All Exams >

Mechanical Engineering >

Mechanical Engineering SSC JE (Technical) >

All Questions

All questions of IC Engine for Mechanical Engineering Exam

In SI engines for higher thermal efficiency- a)compression ratio should be high

- b)heat liberation during combustion should be maximum

- c)surface to volume ratio should be high

- d)long flame travel distance

Correct answer is option 'A'. Can you explain this answer?

In SI engines for higher thermal efficiency

a)

compression ratio should be high

b)

heat liberation during combustion should be maximum

c)

surface to volume ratio should be high

d)

long flame travel distance

|

|

Avinash Mehta answered |

The high compression ratio of air creates high temperatures, which ensures the diesel fuel can self-ignite. .In the case of SI engines the lower compression ratio reduces their potential to achieve higher thermal efficiency

Which cycle consists of two reversible isotherms and two reversible isobars?- a)Carnot cycle

- b)Stirling cycle

- c)Ericsson cycle

- d)Brayton cycle

Correct answer is option 'C'. Can you explain this answer?

Which cycle consists of two reversible isotherms and two reversible isobars?

a)

Carnot cycle

b)

Stirling cycle

c)

Ericsson cycle

d)

Brayton cycle

|

Shivam Sharma answered |

The Ericsson cycle consists of two isothermal and two constant pressure processes.

The processes are:

Process 1-2: Reversible isothermal compression.

Process 2-3: Constant pressure heat addition.

Process 3-4: Reversible isothermal expansion.

Process 4-1: Constant pressure heat rejection.

The heat addition and rejection take place at constant pressure as well as isothermal processes. Since the process 2-3 and 3-4 are parallel to each other on the T-s diagram, the net effect is that the heat need to be added only at constant temperature T3=T4 and rejected at the constant temperature T1=T2. The cycle is shown on p-v and T-s diagrams in Fig.4.3. The advantage of the Ericsson cycle over the Carnot and Stirling cycles is its smaller pressure ratio for a given ratio of maximum to minimum specific volume with higher mean effective pressure.

The object of providing masked inlet valve in the air passes of compression ignition engines is to- a)enhance flow rate

- b)control air flow

- c)induce primary swirl

- d)induce secondary turbulence

Correct answer is option 'C'. Can you explain this answer?

The object of providing masked inlet valve in the air passes of compression ignition engines is to

a)

enhance flow rate

b)

control air flow

c)

induce primary swirl

d)

induce secondary turbulence

|

Shivam Sharma answered |

Induce primary swirl.

The objective of providing masked inlet valve in the air passage of compression ignition engine is to induce primary swirl.

For a conventional SI engine, the value of fuelair ratio in the normal operating range is- a)0.056 – 0.083

- b)0.083 – 0.56

- c)0.0056 – 0.83

- d)0.056 – 0.83

Correct answer is option 'A'. Can you explain this answer?

For a conventional SI engine, the value of fuelair ratio in the normal operating range is

a)

0.056 – 0.083

b)

0.083 – 0.56

c)

0.0056 – 0.83

d)

0.056 – 0.83

|

Swara Dasgupta answered |

Correct Option:(A)

Question Solution:

For SI Engines = Air fuel lies between 12 to 16

Most high speed compression engines operate on- a)Diesel cycle

- b)Otto cycle

- c)Gas turbine

- d)Dual combustion engine

Correct answer is option 'D'. Can you explain this answer?

Most high speed compression engines operate on

a)

Diesel cycle

b)

Otto cycle

c)

Gas turbine

d)

Dual combustion engine

|

Sarthak Kulkarni answered |

Most high speed compression engines operate on Dual combustion cycle

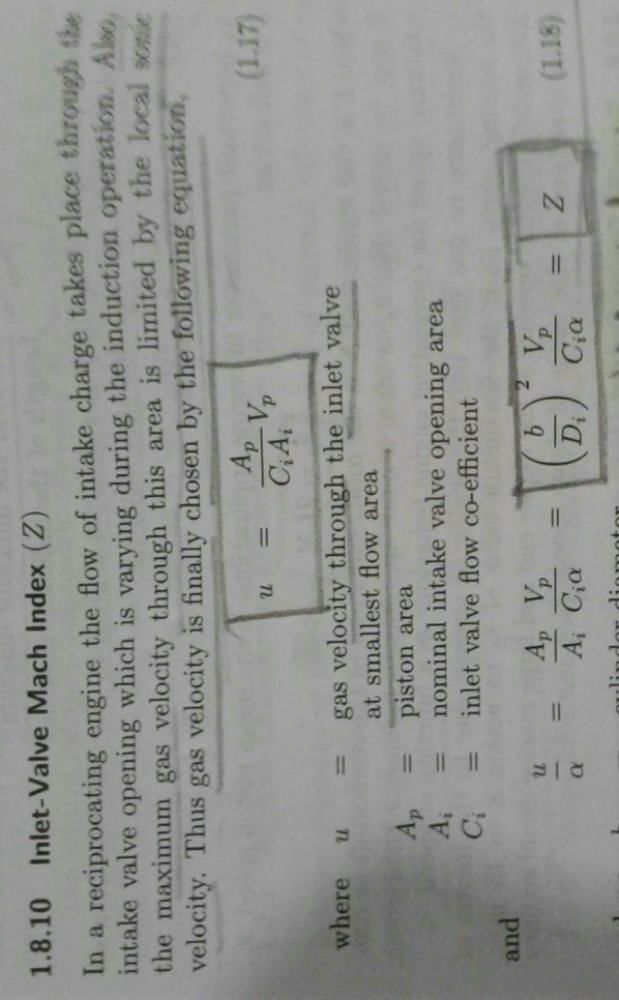

For maximum specific output of a constant volume cycle (Otto cycle)- a)the working fluid should be air

- b)the speed should be high

- c)suction temperature should be high

- d)temperature of the working fluid at the end of compression and expansion should be equal

Correct answer is option 'D'. Can you explain this answer?

For maximum specific output of a constant volume cycle (Otto cycle)

a)

the working fluid should be air

b)

the speed should be high

c)

suction temperature should be high

d)

temperature of the working fluid at the end of compression and expansion should be equal

|

Bijoy Kapoor answered |

Hence,(d) is correct option.

In the operation of four-stoke diesel engines, the term 'squish' refers to the- a)injection of fuel in the precombustion chamber

- b)discharge of gases from the precombustion chamber

- c)entry air into the combustion chamber

- d)stripping of fuel the core

Correct answer is option 'C'. Can you explain this answer?

In the operation of four-stoke diesel engines, the term 'squish' refers to the

a)

injection of fuel in the precombustion chamber

b)

discharge of gases from the precombustion chamber

c)

entry air into the combustion chamber

d)

stripping of fuel the core

|

|

Tanvi Shah answered |

Squish is the flow of air, radially inwards towards the combustion recess by squeezing it out from between the piston and cylinder head as they approach each other at the end of stroke.

The two reference fuels used for cetane rating are- a)cetane and iso-octane

- b)cetane and tetraethyl lead

- c)cetane and n-heptane

- d)cetane and a-methyl naphthalene

Correct answer is option 'D'. Can you explain this answer?

The two reference fuels used for cetane rating are

a)

cetane and iso-octane

b)

cetane and tetraethyl lead

c)

cetane and n-heptane

d)

cetane and a-methyl naphthalene

|

Shivam Sharma answered |

Cetane and alpha-methyl naphthalene are the reference fuels taken for cetane rating.

The stoichiometric air-fuel ratio for petrol is 15 : 1. what is the air-fuel ratio regarded for maximum power?

- a) 16 : 1 – 18 : 1

- b) 15 : 1 – 17 : 1

- c) 12 : 1 – 14 : 1

- d) 9 : 1 – 11 : 1

Correct answer is option 'C'. Can you explain this answer?

