All Exams >

Mechanical Engineering >

Engineering Materials >

All Questions

All questions of Heat Treatment of Steels for Mechanical Engineering Exam

Hardness of steel greatly improves with- a)Annealing

- b)Cyaniding

- c)Normalizing

- d)Tempering

Correct answer is option 'B'. Can you explain this answer?

Hardness of steel greatly improves with

a)

Annealing

b)

Cyaniding

c)

Normalizing

d)

Tempering

|

Jyoti Choudhury answered |

Understanding Cyaniding

Cyaniding is a surface hardening process that enhances the hardness of steel, making it suitable for applications requiring high wear resistance. Here’s how it works:

Process Overview

- Cyaniding involves the introduction of carbon and nitrogen into the surface of low-carbon steel.

- Temperature Range: The process typically occurs at temperatures between 850°C and 950°C, where the steel is immersed in a cyanide salt bath.

Mechanism of Hardening

- Diffusion: The cyanide compounds diffuse into the steel's surface, enriching it with carbon and nitrogen.

- Formation of Hard Phases: This results in the formation of hard phases such as cyanide compounds (e.g., iron nitrides), which significantly increase surface hardness.

Advantages of Cyaniding

- High Hardness: The surface can achieve hardness levels between 60-70 HRC (Rockwell Hardness Scale).

- Improved Wear Resistance: The enhanced hardness contributes to superior wear resistance, making it ideal for components like gears and shafts.

- Tough Core: While the surface becomes hard, the core remains tough, preventing brittleness.

Comparison with Other Processes

- Annealing: This process softens steel, making it more ductile.

- Normalizing: Focuses on refining grain structure without significantly increasing hardness.

- Tempering: Reduces brittleness of hardened steel, but does not enhance its hardness.

In conclusion, cyaniding is the most effective method among the options for significantly increasing the hardness of steel, making it valuable for engineering applications that require durability and wear resistance.

Cyaniding is a surface hardening process that enhances the hardness of steel, making it suitable for applications requiring high wear resistance. Here’s how it works:

Process Overview

- Cyaniding involves the introduction of carbon and nitrogen into the surface of low-carbon steel.

- Temperature Range: The process typically occurs at temperatures between 850°C and 950°C, where the steel is immersed in a cyanide salt bath.

Mechanism of Hardening

- Diffusion: The cyanide compounds diffuse into the steel's surface, enriching it with carbon and nitrogen.

- Formation of Hard Phases: This results in the formation of hard phases such as cyanide compounds (e.g., iron nitrides), which significantly increase surface hardness.

Advantages of Cyaniding

- High Hardness: The surface can achieve hardness levels between 60-70 HRC (Rockwell Hardness Scale).

- Improved Wear Resistance: The enhanced hardness contributes to superior wear resistance, making it ideal for components like gears and shafts.

- Tough Core: While the surface becomes hard, the core remains tough, preventing brittleness.

Comparison with Other Processes

- Annealing: This process softens steel, making it more ductile.

- Normalizing: Focuses on refining grain structure without significantly increasing hardness.

- Tempering: Reduces brittleness of hardened steel, but does not enhance its hardness.

In conclusion, cyaniding is the most effective method among the options for significantly increasing the hardness of steel, making it valuable for engineering applications that require durability and wear resistance.

Heat treatment that requires heating in a part below A, temperature, i.e, between 550°C and 650°C is called as- a)hardening

- b)normalizing

- c)process annealing

- d)fullanealing

Correct answer is option 'C'. Can you explain this answer?

Heat treatment that requires heating in a part below A, temperature, i.e, between 550°C and 650°C is called as

a)

hardening

b)

normalizing

c)

process annealing

d)

fullanealing

|

Shraddha Datta answered |

Process annealing is a sub-critical treatment given to metals to soften them during mechanical processing. It may or may not involve full recrystallization of the cold worked metal.

The Iron-carbon diagram and the TTT curves are determined under- a)equilibrium and non-equilibrium conditions respectively

- b)non-equilibrium and equilibrium conditions respectively

- c)equilibrium conditions for both

- d)non-equilibrium conditions for both

Correct answer is option 'A'. Can you explain this answer?

The Iron-carbon diagram and the TTT curves are determined under

a)

equilibrium and non-equilibrium conditions respectively

b)

non-equilibrium and equilibrium conditions respectively

c)

equilibrium conditions for both

d)

non-equilibrium conditions for both

|

|

Kiran Basu answered |

Iron-carbon diagram are draw in equilibrium condition that is why it is also called iron-carbon equilibrium diagram while T-T-T diagram is drawn for non-equilibrium conditions.

The grain structure obtained by isothermal hardening operation is- a)martensite

- b)aciculartroostite

- c)sorbite

- d)bainite

Correct answer is option 'D'. Can you explain this answer?

The grain structure obtained by isothermal hardening operation is

a)

martensite

b)

aciculartroostite

c)

sorbite

d)

bainite

|

|

Kajal Tiwari answered |

Understanding Isothermal Hardening

Isothermal hardening is a heat treatment process that enhances the mechanical properties of steel, particularly its hardness and strength. The process involves holding the steel at a specific temperature for a designated time, allowing for transformations in the microstructure.

Microstructures Resulting from Isothermal Hardening

- Martensite:

- Formed by rapid cooling, martensite is a very hard and brittle phase, typically produced by quenching from a high temperature.

- Acicular Troostite:

- This microstructure appears as needle-like formations and is not typically associated with isothermal treatments.

- Sorbite:

- A mixture of ferrite and cementite, sorbite results from tempering martensite but is not a direct product of isothermal hardening.

- Bainite:

- This is the correct answer. Bainite is produced through isothermal transformation at intermediate temperatures. It displays a fine, elongated structure and offers a balance of strength and ductility.

Why Bainite is the Correct Answer

- Temperature Range:

- Isothermal hardening occurs at specific temperatures (around 250-550°C), which favor the formation of bainite rather than martensite.

- Mechanical Properties:

- Bainite provides superior toughness compared to martensite, making it ideal for applications requiring both strength and ductility.

- Transformation Mechanism:

- The isothermal process allows for a slower transformation, leading to a more refined microstructure, characteristic of bainite.

In summary, the grain structure obtained from isothermal hardening is bainite, which is preferred for its improved balance of mechanical properties.

Isothermal hardening is a heat treatment process that enhances the mechanical properties of steel, particularly its hardness and strength. The process involves holding the steel at a specific temperature for a designated time, allowing for transformations in the microstructure.

Microstructures Resulting from Isothermal Hardening

- Martensite:

- Formed by rapid cooling, martensite is a very hard and brittle phase, typically produced by quenching from a high temperature.

- Acicular Troostite:

- This microstructure appears as needle-like formations and is not typically associated with isothermal treatments.

- Sorbite:

- A mixture of ferrite and cementite, sorbite results from tempering martensite but is not a direct product of isothermal hardening.

- Bainite:

- This is the correct answer. Bainite is produced through isothermal transformation at intermediate temperatures. It displays a fine, elongated structure and offers a balance of strength and ductility.

Why Bainite is the Correct Answer

- Temperature Range:

- Isothermal hardening occurs at specific temperatures (around 250-550°C), which favor the formation of bainite rather than martensite.

- Mechanical Properties:

- Bainite provides superior toughness compared to martensite, making it ideal for applications requiring both strength and ductility.

- Transformation Mechanism:

- The isothermal process allows for a slower transformation, leading to a more refined microstructure, characteristic of bainite.

In summary, the grain structure obtained from isothermal hardening is bainite, which is preferred for its improved balance of mechanical properties.

Maximum surface hardness is attained by- a)cyaniding

- b)carburising

- c)flame hardening

- d)nitriding

Correct answer is option 'D'. Can you explain this answer?

