Test: Mechanical Properties of Materials - 1 - Mechanical Engineering MCQ

10 Questions MCQ Test - Test: Mechanical Properties of Materials - 1

The following statements are associated with the stress-strain diagram for steel.

- For small values of the strain, the relationship is linear (straight line), and the stress is proportional to the strain. This behavior is valid until the stress reaches the proportional limit.

- If the stress exceeds the proportional limit, the strain begins to increase more rapidly, and the slope of the curve decreases.

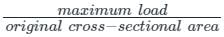

Young's modulus is defined as the ratio of

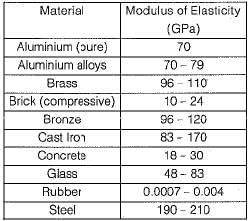

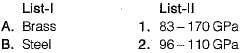

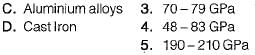

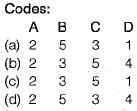

Match List-I (Material) with List-ll (Young’s modulus):

The permanent mode of deformation of a material known as ____________

A thin mid steel wire is loaded by adding loads in equal increments till it breaks. The extensions noted with increasing loads will behave as under

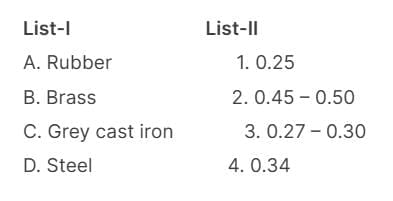

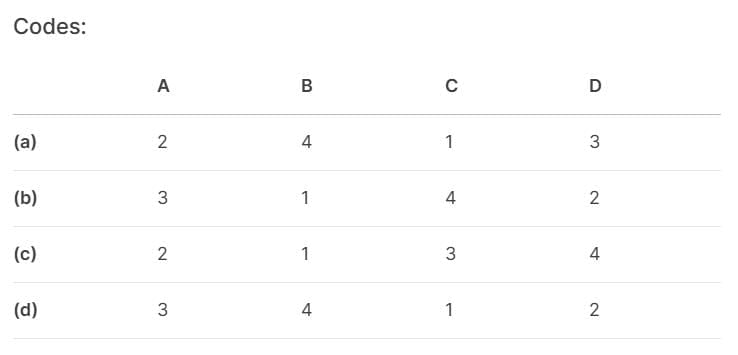

Match List-1 (Materia!) with List-ll (Poisson’s Ratio)

In a tensile testing experiment on a specimen of 1 cm2 area, the maximum load observed was 5 tonnes and neck area 0.25 cm2. The ultimate tensile strength of specimen is

The ability of a material to resist plastic deformation known as _____________

Resilience of a material is considered when it is subjected to