The stoichiometric air-fuel ratio for petrol is 15 : 1. what is the air-fuel ratio regarded for maximum power?

a)

16 : 1 – 18 : 1b)

15 : 1 – 17 : 1c)

12 : 1 – 14 : 1d)

9 : 1 – 11 : 1|

|

Rajeev Sharma answered |

A 'Stoichiometric' AFR has the correct amount of air and fuel to produce a chemically complete combustion event. For gasoline engines, the stoichiometric, A/F ratio is 14.7:1, which means 14.7 parts of air to one part of fuel. The stoichiometric AFR depends on fuel type-- for alcohol it is 6.4:1 and 14.5:1 for diesel.

Pistons of diesel engines are usually cooled by- a)Air

- b)Water

- c)Lubricating oil

- d)Fuel oil

Correct answer is option 'C'. Can you explain this answer?

Pistons of diesel engines are usually cooled by

a)

Air

b)

Water

c)

Lubricating oil

d)

Fuel oil

|

Bijoy Kapoor answered |

Lubrication Oil Cooling System

The lubrication oil, after lubricating the moving parts of the bearings will finally drop down to the sump tank of the engine. From the sump tank, the oil is pumped to the oil cooler for cooling. The controller will ensure that the oil becomes cooled to the required temperatures.

Depending on the engine, there may also be a turbocharger cooling oil system that uses its own cooling system. (The oil is different from the main engine, so it must not mix)

There will also be a cylinder lubrication system that injects small quantities of oil into the cylinder liners. This is for lubricating the rubbing surfaces between the piston rings and the cylinder liner. The oil is not circulated, so there is no necessity for cooling.

The tendency of knocking in CI engine reduced by- a)high self-ignition temperature of fuel

- b)decrease in jacket water temperature

- c)injection of fuel just before TDC

- d)decrease in injection pressure

Correct answer is option 'C'. Can you explain this answer?

The tendency of knocking in CI engine reduced by

a)

high self-ignition temperature of fuel

b)

decrease in jacket water temperature

c)

injection of fuel just before TDC

d)

decrease in injection pressure

|

|

Avik Ghosh answered |

The tendency of knocking in a Compression Ignition (CI) engine can be reduced by injecting fuel just before the Top Dead Center (TDC). This is the correct answer because it helps to control the combustion process and minimize the occurrence of knocking. Let's understand why this is the case in detail.

What is knocking in a CI engine?

Knocking refers to the undesirable phenomenon in CI engines where the air-fuel mixture ignites spontaneously at multiple points within the combustion chamber instead of being ignited by the spark plug. This creates high-pressure waves that collide with each other, resulting in a knocking sound. Knocking causes engine damage, decreased efficiency, and increased emissions.

How does injecting fuel just before TDC reduce knocking?

Injecting the fuel just before the TDC helps to control the combustion process and prevent knocking. Here's how it works:

1. Delaying ignition: By injecting the fuel just before TDC, the ignition delay period is increased. This delay allows the air-fuel mixture to mix more thoroughly, resulting in a more homogeneous mixture. A homogeneous mixture burns more uniformly and reduces the likelihood of knocking.

2. Reducing peak pressure: Injecting fuel just before TDC also helps in reducing the peak pressure inside the combustion chamber. When the fuel is injected earlier, it has more time to mix with the air, resulting in a higher peak pressure. This high pressure can lead to knocking. By injecting fuel just before TDC, the peak pressure is controlled, reducing the chances of knocking.

3. Optimizing combustion: Injecting fuel just before TDC allows for better control over the combustion process. The fuel can be injected in a way that promotes efficient and complete combustion, minimizing the formation of unburned fuel molecules that can contribute to knocking.

Other options and their effects:

Let's briefly discuss the other options mentioned in the question and their effects on knocking:

a) High self-ignition temperature of fuel: While high self-ignition temperature can reduce the chances of knocking, it is not as effective as injecting fuel just before TDC. High self-ignition temperature alone may not be sufficient to prevent knocking in all operating conditions.

b) Decrease in jacket water temperature: Decreasing the jacket water temperature can have some impact on reducing knocking by lowering the overall temperature inside the combustion chamber. However, this approach is not as effective as injecting fuel just before TDC.

d) Decrease in injection pressure: Decreasing the injection pressure can affect the fuel atomization and mixing, but it may not be as effective as injecting fuel just before TDC in reducing knocking.

In conclusion, injecting fuel just before the Top Dead Center (TDC) is an effective way to reduce the tendency of knocking in a Compression Ignition (CI) engine. It helps to control the combustion process, delay ignition, reduce peak pressure, and optimize combustion, resulting in a more efficient and reliable engine operation.

What is knocking in a CI engine?

Knocking refers to the undesirable phenomenon in CI engines where the air-fuel mixture ignites spontaneously at multiple points within the combustion chamber instead of being ignited by the spark plug. This creates high-pressure waves that collide with each other, resulting in a knocking sound. Knocking causes engine damage, decreased efficiency, and increased emissions.

How does injecting fuel just before TDC reduce knocking?

Injecting the fuel just before the TDC helps to control the combustion process and prevent knocking. Here's how it works:

1. Delaying ignition: By injecting the fuel just before TDC, the ignition delay period is increased. This delay allows the air-fuel mixture to mix more thoroughly, resulting in a more homogeneous mixture. A homogeneous mixture burns more uniformly and reduces the likelihood of knocking.

2. Reducing peak pressure: Injecting fuel just before TDC also helps in reducing the peak pressure inside the combustion chamber. When the fuel is injected earlier, it has more time to mix with the air, resulting in a higher peak pressure. This high pressure can lead to knocking. By injecting fuel just before TDC, the peak pressure is controlled, reducing the chances of knocking.

3. Optimizing combustion: Injecting fuel just before TDC allows for better control over the combustion process. The fuel can be injected in a way that promotes efficient and complete combustion, minimizing the formation of unburned fuel molecules that can contribute to knocking.

Other options and their effects:

Let's briefly discuss the other options mentioned in the question and their effects on knocking:

a) High self-ignition temperature of fuel: While high self-ignition temperature can reduce the chances of knocking, it is not as effective as injecting fuel just before TDC. High self-ignition temperature alone may not be sufficient to prevent knocking in all operating conditions.

b) Decrease in jacket water temperature: Decreasing the jacket water temperature can have some impact on reducing knocking by lowering the overall temperature inside the combustion chamber. However, this approach is not as effective as injecting fuel just before TDC.

d) Decrease in injection pressure: Decreasing the injection pressure can affect the fuel atomization and mixing, but it may not be as effective as injecting fuel just before TDC in reducing knocking.

In conclusion, injecting fuel just before the Top Dead Center (TDC) is an effective way to reduce the tendency of knocking in a Compression Ignition (CI) engine. It helps to control the combustion process, delay ignition, reduce peak pressure, and optimize combustion, resulting in a more efficient and reliable engine operation.

The operation of forcing additional air under pressure in the engine cylinder is known as- a)Scavenging

- b)Turbulence

- c)Supercharging

- d)Pre-ignition

Correct answer is option 'C'. Can you explain this answer?

The operation of forcing additional air under pressure in the engine cylinder is known as

a)

Scavenging

b)

Turbulence

c)

Supercharging

d)

Pre-ignition

|

Shivam Sharma answered |

CORRECT OPTION IS (C)

Supercharging is the operation of forcing additional air under pressure in the engine cylinder.

Supercharging is the operation of forcing additional air under pressure in the engine cylinder.

Air injected in IC engines refers to injection of- a)Air only

- b)Liquid fuel only

- c)Liquid fuel and air

- d)Supercharging air

Correct answer is option 'C'. Can you explain this answer?

Air injected in IC engines refers to injection of

a)

Air only

b)

Liquid fuel only

c)

Liquid fuel and air

d)

Supercharging air

|

|

Devansh Nambiar answered |

Air Injection in IC Engines

Air injection in IC engines refers to the process of injecting both liquid fuel and air into the combustion chamber of an engine. This process helps to improve the combustion efficiency of the engine, resulting in better fuel economy and reduced emissions. Let us understand this concept in detail.

