Test: Metal Casting - 2 - Mechanical Engineering MCQ

30 Questions MCQ Test - Test: Metal Casting - 2

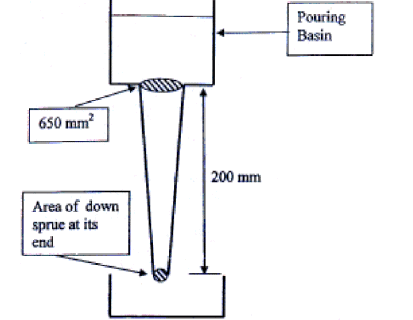

A 200 mm long down sprue has an area of cross section of 650 mm2 where the pouring basin meets the down sprue (i.e. at the beginning of the down sprue). A constant head of molten metal is maintained by the pouring basin. The Molten metal flow rate is 6.5 × 105 mm3/s. Considering the end of down sprue to be open to atmosphere and an acceleration due to gravity of 104mm/s2, the area of the down sprue in mm2 at its end (avoiding aspiration effect) should be

The height of the down-sprue is 175 mm and its cross-sectional area at the base is 200 mm2. The cross-sectional area of the horizontal runner is also 200 mm2. Assuming no losses, indicate the correct choice for the time (in seconds) required to fill a mould cavity of volume 106 mm3. (Use g = m/s2).

Which of the following materials requires the largest shrinkage allowance, while making a pattern for casting?

Which of the following pattern-materials are used in Precision Casting?

1. Plaster of Paris

2. Plastics

3. Anodized Aluminium Alloy

4. Frozen Mercury

Select the correct answer using the codes given below:

Gray cast iron blocks 200 x 100 x 10 mm are to be cast in sand moulds. Shrinkage allowance for pattern making is 1%. The ratio of the volume of pattern to that of the casting will be

Assertion (A): In CO2 casting process, the mould or core attains maximum strength.

Reason (R): The optimum gassing time of CO2 through the mould or core forms Silica Gel which imparts sufficient strength to the mould or core.

In gating system design, which one of the following is the correct sequence in which choke area, pouring time, pouring basin and sprue sizes are calculated?

Which of the following are the requirements of an ideal gating system?

1. The molten metal should enter the mould cavity with as high a velocity as possible

2. It should facilitate complete filling of the mould cavity.

3. It should be able to prevent the absorption of air or gases from the surroundings on the molten metal while flowing through it.

Select the correct answer using the codes given below:

A sand casting mould assembly IS shown in the above figure. The elements marked A and B are respectively

A spherical drop of molten metal of radius 2 mm was found to solidify in 10 seconds. A similar drop of radius 4 mm would solidify in

In a sand casting operation, the total liquid head is maintained constant such that it is equal to the mould height. The time taken to fill the mould with a top gate is tA. If the same mould is filled with a bottom gate, then the time taken is tB. Ignore the time required to fill the runner and frictional effects. Assume atmospheric pressure at the top molten metal surfaces. The relation between tA and tB is

Two streams of liquid metal which are not hot enough to fuse properly result into a casting defect known as

Consider the following ingredients used in moulding:

1. Dry silica sand

2. Clay

3. Phenol formaldehyde

4. Sodium silicate

Those used for shell mould casting include

Consider the following statements in respect of investment castings:

1. The pattern or patterns is/are not joined to a stalk or sprue also of wax to form a tree of patterns.

2. The prepared moulds are placed in an oven and heated gently to dry off the invest and melt out the bulk of wax.

3. The moulds are usually poured by placing the moulds in a vacuum chamber.

Which of the statements given above are correct?

Which of the following pairs are correctly matched?

1. Pit moulding ... For large jobs.

2. Investment moulding ... Lost wax process.

3. Plaster moulding ... Mould prepared in gypsum.

The most preferred process for casting gas turbine blades is:

Which of the following are the most suitable materials for die casting?

Which of the following is not counted among the limitations of pressure die casting?

Assertion (A): Aluminium alloys are cast in hot chamber die casting machine.

Reason (R): Aluminium alloys require high melting when compared to zinc alloys.

Consider the following statements:

1. Zinc die castings have low strength.

2. In the die casting process, very thin sections or complex shapes can be obtained easily.

Which of the statements given above is/are correct?

Match List-I (Name of the Process) with List-II (Advantage) and select the correct answer using the codes given below the lists:

Assertion (A): Die casting yields a product of good accuracy and finish.

Reason (R): Low melting alloys used in die casting.

Match the items of List I (Equipment) with the items of List II (Process) and select the correct answer using the given codes.

Which one of the following is the correct statement?

In a centrifugal casting method

Which of the following are the most likely characteristics in centrifugal casting?