Maximum surface hardness is attained by

a)

cyaniding

b)

carburising

c)

flame hardening

d)

nitriding

|

|

Sai Reddy answered |

Maximum surface hardness is produced by nitriding; next come cyaniding and carburising.

Tempering is a process of annealing- a)Martensite at low temperatures

- b)Martensite at higher temperatures

- c)Bainite at low temperatures

- d)Bainite at higher temperatures

Correct answer is option 'A'. Can you explain this answer?

Tempering is a process of annealing

a)

Martensite at low temperatures

b)

Martensite at higher temperatures

c)

Bainite at low temperatures

d)

Bainite at higher temperatures

|

|

Sharmila Chauhan answered |

Tempering is the process of annealing martensite at low temperature. Although martensite is strong and wear resistant, it is brittle. Its toughness is low, primarily because of residual stresses introduced by the transformation. When tempering is carried out at a occurs. The martensite grains retain their strength, but improve their toughness and donot change shape on storage.

Tempering temperature of most of the material is of the order of- a)100-150°C

- b)200-300°C

- c)350-400°C

- d)400-500°C

Correct answer is option 'B'. Can you explain this answer?

Tempering temperature of most of the material is of the order of

a)

100-150°C

b)

200-300°C

c)

350-400°C

d)

400-500°C

|

|

Anjali Shah answered |

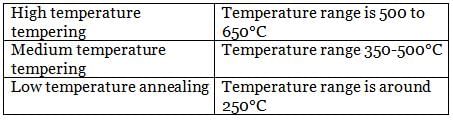

Tempering process is categorised in three category

Cast steel crankshaft surface is hardened by- a)Nitriding

- b)Normalizing

- c)Induction heating

- d)Carburizing

Correct answer is option 'C'. Can you explain this answer?

Cast steel crankshaft surface is hardened by

a)

Nitriding

b)

Normalizing

c)

Induction heating

d)

Carburizing

|

|

Priyanka Tiwari answered |

Nitriding:

Nitriding is a surface hardening process in which nitrogen is diffused into the surface of the steel to create a hardened layer. While nitriding can be a suitable method for hardening certain types of steel components, it is not typically used for surface hardening cast steel crankshafts.

Normalizing:

Normalizing is a heat treatment process that involves heating the steel to a specific temperature, holding it at that temperature for a period of time, and then cooling it in air. Normalizing is primarily used to refine the grain structure of the steel and improve its mechanical properties, but it does not provide surface hardening.

Induction Heating:

Induction heating is a process that uses electromagnetic induction to heat a metal object. In the case of a cast steel crankshaft, induction heating can be used to selectively heat the surface of the crankshaft to a high temperature, allowing for rapid quenching and subsequent hardening of the surface.

Carburizing:

Carburizing is a surface hardening process in which carbon is diffused into the surface of the steel to create a hardened layer. This process is commonly used for hardening steel components such as crankshafts, gears, and bearings. In the case of a cast steel crankshaft, carburizing can be an effective method for achieving the desired surface hardness.

Nitriding is a surface hardening process in which nitrogen is diffused into the surface of the steel to create a hardened layer. While nitriding can be a suitable method for hardening certain types of steel components, it is not typically used for surface hardening cast steel crankshafts.

Normalizing:

Normalizing is a heat treatment process that involves heating the steel to a specific temperature, holding it at that temperature for a period of time, and then cooling it in air. Normalizing is primarily used to refine the grain structure of the steel and improve its mechanical properties, but it does not provide surface hardening.

Induction Heating:

Induction heating is a process that uses electromagnetic induction to heat a metal object. In the case of a cast steel crankshaft, induction heating can be used to selectively heat the surface of the crankshaft to a high temperature, allowing for rapid quenching and subsequent hardening of the surface.

Carburizing:

Carburizing is a surface hardening process in which carbon is diffused into the surface of the steel to create a hardened layer. This process is commonly used for hardening steel components such as crankshafts, gears, and bearings. In the case of a cast steel crankshaft, carburizing can be an effective method for achieving the desired surface hardness.

Which of the following is defined as the ability of the structure to transform into martensite?- a)Strength

- b)Hardenability

- c)Toughness

- d)Hardness

Correct answer is option 'B'. Can you explain this answer?

Which of the following is defined as the ability of the structure to transform into martensite?

a)

Strength

b)

Hardenability

c)

Toughness

d)

Hardness

|

|

Neha Joshi answered |

Hardenability is defined as the ability of the structure to transform into martensite.

Select the wrong statement:- a)In flame hardening, oxy-acetylene flame is used.

- b)In induction hardening, frequency is kept high.

- c)In the nitriding process, both carbon and nitrogen are absorbed by the metal surface to get it hardened.

- d)Carburising, cyaniding and nitriding are case hardening processes.

Correct answer is option 'C'. Can you explain this answer?

Select the wrong statement:

a)

In flame hardening, oxy-acetylene flame is used.

b)

In induction hardening, frequency is kept high.

c)

In the nitriding process, both carbon and nitrogen are absorbed by the metal surface to get it hardened.

d)

Carburising, cyaniding and nitriding are case hardening processes.

|

Moumita Rane answered |

In nitriding, only nitrogen is used.

During carburising, carbon is introduced to form a layer of high carbon at the surface, The carbon is introduced in the form of- a)free carbon

- b)graphite flakes

- c)pearlite

- d)cementite

Correct answer is option 'B'. Can you explain this answer?

During carburising, carbon is introduced to form a layer of high carbon at the surface, The carbon is introduced in the form of

a)

free carbon

b)

graphite flakes

c)

pearlite

d)

cementite

|

|

Dhruv Dasgupta answered |

Carburizing is the most widely method of surface hardening. The surface layers of a low carbon steel (C ≤ 0.2%) is enriched with carbon up to 0.8 - 1 %. The source of carbon may be a solid , liquid or gas medium. In all cases, the carbon enters the steel at the surface-and diffuse into the steel as a function of time at an elevated temperature.

The following structure is obtained by Austempering process of heat treatment- a)Bainite

- b)Troostite

- c)Martensite

- d)Sorbite

Correct answer is option 'A'. Can you explain this answer?

The following structure is obtained by Austempering process of heat treatment

a)

Bainite

b)

Troostite

c)

Martensite

d)

Sorbite

|

|

Nandini Basak answered |

Bainite is produced by austempering process. In this process sample is heated and quenched to room temperature below the nose of T-T-T diagram and this temperature is maintained for a substantial period of time so that cooling curve enters into T-T-T diagram.

Match List-I (Heat Treatment) with List-ll (Effect on the properties) and select the correct answer using the codes given below the lists:

List-I

A. Annealing

B. Nitriding

C. Martempering

D. Normalizing

List-ll

1. Refined grain structure

2. Improves the hardness of the whole mass

3. Increases surface hardness

4. Improves ductility

Codes:

A B C D

(a) 4 3 2 1

(b) 1 3 4 2

(c) 4 2 1 3

(d) 2 1 3 4- a)(a)

- b)(b)

- c)(c)

- d)(d)

Correct answer is option 'A'. Can you explain this answer?