Benefits of Air Injection in IC Engines

1. Improved Combustion Efficiency: The air injection system helps to mix the fuel and air in the combustion chamber in the right proportion, leading to better combustion efficiency. This results in better fuel economy and reduced emissions.

2. Reduced Emissions: The improved combustion efficiency leads to a reduction in emissions such as NOx and particulate matter. This makes the engine more environment-friendly.

3. Better Performance: Air injection can also improve the performance of the engine by increasing the power output and torque.

Types of Air Injection Systems

1. Direct Injection: In this system, air and fuel are injected separately into the combustion chamber. This system is commonly used in diesel engines.

2. Indirect Injection: In this system, the air and fuel are mixed outside the combustion chamber and then injected into the chamber. This system is commonly used in gasoline engines.

Conclusion

Air injection is an important process in IC engines that helps to improve combustion efficiency, reduce emissions, and improve overall engine performance. It is important to choose the right type of air injection system based on the engine type and application.

Air injection in IC engines refers to the process of injecting both liquid fuel and air into the combustion chamber of an engine. This process helps to improve the combustion efficiency of the engine, resulting in better fuel economy and reduced emissions. Let us understand this concept in detail.

Benefits of Air Injection in IC Engines

1. Improved Combustion Efficiency: The air injection system helps to mix the fuel and air in the combustion chamber in the right proportion, leading to better combustion efficiency. This results in better fuel economy and reduced emissions.

2. Reduced Emissions: The improved combustion efficiency leads to a reduction in emissions such as NOx and particulate matter. This makes the engine more environment-friendly.

3. Better Performance: Air injection can also improve the performance of the engine by increasing the power output and torque.

Types of Air Injection Systems

1. Direct Injection: In this system, air and fuel are injected separately into the combustion chamber. This system is commonly used in diesel engines.

2. Indirect Injection: In this system, the air and fuel are mixed outside the combustion chamber and then injected into the chamber. This system is commonly used in gasoline engines.

Conclusion

Air injection is an important process in IC engines that helps to improve combustion efficiency, reduce emissions, and improve overall engine performance. It is important to choose the right type of air injection system based on the engine type and application.

In some carburetors, meter rod and economiser device is used for- a)Cold starting

- b)idling

- c)power enrichment

- d)acceleration

Correct answer is option 'C'. Can you explain this answer?

In some carburetors, meter rod and economiser device is used for

a)

Cold starting

b)

idling

c)

power enrichment

d)

acceleration

|

Swara Dasgupta answered |

Economiser is basically a valve that remain closed at normal cruise operation and gets opened to supply rich mixture at full throttle peration. It regulates the additional fuel supply during full throttle operation. So, it can be called as power enrichment system.

Engine of different cylinder dimensions, power and speed are compared on the basis of- a)maximum pressure

- b)fuel consumption

- c)mean effective pressure

- d)unit power

Correct answer is option 'C'. Can you explain this answer?

Engine of different cylinder dimensions, power and speed are compared on the basis of

a)

maximum pressure

b)

fuel consumption

c)

mean effective pressure

d)

unit power

|

Anushka Bose answered |

Mean Effective Pressure (MEP) is considered as the most appropriate parameter for comparing engines of different cylinder dimensions, power, and speed. MEP is a measure of the average pressure exerted on the piston during the power stroke of the engine cycle. It provides an indication of the overall efficiency of the engine.

Mean Effective Pressure (MEP) as the most appropriate parameter:

1. Maximum Pressure:

- Maximum pressure is the highest pressure reached inside the cylinder during the combustion process.

- Comparing engines based on maximum pressure alone does not provide a comprehensive assessment of their performance.

- Engines with higher maximum pressures may not necessarily have better overall efficiency or power output.

2. Fuel Consumption:

- Fuel consumption is the amount of fuel consumed by the engine to produce a certain amount of power.

- Comparing engines based on fuel consumption alone does not give a complete picture of their efficiency.

- Engines with lower fuel consumption may not necessarily have higher power output or better overall performance.

3. Mean Effective Pressure:

- MEP represents the average pressure exerted on the piston during the power stroke.

- It takes into account the entire combustion process and provides a measure of the overall efficiency of the engine.

- Engines with higher MEP values indicate better utilization of fuel and higher power output.

- Comparing engines based on MEP allows for a fair assessment of their performance, regardless of their cylinder dimensions, power, and speed.

4. Unit Power:

- Unit power refers to the power output per unit displacement (such as kW/L or hp/L) of the engine.

- While unit power can provide an indication of the power density of the engine, it does not consider the efficiency or overall performance.

- Engines with higher unit power may not necessarily have higher overall efficiency or better performance.

In conclusion, Mean Effective Pressure (MEP) is the most appropriate parameter for comparing engines of different cylinder dimensions, power, and speed. It takes into account the overall efficiency and performance of the engine, providing a fair assessment of its capabilities.

Mean Effective Pressure (MEP) as the most appropriate parameter:

1. Maximum Pressure:

- Maximum pressure is the highest pressure reached inside the cylinder during the combustion process.

- Comparing engines based on maximum pressure alone does not provide a comprehensive assessment of their performance.

- Engines with higher maximum pressures may not necessarily have better overall efficiency or power output.

2. Fuel Consumption:

- Fuel consumption is the amount of fuel consumed by the engine to produce a certain amount of power.

- Comparing engines based on fuel consumption alone does not give a complete picture of their efficiency.

- Engines with lower fuel consumption may not necessarily have higher power output or better overall performance.

3. Mean Effective Pressure:

- MEP represents the average pressure exerted on the piston during the power stroke.

- It takes into account the entire combustion process and provides a measure of the overall efficiency of the engine.

- Engines with higher MEP values indicate better utilization of fuel and higher power output.

- Comparing engines based on MEP allows for a fair assessment of their performance, regardless of their cylinder dimensions, power, and speed.

4. Unit Power:

- Unit power refers to the power output per unit displacement (such as kW/L or hp/L) of the engine.

- While unit power can provide an indication of the power density of the engine, it does not consider the efficiency or overall performance.

- Engines with higher unit power may not necessarily have higher overall efficiency or better performance.

In conclusion, Mean Effective Pressure (MEP) is the most appropriate parameter for comparing engines of different cylinder dimensions, power, and speed. It takes into account the overall efficiency and performance of the engine, providing a fair assessment of its capabilities.

Methane burns with stoichiometric quantity of air. The air-fuel ratio by weight is- a)4

- b)14.7

- c)15

- d)17.16

Correct answer is option 'D'. Can you explain this answer?

Methane burns with stoichiometric quantity of air. The air-fuel ratio by weight is

a)

4

b)

14.7

c)

15

d)

17.16

|

|

Mrinalini Sharma answered |

**Answer:**

To determine the air-fuel ratio by weight, we need to calculate the mass of air required to burn one unit mass of methane.

The balanced chemical equation for the combustion of methane (CH4) is as follows:

CH4 + 2O2 -> CO2 + 2H2O

From the balanced equation, we can see that one mole of methane reacts with two moles of oxygen to produce one mole of carbon dioxide and two moles of water.

The molar mass of methane (CH4) is 16 g/mol, and the molar mass of oxygen (O2) is 32 g/mol.

Therefore, the mass of air required to burn one unit mass of methane can be calculated as follows:

Mass of air = (2 * Molar mass of oxygen) / Molar mass of methane

= (2 * 32 g/mol) / 16 g/mol

= 4 grams

So, the air-fuel ratio by weight is 4, which means that 4 grams of air is required to burn 1 gram of methane.

However, the given answer options do not include 4.

To convert the air-fuel ratio by weight to the air-fuel ratio by volume, we need to consider the molar volume of gases at standard temperature and pressure (STP).

At STP, one mole of gas occupies a volume of 22.4 liters.

