Revision Notes: Manufacturing Industries in India-Agro Based | Geography Class 10 ICSE PDF Download

Industrialisation in India

India ranks among the top ten industrialised nations globally. With its vast natural resources and a large pool of manpower, the country is progressing rapidly.

Need for Rapid Industrialisation in India

- Rapid industrialisation is essential for making India self-sufficient and capable of meeting all its needs and requirements.

- Since India is mainly an agricultural country, with about two-thirds of the population dependent on agriculture, there is a need for industries to address unemployment, as agriculture alone cannot support the growing population.

- Industries also support agriculture by manufacturing essential tools and equipment, such as agricultural implements.

- Rapid industrialisation is necessary to keep up with global technological advancements.

- Industries are responsible for producing goods and equipment vital for the country's defence.

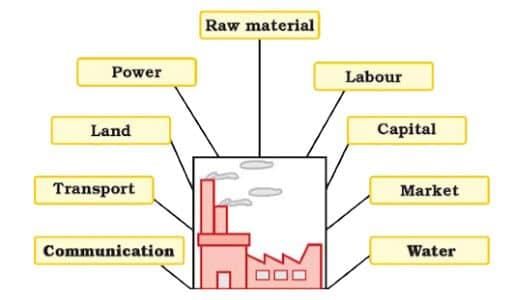

Factors Affecting the Location of Industries

Geographical Factors:

- Raw Materials: Industries are often set up close to sources of raw materials. For instance, iron and steel industries are typically located near iron and coal fields. Perishable goods industries, like sugar production, are situated near raw material sources because these materials have a short shelf life.

- Water Supply: Many industries, such as textiles, require substantial water for processes like bleaching and washing. As a result, these industries are located near water sources.

- Energy: Energy is crucial for processing raw materials. Industries are often found near coal fields or in areas with readily available and affordable energy resources.

- Transport: Efficient transport is necessary for moving raw materials to manufacturing units and finished products to markets. Industries are commonly located in port cities with good road and rail connectivity to major towns and markets.

- Labour: The availability of skilled and unskilled labour at a reasonable cost is a key factor in industrial location. Thus, industries often settle in areas where labour is readily available and affordable.

- Proximity to Markets: Industries need markets to sell their finished products. Heavy industries, for example, are located in industrial areas where their products are needed by smaller industries.

- Climate: Climate is particularly important for agro-based industries. For instance, cotton textile mills are found in Mumbai and Gujarat, where the climate is suitable for storing and manufacturing cotton yarn.

Commercial Factors:

- Government Policies: Government regulations regarding water and electricity supply, as well as policies supporting indigenous industries, significantly influence industrial location.

- Capital: Industries tend to cluster in big cities where financiers and investors are abundant, making these cities major industrial hubs.

Industries

Organisational Skills: Technical knowledge and organisational skills are essential for operating any industry. This is why many industries are situated close to educational and management institutes, allowing them to hire skilled personnel easily.

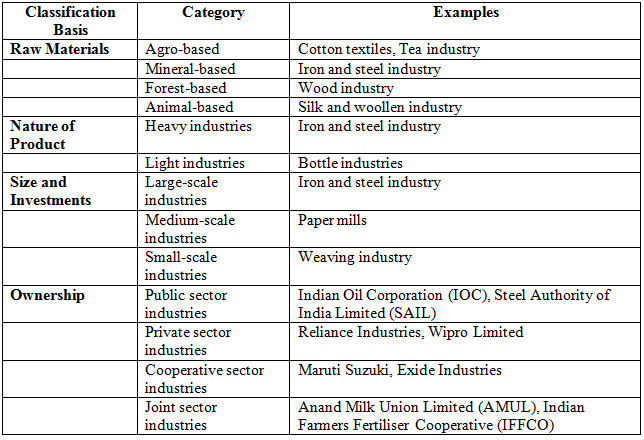

Classification of Industries

Distribution of Industrial Regions in India

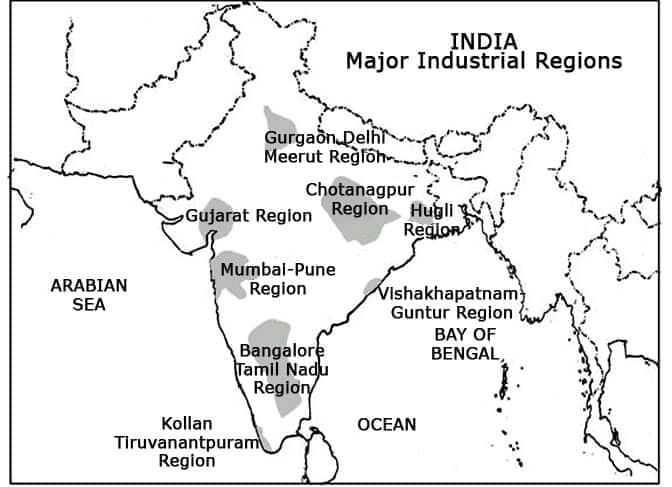

Major Industrial Belts

a. The Hooghly Belt

- Industries: Jute textiles, cotton textiles, chemicals, engineering, paper, leather, etc.