Match List-I (Heat Treatment) with List-ll (Effect on the properties) and select the correct answer using the codes given below the lists:

List-I

A. Annealing

B. Nitriding

C. Martempering

D. Normalizing

List-ll

1. Refined grain structure

2. Improves the hardness of the whole mass

3. Increases surface hardness

4. Improves ductility

Codes:

A B C D

(a) 4 3 2 1

(b) 1 3 4 2

(c) 4 2 1 3

(d) 2 1 3 4

List-I

A. Annealing

B. Nitriding

C. Martempering

D. Normalizing

List-ll

1. Refined grain structure

2. Improves the hardness of the whole mass

3. Increases surface hardness

4. Improves ductility

Codes:

A B C D

(a) 4 3 2 1

(b) 1 3 4 2

(c) 4 2 1 3

(d) 2 1 3 4

a)

(a)

b)

(b)

c)

(c)

d)

(d)

|

Ishani Chauhan answered |

List-I (Heat Treatment) and List-II (Effect on the properties):

List-I:

A. Annealing

B. Nitriding

C. Martempering

D. Normalizing

List-II:

1. Refined grain structure

2. Improves the hardness of the whole mass

3. Increases surface hardness

4. Improves ductility

The correct match between List-I and List-II is:

A. Annealing - 4. Improves ductility

B. Nitriding - 3. Increases surface hardness

C. Martempering - 2. Improves the hardness of the whole mass

D. Normalizing - 1. Refined grain structure

Explanation:

1. Annealing:

- Annealing is a heat treatment process in which a material is heated to a specific temperature and then slowly cooled to improve its ductility.

- It helps in reducing the hardness of the material and makes it more malleable, allowing for easier shaping and forming.

- The process also helps in relieving internal stresses and improving the uniformity of the material's structure, leading to a refined grain structure.

2. Nitriding:

- Nitriding is a surface hardening process in which nitrogen is diffused into the surface of a material to increase its hardness.

- It forms a hard and wear-resistant layer on the surface, which significantly improves the surface hardness of the material.

- Nitriding is commonly used for improving the wear resistance, fatigue strength, and corrosion resistance of materials.

3. Martempering:

- Martempering is a heat treatment process that involves quenching the material to a temperature just above the martensite transformation temperature and then holding it at that temperature until it is fully transformed.

- This process helps in achieving a uniform and desired hardness throughout the entire material, improving the hardness of the whole mass.

- Martempering is often used to achieve a combination of high hardness and good toughness in materials.

4. Normalizing:

- Normalizing is a heat treatment process in which a material is heated to a temperature above its critical transformation temperature and then air-cooled in still air.

- It helps in refining the grain structure of the material, making it more uniform and reducing the presence of internal defects.

- Normalizing also improves the mechanical properties of the material, including its strength, toughness, and machinability.

Therefore, the correct match between List-I and List-II is:

A. Annealing - 4. Improves ductility

B. Nitriding - 3. Increases surface hardness

C. Martempering - 2. Improves the hardness of the whole mass

D. Normalizing - 1. Refined grain structure

List-I:

A. Annealing

B. Nitriding

C. Martempering

D. Normalizing

List-II:

1. Refined grain structure

2. Improves the hardness of the whole mass

3. Increases surface hardness

4. Improves ductility

The correct match between List-I and List-II is:

A. Annealing - 4. Improves ductility

B. Nitriding - 3. Increases surface hardness

C. Martempering - 2. Improves the hardness of the whole mass

D. Normalizing - 1. Refined grain structure

Explanation:

1. Annealing:

- Annealing is a heat treatment process in which a material is heated to a specific temperature and then slowly cooled to improve its ductility.

- It helps in reducing the hardness of the material and makes it more malleable, allowing for easier shaping and forming.

- The process also helps in relieving internal stresses and improving the uniformity of the material's structure, leading to a refined grain structure.

2. Nitriding:

- Nitriding is a surface hardening process in which nitrogen is diffused into the surface of a material to increase its hardness.

- It forms a hard and wear-resistant layer on the surface, which significantly improves the surface hardness of the material.

- Nitriding is commonly used for improving the wear resistance, fatigue strength, and corrosion resistance of materials.

3. Martempering:

- Martempering is a heat treatment process that involves quenching the material to a temperature just above the martensite transformation temperature and then holding it at that temperature until it is fully transformed.

- This process helps in achieving a uniform and desired hardness throughout the entire material, improving the hardness of the whole mass.

- Martempering is often used to achieve a combination of high hardness and good toughness in materials.

4. Normalizing:

- Normalizing is a heat treatment process in which a material is heated to a temperature above its critical transformation temperature and then air-cooled in still air.

- It helps in refining the grain structure of the material, making it more uniform and reducing the presence of internal defects.

- Normalizing also improves the mechanical properties of the material, including its strength, toughness, and machinability.

Therefore, the correct match between List-I and List-II is:

A. Annealing - 4. Improves ductility

B. Nitriding - 3. Increases surface hardness

C. Martempering - 2. Improves the hardness of the whole mass

D. Normalizing - 1. Refined grain structure

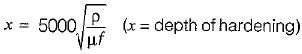

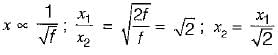

Doubling the frequency of current in an induction hardening process- a)doubles the depth of hardening

- b)half the depth of hardening

- c)increases the depth of hardening by a factor of √2

- d)reduces the depth of hardening by a factor of √2

Correct answer is option 'D'. Can you explain this answer?

Doubling the frequency of current in an induction hardening process

a)

doubles the depth of hardening

b)

half the depth of hardening

c)

increases the depth of hardening by a factor of √2

d)

reduces the depth of hardening by a factor of √2

|

|

Saranya Saha answered |

During heat treatment of steel, the hardness of various structure in increasing order is- a)Martensite, fine pearlite, coarse pearlite, spheroidite

- b)Fine pearlite, martensite, spheroidite, coarse pearlite

- c)Martensite, coarse pearlite, fine pearlite, spheroidite

- d)Spheroidite, coarse pearlite, fine pearlite, martensite

Correct answer is option 'D'. Can you explain this answer?

During heat treatment of steel, the hardness of various structure in increasing order is

a)

Martensite, fine pearlite, coarse pearlite, spheroidite

b)

Fine pearlite, martensite, spheroidite, coarse pearlite

c)

Martensite, coarse pearlite, fine pearlite, spheroidite

d)

Spheroidite, coarse pearlite, fine pearlite, martensite

|

Anagha Mehta answered |

Heat Treatment of Steel and Hardness

Introduction:

Heat treatment is a process used to alter the physical and mechanical properties of steel by heating and cooling it. It involves heating the steel to a specific temperature and then cooling it at a controlled rate. One of the important properties that can be affected by heat treatment is hardness.

Hardness:

Hardness is a measure of a material's resistance to deformation, particularly indentation or scratching. It is an important property in many applications as it determines the material's ability to withstand wear, abrasion, and impact. In the context of steel, hardness is often related to its microstructure.

Microstructure of Steel:

The microstructure of steel refers to the arrangement of its constituent phases and grains. The microstructure is primarily determined by the cooling rate during heat treatment. Different microstructures have different hardness levels.

Heat Treatment and Hardness:

During heat treatment, steel undergoes various phase transformations that result in different microstructures and hardness levels. The hardness of the structures formed during heat treatment of steel can be listed in increasing order as follows:

1. Spheroidite:

Spheroidite is a microstructure formed by heating the steel to a temperature just below the eutectoid point and holding it there for an extended period. It consists of spherical particles of cementite embedded in a ferrite matrix. Spheroidite has relatively low hardness due to the coarsening of the cementite particles.

2. Coarse Pearlite:

Coarse pearlite is a microstructure formed by cooling the steel at a relatively slow rate. It consists of alternating layers of ferrite and cementite. Coarse pearlite has higher hardness compared to spheroidite due to the presence of a fine lamellar structure.

3. Fine Pearlite:

Fine pearlite is a microstructure formed by cooling the steel at a faster rate than coarse pearlite. It has a finer lamellar structure and higher hardness compared to coarse pearlite.

4. Martensite:

Martensite is a microstructure formed by rapidly cooling the steel from an elevated temperature. It is characterized by a highly distorted lattice structure and high hardness. Martensite has the highest hardness among the structures formed during heat treatment of steel.

Conclusion:

In summary, the hardness of the steel structures formed during heat treatment can be listed in increasing order as spheroidite, coarse pearlite, fine pearlite, and martensite. This order is primarily determined by the cooling rate during heat treatment, with faster cooling resulting in higher hardness.

