Revision Notes: Manufacturing Industries in India-Mineral Based | Geography Class 10 ICSE PDF Download

| Table of contents |

|

| Mineral-Based Industries in India |

|

| Iron and Steel Industry |

|

| Heavy Engineering Industries |

|

| Electronics |

|

| Petrochemical Industry |

|

Mineral-Based Industries in India

Mineral-based industries are those that utilize minerals as their primary raw materials. One of the most significant sectors within this category is the iron and steel industry, which plays a crucial role in India's industrial landscape.

Iron and Steel Industry

The establishment of the Tata Iron and Steel Company in Jamshedpur in 1907 marked a pivotal moment in India's industrialization journey. Today, India stands as the fifth-largest producer of crude steel globally.

Raw Materials

The iron and steel industry relies on several key raw materials, including:

- Iron Ore: The primary source of iron, often found in regions rich in this mineral.

- Manganese: Used for hardening steel and removing impurities.

- Limestone: Acts as a flux in the steel-making process.

- Silica and Feldspar: Used in various stages of production.

- Scrap Iron: Recycled material used in steel production.

- Coking Coal: Essential for the production of coke, a crucial ingredient in steel making. This coal is primarily sourced from regions such as Jharia, Raniganj, Bokaro, Giridih, and Korba.

Steel Making

Iron ore contains impurities like sulphur, silica, and lime that need to be removed to obtain pure iron for making steel. The process of converting iron ore to steel involves several steps:

Ore Reduction

- Ore reduction takes place in a blast furnace where coke, limestone, and dolomite are added to help remove impurities from the ore.

- These impurities combine to form slag, which floats on top of the molten iron and can be easily separated.

- The molten iron is collected at the base of the furnace and removed at regular intervals.

- This product is called pig iron, which can later be transformed into wrought iron, steel, or cast iron.

Steel Melting Furnace

- To convert pig iron into steel, impurities are removed through a process called deoxidation.

- Carbon, a hardening material, is then added to the molten iron.

Rolling Mills

- The steel is cast into ingots and rolled into various sizes according to the desired specifications.

Tata Iron and Steel Plant at Jamshedpur

The Tata Iron and Steel Company (TISCO) is situated in Jamshedpur, approximately 240 km northwest of Kolkata.

Availability of Raw Materials

- Iron Ore: The plant sources iron ore from the Gurumahisani mines in the Mayurbhanj district of Odisha and the Noamundi mines in the Singbhum district of Jharkhand.

- Manganese: Manganese is obtained from Joda in the Keonjhar district of Odisha.

- Limestone, Dolomite, and Fire Clay: These materials are sourced from the Sundargarh district of Odisha.

- Coal: Coal is supplied from the Jharia and Bokaro coalfields, located about 177 km away.

- Power Supply: The main source of power is coal from the Jharia and Bokaro coalfields.

- Water Supply: Water is sourced from the Kharkai and Subarnarekha rivers.

- Labour Force: The labor force is primarily from the densely populated states of Bihar, West Bengal, Jharkhand, Chhattisgarh, and Uttar Pradesh.

- Markets: Kolkata serves as a significant market for finished steel products.

- Transport Facilities: Jamshedpur is well-connected by road and rail, facilitating transport to other parts of the country. It is linked to Eastern Railways and the Kolkata Port for steel exports.

- Products: The plant produces high-grade carbon steel and acid steel, used for manufacturing railway wheels, axles, bars, and rods. It also produces special alloy steel.

