Production - Mechanical Engineering MCQ

30 Questions MCQ Test - Production

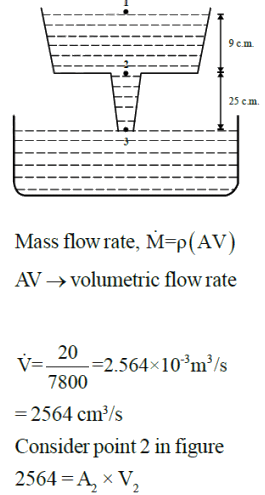

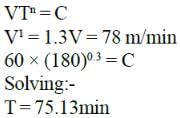

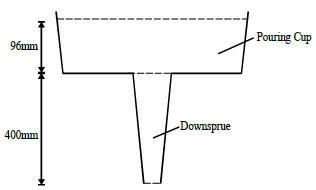

Consider the figure shown below:-

Reason for the aspiration effect is the:-

Consider the figure shown below. There is a downsprue of length 400mm has a diameter of 30mm at its top end. Height of 96mm of liquid metal is maintained in pouring cup. If aspiration effect is to be avoided, then diameter of downsprue at its lower end is:-

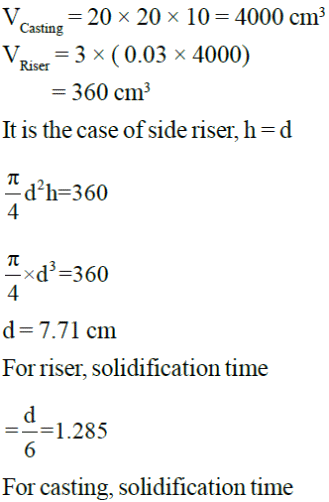

Riser design with its height equal to diameter is used to feed a casting 20cm × 20cm × 0cm. On solidification, volume shrinkage is 3% and volume of riser is 3 times of shrinkage volume. Height of riser is :-

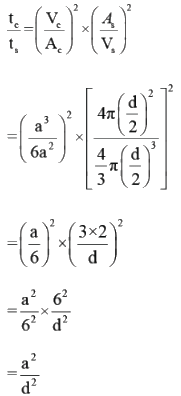

Casting with dimensions 50cm × 40cm × 10cm size solidifies in 20min. The solidification time for 40cm × 30cm × 5cm casting under similar condition is:-

A sprue for avoiding aspiration to deliver liquid iron at a rate of 20 kg/s. The density of iron is 7800 kg/m3. The height of pouring basin is 9cm. and height of sprue is 25cm. Diameter of sprue base is:-

Cube of side ‘a’ and solid sphere of diameter ‘d’ are made from same material. Ratio of their solidification time is :-;

Which of the following are the requirements of an ideal gating system?

1. Molten metal should enter mould cavity with as high velocity as possible.

2. It should facilitate complete filling of mould cavity.

3. It should be able to prevent absorption of air or gases from the surroundings by molten metal while flowing through it.

Select the correct answer using codes given below:-

Match the following contents of green sand in Group1 with their approximate percentage in Group2

1. Silica A. 5-10%

2. Clay B. 2-5%

3. Bentonite C. 8-15%

4. Coal Dust D. 7-8%

5. Water E. upto 75%

Correctly match Group-I and Group-II

Group-I

P. Coal Dust

Q. Dextrin & Molasses

R. Al2O3

S. Wood Flour

Group-II

E. Mould Hardness

F. Hot Strength

G. Surface Finish

H. Collapsibility

Common data for 11 & 12

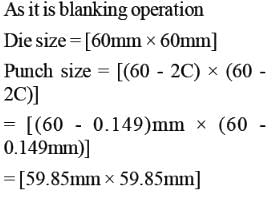

A square plate [60mm × 60mm] is to be cut from a sheet of 1.5mm thickness. Shear strength of the

sheet material is 240 MPa

Q. Size of the punch and the die respectively are

Common data for 11 & 12

A square plate [60mm × 60mm] is to be cut from a sheet of 1.5mm thickness. Shear strength of the sheet material is 240 MPa

Q. If cutting is complete at 60% penetration of the punch. Suitable shear angle for the punch to bring the work within the capacity of 38880 kN is