- Major City: Kolkata

- Advantages: Proximity to coal and iron ore mines in Jharkhand and Bihar, cheap labor, freshwater from the River Hooghly.

b. The Mumbai–Pune Belt

- Industries: Cotton textiles, oil refineries, chemicals, and fertilizers.

- Advantages: Development of hydroelectric power in the Sahyadris, cheap labor from Gujarat and Maharashtra, and the port of Mumbai facilitating transport.

c. The Ahmedabad–Vadodara Region

- Major City: Ahmedabad

- Industries: Cotton textiles, chemicals, fertilizers, plastics, and engineering.

- Advantages: Availability of skilled and unskilled labor.

d. The Chennai–Coimbatore–Bengaluru Region

- Industries: Various, supported by cheap and skilled labor, cotton, and large markets.

- Major Cities: Chennai, Coimbatore, and Madurai.

e. The Chotanagpur Plateau Region

- States: Parts of West Bengal and Jharkhand

- Resources: Rich in minerals such as iron ore, coal, manganese, bauxite, and mica.

- Major Cities: Jamshedpur (steel production), Bokaro (steel), Durgapur (steel), Asansol, Ranchi, and Dhanbad (metallurgy and heavy industries).

f. The Mathura–Delhi–Saharanpur–Ambala Region

- Description: Two separate belts merging around Delhi.

- Industries: Cotton textiles, glass, chemicals, fertilizers, sugar, and engineering.

- Advantages: Cheap raw materials, good transport system, and large markets.

Agro-Based Industries

Sugar Industry

- The sugar industry is the second largest organized industry in India, following cotton textile industries. Sugarcane, which is a cash crop, is the primary raw material for this industry.

- Products of the sugarcane industry include sugar, gur (jaggery), and khandsari (a type of unrefined sugar).

- By-products of the sugarcane industry include:

- Molasses: A thick syrup obtained during the sugar manufacturing process. It is used in the alcohol industry for distilling liquor and for producing certain chemicals and synthetic rubber.

- Bagasse: The leftover cane after juice extraction. Bagasse is used to produce steam, which generates power for the sugarcane industry. It is also used for making wax, carbon paper, and shoe polish.

- Press mud: The residual mud from the sugar extraction process, used for making wax, carbon paper, and shoe polish.

Distribution of Sugar Industries

Maharashtra: The leading producer of sugar in India, with 119 sugar mills, mostly large-scale operations.

Uttar Pradesh:The second-largest producer of sugarcane, with factories located in:

- Ganga-Yamuna Doab: Regions such as Saharanpur, Meerut, Bulandshahr, and Ghaziabad.

- Terai Belt: Areas like Basti, Gonda, and Gorakhpur.

Other Northern States: Sugar mills are also found in Punjab, Haryana, Madhya Pradesh, and Gujarat.

Peninsular India:

- Tamil Nadu: The leading producer in the region, due to higher per hectare yields, higher sucrose content, and a longer crushing season.

- Andhra Pradesh: Mills located in cities like Hyderabad, Vijayawada, and Chittoor.

- Karnataka: Factories in regions such as Belgaum, Bellary, and Bijapur.

Reasons for the Shift of Sugar Industries to South India

- Favorable Climate: South India has a climate that is free from the harsh summer loo and winter frost. This climate is ideal for growing superior varieties of sugarcane, and the production period is also longer.

- Soil Quality: The black soil in South India is more fertile than the alluvial soil found in North India. Sugarcane grown in this region is of superior quality and yields are higher.

- Transport Facilities: Maharashtra and Tamil Nadu offer excellent transport facilities, which have led to an increased number of sugarcane mills in these regions.

- Cooperative Farming: Sugarcane farmers in South India manage larger areas of land and are organized into cooperative societies, enhancing production efficiency.

Challenges Faced by Sugarcane Industries

- Poor Quality Sugarcane: There is a problem with the growth of low-quality sugarcane that has a low sucrose content.

- High Production Costs: The cost of production is high due to low yields and a short crushing season.

- Harvesting Pressure: Since most sugarcane is harvested at the same time, there is significant pressure on industries during the harvest period.

- Irregular Supply: The supply of raw materials to sugar industries is irregular because there are no plantation industries located around the factories.

