Railways Exam > Railways Questions > In case of centrifugal pumps, the starting to...

Start Learning for Free

In case of centrifugal pumps, the starting torque is usually:

- a)Less than running torque

- b)Same as running torque

- c)Slightly higher than running torque

- d)Double of running torque

Correct answer is option 'A'. Can you explain this answer?

| FREE This question is part of | Download PDF Attempt this Test |

Verified Answer

In case of centrifugal pumps, the starting torque is usually:a)Less th...

Starting torque is the torque transferred by the shaft coupling during run-up. In case of centrifugal pumps, the starting torque is usually less than running torque.

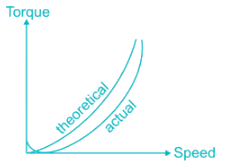

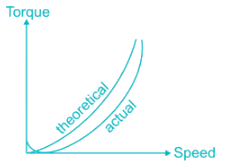

The speed torque characteristic of a centrifugal pump is a parabola starting from the origin and proportional to the square of the speed and curve is shown below.

Most Upvoted Answer

In case of centrifugal pumps, the starting torque is usually:a)Less th...

Starting torque in centrifugal pumps

Starting torque refers to the amount of torque required to start a motor or pump from a stationary position. In the case of centrifugal pumps, the starting torque is usually less than the running torque.

Explanation:

1. How centrifugal pumps work:

Centrifugal pumps are widely used in various industries to transport fluids. They work based on the principle of centrifugal force. When the pump is operational, the impeller rotates, creating a centrifugal force that pushes the fluid towards the outer edge of the impeller. This creates a low-pressure region at the center of the impeller, causing the fluid to be drawn into the pump. The fluid is then discharged at a higher pressure through the pump's outlet.

2. Starting torque:

When a centrifugal pump is started, it requires a certain amount of torque to overcome the initial static friction and inertia of the rotating components. This torque is known as the starting torque. It is needed to get the pump up and running from a stationary position.

3. Factors influencing starting torque:

Several factors affect the starting torque of a centrifugal pump, including:

- Size and weight of the impeller

- Fluid viscosity

- Pump design and efficiency

- Inertia of the rotating components

4. Relationship between starting torque and running torque:

The running torque refers to the amount of torque required to maintain the pump's operation at a constant speed once it is up and running. In centrifugal pumps, the starting torque is usually less than the running torque. This is because once the pump is in motion, the fluid flow helps to reduce the static friction and inertia, thereby reducing the torque required to keep the pump running.

5. Importance of lower starting torque:

Having a lower starting torque is beneficial for several reasons:

- It reduces the strain on the motor and pump components during startup, leading to longer equipment life.

- It requires less electrical power to start the pump, resulting in energy savings.

- It allows for smoother and more gradual acceleration, minimizing the risk of sudden pressure surges or water hammer.

Conclusion:

In conclusion, the starting torque in centrifugal pumps is usually less than the running torque. This is because once the pump is in motion, the fluid flow assists in reducing the static friction and inertia, resulting in a lower torque requirement. Lower starting torque is advantageous for the pump's longevity, energy efficiency, and overall operational performance.

Starting torque refers to the amount of torque required to start a motor or pump from a stationary position. In the case of centrifugal pumps, the starting torque is usually less than the running torque.

Explanation:

1. How centrifugal pumps work:

Centrifugal pumps are widely used in various industries to transport fluids. They work based on the principle of centrifugal force. When the pump is operational, the impeller rotates, creating a centrifugal force that pushes the fluid towards the outer edge of the impeller. This creates a low-pressure region at the center of the impeller, causing the fluid to be drawn into the pump. The fluid is then discharged at a higher pressure through the pump's outlet.

2. Starting torque:

When a centrifugal pump is started, it requires a certain amount of torque to overcome the initial static friction and inertia of the rotating components. This torque is known as the starting torque. It is needed to get the pump up and running from a stationary position.

3. Factors influencing starting torque:

Several factors affect the starting torque of a centrifugal pump, including:

- Size and weight of the impeller

- Fluid viscosity

- Pump design and efficiency

- Inertia of the rotating components

4. Relationship between starting torque and running torque:

The running torque refers to the amount of torque required to maintain the pump's operation at a constant speed once it is up and running. In centrifugal pumps, the starting torque is usually less than the running torque. This is because once the pump is in motion, the fluid flow helps to reduce the static friction and inertia, thereby reducing the torque required to keep the pump running.