Introduction:

Heat treatment is a process used to alter the physical and mechanical properties of steel by heating and cooling it. It involves heating the steel to a specific temperature and then cooling it at a controlled rate. One of the important properties that can be affected by heat treatment is hardness.

Hardness:

Hardness is a measure of a material's resistance to deformation, particularly indentation or scratching. It is an important property in many applications as it determines the material's ability to withstand wear, abrasion, and impact. In the context of steel, hardness is often related to its microstructure.

Microstructure of Steel:

The microstructure of steel refers to the arrangement of its constituent phases and grains. The microstructure is primarily determined by the cooling rate during heat treatment. Different microstructures have different hardness levels.

Heat Treatment and Hardness:

During heat treatment, steel undergoes various phase transformations that result in different microstructures and hardness levels. The hardness of the structures formed during heat treatment of steel can be listed in increasing order as follows:

1. Spheroidite:

Spheroidite is a microstructure formed by heating the steel to a temperature just below the eutectoid point and holding it there for an extended period. It consists of spherical particles of cementite embedded in a ferrite matrix. Spheroidite has relatively low hardness due to the coarsening of the cementite particles.

2. Coarse Pearlite:

Coarse pearlite is a microstructure formed by cooling the steel at a relatively slow rate. It consists of alternating layers of ferrite and cementite. Coarse pearlite has higher hardness compared to spheroidite due to the presence of a fine lamellar structure.

3. Fine Pearlite:

Fine pearlite is a microstructure formed by cooling the steel at a faster rate than coarse pearlite. It has a finer lamellar structure and higher hardness compared to coarse pearlite.

4. Martensite:

Martensite is a microstructure formed by rapidly cooling the steel from an elevated temperature. It is characterized by a highly distorted lattice structure and high hardness. Martensite has the highest hardness among the structures formed during heat treatment of steel.

Conclusion:

In summary, the hardness of the steel structures formed during heat treatment can be listed in increasing order as spheroidite, coarse pearlite, fine pearlite, and martensite. This order is primarily determined by the cooling rate during heat treatment, with faster cooling resulting in higher hardness.

Maximum surface hardness is achieved by- a)Cyaniding

- b)Nitriding

- c)Carburizing

- d)Flame hardening

Correct answer is option 'B'. Can you explain this answer?

Maximum surface hardness is achieved by

a)

Cyaniding

b)

Nitriding

c)

Carburizing

d)

Flame hardening

|

|

Sagarika Mukherjee answered |

Maximum surface hardness is produced by nitriding followed by cyaniding and carburising.

Primary objective of full annealing is to- a)increase toughness and yield point

- b)reduce ductility and resilience

- c)remove foreign impurities and improve surface finish

- d)increase ductility and machinability

Correct answer is option 'D'. Can you explain this answer?

Primary objective of full annealing is to

a)

increase toughness and yield point

b)

reduce ductility and resilience

c)

remove foreign impurities and improve surface finish

d)

increase ductility and machinability

|

|

Jhanvi Datta answered |

The primary objective of the full annealing is to reduce the hardness and brittleness or to improve ductility of the material.

The essential constituent of a hardened steel is- a)Pearlite

- b)Austenite

- c)Martensite

- d)Troostite

Correct answer is option 'C'. Can you explain this answer?

The essential constituent of a hardened steel is

a)

Pearlite

b)

Austenite

c)

Martensite

d)

Troostite

|

|

Jyoti Deshpande answered |

Martensite is an essential constituent of hardened steel.

Which one of the following cooling methods is best suited for converting Austenite steel into very fine Peariite steel?- a)Oil quenching

- b)Water quenching

- c)Air cooling

- d)Furnace cooling

Correct answer is option 'A'. Can you explain this answer?

Which one of the following cooling methods is best suited for converting Austenite steel into very fine Peariite steel?

a)

Oil quenching

b)

Water quenching

c)

Air cooling

d)

Furnace cooling

|

|

Asha Basu answered |

The oil quenching is the best suited for Austenite steel into very fine pearlite steel.

The machine tool guide ways are hardened by- a)induction hardening

- b)flame hardening

- c)martempering

- d)none of these

Correct answer is option 'B'. Can you explain this answer?

The machine tool guide ways are hardened by

a)

induction hardening

b)

flame hardening

c)

martempering

d)

none of these

|

|

Yash Das answered |

Hardening of Machine Tool Guide Ways

Machine tool guide ways are hardened to increase their wear resistance and improve their durability. Hardening is a heat treatment process that involves heating the material to a specific temperature and then rapidly cooling it to increase its hardness. There are various methods of hardening, including induction hardening, flame hardening, martempering, and others.

1. Induction Hardening:

Induction hardening is a surface hardening process in which the guide ways are heated using an induction coil. The high-frequency alternating current induces a current in the guide ways, causing them to heat up. Once the desired temperature is reached, the guide ways are quenched to cool them rapidly, resulting in a hardened surface. Induction hardening is commonly used for hardening machine tool guide ways due to its ability to provide localized hardening and precise control over the hardened depth.

2. Flame Hardening:

Flame hardening is another method used for hardening machine tool guide ways. In this process, a flame is directed onto the surface of the guide ways using a torch. The heat from the flame rapidly heats up the surface, and then the guide ways are quenched to achieve the desired hardness. Flame hardening is suitable for large and complex-shaped components and is known for its flexibility and cost-effectiveness.

3. Martempering:

Martempering, also known as marquenching, is a process that involves quenching the guide ways in a bath of molten salt or oil. Unlike conventional quenching, martempering provides a more uniform and controlled cooling rate, resulting in reduced distortion and cracking. The guide ways are heated to the austenitizing temperature and then quickly transferred to the quenching medium for a specific duration. Martempering is commonly used for medium to large-sized machine tool guide ways.

Conclusion:

Among the options provided, the correct answer is option 'B', flame hardening. Flame hardening is a widely used method for hardening machine tool guide ways due to its flexibility, cost-effectiveness, and suitability for complex-shaped components. It involves heating the guide ways using a torch flame and then quenching them to achieve the desired hardness.

Machine tool guide ways are hardened to increase their wear resistance and improve their durability. Hardening is a heat treatment process that involves heating the material to a specific temperature and then rapidly cooling it to increase its hardness. There are various methods of hardening, including induction hardening, flame hardening, martempering, and others.

1. Induction Hardening:

Induction hardening is a surface hardening process in which the guide ways are heated using an induction coil. The high-frequency alternating current induces a current in the guide ways, causing them to heat up. Once the desired temperature is reached, the guide ways are quenched to cool them rapidly, resulting in a hardened surface. Induction hardening is commonly used for hardening machine tool guide ways due to its ability to provide localized hardening and precise control over the hardened depth.

2. Flame Hardening:

Flame hardening is another method used for hardening machine tool guide ways. In this process, a flame is directed onto the surface of the guide ways using a torch. The heat from the flame rapidly heats up the surface, and then the guide ways are quenched to achieve the desired hardness. Flame hardening is suitable for large and complex-shaped components and is known for its flexibility and cost-effectiveness.

3. Martempering:

Martempering, also known as marquenching, is a process that involves quenching the guide ways in a bath of molten salt or oil. Unlike conventional quenching, martempering provides a more uniform and controlled cooling rate, resulting in reduced distortion and cracking. The guide ways are heated to the austenitizing temperature and then quickly transferred to the quenching medium for a specific duration. Martempering is commonly used for medium to large-sized machine tool guide ways.

Conclusion:

Among the options provided, the correct answer is option 'B', flame hardening. Flame hardening is a widely used method for hardening machine tool guide ways due to its flexibility, cost-effectiveness, and suitability for complex-shaped components. It involves heating the guide ways using a torch flame and then quenching them to achieve the desired hardness.