The molar volume of air can be calculated as follows:

Molar volume of air = (2 * Molar volume of oxygen) + (79 * Molar volume of nitrogen)

= (2 * 22.4 liters/mol) + (79 * 22.4 liters/mol)

= 1592.8 liters/mol

The molar volume of methane can be calculated as follows:

Molar volume of methane = Molar volume of carbon dioxide

= 22.4 liters/mol

Therefore, the air-fuel ratio by volume can be calculated as follows:

Air-fuel ratio by volume = (Molar volume of air) / (Molar volume of methane)

= 1592.8 liters/mol / 22.4 liters/mol

= 71.2

The air-fuel ratio by volume is 71.2, which is equivalent to an air-fuel ratio by weight of 17.16 (since air is about 3.76 times heavier than methane).

Hence, the correct answer is option D) 17.16.

To determine the air-fuel ratio by weight, we need to calculate the mass of air required to burn one unit mass of methane.

The balanced chemical equation for the combustion of methane (CH4) is as follows:

CH4 + 2O2 -> CO2 + 2H2O

From the balanced equation, we can see that one mole of methane reacts with two moles of oxygen to produce one mole of carbon dioxide and two moles of water.

The molar mass of methane (CH4) is 16 g/mol, and the molar mass of oxygen (O2) is 32 g/mol.

Therefore, the mass of air required to burn one unit mass of methane can be calculated as follows:

Mass of air = (2 * Molar mass of oxygen) / Molar mass of methane

= (2 * 32 g/mol) / 16 g/mol

= 4 grams

So, the air-fuel ratio by weight is 4, which means that 4 grams of air is required to burn 1 gram of methane.

However, the given answer options do not include 4.

To convert the air-fuel ratio by weight to the air-fuel ratio by volume, we need to consider the molar volume of gases at standard temperature and pressure (STP).

At STP, one mole of gas occupies a volume of 22.4 liters.

The molar volume of air can be calculated as follows:

Molar volume of air = (2 * Molar volume of oxygen) + (79 * Molar volume of nitrogen)

= (2 * 22.4 liters/mol) + (79 * 22.4 liters/mol)

= 1592.8 liters/mol

The molar volume of methane can be calculated as follows:

Molar volume of methane = Molar volume of carbon dioxide

= 22.4 liters/mol

Therefore, the air-fuel ratio by volume can be calculated as follows:

Air-fuel ratio by volume = (Molar volume of air) / (Molar volume of methane)

= 1592.8 liters/mol / 22.4 liters/mol

= 71.2

The air-fuel ratio by volume is 71.2, which is equivalent to an air-fuel ratio by weight of 17.16 (since air is about 3.76 times heavier than methane).

Hence, the correct answer is option D) 17.16.

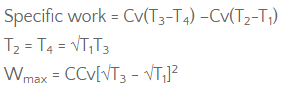

The correct sequence of the cycles given in the above T-s diagram is

- a)Vapour compression refrigeration, Rankine, Diesel, Brayton

- b)Rankine, Vapour compression refrigeration, Diesel, Brayton

- c)Rankine, Carnot, Otto, Brayton

- d)Vapour Compression refrigeration, Carnot, Diesel, Otto

Correct answer is option 'B'. Can you explain this answer?

The correct sequence of the cycles given in the above T-s diagram is

a)

Vapour compression refrigeration, Rankine, Diesel, Brayton

b)

Rankine, Vapour compression refrigeration, Diesel, Brayton

c)

Rankine, Carnot, Otto, Brayton

d)

Vapour Compression refrigeration, Carnot, Diesel, Otto

|

H C Rajpoot answered |

First cycle represents a power (work producing) cycle as it is CW cycle with a working fluid undergoing phase transformation which happens only in Rankine cycle

Second cycle represents a refrigeration (work consuming) cycle as it is CCW cycle with a working fluid undergoing phase transformation which happens only in vapor compression refrigeration cycle

Third cycle represents a power (work producing) cycle as it is CW cycle with isobaric heat addition and isochoric heat rejection which happens only in Diesel cycle

Fourth cycle represents a power (work producing) cycle as it is CW cycle with isobaric heat addition and isobaric heat rejection which happens only in Brayton cycle

Pick the odd one- a)2-stroke SI engine

- b)4-stroke SI engine

- c)CI engine

- d)Gas turbine

Correct answer is option 'D'. Can you explain this answer?

Pick the odd one

a)

2-stroke SI engine

b)

4-stroke SI engine

c)

CI engine

d)

Gas turbine

|

|

Anshul Sharma answered |

Explanation:

Odd one: Gas turbine

The odd one out in this list is the gas turbine. Let's analyze each option to understand why.

2-stroke SI engine:

- A 2-stroke SI (spark-ignition) engine is a type of internal combustion engine commonly used in motorcycles, marine engines, and small power equipment.

- It operates on the principle of two strokes (upward and downward movements of the piston) to complete one power cycle.

- The fuel-air mixture is ignited by a spark plug, and the resulting combustion drives the piston down, generating power.

- The intake and exhaust processes occur simultaneously, resulting in a simpler design and higher power-to-weight ratio compared to 4-stroke engines.

4-stroke SI engine:

- A 4-stroke SI engine is another type of internal combustion engine commonly used in automobiles, trucks, and other larger applications.

- It operates on the principle of four strokes (intake, compression, power, and exhaust) to complete one power cycle.

- The fuel-air mixture is drawn into the cylinder during the intake stroke, compressed during the compression stroke, ignited by a spark plug during the power stroke, and the resulting combustion drives the piston down, generating power.

- The exhaust stroke expels the burned gases from the cylinder.

- 4-stroke engines provide better fuel efficiency, smoother operation, and lower emissions compared to 2-stroke engines.

CI engine:

- A CI (compression-ignition) engine is also known as a diesel engine.

- It operates on the principle of compressing the air inside the cylinder to a high enough temperature that it ignites the fuel (diesel) without the need for a spark plug.

- The fuel is injected directly into the cylinder during the compression stroke, and the resulting combustion drives the piston down, generating power.

- CI engines are commonly used in heavy-duty applications such as trucks, buses, and construction equipment.

- They are known for their high torque output, fuel efficiency, and durability.

Gas turbine:

- A gas turbine is a type of engine that converts the energy of hot gases into mechanical power.

- It operates on the Brayton cycle, which consists of compressing air, adding fuel and igniting it, and then expanding the resulting gas to extract energy.

- Gas turbines are commonly used in power generation, aircraft propulsion, and industrial applications.

- Unlike internal combustion engines, gas turbines do not have pistons or cylinders.

- They have a continuous flow design, where the air is continuously compressed, mixed with fuel, and burned in a combustion chamber.

- Gas turbines are known for their high power output, compact size, and rapid start-up capabilities.

Conclusion:

The odd one out is the gas turbine because it is not an internal combustion engine like the other options. It operates on a different cycle and does not have pistons or cylinders.

Odd one: Gas turbine

The odd one out in this list is the gas turbine. Let's analyze each option to understand why.

2-stroke SI engine:

- A 2-stroke SI (spark-ignition) engine is a type of internal combustion engine commonly used in motorcycles, marine engines, and small power equipment.

- It operates on the principle of two strokes (upward and downward movements of the piston) to complete one power cycle.

- The fuel-air mixture is ignited by a spark plug, and the resulting combustion drives the piston down, generating power.

- The intake and exhaust processes occur simultaneously, resulting in a simpler design and higher power-to-weight ratio compared to 4-stroke engines.

4-stroke SI engine:

- A 4-stroke SI engine is another type of internal combustion engine commonly used in automobiles, trucks, and other larger applications.

- It operates on the principle of four strokes (intake, compression, power, and exhaust) to complete one power cycle.

- The fuel-air mixture is drawn into the cylinder during the intake stroke, compressed during the compression stroke, ignited by a spark plug during the power stroke, and the resulting combustion drives the piston down, generating power.

- The exhaust stroke expels the burned gases from the cylinder.