If A0 is the initial cross-sectional area of the billet and Af, final crosssectional area of the extruded part, then the reduction ratio is expressed as

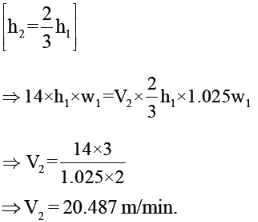

In a rolling operation of mild steel plate, in a single pass the final thickness is reduced to two third of initial thickness. The entrance speed is 14 m/min and roll diameter is 450mm. If the plate width is increased by 2.5% during the operation. The exit velocity is ___ m/min.

(Important - Enter only the numerical value in the answer)

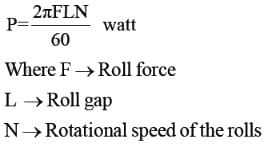

In rolling operation, the power required varies.

1) Directly proportional to the roll gap

2) Inversely proportional to the roll gap

3) Directly proportional to the roll force

4) Directly proportional to roll speed

Which of the statements are true

Which one of the following is a heat treatment process for surface hardening?

A copper strip of 200mm width and 30mm thickness is to be rolled to a thickness of 25mm. The roll of radius 300mm rotates at 100rpm. The average shear strength of the work material is 180Mpa. The roll strip contact length and the roll force are

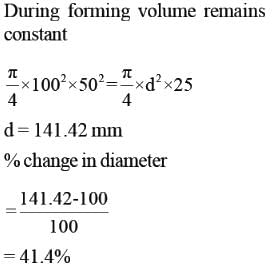

A solid cylinder of diameter 1000mm and height 50mm is forged between two friction-less flat dies to a height of 25 mm.

The percentage change in diameter is

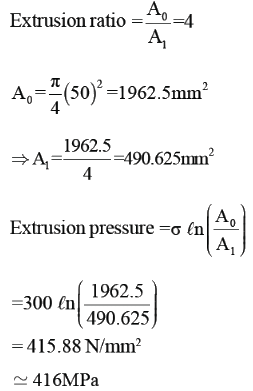

Using direct extrusion process, a round billet of 100mm length and 50mm diameter is extruded. Considering an ideal deformation process (no friction and no redundant work) extrusion ratio 4 and average flow stress of material 300 MPa, the Pressure (MPa) on the ram will be

Which one of the following statements regarding the formation of continuous chips is incorrect?

14-A drill bit of 20mm diameter rotating at 500 rpm with a feed rate of 0.2 mm/revolution is used to drill a through hole in Mild Steel plate of 20mm thickness. The depth of cut in this drilling operation is

Common data for 24 & 25

During orthogonal cutting process, following data have been observed:-

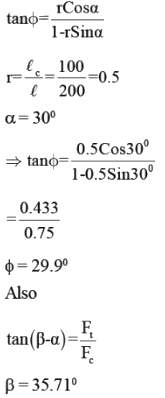

Q. Value of shear plane angle is:-

Common data for 24 & 25

During orthogonal cutting process, following data have been observed:-

Q. Friction angle is given by:-

In orthogonal cutting operation, rake angle is 150 and coefficient of friction is 0.5. Using Merchant’s theory, that will be the percentage change in chip thickness if friction is doubled?

In orthogonal cutting of MS tube with HSS tool, cutting speed and rake angle are 15m/min and 150. Chip thickness ratio is 0.35. Friction force and coefficient of friction are 470N and 0.6 respectively. Value of cutting force is:-

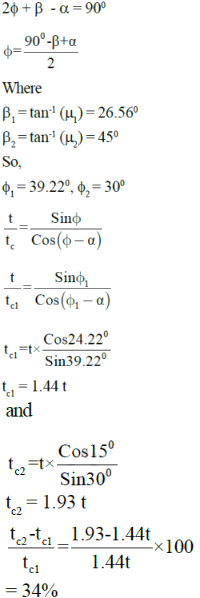

A carbide tool workpiece was found to have life of 3 hours while cutting mild steel workpiece, at the speed of 60m/min. The Taylor’s exponent used be n = 0.3. If the same tool is used at speed 30% higher than the previous one, then the new tool life will be