Revision Notes: Metallurgy | Chemistry Class 10 ICSE PDF Download

Metallurgy

Metals and Non-metals

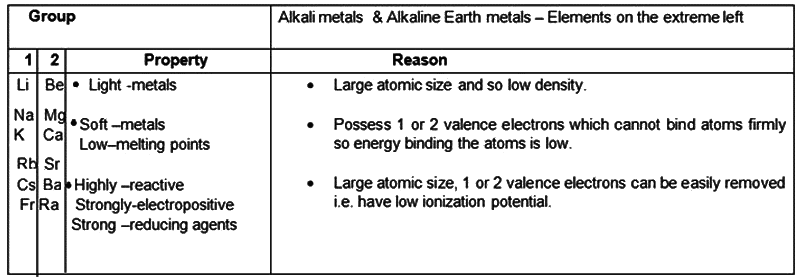

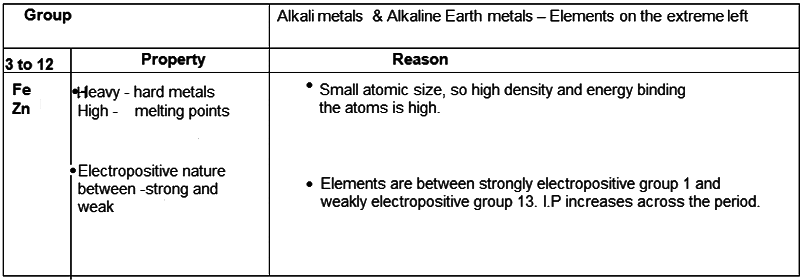

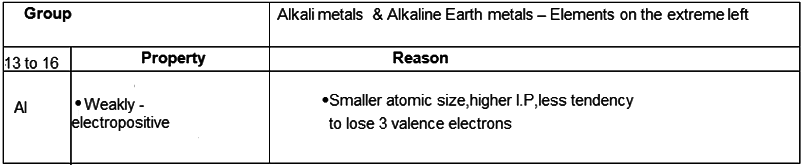

Position and characteristics of metals in the periodic table

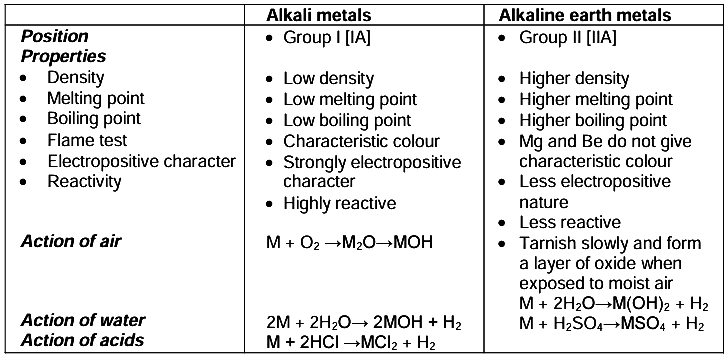

Characteristics of Alkali Metals and Alkaline Earth Metals

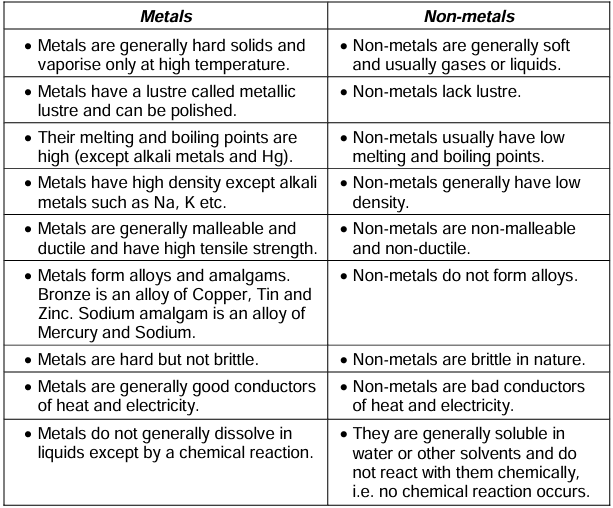

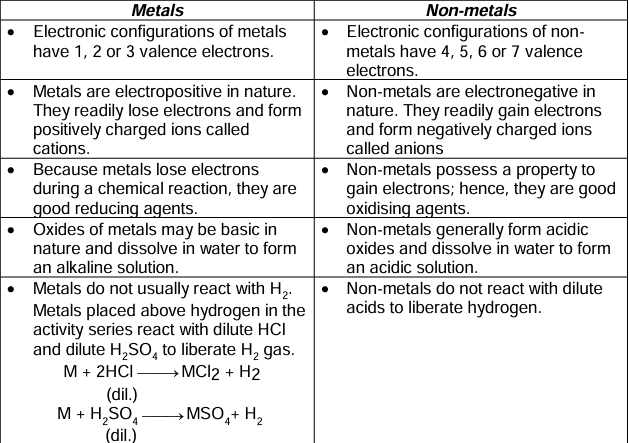

Comparison of Metals and Non-metals

- Physical Properties of Metals and Non-metals

- Chemical properties of metals and non-metals

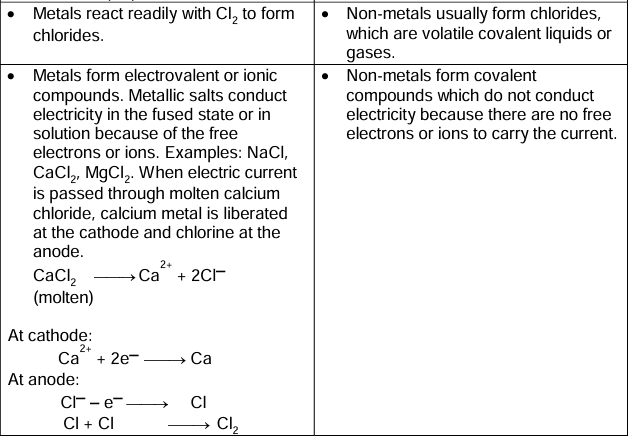

Study of Activity Series of Metals

Activity Series of Metals

Metals differ in tendency to lose electrons and hence can be arranged in a series according to their tendency to give up valence electrons.

Activity Series

It is a series of metals arranged according to their decreasing reactivity.

The metals at the top of the series are:

- Most easily oxidised

- Most electropositive

- Capable of displacing the metal below from its salt solution

Reactions of Metals

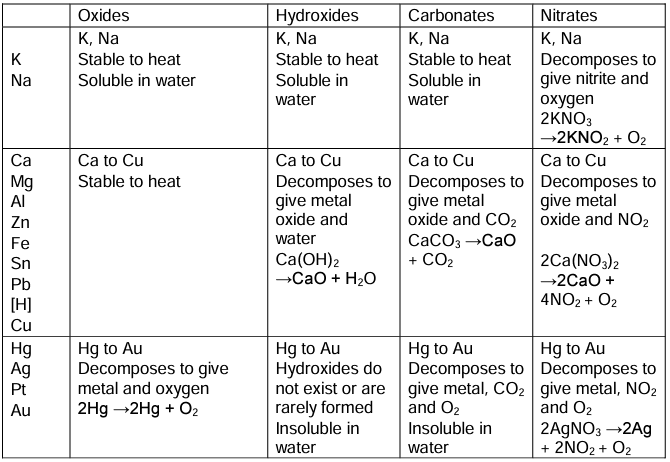

Characteristics of Metallic Compounds

Corrosion

When the surface of a metal is exposed to air, moisture or any other substance around it, the metal is said to corrode, and the phenomenon is known as corrosion.

- Corrosion of Iron

Corrosion of iron is known as rusting.

Rusting is the slow oxidation of iron by atmospheric oxygen in the presence of water.

4Fe + 3O2 + 2xH2O → 2Fe2O3.xH2O - Conditions Necessary for Rusting

Presence of water (or moisture)

Presence of air (or oxygen) - Prevention of Corrosion

Barrier protection: The process in which the metal surface is not allowed to come in contact with atmospheric agents such as air or water is known as barrier protection.

For example, the metal (iron) is coated with another metal by using electricity in the process called electroplating.

Sacrificial protection: The metal to be protected is covered with a more electropositive metal such as zinc or magnesium. For example, iron is coated with zinc in the process called galvanisation.

Extraction of Metals Based on the Activity Series

Common terms used in extraction

- Metallurgy: The process used for the extraction of metals in their pure form from their ores is called metallurgy.