- 4-stroke engines provide better fuel efficiency, smoother operation, and lower emissions compared to 2-stroke engines.

CI engine:

- A CI (compression-ignition) engine is also known as a diesel engine.

- It operates on the principle of compressing the air inside the cylinder to a high enough temperature that it ignites the fuel (diesel) without the need for a spark plug.

- The fuel is injected directly into the cylinder during the compression stroke, and the resulting combustion drives the piston down, generating power.

- CI engines are commonly used in heavy-duty applications such as trucks, buses, and construction equipment.

- They are known for their high torque output, fuel efficiency, and durability.

Gas turbine:

- A gas turbine is a type of engine that converts the energy of hot gases into mechanical power.

- It operates on the Brayton cycle, which consists of compressing air, adding fuel and igniting it, and then expanding the resulting gas to extract energy.

- Gas turbines are commonly used in power generation, aircraft propulsion, and industrial applications.

- Unlike internal combustion engines, gas turbines do not have pistons or cylinders.

- They have a continuous flow design, where the air is continuously compressed, mixed with fuel, and burned in a combustion chamber.

- Gas turbines are known for their high power output, compact size, and rapid start-up capabilities.

Conclusion:

The odd one out is the gas turbine because it is not an internal combustion engine like the other options. It operates on a different cycle and does not have pistons or cylinders.

Where does mixing of fuel and air take place in case o diesel engine?- a)Injection pump

- b)Bronze

- c)Aluminium

- d)White metal

Correct answer is option 'A'. Can you explain this answer?

Where does mixing of fuel and air take place in case o diesel engine?

a)

Injection pump

b)

Bronze

c)

Aluminium

d)

White metal

|

|

Aditya Deshmukh answered |

An upgraded Fuel Lift Pump is a necessity once you start pushing your Cummins, Powerstroke, or Duramax-powered truck past the factory power levels. The injection pumps used in most diesel engines feed the can create up to 30,000 psi and need to maintain that pressure to ensure proper operation of the injectors.

By higher octane number of SI fuel, it is meant that the fuel has- a)higher heating value

- b)higher flash point

- c)lower volatility

- d)Longer ignition delay

Correct answer is option 'D'. Can you explain this answer?

By higher octane number of SI fuel, it is meant that the fuel has

a)

higher heating value

b)

higher flash point

c)

lower volatility

d)

Longer ignition delay

|

Sravya Rane answered |

Explanation:

1. Higher Octane Number:

- The octane number of a spark-ignition (SI) fuel is a measure of its resistance to knocking or pinging during combustion in an engine.

2. Longer Ignition Delay:

- A higher octane number indicates that the fuel has a longer ignition delay, which means that the fuel takes longer to ignite when exposed to high temperatures and pressures in the engine cylinder.

3. Ignition Delay:

- Ignition delay is the time interval between the start of injection and the start of combustion in the engine cylinder. A longer ignition delay helps prevent knocking or premature ignition, which can cause engine damage.

4. Benefits of Higher Octane Number:

- Using a fuel with a higher octane number allows for more precise control of the combustion process, resulting in improved engine performance, efficiency, and reliability.

5. Conclusion:

- Therefore, by having a higher octane number, an SI fuel has a longer ignition delay, which is beneficial for the overall performance and durability of the engine.

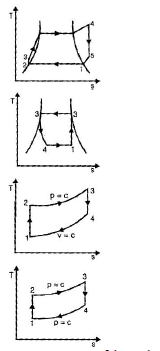

The correct sequence of the given four cycles on T-s plane in Figure (1), (2), (3), (4) is

- a)Ranking, Otto, Carnot and Diesel

- b)Rankine, Otto, Diesel and Carnot

- c)Otto, Rankine, Diesel and Carnot

- d)Otto, Rankine, Carnot and Diesel

Correct answer is option 'B'. Can you explain this answer?

The correct sequence of the given four cycles on T-s plane in Figure (1), (2), (3), (4) is

a)

Ranking, Otto, Carnot and Diesel

b)

Rankine, Otto, Diesel and Carnot

c)

Otto, Rankine, Diesel and Carnot

d)

Otto, Rankine, Carnot and Diesel

|

|

Durgesh Tiwari answered |

B

What is the purpose of supercharging an engine?- a)To increase the power output of engine

- b)To reduce specific fuel consumption

- c)To reduce the noise of the engine

- d)To improve cooling of cylinders

Correct answer is option 'A'. Can you explain this answer?

What is the purpose of supercharging an engine?

a)

To increase the power output of engine

b)

To reduce specific fuel consumption

c)

To reduce the noise of the engine

d)

To improve cooling of cylinders

|

Moumita Dasgupta answered |

Supercharging an Engine

Supercharging an engine refers to the process of increasing the power output of the engine by forcing more air into the combustion chamber. This is achieved by using a supercharger, which is a device that compresses the incoming air, increasing its density before it enters the engine.

There are several reasons why supercharging an engine is done, but the main purpose is to increase the power output of the engine. By forcing more air into the combustion chamber, more fuel can be burned, resulting in a larger and more powerful explosion. This leads to increased horsepower and torque, allowing the engine to produce more power.

Benefits of Supercharging

There are several benefits of supercharging an engine, which include:

1. Increased Power Output: Supercharging significantly increases the power output of the engine. This is particularly beneficial for high-performance vehicles, as it improves acceleration, top speed, and overall performance.

2. Improved Engine Response: Supercharging reduces the lag time between pressing the accelerator pedal and the engine delivering power. This results in improved throttle response and quicker acceleration.

3. Enhanced Torque: Supercharging increases the amount of torque produced by the engine, which is important for tasks such as towing or hauling heavy loads. The additional torque allows the engine to work more efficiently under heavy load conditions.

4. Higher Altitude Performance: Supercharging is especially advantageous at higher altitudes, where the air is thinner. By compressing the incoming air, a supercharger ensures that the engine receives a sufficient amount of oxygen for combustion, maintaining performance even at high altitudes.

5. Increased Engine Efficiency: While supercharging does increase the power output of the engine, it can also improve fuel efficiency. By increasing the amount of air available for combustion, the engine can burn fuel more efficiently, resulting in better fuel economy.

6. Flexibility: Supercharging provides flexibility in engine design as it allows for smaller engines to produce the same power as larger naturally aspirated engines. This can result in weight savings and improved vehicle packaging.

In conclusion, the purpose of supercharging an engine is primarily to increase its power output. This is achieved by compressing the incoming air, allowing for a larger amount of fuel to be burned and producing a more powerful explosion. Supercharging provides numerous benefits, including increased power, improved engine response, enhanced torque, higher altitude performance, increased engine efficiency, and flexibility in engine design.

Supercharging an engine refers to the process of increasing the power output of the engine by forcing more air into the combustion chamber. This is achieved by using a supercharger, which is a device that compresses the incoming air, increasing its density before it enters the engine.

There are several reasons why supercharging an engine is done, but the main purpose is to increase the power output of the engine. By forcing more air into the combustion chamber, more fuel can be burned, resulting in a larger and more powerful explosion. This leads to increased horsepower and torque, allowing the engine to produce more power.

Benefits of Supercharging

There are several benefits of supercharging an engine, which include:

1. Increased Power Output: Supercharging significantly increases the power output of the engine. This is particularly beneficial for high-performance vehicles, as it improves acceleration, top speed, and overall performance.

2. Improved Engine Response: Supercharging reduces the lag time between pressing the accelerator pedal and the engine delivering power. This results in improved throttle response and quicker acceleration.

3. Enhanced Torque: Supercharging increases the amount of torque produced by the engine, which is important for tasks such as towing or hauling heavy loads. The additional torque allows the engine to work more efficiently under heavy load conditions.

4. Higher Altitude Performance: Supercharging is especially advantageous at higher altitudes, where the air is thinner. By compressing the incoming air, a supercharger ensures that the engine receives a sufficient amount of oxygen for combustion, maintaining performance even at high altitudes.

