flow and material/product nature.

Stores Design:

- In store design, we allocate space for store and inventory to ensure zero delivery failure and zero line stop, while optimizing inventory to reduce material handling costs and travel distance. This includes designing finished goods storage, raw material storage, and WIP place/line side stores. Finished goods racks and storage are planned based on product quantity, size, and stacking needs. Raw material storage is calculated based on customer demand and lead time, with planned racks for the storage system. WIP space is planned according to product requirements and process flow, with a WIP calculation sheet provided.

Machine and Workstation Design:

- After store design, we focus on machine and workstation design to prevent machine stoppages due to material unavailability, reduce manual transfers, and ensure quick maintenance. This involves machine sequencing, tool and fixture space design, machine accessibility, and input/output space design. Machines are sequenced based on process requirements and company discussions. Tool and fixture space design, machine accessibility for maintenance, and machine input/output space design are tailored to the company's space needs.

Facility Support Design:

- Facility support design addresses safety, ergonomics, security, and other environmental factors. This includes industrial safety, fire protection, noise control, dust control (if applicable), ventilation, lighting (natural and artificial), industrial sanitation, plumbing, and security. The facility is designed for safety and performance, utilizing natural light for energy savings. Ergonomic and behavioral training may also be provided. Production support focuses on minimizing movement costs and ensuring efficient interdepartmental movements and material handling.

Validation, Iteration & Confirmation:

- In the final stage, we prepare to hand over the design, making adjustments as needed to ensure optimum layout efficiency. The draft layout is iterated for improvement, validated by management, and then confirmed. We hand over both 2D and 3D designs and are ready for 3D (live) simulation, providing a future state value stream map to the company.

|

30 videos|64 docs|30 tests

|

FAQs on Plant Layout - Industrial Engineering - Mechanical Engineering

| 1. What are the different types of factory layouts commonly used in manufacturing industries? |  |

| 2. How can a company determine the optimum layout for their factory? |  |

| 3. Can you provide an example of a Lean Layouting case study in the furniture manufacturing industry? |  |

| 4. What are some common pain areas faced by furniture manufacturing companies in terms of plant layout? |  |

| 5. What are the key steps involved in implementing a lean plant layout in a manufacturing facility? |  |