Case hardening is done by following, except- a)electroplating

- b)cyaniding

- c)flame hardening

- d)induction hardening

Correct answer is option 'A'. Can you explain this answer?

Case hardening is done by following, except

a)

electroplating

b)

cyaniding

c)

flame hardening

d)

induction hardening

|

|

Jhanvi Datta answered |

Understanding Case Hardening

Case hardening is a process used to harden the surface of steel while maintaining a softer, ductile interior. This technique enhances wear resistance and improves fatigue strength, making components more durable. However, not all methods of hardening are categorized as case hardening.

Methods of Case Hardening

- Cyaniding: This method involves the diffusion of nitrogen and carbon into the surface of the steel, resulting in a hard, wear-resistant layer. It is typically performed at lower temperatures and is effective for producing a thin hard layer.

- Flame Hardening: In this process, a high-temperature flame is directed onto the surface of the steel, rapidly heating it. The heated area is then quenched with water or oil, leading to a hardened surface layer. This method is often used for large components.

- Induction Hardening: Similar to flame hardening, induction hardening uses electromagnetic induction to heat the surface of steel. The rapid heating followed by quenching produces a hard outer layer, while the core remains tough and ductile.

Why Electroplating is Not Case Hardening

Electroplating is a different process primarily aimed at coating a substrate with a metal layer. The primary objectives of electroplating include:

- Corrosion Resistance: It protects the underlying metal from oxidation and wear.

- Aesthetic Enhancement: It improves the appearance of components by providing a shiny finish.

- Conductivity Improvement: In some applications, it enhances electrical conductivity.

While electroplating improves surface properties, it does not alter the hardness of the substrate in the same way as case hardening methods. Therefore, option 'A' is correct as it does not belong to case hardening techniques.

Case hardening is a process used to harden the surface of steel while maintaining a softer, ductile interior. This technique enhances wear resistance and improves fatigue strength, making components more durable. However, not all methods of hardening are categorized as case hardening.

Methods of Case Hardening

- Cyaniding: This method involves the diffusion of nitrogen and carbon into the surface of the steel, resulting in a hard, wear-resistant layer. It is typically performed at lower temperatures and is effective for producing a thin hard layer.

- Flame Hardening: In this process, a high-temperature flame is directed onto the surface of the steel, rapidly heating it. The heated area is then quenched with water or oil, leading to a hardened surface layer. This method is often used for large components.

- Induction Hardening: Similar to flame hardening, induction hardening uses electromagnetic induction to heat the surface of steel. The rapid heating followed by quenching produces a hard outer layer, while the core remains tough and ductile.

Why Electroplating is Not Case Hardening

Electroplating is a different process primarily aimed at coating a substrate with a metal layer. The primary objectives of electroplating include:

- Corrosion Resistance: It protects the underlying metal from oxidation and wear.

- Aesthetic Enhancement: It improves the appearance of components by providing a shiny finish.

- Conductivity Improvement: In some applications, it enhances electrical conductivity.

While electroplating improves surface properties, it does not alter the hardness of the substrate in the same way as case hardening methods. Therefore, option 'A' is correct as it does not belong to case hardening techniques.

Select the WRONG statement:- a)The main purpose of heat treatment is to change the mechanical properties.

- b)Tempering is the process of annealing martensite at low temperatures.

- c)Case hardening is the only method suitable for (ow carbon steel.

- d)A eutectoid steel consists of wholly austenite.

Correct answer is option 'D'. Can you explain this answer?

Select the WRONG statement:

a)

The main purpose of heat treatment is to change the mechanical properties.

b)

Tempering is the process of annealing martensite at low temperatures.

c)

Case hardening is the only method suitable for (ow carbon steel.

d)

A eutectoid steel consists of wholly austenite.

|

|

Manoj Pillai answered |

Explanation:

Heat treatment is a process used to alter the physical and mechanical properties of materials, specifically metals and alloys. It involves heating and cooling the material in a controlled manner to achieve the desired properties. The main purpose of heat treatment is indeed to change the mechanical properties of the material.

Incorrect Statement:

d) A eutectoid steel consists of wholly austenite.

Explanation:

Eutectoid steel is a type of steel that contains a eutectoid composition, which is approximately 0.76% carbon. It undergoes a phase transformation during heat treatment, where it is heated above the critical temperature (known as the upper critical temperature) and then cooled at a controlled rate. The phase transformation involves the formation of a mixture of ferrite and cementite known as pearlite.

During the heat treatment process, when the eutectoid steel is heated above the upper critical temperature (around 727°C for plain carbon steels), the existing microstructure (typically ferrite and pearlite) transforms into austenite, which is a face-centered cubic (FCC) crystal structure. This austenite is not wholly austenite, but rather a temporary phase formed during the heating process.

As the eutectoid steel is cooled, the austenite transforms back into a two-phase mixture of ferrite and cementite, known as pearlite. This transformation occurs at a specific temperature called the lower critical temperature. The resulting microstructure of eutectoid steel consists of ferrite and pearlite, not wholly austenite.

Therefore, statement d) is incorrect because a eutectoid steel does not consist of wholly austenite.

Heat treatment is a process used to alter the physical and mechanical properties of materials, specifically metals and alloys. It involves heating and cooling the material in a controlled manner to achieve the desired properties. The main purpose of heat treatment is indeed to change the mechanical properties of the material.

Incorrect Statement:

d) A eutectoid steel consists of wholly austenite.

Explanation:

Eutectoid steel is a type of steel that contains a eutectoid composition, which is approximately 0.76% carbon. It undergoes a phase transformation during heat treatment, where it is heated above the critical temperature (known as the upper critical temperature) and then cooled at a controlled rate. The phase transformation involves the formation of a mixture of ferrite and cementite known as pearlite.

During the heat treatment process, when the eutectoid steel is heated above the upper critical temperature (around 727°C for plain carbon steels), the existing microstructure (typically ferrite and pearlite) transforms into austenite, which is a face-centered cubic (FCC) crystal structure. This austenite is not wholly austenite, but rather a temporary phase formed during the heating process.

As the eutectoid steel is cooled, the austenite transforms back into a two-phase mixture of ferrite and cementite, known as pearlite. This transformation occurs at a specific temperature called the lower critical temperature. The resulting microstructure of eutectoid steel consists of ferrite and pearlite, not wholly austenite.

Therefore, statement d) is incorrect because a eutectoid steel does not consist of wholly austenite.

Killed steels- a)have minimum impurity level

- b)have almost zero percentage of phosphorus and sulphure

- c)are produced by LD process

- d)are free from oxygen

Correct answer is option 'D'. Can you explain this answer?

Killed steels

a)

have minimum impurity level

b)

have almost zero percentage of phosphorus and sulphure

c)

are produced by LD process

d)

are free from oxygen

|

Janhavi Datta answered |

Introduction:

Killed steels are a type of steel that is produced with a controlled amount of oxygen to ensure that the steel is free from any impurities. This process is essential to enhance the mechanical properties and overall quality of the steel.

Explanation:

Killed steels are produced by a specific steelmaking process known as the LD process, which stands for Linz-Donawitz process. This process involves the removal of impurities to obtain a high-quality steel product. There are several key characteristics of killed steels that make them desirable for various applications.

Minimum Impurity Level:

Killed steels have a minimum impurity level, which means they are produced with a controlled amount of impurities. Impurities, such as phosphorus and sulfur, can negatively affect the mechanical properties and overall quality of steel. Therefore, by minimizing the impurity level, killed steels offer improved strength, toughness, and weldability.

Zero Percentage of Phosphorus and Sulfur:

Killed steels have almost zero percentage of phosphorus and sulfur. Phosphorus can cause brittleness in steel, reducing its ductility and impact resistance. Similarly, sulfur can lead to the formation of sulfides, which can weaken the steel's structure. By minimizing these elements, killed steels ensure a high-quality product with enhanced mechanical properties.