5. Increased Engine Efficiency: While supercharging does increase the power output of the engine, it can also improve fuel efficiency. By increasing the amount of air available for combustion, the engine can burn fuel more efficiently, resulting in better fuel economy.

6. Flexibility: Supercharging provides flexibility in engine design as it allows for smaller engines to produce the same power as larger naturally aspirated engines. This can result in weight savings and improved vehicle packaging.

In conclusion, the purpose of supercharging an engine is primarily to increase its power output. This is achieved by compressing the incoming air, allowing for a larger amount of fuel to be burned and producing a more powerful explosion. Supercharging provides numerous benefits, including increased power, improved engine response, enhanced torque, higher altitude performance, increased engine efficiency, and flexibility in engine design.

The Stoichiometric air-fuel ratio by volume for combustion of carbon monoxide in air is- a)1.19

- b)2.38

- c)2.45

- d)4.76

Correct answer is option 'B'. Can you explain this answer?

The Stoichiometric air-fuel ratio by volume for combustion of carbon monoxide in air is

a)

1.19

b)

2.38

c)

2.45

d)

4.76

|

Bhargavi Sengupta answered |

Stoichiometric Air-Fuel Ratio for Combustion of Carbon Monoxide in Air

Stoichiometric air-fuel ratio is the ratio of air to fuel in a combustion process that produces complete combustion with no excess fuel or air. For combustion of carbon monoxide (CO) in air, the stoichiometric air-fuel ratio by volume is 2.38.

Explanation:

Combustion of carbon monoxide (CO) in air can be represented by the following balanced equation:

2CO + O2 → 2CO2

From the balanced equation, it can be seen that 2 moles of CO react with 1 mole of O2 to produce 2 moles of CO2.

To determine the stoichiometric air-fuel ratio, we need to calculate the amount of air required to completely combust 1 mole of CO.

1 mole of CO requires 0.5 mole of O2 for complete combustion (from the balanced equation above). Therefore, the air required for combustion of 1 mole of CO is:

Air required = 0.5 mole O2 + N2 (from air)

Assuming air contains 79% nitrogen (N2) and 21% oxygen (O2) by volume, we can calculate the volume of air required as:

Air required = (0.5/0.21) + (0.79/0.21) x 0.5

Air required = 2.38 volume of air

Therefore, the stoichiometric air-fuel ratio by volume for combustion of carbon monoxide in air is 2.38.

Conclusion:

The correct answer to the given question is option B (2.38). The stoichiometric air-fuel ratio is an important parameter in combustion processes as it affects the efficiency of the process and the emissions produced.

Stoichiometric air-fuel ratio is the ratio of air to fuel in a combustion process that produces complete combustion with no excess fuel or air. For combustion of carbon monoxide (CO) in air, the stoichiometric air-fuel ratio by volume is 2.38.

Explanation:

Combustion of carbon monoxide (CO) in air can be represented by the following balanced equation:

2CO + O2 → 2CO2

From the balanced equation, it can be seen that 2 moles of CO react with 1 mole of O2 to produce 2 moles of CO2.

To determine the stoichiometric air-fuel ratio, we need to calculate the amount of air required to completely combust 1 mole of CO.

1 mole of CO requires 0.5 mole of O2 for complete combustion (from the balanced equation above). Therefore, the air required for combustion of 1 mole of CO is:

Air required = 0.5 mole O2 + N2 (from air)

Assuming air contains 79% nitrogen (N2) and 21% oxygen (O2) by volume, we can calculate the volume of air required as:

Air required = (0.5/0.21) + (0.79/0.21) x 0.5

Air required = 2.38 volume of air

Therefore, the stoichiometric air-fuel ratio by volume for combustion of carbon monoxide in air is 2.38.

Conclusion:

The correct answer to the given question is option B (2.38). The stoichiometric air-fuel ratio is an important parameter in combustion processes as it affects the efficiency of the process and the emissions produced.

In spark ignition engines knocking can be reduced by:- a)Increasing the compression ratio

- b)Increasing the cooling water temperature

- c)retarding the spark advance

- d)increasing the inlet air temperature

Correct answer is option 'C'. Can you explain this answer?

In spark ignition engines knocking can be reduced by:

a)

Increasing the compression ratio

b)

Increasing the cooling water temperature

c)

retarding the spark advance

d)

increasing the inlet air temperature

|

|

Stuti Mishra answered |

Reducing knocking in spark ignition engines is crucial for improving engine performance and preventing damage to the engine components. Knocking, also known as detonation, is an undesirable phenomenon that occurs when the air-fuel mixture in the combustion chamber ignites spontaneously and unevenly, causing a knocking sound. This can lead to reduced engine efficiency, increased fuel consumption, and potential engine damage.

The correct answer to reducing knocking in spark ignition engines is option 'C', which suggests retarding the spark advance. The spark advance refers to the timing at which the spark plug ignites the air-fuel mixture in the combustion chamber. By retarding the spark advance, the ignition timing is delayed, ensuring that the combustion process occurs at the optimal moment for efficient and controlled burning of the fuel.

Here's a detailed explanation of why retarding the spark advance helps reduce knocking in spark ignition engines:

1. Understanding Knocking:

- Knocking occurs when the air-fuel mixture in the combustion chamber ignites prematurely, before the spark plug fires.

- This can happen due to several factors, including high compression ratio, high combustion chamber temperature, and low octane rating of the fuel.

- When the unburned mixture ignites, it creates a shockwave that collides with the expanding flame front, leading to pressure waves and vibrations that cause the knocking sound.

2. Effect of Spark Advance:

- The spark advance determines when the spark plug fires in relation to the piston position.

- Advancing the spark means firing it earlier in the compression stroke, allowing more time for complete combustion.

- However, advancing the spark too much can lead to knocking if the air-fuel mixture ignites prematurely.

3. Retarding the Spark Advance:

- Retarding the spark advance means delaying the ignition timing, firing the spark plug later in the compression stroke.

- By delaying the spark, the combustion process starts when the piston is closer to the top dead center, reducing the likelihood of premature ignition.

- This helps to avoid the collision between the unburned mixture and the expanding flame front, minimizing knocking.

4. Other Methods to Reduce Knocking:

- While retarding the spark advance is an effective method, other techniques can also help reduce knocking in spark ignition engines.

- Increasing the compression ratio can improve engine efficiency, but it can also increase the likelihood of knocking.

- Increasing the cooling water temperature and the inlet air temperature can help reduce knocking by reducing the overall combustion chamber temperature.

- These methods can help cool down the air-fuel mixture, making it less prone to spontaneous ignition.

In conclusion, retarding the spark advance is an effective way to reduce knocking in spark ignition engines. By delaying the ignition timing, the likelihood of premature combustion and knocking is minimized. However, it's important to note that other factors like compression ratio, combustion chamber temperature, and fuel quality also play a significant role in knocking, and addressing them collectively can further enhance engine performance and reliability.

The correct answer to reducing knocking in spark ignition engines is option 'C', which suggests retarding the spark advance. The spark advance refers to the timing at which the spark plug ignites the air-fuel mixture in the combustion chamber. By retarding the spark advance, the ignition timing is delayed, ensuring that the combustion process occurs at the optimal moment for efficient and controlled burning of the fuel.

Here's a detailed explanation of why retarding the spark advance helps reduce knocking in spark ignition engines:

1. Understanding Knocking:

- Knocking occurs when the air-fuel mixture in the combustion chamber ignites prematurely, before the spark plug fires.

- This can happen due to several factors, including high compression ratio, high combustion chamber temperature, and low octane rating of the fuel.

- When the unburned mixture ignites, it creates a shockwave that collides with the expanding flame front, leading to pressure waves and vibrations that cause the knocking sound.

2. Effect of Spark Advance:

- The spark advance determines when the spark plug fires in relation to the piston position.

- Advancing the spark means firing it earlier in the compression stroke, allowing more time for complete combustion.

- However, advancing the spark too much can lead to knocking if the air-fuel mixture ignites prematurely.