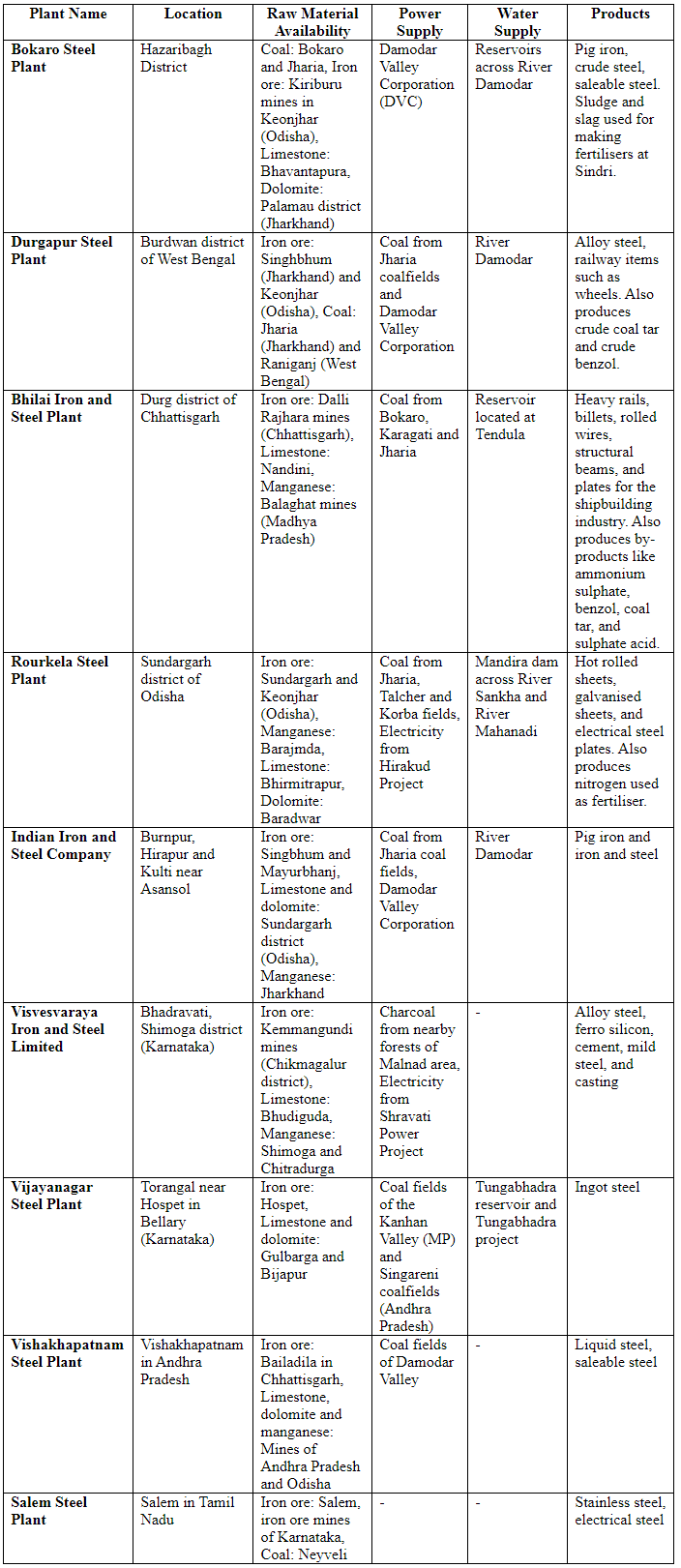

Other Large Iron and Steel Plants

Mini Steel Plants

Mini steel plants utilize ferrous scrap, pig iron, or sponge as their primary raw materials. The government is promoting the establishment of mini plants due to their various advantages:

- Cost-effective Raw Materials: Mini steel plants use scrap iron, which is inexpensive and readily available.

- Environmental Benefits: These plants rely on electric power, minimizing pollution.

- Lower Investment Requirements: Mini plants do not require heavy investments, making them more accessible.

- Local Market Demand: By meeting local market demands, these plants alleviate pressure on larger steel production facilities.

Heavy Engineering Industries

Heavy engineering industries play a crucial role as they provide machinery for various sectors, including agriculture, transport, mining, and construction. These industries have specific requirements such as:

- Bulky Raw Materials: The industries rely on large and heavy raw materials for production.

- Advanced Technology and Capital: Heavy engineering industries require advanced technology and substantial capital resources for their operations.

- Large Workforce: A significant workforce is necessary to manage and operate the machinery and equipment.

Examples of heavy industries include the iron and steel industry, shipbuilding industry, and automobile industry.

Shipbuilding Industry

Factors that support the growth of the shipbuilding industry in India include:

- Proximity to Raw Materials: The shipbuilding industry requires bulky raw materials, so it is located close to the source of these materials.

- Skilled Labour: The industry needs a skilled workforce, which is another reason for its specific location.

- Access to Deep Waters: Shipbuilding sites are also situated near deep waters that are suitable for navigation.

- Land Requirements: The industry requires large tracts of level land for construction and assembly.

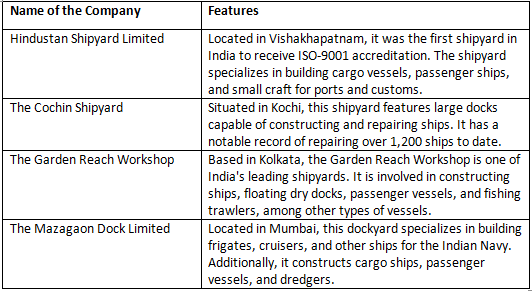

Major Shipyards in India

Automobile Industry

The automobile industry in India requires the following:

- Raw materials such as iron, steel, and paint

- Tools and machinery for running and maintaining factories

- Finished goods such as tyres, tubes, and batteries

- Energy sources like coal and hydropower

India is home to several automobile manufacturing units and is the sixth largest producer of passenger cars and commercial vehicles in the world.

Railway Locomotives

Railways play a crucial role in transportation across India. The production of locomotives and coaches for the railways falls under the Ministry of Railways. The major units involved in this production include:

- The Chittaranjan Locomotive Works, located in Chittaranjan, West Bengal, manufactures electric railway engines, broad gauge and metre gauge diesel locomotives.

- The Diesel Locomotive Works (DLW) in Varanasi produces broad gauge and metre gauge diesel engines.

- The Integral Coach Factory in Perambur, near Chennai, manufactures fully furnished passenger coaches.

- The Rail Coach Factory in Kapurthala, Punjab, produces high-speed lightweight railway coaches.

Additionally, plants producing diesel electrical engines are also located in Jamshedpur and Patiala.

