Difference between cylindrical Rotor and Salient pole type rotor | Electrical Machines - Electrical Engineering (EE) PDF Download

A synchronous generator, also called alternator, is a most widely used electric generator that produces alternating current supply. It is the main component of every power generating station.

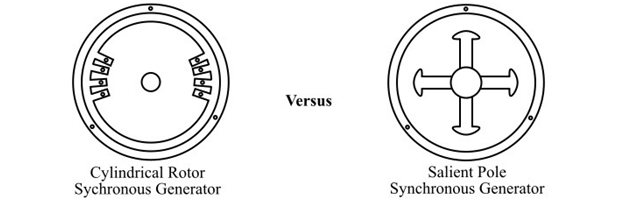

Based on the rotor construction, the synchronous generators are of two types namely −

- Cylindrical Rotor Synchronous Generator

- Salient Pole Rotor Synchronous Generator

However, both types of generators are similar in stator construction. The stator of both types of generators consist of a three-phase winding distributed over its inner periphery.

In this article, we will explain the key differences between cylindrical rotor and salient pole rotor synchronous generators along with their basic description.

What is a Cylindrical Rotor Synchronous Generator?

When the rotor of a synchronous generator has non-salient pole or smooth cylindrical construction, the generator is called cylindrical rotor synchronous generator or cylindrical rotor alternator.

In the cylindrical rotor alternator, the rotor has a smooth cylinder made of solid forged steel and has a number of slots on its outer periphery. The rotor winding is placed in these slots. The cylindrical rotor has smooth surface because there is no poles projected on it. Hence, it maintains a uniform air-gap between the stator and rotor in the alternator.

The cylindrical rotor synchronous generators are usually driven by steam turbines and mostly used in very high speed applications such as turbo alternators.

What is a Salient Pole Rotor Synchronous Generator?

When the synchronous generator uses a projected pole type rotor, it is known as salient pole rotor synchronous generator or salient pole alternator.

In a salient pole alternator, the rotor poles are made of steel laminations and are fixed to the rotor hub. This type of rotor has rotor poles that are physically separated. Each pole carries a concentrated excitation winding. The salient pole rotor is usually used in alternators having 4 poles or more.

The salient pole alternators are mainly used in the applications where the speed of the prime mover is less because at high speeds the centrifugal forces will be large and may damage the poles of the rotor.

Difference between Cylindrical Rotor and Salient-Pole Rotor Synchronous Generator

The following table highlights all the significant differences between a cylindrical rotor alternator and a salient-pole alternator −

Basis of Difference | Cylindrical Rotor Synchronous Generator | Salient-Pole Synchronous Generator |

Description | A synchronous generator that has its rotor which is cylindrical in shape is known as cylindrical rotor synchronous generator. | A synchronous generator whose rotor has poles projected on the rotor surface is called salient pole rotor synchronous generator. |

Pole | In a cylindrical rotor alternator, the portion without the slots of the cylindrical rotor acts as poles. Thus, the poles are non-projecting type. | In salient pole alternator, the rotor poles are projecting out from the surface of the rotor. |

Rotor diameter | The diameter of the cylindrical rotor alternator is relatively smaller. | The diameter of the salient-pole rotor alternator is larger than that of cylindrical rotor alternator. |

Axial length | Cylindrical rotor alternator has large axial length. | The axial length of the salient-pole rotor alternator is small. |

Air gap | In cylindrical rotor alternator, the air-gap between stator and rotor is uniform because it has smooth cylindrical periphery. | Salient pole rotor alternator has non-uniform air gap because the poles are projecting out from the surface. |

Also called | Cylindrical rotor alternator is also called “non-salient rotor alternator” or “non-projected pole type alternator”. | Salient pole alternator is also known as “projected pole type rotor alternator”. |

Rating (For the same size) | The rating of the cylindrical rotor alternator is higher than salient pole alternator. | Salient pole alternator has smaller rating than the cylindrical type alternator. |

Mechanical strength | The mechanical strength of the cylindrical rotor alternator is high. | Salient pole alternator has relatively less mechanical strength. |

Damper winding | Cylindrical rotor alternator does not have separate damper winding. | Salient pole alternator have separate damper winding. |

Suitability | Cylindrical rotor alternator is suitable for high speed applications. Where, the speed ranges from 1500 to 3000 RPM. | Salient pole rotor alternator is most suitable for low speed applications, where the rotor speed ranges from 125 to 500 RPM. |

Prime mover | The prime movers used for running the cylindrical rotor alternator are steam turbines used in thermal, gas and nuclear power plants. | The prime movers used for driving the salient pole alternators are hydro turbines and IC engines. |

Conclusion

We have highlighted all the major differences between salient pole rotors and cylindrical rotor synchronous generators in the above table. Depending on their suitability, both types of alternators are widely used in various types of power plants to produce electricity.

|

19 videos|90 docs|25 tests

|

|

Explore Courses for Electrical Engineering (EE) exam

|

|