- Outdated Machinery: Many sugar industries are still using old and obsolete machinery, which has not been replaced with new equipment and modern technology.

Cotton Textile Industries in India

India ranks as the third largest producer of cotton textiles globally, following the USA and the UK. It is also the third largest exporter of cotton textiles. This industry supports nearly 40% of the country’s labor force.

The majority of cotton textile industries are found in Maharashtra, Gujarat, and Tamil Nadu, which together produce three-fourths of the total yarn output. The remaining one-fourth is produced by states such as West Bengal, Uttar Pradesh, Madhya Pradesh, Rajasthan, Andhra Pradesh, and Karnataka.

Cotton textile industries are present in almost all Indian states. Mumbai and Ahmedabad account for about half of the total cotton mills. Mumbai is often called the ‘cottonpolis’ of India due to its significance in cotton production.

Reasons for the prominence of Mumbai and Ahmedabad :

- Both cities are situated near the cotton-growing areas of the Deccan Plateau.

- The humid coastal climate has been beneficial for industrial establishment in both cities.

- Connectivity by rail and road routes to cotton-growing regions and by sea routes to foreign markets has facilitated growth.

- Mumbai, being a major port city, and Ahmedabad, which utilizes port facilities from Kandla, have strong logistical advantages.

- Both cities host large financial centres, supporting industrial activities.

- Regular power supply is another advantage, with Mumbai receiving electricity from the Tata hydroelectric system and Gujarat relying on the Ukai and Kakrapara hydroelectric projects.

Problems Faced by Cotton Textile Industries

- Yarn Production and Fabric Supply: In India, yarn is produced by small industries and units that primarily serve local markets. This creates a mismatch where many spinners export cotton yarn, while garment manufacturers are forced to import fabric.

- Outdated Machinery: Most of the machinery in cotton mills is outdated and requires replacement, hindering production efficiency.

- Irregular Power Supply: Inconsistent power supply has negatively impacted production capabilities in the cotton textile industry.

- Raw Material Procurement and Labour Productivity: Issues such as uncertainty in procuring raw materials, low labour productivity, and lack of modernisation are causing losses for sugar industries.

- Competition from Fibre Industry: The cotton industry is facing intense competition from the fibre industry, which poses a significant challenge.

Handloom and Khadi Industries

Overview: The handloom and khadi industries are among the oldest in India, providing employment to approximately 10 million people and contributing over 23% to the total cloth production in the country. These industries are spread across various Indian states, including Tamil Nadu, Manipur, West Bengal, Nagaland, Kerala, Madhya Pradesh, Karnataka, and Rajasthan.

Problems Faced by Khadi and Handloom Industries

- Raw Material Quality: There is a shortage of sufficient and high-quality raw materials needed for production.

- Technical Skills: Many craftsmen lack the necessary technical skills, impacting the quality of workmanship.

- Technology: The industries are using old and obsolete technology, which affects productivity and efficiency.

- Fashion and Design Relevance: The products being produced are not keeping up with the rapidly changing fashion trends and design preferences.

- Competition: Handloom and khadi products face stiff competition from mill-made cloth, which is often produced at a lower cost and in larger quantities.

- Capital and Credit: There is a lack of capital and access to cheap credit facilities, hindering the growth and sustainability of these industries.

Silk Textile Industries

India is among the top producers of silk globally, producing four main types: mulberry, eri, tussar, and muga. The first modern silk industry in India was established in Howrah by the East India Company.

Mulberry Silk

- Mulberry silk makes up about 90% of the total natural silk produced in India.

- It is made from silkworms that are fed mulberry leaves. This process of rearing silkworms is called sericulture.

- Major producing states for mulberry silk include Karnataka, Andhra Pradesh, West Bengal, Tamil Nadu, and Jammu and Kashmir.

Distribution of Mulberry Silk

Karnataka:

- Major cities: Bengaluru, Mysore, Kolar, Mandya, Belgaum, and Coorg

Andhra Pradesh:

- Major regions: Chittoor, Warangal, Karimnagar, Vishakhapatnam, and Anantapur

West Bengal:

- Major regions: Malda, Murshidabad, Birbhum, and Bankura

Tamil Nadu:

- Major regions: Coimbatore, Dharmapuri, Nilgiris, Salem, and Tirunelveli

Bihar and Jharkhand (Tussar silk):

- Major regions: Bhagalpur, Palamau, Hazaribagh, and Ranchi

Assam (Tussar, Eri, and Muga silk):

- Major regions: Goalpara, Kamrup, and Nagaon

Challenges Faced by the Silk Industry

- Competition from artificial silk: The silk industry is under pressure from artificial silk, which is often cheaper and more widely available.