3. Retarding the Spark Advance:

- Retarding the spark advance means delaying the ignition timing, firing the spark plug later in the compression stroke.

- By delaying the spark, the combustion process starts when the piston is closer to the top dead center, reducing the likelihood of premature ignition.

- This helps to avoid the collision between the unburned mixture and the expanding flame front, minimizing knocking.

4. Other Methods to Reduce Knocking:

- While retarding the spark advance is an effective method, other techniques can also help reduce knocking in spark ignition engines.

- Increasing the compression ratio can improve engine efficiency, but it can also increase the likelihood of knocking.

- Increasing the cooling water temperature and the inlet air temperature can help reduce knocking by reducing the overall combustion chamber temperature.

- These methods can help cool down the air-fuel mixture, making it less prone to spontaneous ignition.

In conclusion, retarding the spark advance is an effective way to reduce knocking in spark ignition engines. By delaying the ignition timing, the likelihood of premature combustion and knocking is minimized. However, it's important to note that other factors like compression ratio, combustion chamber temperature, and fuel quality also play a significant role in knocking, and addressing them collectively can further enhance engine performance and reliability.

The purpose of balance weight in crankshaft is to- a)balance the rotating system

- b)time the valve train

- c)improve the net torque

- d)control the mean speed

Correct answer is option 'A'. Can you explain this answer?

The purpose of balance weight in crankshaft is to

a)

balance the rotating system

b)

time the valve train

c)

improve the net torque

d)

control the mean speed

|

|

Anirudh Banerjee answered |

Balance Weight in Crankshaft

The balance weight in a crankshaft is added to balance the rotating system. The crankshaft is an essential component of an engine as it converts the reciprocating motion of the piston into rotational motion. However, during operation, the mass of the piston and connecting rod creates an unbalanced force on the crankshaft. Without proper balancing, this unbalanced force can cause vibrations, leading to engine damage and reduced performance. The balance weight is added to counteract this force and provide a smooth, balanced rotation of the crankshaft.

Importance of balancing the rotating system

Balancing the rotating system is crucial to ensure proper engine operation and longevity. An unbalanced system can cause:

1. Vibration: An unbalanced system can cause vibrations that can lead to engine damage and reduced performance.

2. Noise: The unbalanced system can also produce noise and cause discomfort to the driver and passengers.

3. Wear and tear: Unbalanced forces can cause excessive wear and tear on engine components, leading to premature failure of parts.

4. Reduced efficiency: An unbalanced system can reduce engine efficiency, resulting in decreased power, fuel economy, and increased emissions.

Conclusion

The balance weight in a crankshaft plays a vital role in balancing the rotating system and ensuring proper engine operation. It is essential to maintain the balance of the crankshaft to prevent engine damage and reduce wear and tear on the engine components. Proper balancing also improves engine performance, fuel efficiency, and reduces emissions.

The balance weight in a crankshaft is added to balance the rotating system. The crankshaft is an essential component of an engine as it converts the reciprocating motion of the piston into rotational motion. However, during operation, the mass of the piston and connecting rod creates an unbalanced force on the crankshaft. Without proper balancing, this unbalanced force can cause vibrations, leading to engine damage and reduced performance. The balance weight is added to counteract this force and provide a smooth, balanced rotation of the crankshaft.

Importance of balancing the rotating system

Balancing the rotating system is crucial to ensure proper engine operation and longevity. An unbalanced system can cause:

1. Vibration: An unbalanced system can cause vibrations that can lead to engine damage and reduced performance.

2. Noise: The unbalanced system can also produce noise and cause discomfort to the driver and passengers.

3. Wear and tear: Unbalanced forces can cause excessive wear and tear on engine components, leading to premature failure of parts.

4. Reduced efficiency: An unbalanced system can reduce engine efficiency, resulting in decreased power, fuel economy, and increased emissions.

Conclusion

The balance weight in a crankshaft plays a vital role in balancing the rotating system and ensuring proper engine operation. It is essential to maintain the balance of the crankshaft to prevent engine damage and reduce wear and tear on the engine components. Proper balancing also improves engine performance, fuel efficiency, and reduces emissions.

Auto- ignition time for petrol-air mixture is minimum when the ratio of actual fuel-air ratio and chemically correct fuel-air ratio is- a)0.8

- b)1.0

- c)1.2

- d)1.5

Correct answer is option 'C'. Can you explain this answer?

Auto- ignition time for petrol-air mixture is minimum when the ratio of actual fuel-air ratio and chemically correct fuel-air ratio is

a)

0.8

b)

1.0

c)

1.2

d)

1.5

|

|

Saikat Choudhary answered |

Auto-Ignition Time for Petrol-Air Mixture

Auto-ignition time is the time required for the fuel-air mixture to ignite on its own without the need for a spark or any other external ignition source. This time can be affected by several factors, including the fuel-air ratio.

Chemically Correct Fuel-Air Ratio

The chemically correct fuel-air ratio is the theoretical ratio of fuel and air that would produce complete combustion without any excess fuel or air. For petrol, the chemically correct fuel-air ratio is about 14.7:1.

Actual Fuel-Air Ratio

The actual fuel-air ratio is the ratio of fuel and air that is present in the combustion chamber during operation. This ratio can be affected by several factors, including the fuel injection system, the air intake system, and the engine load.

Minimum Auto-Ignition Time

The minimum auto-ignition time occurs when the actual fuel-air ratio is slightly higher than the chemically correct fuel-air ratio. This is because a slightly richer mixture will ignite more easily and burn more completely, resulting in a shorter auto-ignition time.

Ratio of Actual Fuel-Air Ratio to Chemically Correct Fuel-Air Ratio

The ratio of actual fuel-air ratio to chemically correct fuel-air ratio is a measure of how rich or lean the mixture is relative to the theoretical ideal. A ratio of 1.0 indicates that the mixture is at the chemically correct ratio, while a ratio greater than 1.0 indicates a richer mixture and a ratio less than 1.0 indicates a leaner mixture.

Therefore, the correct answer is option C, 1.2, which indicates that the actual fuel-air ratio is slightly richer than the chemically correct ratio, resulting in a minimum auto-ignition time.

Auto-ignition time is the time required for the fuel-air mixture to ignite on its own without the need for a spark or any other external ignition source. This time can be affected by several factors, including the fuel-air ratio.

Chemically Correct Fuel-Air Ratio

The chemically correct fuel-air ratio is the theoretical ratio of fuel and air that would produce complete combustion without any excess fuel or air. For petrol, the chemically correct fuel-air ratio is about 14.7:1.

Actual Fuel-Air Ratio

The actual fuel-air ratio is the ratio of fuel and air that is present in the combustion chamber during operation. This ratio can be affected by several factors, including the fuel injection system, the air intake system, and the engine load.

Minimum Auto-Ignition Time

The minimum auto-ignition time occurs when the actual fuel-air ratio is slightly higher than the chemically correct fuel-air ratio. This is because a slightly richer mixture will ignite more easily and burn more completely, resulting in a shorter auto-ignition time.

Ratio of Actual Fuel-Air Ratio to Chemically Correct Fuel-Air Ratio

The ratio of actual fuel-air ratio to chemically correct fuel-air ratio is a measure of how rich or lean the mixture is relative to the theoretical ideal. A ratio of 1.0 indicates that the mixture is at the chemically correct ratio, while a ratio greater than 1.0 indicates a richer mixture and a ratio less than 1.0 indicates a leaner mixture.

Therefore, the correct answer is option C, 1.2, which indicates that the actual fuel-air ratio is slightly richer than the chemically correct ratio, resulting in a minimum auto-ignition time.

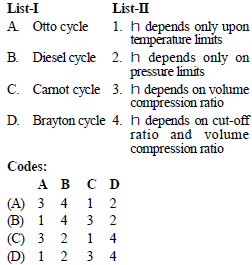

Match List-I (Cycle operating between fixed temperature limits) with List-II (Characteristics of cycle efficiency h temperature) and select correct answer using the codes given below the lists:

- a)A

- b)B

- c)C

- d)D

Correct answer is option 'A'. Can you explain this answer?

