Mechanical Engineering Exam > Mechanical Engineering Questions > Which of the following work material has high...

Start Learning for Free

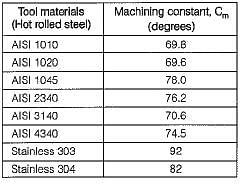

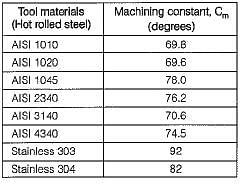

Which of the following work material has highest machining constant?

- a)High carbon steel

- b)Stainless 303

- c)Stainless 304

- d)AISI 1045

Correct answer is option 'B'. Can you explain this answer?

| FREE This question is part of | Download PDF Attempt this Test |

Verified Answer

Which of the following work material has highest machining constant?a)...

Most Upvoted Answer

Which of the following work material has highest machining constant?a)...

Overview:

The machining constant is a measure of the machinability of a material. It represents the amount of power required to remove a unit volume of material during machining operations. A higher machining constant indicates a higher level of difficulty in machining the material.

Explanation:

To determine which work material has the highest machining constant among the options provided, we need to consider the properties of each material.

a) High carbon steel:

High carbon steel is known for its hardness and wear resistance. It contains a higher percentage of carbon compared to other steels, which contributes to its strength. However, high carbon steel can be challenging to machine due to its hardness. The high carbon content can lead to increased tool wear and higher cutting forces, resulting in a higher machining constant.

b) Stainless 303:

Stainless 303 is a free-machining grade of stainless steel. It contains sulfur, which improves its machinability by promoting chip breaking and reducing tool wear. Stainless 303 is often used in applications that require excellent machining characteristics. Its lower carbon content compared to high carbon steel results in a lower machining constant.

c) Stainless 304:

Stainless 304 is a commonly used austenitic stainless steel with good corrosion resistance. It has a higher chromium content than stainless 303, providing better resistance to oxidation and scaling at high temperatures. However, stainless 304 has a lower sulfur content, which can make it slightly more challenging to machine compared to stainless 303. Therefore, stainless 304 would have a higher machining constant than stainless 303.

d) AISI 1045:

AISI 1045 is a medium carbon steel known for its good strength and impact toughness. It is often used in applications that require high strength and wear resistance. While AISI 1045 is a machinable steel, its higher carbon content compared to stainless 303 and 304 would result in a higher machining constant.

Conclusion:

Among the given options, stainless 303 has the highest machining constant. This is because stainless 303 is specifically designed to have excellent machinability due to the presence of sulfur, which promotes chip breaking and reduces tool wear. High carbon steel and AISI 1045 have higher carbon contents, making them more difficult to machine and resulting in higher machining constants. Stainless 304, although similar to stainless 303, has a lower sulfur content, making it slightly more challenging to machine and giving it a higher machining constant than stainless 303.

The machining constant is a measure of the machinability of a material. It represents the amount of power required to remove a unit volume of material during machining operations. A higher machining constant indicates a higher level of difficulty in machining the material.

Explanation:

To determine which work material has the highest machining constant among the options provided, we need to consider the properties of each material.

a) High carbon steel:

High carbon steel is known for its hardness and wear resistance. It contains a higher percentage of carbon compared to other steels, which contributes to its strength. However, high carbon steel can be challenging to machine due to its hardness. The high carbon content can lead to increased tool wear and higher cutting forces, resulting in a higher machining constant.

b) Stainless 303:

Stainless 303 is a free-machining grade of stainless steel. It contains sulfur, which improves its machinability by promoting chip breaking and reducing tool wear. Stainless 303 is often used in applications that require excellent machining characteristics. Its lower carbon content compared to high carbon steel results in a lower machining constant.

c) Stainless 304:

Stainless 304 is a commonly used austenitic stainless steel with good corrosion resistance. It has a higher chromium content than stainless 303, providing better resistance to oxidation and scaling at high temperatures. However, stainless 304 has a lower sulfur content, which can make it slightly more challenging to machine compared to stainless 303. Therefore, stainless 304 would have a higher machining constant than stainless 303.

d) AISI 1045:

AISI 1045 is a medium carbon steel known for its good strength and impact toughness. It is often used in applications that require high strength and wear resistance. While AISI 1045 is a machinable steel, its higher carbon content compared to stainless 303 and 304 would result in a higher machining constant.