5. Importance of lower starting torque:

Having a lower starting torque is beneficial for several reasons:

- It reduces the strain on the motor and pump components during startup, leading to longer equipment life.

- It requires less electrical power to start the pump, resulting in energy savings.

- It allows for smoother and more gradual acceleration, minimizing the risk of sudden pressure surges or water hammer.

Conclusion:

In conclusion, the starting torque in centrifugal pumps is usually less than the running torque. This is because once the pump is in motion, the fluid flow assists in reducing the static friction and inertia, resulting in a lower torque requirement. Lower starting torque is advantageous for the pump's longevity, energy efficiency, and overall operational performance.

Attention Railways Students!

To make sure you are not studying endlessly, EduRev has designed Railways study material, with Structured Courses, Videos, & Test Series. Plus get personalized analysis, doubt solving and improvement plans to achieve a great score in Railways.

|

Explore Courses for Railways exam

|

|

Similar Railways Doubts

In case of centrifugal pumps, the starting torque is usually:a)Less than running torqueb)Same as running torquec)Slightly higher than running torqued)Double of running torqueCorrect answer is option 'A'. Can you explain this answer?

Question Description

In case of centrifugal pumps, the starting torque is usually:a)Less than running torqueb)Same as running torquec)Slightly higher than running torqued)Double of running torqueCorrect answer is option 'A'. Can you explain this answer? for Railways 2024 is part of Railways preparation. The Question and answers have been prepared according to the Railways exam syllabus. Information about In case of centrifugal pumps, the starting torque is usually:a)Less than running torqueb)Same as running torquec)Slightly higher than running torqued)Double of running torqueCorrect answer is option 'A'. Can you explain this answer? covers all topics & solutions for Railways 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for In case of centrifugal pumps, the starting torque is usually:a)Less than running torqueb)Same as running torquec)Slightly higher than running torqued)Double of running torqueCorrect answer is option 'A'. Can you explain this answer?.

In case of centrifugal pumps, the starting torque is usually:a)Less than running torqueb)Same as running torquec)Slightly higher than running torqued)Double of running torqueCorrect answer is option 'A'. Can you explain this answer? for Railways 2024 is part of Railways preparation. The Question and answers have been prepared according to the Railways exam syllabus. Information about In case of centrifugal pumps, the starting torque is usually:a)Less than running torqueb)Same as running torquec)Slightly higher than running torqued)Double of running torqueCorrect answer is option 'A'. Can you explain this answer? covers all topics & solutions for Railways 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for In case of centrifugal pumps, the starting torque is usually:a)Less than running torqueb)Same as running torquec)Slightly higher than running torqued)Double of running torqueCorrect answer is option 'A'. Can you explain this answer?.

Solutions for In case of centrifugal pumps, the starting torque is usually:a)Less than running torqueb)Same as running torquec)Slightly higher than running torqued)Double of running torqueCorrect answer is option 'A'. Can you explain this answer? in English & in Hindi are available as part of our courses for Railways.

Download more important topics, notes, lectures and mock test series for Railways Exam by signing up for free.

Here you can find the meaning of In case of centrifugal pumps, the starting torque is usually:a)Less than running torqueb)Same as running torquec)Slightly higher than running torqued)Double of running torqueCorrect answer is option 'A'. Can you explain this answer? defined & explained in the simplest way possible. Besides giving the explanation of

In case of centrifugal pumps, the starting torque is usually:a)Less than running torqueb)Same as running torquec)Slightly higher than running torqued)Double of running torqueCorrect answer is option 'A'. Can you explain this answer?, a detailed solution for In case of centrifugal pumps, the starting torque is usually:a)Less than running torqueb)Same as running torquec)Slightly higher than running torqued)Double of running torqueCorrect answer is option 'A'. Can you explain this answer? has been provided alongside types of In case of centrifugal pumps, the starting torque is usually:a)Less than running torqueb)Same as running torquec)Slightly higher than running torqued)Double of running torqueCorrect answer is option 'A'. Can you explain this answer? theory, EduRev gives you an

ample number of questions to practice In case of centrifugal pumps, the starting torque is usually:a)Less than running torqueb)Same as running torquec)Slightly higher than running torqued)Double of running torqueCorrect answer is option 'A'. Can you explain this answer? tests, examples and also practice Railways tests.

|

Explore Courses for Railways exam

|

|

Suggested Free Tests

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.