- Minerals: The naturally occurring compounds of metals which are generally mixed with other matter such as soil, sand, limestone and rocks are known as minerals.

- Gangue: Earthy impurities, including silica and mud, associated with the ore is called gangue.

- Ores: Those minerals from which metals are extracted commercially at a comparatively low cost and with minimum effort are called ores.

- Flux: A flux is a substance which is added to the charge in a furnace to remove the gangue.

- Slag: It is the fusible product formed when flux reacts with impurities during the extraction of metals.

- Smelting: It is the process of reducing the roasted oxide ore and removing the gangue with the help of an appropriate flux added with the ore.

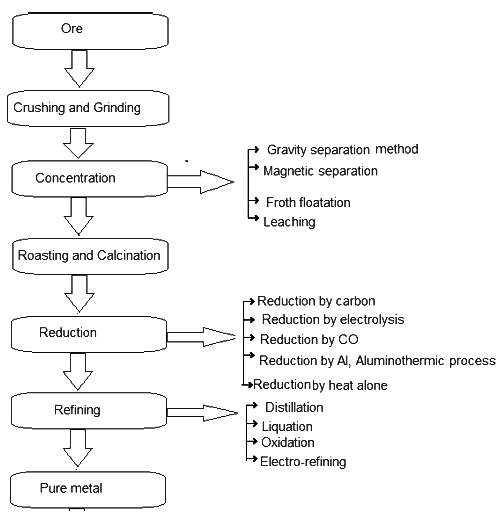

Steps Involved in Extraction

Crushing and Grinding

Ores are crushed into a fine powder in big jaw crushers and ball mills. This process is called pulverisation.

Concentration of Ores

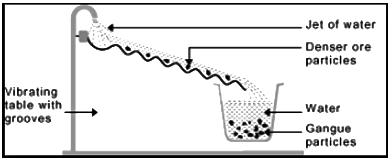

Gravity separation

Principle: Separation of

Process: The ore is poured over a vibrating sloped table with grooves, and a jet of water is allowed to flow over it. The dense ore particles settle down in the grooves.

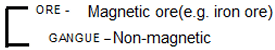

Magnetic separation

Principle: Separation of

Process: The pulverised ore is placed on a conveyor belt. The magnetic particles are attracted to the magnetic wheel and fall away separately from the non-magnetic particles.

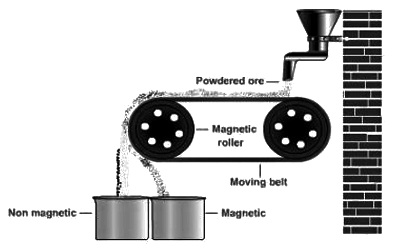

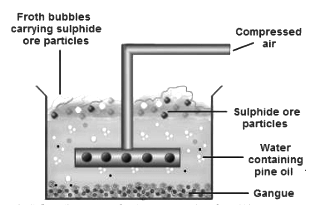

Froth flotation

Principle: Separation of

Process: This method is generally applied for sulphide ores. The ore is taken in a large tank containing oil and water and is agitated with a current of compressed air. The ore is wetted by the oil and separates from the gangue in the form of froth.

Roasting and Calcination (If the ore is not an oxide)

A. Roasting

The process of heating the concentrated ore to a high temperature in the presence of excess air.

2ZnS + 3O2 → 2ZnO + 2SO2

B. Calcination

The process of heating the concentrated ore in the absence of air at a temperature not sufficient to melt the ore.

ZnCO3 → ZnO + CO2

Reduction in Metallic Oxides

Reduction by electrolysis

Reduction in highly electropositive metals such as K, Na, Ca, Mg and Al oxides/halides.

Electrolysis of fused metallic salts

Al2O3 ⇌ 2Al+3 + 3O2−

Cathode: 2Al +3 + 6e− → 2Al

Anode: 3O2− - 6e- → 3[O] → 3O2

Product at cathode: Pure aluminium metal

Product at anode: Oxygen gas

Reduction by reducing agents

ZnO + C → Zn + CO

2PbO + C → 2Pb + CO2

Refining of Impure Metal

- Distillation: For refining volatile metals. Examples: Zinc, mercury

- Liquation: For refining low-melting-point metals. Examples: Lead, tin

- Oxidation: For refining metals by oxidation of their impurities. Example: Iron

- Electrolytic refining: For refining impure metals by electrolysis. Examples: Cu, Al, Pb