- Import of better quality and cheap raw silk from China: The influx of high-quality, low-cost raw silk from China poses a significant challenge to local producers.

- No systematic testing and grading of silk: The lack of a standardized system for testing and grading silk quality hampers the industry's ability to ensure high standards.

- Lack of modern power looms for increasing production: The industry suffers from outdated technology, with insufficient modern power looms to boost production capacity.

Woollen Industry

The woollen industry in India is primarily concentrated in northern regions, with over 80% of woollen mills located there. The main centres of woollen production include Delhi, Srinagar, Kanpur, Dhariwal, Mumbai, Ahmedabad, and Gwalior. However, the woollen industry is not as advanced as the cotton textile sector due to lower demand for woollen clothing. Woollen clothes are typically needed only for three to four months during winter, primarily in northern India, while peninsular India does not experience severe winters, resulting in reduced demand for woollen garments.

Challenges Faced by the Woollen Industry

- Seasonal Demand: India’s tropical climate means that woollen clothes are only needed during the winter months, and primarily in northern India.

- Affordability: A significant portion of the Indian population is not able to afford expensive woollen garments.

- Quality of Raw Materials: India relies on imported high-quality wool, as domestic supply is insufficient.

- Competition from Synthetic Fibres: Synthetic materials are increasingly replacing wool in the market, posing a threat to the woollen industry.

- Investment Preferences: Investors are more inclined to put their money into cotton industries due to higher demand for cotton and synthetic clothing.

To address these challenges, the Indian government is taking steps to enhance the woollen industry. This includes promoting the production of high-quality wool domestically and setting up sheep-breeding farms in northwest India. Additionally, breeds like Merino and Corriedale sheep are being imported and reared in India to improve wool quality.

Jute Industry

The jute industry is the second most important agro-based industry in India, following the cotton textiles industry. It plays a significant role in earning foreign exchange for the country.

This industry produces various items such as gunny bags, hessian cloth, coarse carpets, rugs, and cordage. Jute fibres are also used for packing goods.

The jute industry is primarily concentrated in the Hooghly region of West Bengal, where jute is extensively grown in the Ganga Delta and the Lower Ganga Valley. Other notable jute-growing areas in Bengal include Howrah, Titagarh, Jagatdal, Serampore, Bansberia, and Sibpur. Jute mills are also situated in states like Bihar, Uttar Pradesh, Andhra Pradesh, Odisha, and Madhya Pradesh.

Factors Promoting the Jute Industry around Kolkata

- Fertile Soil: The Ganga-Brahmaputra Delta has fertile soil that is replenished annually, contributing to increased jute production.

- Favorable Climate: The humid climate and adequate rainfall (ranging from 175 to 200 cm) are conducive to jute cultivation.

- Water Availability: The River Hooghly provides ample freshwater for retting and cleaning jute fibres.

- Labor Supply: There is a readily available labor force from nearby areas such as Odisha and Uttar Pradesh, supporting the growth of jute industries in the region.

- Infrastructure: Kolkata, being a port city, is well-connected to other parts of the country by rail and road, facilitating industry operations.

Challenges Encountered by the Jute Industry

- Post-Independence Setback: After India gained independence, around 70% of the jute-producing regions became part of Bangladesh. This led to a significant shortage of jute supply for the Indian industry.

- International Competition: The Indian jute industry faces stiff competition from other countries such as Bangladesh, Brazil, Egypt, and Thailand, which also produce jute products.

- Outdated Machinery: Many jute industries in India are equipped with old and obsolete machinery, which hampers productivity and efficiency. Additionally, the cost of production has increased over time.

- Substitute Products: There has been a rise in the use of substitute products made from paper, plastic, and hemp, which are now commonly used instead of jute products.

Government Initiatives to Support the Jute Industry

- Jute Consultative Council: The government has established a Jute Consultative Council to provide guidance and advice on matters related to the jute industry.

- Research and Development: Various research programs have been initiated to expand the range of jute products. New products being developed include tarpaulins and jute carpets, among others.

- Modernization of Machinery: Efforts are being made to install modern machinery in jute industries to improve production efficiency and reduce costs.

- Price Stabilization: The government is taking steps to stabilize jute prices to ensure fair returns for producers and maintain industry viability.

|

33 videos|86 docs|17 tests

|

FAQs on Revision Notes: Manufacturing Industries in India-Agro Based - Geography Class 10 ICSE

| 1. What are the key reasons for the need for rapid industrialisation in India? |  |

| 2. What factors affect the location of industries in India? |  |

| 3. How are industries classified in India? |  |

| 4. What are agro-based industries and their significance in India? |  |

| 5. What is the status of the cotton textile industry in India? |  |