Match List-I (Cycle operating between fixed temperature limits) with List-II (Characteristics of cycle efficiency h temperature) and select correct answer using the codes given below the lists:

a)

A

b)

B

c)

C

d)

D

|

Kapil Shelke answered |

If you look at the P-V diagram of each of these cycles it is observed that

1. Otto cycle efficiency depends upon the compressed volume of the air fuel mixture.

2. Diesel cycle has heat addition at constant pressure and hear rejection at constant volume so efficiency depends upon these two factors.

3. Carnot cycle has nothing to do with pressure or volume for it's efficiency calculation. It simply depends upon the temperature difference between source and sink. More the difference more is the efficiency.

4. Brayton cycle heat addition and rejection takes place at constant pressure so efficiency depends upon pressure ratio.

Increase in the compression ratio in Otto cycle may cause- a)Misfiring

- b)Detonation

- c)Knocking

- d)longer ignition delay

Correct answer is option 'C'. Can you explain this answer?

Increase in the compression ratio in Otto cycle may cause

a)

Misfiring

b)

Detonation

c)

Knocking

d)

longer ignition delay

|

Simran Saha answered |

Introduction:

The compression ratio is an important parameter in the Otto cycle, which is used in spark-ignition engines. It is defined as the ratio of the maximum volume to the minimum volume in the cylinder during the compression stroke. Increasing the compression ratio can have several effects on the engine performance and operation.

Effects of increased compression ratio:

Increasing the compression ratio in the Otto cycle can lead to several undesirable consequences, including knocking.

1. Knocking:

Knocking is an undesirable phenomenon that occurs when the air-fuel mixture in the combustion chamber ignites spontaneously before the spark plug fires. This premature ignition causes a rapid and uncontrolled burning of the mixture, resulting in a knocking or pinging sound. Knocking can lead to engine damage and reduced performance.

Reason for knocking:

When the compression ratio is increased, the pressure and temperature in the combustion chamber also increase. This higher pressure and temperature can cause the air-fuel mixture to autoignite before the spark plug fires. This spontaneous combustion can create pressure waves that collide with the rising piston, resulting in the knocking sound.

Prevention of knocking:

To prevent knocking, it is important to select a compression ratio that is suitable for the fuel being used. The octane rating of the fuel plays a crucial role in determining its resistance to knocking. Fuels with higher octane ratings have higher resistance to knocking. Additionally, using fuel additives or adjusting the ignition timing can also help reduce or eliminate knocking.

Other effects of increased compression ratio:

While knocking is the most significant consequence of increased compression ratio, there are a few other effects that may also occur:

1. Misfiring:

If the compression ratio is increased excessively, it can lead to misfiring. Misfiring occurs when the air-fuel mixture fails to ignite properly or at the right time. This can result in engine hesitation, rough idling, and decreased power output.

2. Detonation:

Detonation is similar to knocking but occurs at higher temperatures and pressures. It is a more severe form of knocking and can cause significant engine damage. Detonation can occur when the compression ratio is too high, leading to spontaneous and uncontrolled combustion.

3. Longer ignition delay:

Increasing the compression ratio can also result in a longer ignition delay. The ignition delay is the time between the spark plug firing and the start of combustion. A longer ignition delay can lead to inefficient combustion and increased emissions.

Conclusion:

Increasing the compression ratio in the Otto cycle can have several consequences, including knocking, misfiring, detonation, and longer ignition delay. These effects can lead to decreased engine performance, increased emissions, and potential engine damage. It is important to carefully select the compression ratio based on the fuel being used and take necessary measures to prevent knocking and other undesirable phenomena.

The compression ratio is an important parameter in the Otto cycle, which is used in spark-ignition engines. It is defined as the ratio of the maximum volume to the minimum volume in the cylinder during the compression stroke. Increasing the compression ratio can have several effects on the engine performance and operation.

Effects of increased compression ratio:

Increasing the compression ratio in the Otto cycle can lead to several undesirable consequences, including knocking.

1. Knocking:

Knocking is an undesirable phenomenon that occurs when the air-fuel mixture in the combustion chamber ignites spontaneously before the spark plug fires. This premature ignition causes a rapid and uncontrolled burning of the mixture, resulting in a knocking or pinging sound. Knocking can lead to engine damage and reduced performance.

Reason for knocking:

When the compression ratio is increased, the pressure and temperature in the combustion chamber also increase. This higher pressure and temperature can cause the air-fuel mixture to autoignite before the spark plug fires. This spontaneous combustion can create pressure waves that collide with the rising piston, resulting in the knocking sound.

Prevention of knocking:

To prevent knocking, it is important to select a compression ratio that is suitable for the fuel being used. The octane rating of the fuel plays a crucial role in determining its resistance to knocking. Fuels with higher octane ratings have higher resistance to knocking. Additionally, using fuel additives or adjusting the ignition timing can also help reduce or eliminate knocking.

Other effects of increased compression ratio:

While knocking is the most significant consequence of increased compression ratio, there are a few other effects that may also occur:

1. Misfiring:

If the compression ratio is increased excessively, it can lead to misfiring. Misfiring occurs when the air-fuel mixture fails to ignite properly or at the right time. This can result in engine hesitation, rough idling, and decreased power output.

2. Detonation:

Detonation is similar to knocking but occurs at higher temperatures and pressures. It is a more severe form of knocking and can cause significant engine damage. Detonation can occur when the compression ratio is too high, leading to spontaneous and uncontrolled combustion.

3. Longer ignition delay:

Increasing the compression ratio can also result in a longer ignition delay. The ignition delay is the time between the spark plug firing and the start of combustion. A longer ignition delay can lead to inefficient combustion and increased emissions.

Conclusion:

Increasing the compression ratio in the Otto cycle can have several consequences, including knocking, misfiring, detonation, and longer ignition delay. These effects can lead to decreased engine performance, increased emissions, and potential engine damage. It is important to carefully select the compression ratio based on the fuel being used and take necessary measures to prevent knocking and other undesirable phenomena.

Gudgeon pin forms the link between- a)piston and big end of connecting rod

- b)piston and small end of connecting rod

- c)connecting rod and crank

- d)big end and small end

Correct answer is option 'B'. Can you explain this answer?

Gudgeon pin forms the link between

a)

piston and big end of connecting rod

b)

piston and small end of connecting rod

c)

connecting rod and crank

d)

big end and small end

|

|

Ananya Kumari answered |

Gudgeon pin forms the link between

connecting rod and rank ans

connecting rod and rank ans

Chapter doubts & questions for IC Engine - Mechanical Engineering SSC JE (Technical) 2025 is part of Mechanical Engineering exam preparation. The chapters have been prepared according to the Mechanical Engineering exam syllabus. The Chapter doubts & questions, notes, tests & MCQs are made for Mechanical Engineering 2025 Exam. Find important definitions, questions, notes, meanings, examples, exercises, MCQs and online tests here.

Chapter doubts & questions of IC Engine - Mechanical Engineering SSC JE (Technical) in English & Hindi are available as part of Mechanical Engineering exam.

Download more important topics, notes, lectures and mock test series for Mechanical Engineering Exam by signing up for free.

Mechanical Engineering SSC JE (Technical)

6 videos|104 docs|59 tests

|

Contact Support

Our team is online on weekdays between 10 AM - 7 PM

Typical reply within 3 hours

|

Free Exam Preparation

at your Fingertips!

Access Free Study Material - Test Series, Structured Courses, Free Videos & Study Notes and Prepare for Your Exam With Ease

Join the 10M+ students on EduRev

Join the 10M+ students on EduRev

|

|

Create your account for free

OR

Forgot Password

OR

Signup to see your scores

go up

within 7 days!

within 7 days!

Takes less than 10 seconds to signup