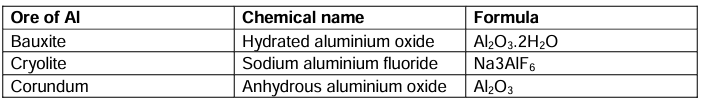

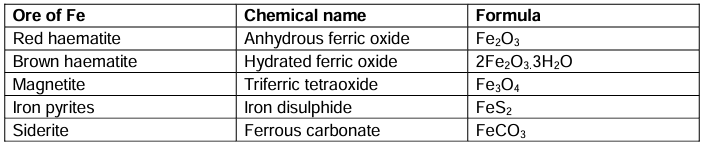

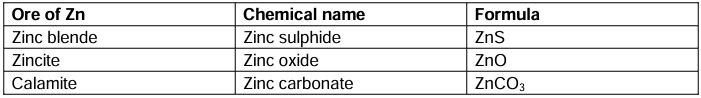

Common Ores of Aluminium, Iron and Zinc

Extraction of Aluminium

Process for Extraction of Aluminium from Bauxite

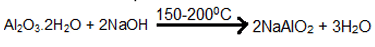

- Concentration of Ore - Bayer process

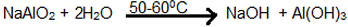

i. Conversion of impure bauxite to sodium aluminate ii. Conversion of sodium aluminate to aluminium hydroxide

ii. Conversion of sodium aluminate to aluminium hydroxide iii. Conversion of Al(OH)3 to pure alumina

iii. Conversion of Al(OH)3 to pure alumina

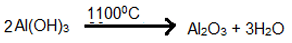

- Electrolytic Reduction in Metallic oxide – Hall Heroult process

Electrolyte: Mixture of molten alumina 20%, cryolite 60% and fluorspar 20%.

Electrolytic cell: Rectangular steel tank with carbon lining.

Electrodes:

Cathode: Carbon lining (gas carbon)

Anode: Thick carbon (graphite)

Temperature: 950°C

Current: 100 amperes at 6–7 volts

Electrolytic reaction:

Cryolite: Na3AlF6 ⇌ 3Na1+ + Al3+ +6F1−

Fluorspar: CaF2 ⇌ Ca2+ + 2F1−

Alumina: Al2O3 ⇌ Al3+ + 3O2-

Cathode: 2Al3+ + 6e- → 2Al

Anode: 3O2- − 6e- → 3[O] →3O2

Products formed:

At cathode: Pure aluminium metal

At anode: Oxygen gas

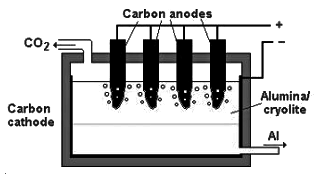

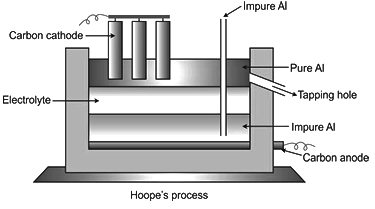

Refining of Aluminium (Hoope’s electrolytic process)

Tank contains three immiscible layers

Upper layer: Pure molten Al with carbon electrodes serves as cathode.

Middle layer: Mixture of cryolite, BaF2, AlF and CaF2 serves as the electrolyte.

Lower layer: Impure Al at the bottom along with carbon lining acts as the anode.

Electrolytic reaction:

Cathode: Al3+ + 3e− → Al

Anode: Al – 3e− → Al3+

Collection: Pure Al [about 99.9% pure] is withdrawn from the tapping hole.

Properties of Aluminium

Physical propertiesNature: Silvery light metal, malleable and ductile

Conductivity: Good conductor of heat and electricity

Boiling point: 2050°C

Melting point: 660°C

Chemical Properties

- Action with Air

4Al + 3O2 → 2Al2O3

2Al + N2 → 2Al - Action with Water

2 Al + 3H2O (steam) → Al2O3 + 3H2 - Action with Non-metals

2Al + 3Cl2 → 2AlCl3

2Al + 3S → Al2S - Action with Alkalis

2Al + 2NaOH + 2H2O → 2NaAlO2 + 3H2 - Action with Acids

2Al + 6HCl → 2AlCl3 + 3H2

2Al + 3H2SO4(dil.) → Al2(SO4)3 + 3H2

2Al + 3H2SO4(conc.) → Al2(SO4)3 + 6H2O + 3SO2

Nitric acid is rendered passive due to the formation of a thin aluminium oxide layer. - Reducing Action

Reduces heated metallic oxides of Fe, Cr and Mn to metals.