LD Process:

The LD process is the most commonly used method for producing killed steels. In this process, a mixture of iron ore, limestone, and coke is fed into a blast furnace, where it is heated to high temperatures. This process helps to remove impurities, such as carbon, silicon, and manganese, from the molten iron. The molten iron is then transferred to a converter, where it is further refined and decarburized. The addition of a controlled amount of oxygen during the LD process ensures that all the impurities are removed, resulting in a high-quality steel product.

Free from Oxygen:

The key characteristic of killed steels is that they are free from oxygen. This is achieved by adding a deoxidizer, such as aluminum or silicon, to the molten steel. The deoxidizer reacts with the oxygen present in the steel, forming solid oxide compounds that float to the surface and are removed. This deoxidation process ensures that the steel is free from any residual oxygen, which can cause the formation of undesirable oxides and impede the steel's mechanical properties.

Conclusion:

In summary, killed steels are produced with a minimum impurity level and almost zero percentage of phosphorus and sulfur. They are manufactured using the LD process, which involves the removal of impurities to obtain a high-quality steel product. The key characteristic of killed steels is that they are free from oxygen, which is achieved by adding a deoxidizer during the steelmaking process. This ensures that the steel has improved mechanical properties and can be used for various applications.

Killed steels are a type of steel that is produced with a controlled amount of oxygen to ensure that the steel is free from any impurities. This process is essential to enhance the mechanical properties and overall quality of the steel.

Explanation:

Killed steels are produced by a specific steelmaking process known as the LD process, which stands for Linz-Donawitz process. This process involves the removal of impurities to obtain a high-quality steel product. There are several key characteristics of killed steels that make them desirable for various applications.

Minimum Impurity Level:

Killed steels have a minimum impurity level, which means they are produced with a controlled amount of impurities. Impurities, such as phosphorus and sulfur, can negatively affect the mechanical properties and overall quality of steel. Therefore, by minimizing the impurity level, killed steels offer improved strength, toughness, and weldability.

Zero Percentage of Phosphorus and Sulfur:

Killed steels have almost zero percentage of phosphorus and sulfur. Phosphorus can cause brittleness in steel, reducing its ductility and impact resistance. Similarly, sulfur can lead to the formation of sulfides, which can weaken the steel's structure. By minimizing these elements, killed steels ensure a high-quality product with enhanced mechanical properties.

LD Process:

The LD process is the most commonly used method for producing killed steels. In this process, a mixture of iron ore, limestone, and coke is fed into a blast furnace, where it is heated to high temperatures. This process helps to remove impurities, such as carbon, silicon, and manganese, from the molten iron. The molten iron is then transferred to a converter, where it is further refined and decarburized. The addition of a controlled amount of oxygen during the LD process ensures that all the impurities are removed, resulting in a high-quality steel product.

Free from Oxygen:

The key characteristic of killed steels is that they are free from oxygen. This is achieved by adding a deoxidizer, such as aluminum or silicon, to the molten steel. The deoxidizer reacts with the oxygen present in the steel, forming solid oxide compounds that float to the surface and are removed. This deoxidation process ensures that the steel is free from any residual oxygen, which can cause the formation of undesirable oxides and impede the steel's mechanical properties.

Conclusion:

In summary, killed steels are produced with a minimum impurity level and almost zero percentage of phosphorus and sulfur. They are manufactured using the LD process, which involves the removal of impurities to obtain a high-quality steel product. The key characteristic of killed steels is that they are free from oxygen, which is achieved by adding a deoxidizer during the steelmaking process. This ensures that the steel has improved mechanical properties and can be used for various applications.

The heat treatment process used for hardening of steel is- a)tempering

- b)quenching

- c)normalising

- d)annealing

Correct answer is option 'B'. Can you explain this answer?

The heat treatment process used for hardening of steel is

a)

tempering

b)

quenching

c)

normalising

d)

annealing

|

|

Raghav Saini answered |

Quenching:

Quenching is a heat treatment process used for hardening steel. It involves heating the steel to a specific temperature and then rapidly cooling it in a quenching medium, such as oil or water. This rapid cooling changes the structure of the steel, making it harder and stronger.

Process:

- The steel is heated to a temperature above its critical point, which varies depending on the type of steel.

- Once the steel reaches the desired temperature, it is quickly immersed in the quenching medium.

- The rapid cooling causes the formation of martensite, a hard and brittle microstructure, within the steel.

- The steel is then often tempered to reduce the brittleness and improve its toughness and ductility.

Benefits:

- Quenching increases the hardness and strength of the steel, making it suitable for applications where wear resistance and durability are important.

- It can be used to create a wide range of hardness levels, depending on the specific requirements of the application.

- Quenched steel has improved machinability and can be easily shaped and formed.

Applications:

- Quenching is commonly used in the production of tools, gears, springs, and other components that require high strength and wear resistance.

- It is also used in the automotive, aerospace, and construction industries to manufacture parts that need to withstand harsh operating conditions.

In conclusion, quenching is a vital heat treatment process for hardening steel, providing the necessary properties for various industrial applications.

Quenching is a heat treatment process used for hardening steel. It involves heating the steel to a specific temperature and then rapidly cooling it in a quenching medium, such as oil or water. This rapid cooling changes the structure of the steel, making it harder and stronger.

Process:

- The steel is heated to a temperature above its critical point, which varies depending on the type of steel.

- Once the steel reaches the desired temperature, it is quickly immersed in the quenching medium.

- The rapid cooling causes the formation of martensite, a hard and brittle microstructure, within the steel.

- The steel is then often tempered to reduce the brittleness and improve its toughness and ductility.

Benefits:

- Quenching increases the hardness and strength of the steel, making it suitable for applications where wear resistance and durability are important.

- It can be used to create a wide range of hardness levels, depending on the specific requirements of the application.

- Quenched steel has improved machinability and can be easily shaped and formed.

Applications:

- Quenching is commonly used in the production of tools, gears, springs, and other components that require high strength and wear resistance.

- It is also used in the automotive, aerospace, and construction industries to manufacture parts that need to withstand harsh operating conditions.

In conclusion, quenching is a vital heat treatment process for hardening steel, providing the necessary properties for various industrial applications.

The property of a material that cannot be significantly changed by heat treatment is- a)yield strength

- b)ultimate,tensile strength

- c)ductility

- d)elastic modulus

Correct answer is option 'D'. Can you explain this answer?

The property of a material that cannot be significantly changed by heat treatment is

a)

yield strength

b)

ultimate,tensile strength

c)

ductility

d)

elastic modulus

|

Aditi Sarkar answered |

The correct answer is option 'D', which states that the property of a material that cannot be significantly changed by heat treatment is the elastic modulus. Let's delve into the explanation below:

Heat treatment is a process that involves the controlled heating and cooling of a material to alter its properties. It is commonly used to improve mechanical properties such as strength, hardness, and ductility. However, there are certain properties of a material that remain relatively unaffected by heat treatment, and one of those properties is the elastic modulus.

The elastic modulus, also known as Young's modulus, is a measure of a material's stiffness or rigidity. It describes how much a material deforms under a given amount of stress. Mathematically, it is defined as the ratio of stress to strain within the elastic range of a material.

The elastic modulus is primarily determined by the nature of the atomic and molecular bonds within a material. These bonds define the material's inherent stiffness and are not significantly affected by heat treatment. Therefore, regardless of the heat treatment process applied, the elastic modulus of a material remains relatively constant.

Other material properties, such as yield strength, ultimate tensile strength, and ductility, can be significantly changed by heat treatment.

- Yield strength is the amount of stress a material can withstand before it starts to deform plastically. Heat treatment can alter the yield strength by modifying the material's microstructure, such as grain size and dislocation density.