Aircraft Industry

Hindustan Aeronautics Limited (HAL) was established in 1964 with its headquarters in Bengaluru, making it the first aircraft industry in India. Its primary functions include:

- Designing, manufacturing, repairing, and overhauling various types of aircraft, aero engines, avionics, instruments, and accessories.

- Developing advanced light helicopters and light combat aircraft.

Heavy Electrical Industry

This industry encompasses equipment used for the generation, transmission, distribution, and utilization of power. It includes items such as generators, boilers, turbines, and cables. Three major heavy electrical industries in India are:

- Heavy Electricals Limited in Bhopal, Madhya Pradesh.

- Bharat Heavy Electricals Limited in New Delhi.

- Hindustan Cables Factory in Rupnarainpur, West Bengal.

Heavy Machinery and Tools

Heavy Machinery and Tools play a crucial role in providing machines to various sectors of the economy.

Electronics

The electronics industry in India began its development around 1950 and has since become the fastest-growing sector. Established in Bengaluru in 1950, the Indian Telephone Industry produces equipment tailored for the needs of the post and telegraph departments, railways, defense, and electricity boards. It also creates automatic telephone switching systems and teleprinter exchanges.

Located in Hyderabad, the Electronics Corporation of India focuses on producing modular systems for nuclear uses and applications in the medical, agricultural, and industrial sectors.

Bharat Electronics Limited (BEL), based in Bengaluru, serves the defense sector, All India Radio, and the Meteorological Department, meeting their specific electronic requirements.

Space Technology

Space Technology in India

- Overview: Space technology in India is supported by a robust electronic industry. Key institutions involved in space research and satellite launching include:

(a) Indian Space Research Organisation (ISRO): Located in Bengaluru, ISRO is the primary agency for space research and exploration in India.

(b) Satellite Launching Station: Situated at Sriharikota, this facility is responsible for launching satellites into space.

(c) National Remote Sensing Agency: Based in Hyderabad, this agency focuses on remote sensing and satellite data analysis. - Indigenous Satellites: India has successfully launched various indigenous satellites, including the Apple series and the Indian National Satellite (INSAT) series. These satellites play a crucial role in communication, weather forecasting, and other essential services.

- Rocket Development: ISRO has developed rockets capable of placing satellites into polar orbits. This capability is essential for various applications, including Earth observation and climate monitoring.

- Mars Orbital Mission: Recently, India undertook a significant achievement by launching a Mars orbital mission, showcasing its growing prowess in space exploration.

Software Industry

- Rapid Growth: The software industry in India has become one of the fastest-growing sectors. The country has developed the capability to design supercomputers and provides expert IT services to global markets.

- Leading Centers: Bengaluru and Hyderabad have emerged as the leading centers for software industries in India, contributing significantly to the sector's growth.

Entertainment Products Industry

The entertainment products industry encompasses the manufacturing and sales of televisions and audio systems, which saw significant growth in the 1990s due to advancements in the electronic industry. Major companies in this sector include BPL, Videocon, Onida, and Philips, with production centers mainly located in Mumbai, Pune, Kolkata, and Chennai.

Petrochemical Industry

The petrochemical industry relies on raw materials derived from petroleum, LPG, and coal. These industries are typically situated near oil refineries that provide essential inputs like naphtha and benzene.

Petrochemical industries produce a wide range of products, including synthetic fibres, dyestuffs, synthetic rubber, plastics, drugs and pharmaceuticals, fertilisers, insecticides, adhesives, and resins.

The advantages of petrochemical products include their lower cost, large-scale production capabilities, and the easy availability of raw materials. Many traditional materials have been replaced by petrochemical products, such as synthetic fibres replacing jute fibres, PVC pipes replacing steel pipes, and polythene bags replacing jute bags.

Main Petrochemical Plants in India

- Herdillia Chemicals Limited, situated in Chennai, produces acetone, phenol, and diacetone alcohol. National Organic Chemicals Industries Limited, located near Mumbai in Thane, is recognized as the first facility to employ advanced technology, manufacturing ethylene, benzene, and PVC.

- Petrofils Cooperative Limited (PCL), a collaborative effort between Weavers’ Cooperative Societies and the Government of India, operates facilities in Vadodara and Naldhari, producing polyester filament, swim suits, and yarn.

- Near Vadodara, India Petrochemical Cooperation specializes in producing organic chemicals and fibers. Reliance Industries operates out of Hazira in Gujarat. Additionally, Indian Oil Corporation has established one petrochemical plant in Gujarat and two in Panipat, Haryana.

|

33 videos|148 docs|19 tests

|

FAQs on Revision Notes: Manufacturing Industries in India-Mineral Based - Geography Class 10 ICSE

| 1. What are the key characteristics of the Iron and Steel Industry in India? |  |

| 2. How do Heavy Engineering Industries contribute to India's manufacturing sector? |  |

| 3. What role does the Electronics industry play in India's economy? |  |

| 4. What is the significance of the Petrochemical Industry in India? |  |

| 5. How do mineral-based industries impact the environment in India? |  |