Fe2O3 + 2Al → Al2O3 + 2Fe

Uses of Metals and Alloys

- Uses of Aluminium

i. Being a strong, light and corrosion-resistant metal, it is used in alloys.

ii. Being a good conductor of electricity, it is used in the manufacture of cables for power transmission.

iii. Ships are made of alloys of aluminium because it is unaffected by sea water. - Uses of iron

i. Cast iron is used in drain pipes, gutter covers, weights and railings.

ii. Wrought iron is used in chains, horse shoes and electromagnets.

iii. Steel is used in the construction of buildings, overhead structures, machines and in various alloys. - Uses of Zinc

i. Mostly used for coating iron and steel sheets to prevent them from rusting.

ii. For making useful alloys such as brass, bronze and German silver.

iii. Zinc dust is used as a reducing agent for many organic reactions.

iv. Zinc compounds are used in paints, electroplast, preservatives for leather and a mordant for the dyeing of textiles.

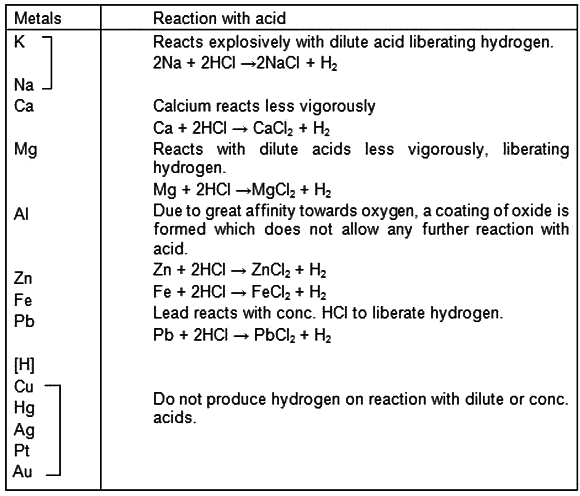

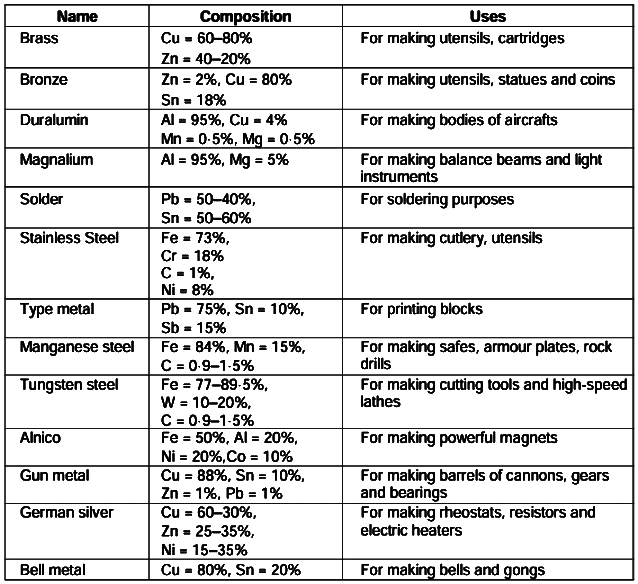

Alloys

An alloy is a homogeneous mixture of two or more metals or of one or more metals with certain non-metallic elements.

- Reasons for Alloying

i. To modify appearance and colour

ii. To modify chemical reactivity

iii. To modify casting ability

iv. To lower the melting point

v. To increase hardness and tensile strength

vi. To increase resistance to electricity

Some Important Alloys and their Uses

|

40 videos|140 docs|14 tests

|

FAQs on Revision Notes: Metallurgy - Chemistry Class 10 ICSE

| 1. What is the activity series of metals and why is it important in metallurgy? |  |

| 2. How does corrosion occur and what are its effects on metals? |  |

| 3. What are the common ores of aluminium, iron, and zinc? |  |

| 4. What are the main steps involved in the extraction of metals from their ores? |  |

| 5. What are the uses of metals and alloys in daily life? |  |