- Ultimate tensile strength is the maximum stress a material can withstand before it fractures. Heat treatment can enhance the ultimate tensile strength by promoting the formation of stronger phases or by refining the microstructure.

- Ductility is the ability of a material to undergo plastic deformation before fracturing. Heat treatment can increase or decrease the ductility of a material depending on the specific heat treatment process employed.

In summary, while properties such as yield strength, ultimate tensile strength, and ductility can be significantly changed by heat treatment, the elastic modulus remains relatively constant regardless of the heat treatment process.

Heat treatment is a process that involves the controlled heating and cooling of a material to alter its properties. It is commonly used to improve mechanical properties such as strength, hardness, and ductility. However, there are certain properties of a material that remain relatively unaffected by heat treatment, and one of those properties is the elastic modulus.

The elastic modulus, also known as Young's modulus, is a measure of a material's stiffness or rigidity. It describes how much a material deforms under a given amount of stress. Mathematically, it is defined as the ratio of stress to strain within the elastic range of a material.

The elastic modulus is primarily determined by the nature of the atomic and molecular bonds within a material. These bonds define the material's inherent stiffness and are not significantly affected by heat treatment. Therefore, regardless of the heat treatment process applied, the elastic modulus of a material remains relatively constant.

Other material properties, such as yield strength, ultimate tensile strength, and ductility, can be significantly changed by heat treatment.

- Yield strength is the amount of stress a material can withstand before it starts to deform plastically. Heat treatment can alter the yield strength by modifying the material's microstructure, such as grain size and dislocation density.

- Ultimate tensile strength is the maximum stress a material can withstand before it fractures. Heat treatment can enhance the ultimate tensile strength by promoting the formation of stronger phases or by refining the microstructure.

- Ductility is the ability of a material to undergo plastic deformation before fracturing. Heat treatment can increase or decrease the ductility of a material depending on the specific heat treatment process employed.

In summary, while properties such as yield strength, ultimate tensile strength, and ductility can be significantly changed by heat treatment, the elastic modulus remains relatively constant regardless of the heat treatment process.

Which is false statement about annealing? Annealing is done to- a)relieve stresses

- b)harden steel slightly

- c)improve machining characteristics

- d)permit further cold working

Correct answer is option 'B'. Can you explain this answer?

Which is false statement about annealing? Annealing is done to

a)

relieve stresses

b)

harden steel slightly

c)

improve machining characteristics

d)

permit further cold working

|

|

Ruchi Ahuja answered |

False Statement about Annealing: Annealing does not harden steel slightly.

Annealing is a heat treatment process that involves heating a material, such as steel, to a specific temperature and then cooling it slowly to modify its properties. It is typically done to relieve stresses, improve machinability, and permit further cold working. However, the statement that annealing hardens steel slightly is false. Here's why:

- Relieve stresses: One of the primary purposes of annealing is to relieve internal stresses that may have built up in the material due to various manufacturing processes, such as casting, machining, or welding. These stresses can cause distortion, warping, or even material failure if not properly addressed.

- Improve machining characteristics: Annealing helps to enhance the machinability of the material by softening it, making it easier to cut, drill, or shape. It reduces the hardness and brittleness of the material, allowing for better tool life and improved surface finish during machining operations.

- Permit further cold working: Cold working refers to the process of deforming a metal below its recrystallization temperature, such as rolling, bending, or drawing. Annealing before cold working helps to restore the material's ductility and improve its ability to undergo plastic deformation without cracking or fracturing.

- Hardening of steel involves increasing its hardness and strength by subjecting it to a heat treatment process called quenching. During quenching, the steel is heated to a high temperature and then rapidly cooled by immersing it in a cooling medium, such as oil or water. This rapid cooling prevents the formation of large crystals and results in a hardened microstructure.

- Annealing, on the other hand, requires slow cooling to allow for the formation of larger crystals and to relieve internal stresses. The purpose is to soften the material, not to increase its hardness. Therefore, annealing does not harden steel slightly; it actually has the opposite effect.

In conclusion, annealing is a heat treatment process that relieves stresses, improves machining characteristics, and permits further cold working of materials like steel. However, it does not harden steel slightly. Hardening of steel is achieved through a different heat treatment process called quenching.

Explanation:

Annealing is a heat treatment process that involves heating a material, such as steel, to a specific temperature and then cooling it slowly to modify its properties. It is typically done to relieve stresses, improve machinability, and permit further cold working. However, the statement that annealing hardens steel slightly is false. Here's why:

1. Purpose of Annealing:

- Relieve stresses: One of the primary purposes of annealing is to relieve internal stresses that may have built up in the material due to various manufacturing processes, such as casting, machining, or welding. These stresses can cause distortion, warping, or even material failure if not properly addressed.

- Improve machining characteristics: Annealing helps to enhance the machinability of the material by softening it, making it easier to cut, drill, or shape. It reduces the hardness and brittleness of the material, allowing for better tool life and improved surface finish during machining operations.

- Permit further cold working: Cold working refers to the process of deforming a metal below its recrystallization temperature, such as rolling, bending, or drawing. Annealing before cold working helps to restore the material's ductility and improve its ability to undergo plastic deformation without cracking or fracturing.

2. Steel Hardening:

- Hardening of steel involves increasing its hardness and strength by subjecting it to a heat treatment process called quenching. During quenching, the steel is heated to a high temperature and then rapidly cooled by immersing it in a cooling medium, such as oil or water. This rapid cooling prevents the formation of large crystals and results in a hardened microstructure.

- Annealing, on the other hand, requires slow cooling to allow for the formation of larger crystals and to relieve internal stresses. The purpose is to soften the material, not to increase its hardness. Therefore, annealing does not harden steel slightly; it actually has the opposite effect.

In conclusion, annealing is a heat treatment process that relieves stresses, improves machining characteristics, and permits further cold working of materials like steel. However, it does not harden steel slightly. Hardening of steel is achieved through a different heat treatment process called quenching.

Which one of the following advantage of cyaniding is incorrect?- a)Distortion is more easily avoided

- b)Hardness change from case to core is gradual

- c)Flaking is eliminated

- d)Process can be used for high carbon steels

Correct answer is option 'D'. Can you explain this answer?

Which one of the following advantage of cyaniding is incorrect?

a)

Distortion is more easily avoided

b)

Hardness change from case to core is gradual

c)

Flaking is eliminated

d)

Process can be used for high carbon steels

|

|

Dishani Desai answered |

Understanding Cyaniding Process in Mechanical Engineering

Cyaniding is a surface hardening process that enhances the wear resistance of steel components. However, it has specific limitations regarding the types of materials it can be applied to.

Incorrect Advantage: Process Can Be Used for High Carbon Steels

- Cyaniding is not suitable for high carbon steels:

Cyaniding involves the absorption of carbon and nitrogen into the surface of the steel, creating a hardened layer. High carbon steels already possess a high carbon content, which can lead to excessive brittleness if subjected to the cyaniding process.

- Risk of brittleness and flaking:

When high carbon steels undergo cyaniding, the resulting microstructure may become too hard and brittle, increasing the risk of flaking or cracking under stress. This makes them less ideal candidates for this treatment.

- Best suited for low to medium carbon steels:

Cyaniding works best on low to medium carbon steels, where it can effectively improve surface hardness without compromising the overall toughness of the material.

Other Advantages of Cyaniding

- Distortion is more easily avoided:

The process is designed to minimize distortion during hardening.

- Hardness change from case to core is gradual:

This gradual transition ensures that the material maintains strength and ductility in the core.

- Flaking is eliminated:

The controlled nature of cyaniding reduces the likelihood of surface flaking.

In conclusion, while cyaniding offers several advantages in surface hardening, it is not suitable for high carbon steels due to the risk of brittleness. Understanding these limitations is crucial for engineers when selecting materials for specific applications.

Cyaniding is a surface hardening process that enhances the wear resistance of steel components. However, it has specific limitations regarding the types of materials it can be applied to.

Incorrect Advantage: Process Can Be Used for High Carbon Steels

- Cyaniding is not suitable for high carbon steels:

Cyaniding involves the absorption of carbon and nitrogen into the surface of the steel, creating a hardened layer. High carbon steels already possess a high carbon content, which can lead to excessive brittleness if subjected to the cyaniding process.

- Risk of brittleness and flaking:

When high carbon steels undergo cyaniding, the resulting microstructure may become too hard and brittle, increasing the risk of flaking or cracking under stress. This makes them less ideal candidates for this treatment.

- Best suited for low to medium carbon steels:

Cyaniding works best on low to medium carbon steels, where it can effectively improve surface hardness without compromising the overall toughness of the material.

Other Advantages of Cyaniding

- Distortion is more easily avoided:

The process is designed to minimize distortion during hardening.

- Hardness change from case to core is gradual:

This gradual transition ensures that the material maintains strength and ductility in the core.

- Flaking is eliminated:

The controlled nature of cyaniding reduces the likelihood of surface flaking.

In conclusion, while cyaniding offers several advantages in surface hardening, it is not suitable for high carbon steels due to the risk of brittleness. Understanding these limitations is crucial for engineers when selecting materials for specific applications.

Hardenability of steel is assessed by- a)impact-test

- b)jominy end-quenchtest

- c)hardness test

- d)non-destructive test

Correct answer is option 'B'. Can you explain this answer?

Hardenability of steel is assessed by

a)

impact-test

b)

jominy end-quenchtest

c)

hardness test

d)

non-destructive test

|

Nandita Datta answered |

Assessing the Hardenability of Steel

Jominy End-Quench Test:

The Jominy end-quench test is used to assess the hardenability of steel. It involves heating a cylindrical steel specimen to a specific temperature and then quenching it by spraying water on one end. The quenching process rapidly cools the steel, simulating the cooling conditions that occur during the hardening process. The test is named after Walter E. Jominy, who developed it in the early 20th century.

Procedure:

1. A cylindrical steel specimen is machined and prepared for testing.

2. The specimen is heated to a specific temperature, typically between 800°C and 950°C, depending on the type of steel.

3. Once the specimen reaches the desired temperature, it is quickly transferred to the Jominy end-quenching apparatus.

4. A water jet is directed onto one end of the specimen, rapidly cooling it.

5. After quenching, the specimen is sectioned longitudinally.

6. The hardness of the quenched specimen is measured at various distances from the quenched end.

7. The hardness values are plotted on a Jominy curve, which represents the hardness as a function of distance from the quenched end.

Interpretation:

The Jominy curve provides information about the hardenability of the steel. Hardenability refers to the ability of a steel alloy to be hardened by heat treatment. It indicates how deep and uniform the hardened layer will be after quenching.

The Jominy curve typically shows a decreasing trend in hardness as the distance from the quenched end increases. This is because the cooling rate decreases with distance, resulting in slower transformation of the steel structure. The hardness at various distances can be used to determine the critical cooling rate required for complete transformation and the depth of hardening.

Significance:

The Jominy end-quench test is crucial in the design and selection of steel materials for specific applications. It helps engineers and metallurgists understand the hardenability characteristics of different steel grades and their suitability for various manufacturing processes. By assessing the hardenability, manufacturers can optimize heat treatment processes and select appropriate steel grades to achieve the desired mechanical properties in the final product.

It is worth noting that while the Jominy end-quench test is an essential method for assessing hardenability, it is not the only test used. Other tests, such as impact tests, hardness tests, and non-destructive tests, may also be employed to provide a comprehensive evaluation of steel properties. However, in the context of assessing hardenability specifically, the Jominy end-quench test is the most appropriate option.

Jominy End-Quench Test:

The Jominy end-quench test is used to assess the hardenability of steel. It involves heating a cylindrical steel specimen to a specific temperature and then quenching it by spraying water on one end. The quenching process rapidly cools the steel, simulating the cooling conditions that occur during the hardening process. The test is named after Walter E. Jominy, who developed it in the early 20th century.

Procedure:

1. A cylindrical steel specimen is machined and prepared for testing.

2. The specimen is heated to a specific temperature, typically between 800°C and 950°C, depending on the type of steel.

3. Once the specimen reaches the desired temperature, it is quickly transferred to the Jominy end-quenching apparatus.

4. A water jet is directed onto one end of the specimen, rapidly cooling it.

5. After quenching, the specimen is sectioned longitudinally.

6. The hardness of the quenched specimen is measured at various distances from the quenched end.

7. The hardness values are plotted on a Jominy curve, which represents the hardness as a function of distance from the quenched end.

Interpretation:

The Jominy curve provides information about the hardenability of the steel. Hardenability refers to the ability of a steel alloy to be hardened by heat treatment. It indicates how deep and uniform the hardened layer will be after quenching.

The Jominy curve typically shows a decreasing trend in hardness as the distance from the quenched end increases. This is because the cooling rate decreases with distance, resulting in slower transformation of the steel structure. The hardness at various distances can be used to determine the critical cooling rate required for complete transformation and the depth of hardening.

Significance:

The Jominy end-quench test is crucial in the design and selection of steel materials for specific applications. It helps engineers and metallurgists understand the hardenability characteristics of different steel grades and their suitability for various manufacturing processes. By assessing the hardenability, manufacturers can optimize heat treatment processes and select appropriate steel grades to achieve the desired mechanical properties in the final product.

It is worth noting that while the Jominy end-quench test is an essential method for assessing hardenability, it is not the only test used. Other tests, such as impact tests, hardness tests, and non-destructive tests, may also be employed to provide a comprehensive evaluation of steel properties. However, in the context of assessing hardenability specifically, the Jominy end-quench test is the most appropriate option.

As per the TTT diagram, bainite will form in eutectoid plain carbon steel when heated to 8500C followed by- a)air-cooling to room temperature

- b)isothermal holding between eutectoid temperature and the nose

- c)quenching to room temperature

- d)isothermal holding between the nose and the Ms temperature

Correct answer is option 'D'. Can you explain this answer?

As per the TTT diagram, bainite will form in eutectoid plain carbon steel when heated to 8500C followed by

a)

air-cooling to room temperature

b)

isothermal holding between eutectoid temperature and the nose

c)

quenching to room temperature

d)

isothermal holding between the nose and the Ms temperature

|

|

Nayanika Yadav answered |

Bainite Formation in Eutectoid Plain Carbon Steel

The TTT (Time-Temperature-Transformation) diagram is a graph that represents the transformation of phases in a material as a function of time and temperature. It is widely used in materials science and metallurgy to predict and understand the microstructural changes that occur during heat treatment processes.

In the case of plain carbon steel, the TTT diagram provides information about the transformation of austenite (the high-temperature phase) into different microstructures such as pearlite, bainite, and martensite.

Bainite is a microstructure that forms in steel when it is cooled rapidly from the austenite phase to a temperature above the nose of the TTT diagram, followed by an isothermal hold at a temperature between the nose and the Ms (martensite start) temperature.

Now let's go through each option mentioned in the question and understand why option 'D' is the correct answer:

a) Air-cooling to room temperature:

- Air-cooling to room temperature does not involve any isothermal hold, which is required for bainite formation. Therefore, bainite cannot form under this condition.

b) Isothermal holding between eutectoid temperature and the nose:

- Isothermal holding between the eutectoid temperature and the nose of the TTT diagram results in the formation of pearlite, not bainite. This is because pearlite forms when the transformation occurs at a relatively higher temperature range compared to bainite.