Conclusion:

Among the given options, stainless 303 has the highest machining constant. This is because stainless 303 is specifically designed to have excellent machinability due to the presence of sulfur, which promotes chip breaking and reduces tool wear. High carbon steel and AISI 1045 have higher carbon contents, making them more difficult to machine and resulting in higher machining constants. Stainless 304, although similar to stainless 303, has a lower sulfur content, making it slightly more challenging to machine and giving it a higher machining constant than stainless 303.

Free Test

FREE

| Start Free Test |

Community Answer

Which of the following work material has highest machining constant?a)...

Attention Mechanical Engineering Students!

To make sure you are not studying endlessly, EduRev has designed Mechanical Engineering study material, with Structured Courses, Videos, & Test Series. Plus get personalized analysis, doubt solving and improvement plans to achieve a great score in Mechanical Engineering.

|

Explore Courses for Mechanical Engineering exam

|

|

Similar Mechanical Engineering Doubts

Which of the following work material has highest machining constant?a)High carbon steelb)Stainless 303c)Stainless 304d)AISI 1045Correct answer is option 'B'. Can you explain this answer?

Question Description

Which of the following work material has highest machining constant?a)High carbon steelb)Stainless 303c)Stainless 304d)AISI 1045Correct answer is option 'B'. Can you explain this answer? for Mechanical Engineering 2024 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about Which of the following work material has highest machining constant?a)High carbon steelb)Stainless 303c)Stainless 304d)AISI 1045Correct answer is option 'B'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for Which of the following work material has highest machining constant?a)High carbon steelb)Stainless 303c)Stainless 304d)AISI 1045Correct answer is option 'B'. Can you explain this answer?.

Which of the following work material has highest machining constant?a)High carbon steelb)Stainless 303c)Stainless 304d)AISI 1045Correct answer is option 'B'. Can you explain this answer? for Mechanical Engineering 2024 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about Which of the following work material has highest machining constant?a)High carbon steelb)Stainless 303c)Stainless 304d)AISI 1045Correct answer is option 'B'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for Which of the following work material has highest machining constant?a)High carbon steelb)Stainless 303c)Stainless 304d)AISI 1045Correct answer is option 'B'. Can you explain this answer?.

Solutions for Which of the following work material has highest machining constant?a)High carbon steelb)Stainless 303c)Stainless 304d)AISI 1045Correct answer is option 'B'. Can you explain this answer? in English & in Hindi are available as part of our courses for Mechanical Engineering.

Download more important topics, notes, lectures and mock test series for Mechanical Engineering Exam by signing up for free.

Here you can find the meaning of Which of the following work material has highest machining constant?a)High carbon steelb)Stainless 303c)Stainless 304d)AISI 1045Correct answer is option 'B'. Can you explain this answer? defined & explained in the simplest way possible. Besides giving the explanation of

Which of the following work material has highest machining constant?a)High carbon steelb)Stainless 303c)Stainless 304d)AISI 1045Correct answer is option 'B'. Can you explain this answer?, a detailed solution for Which of the following work material has highest machining constant?a)High carbon steelb)Stainless 303c)Stainless 304d)AISI 1045Correct answer is option 'B'. Can you explain this answer? has been provided alongside types of Which of the following work material has highest machining constant?a)High carbon steelb)Stainless 303c)Stainless 304d)AISI 1045Correct answer is option 'B'. Can you explain this answer? theory, EduRev gives you an

ample number of questions to practice Which of the following work material has highest machining constant?a)High carbon steelb)Stainless 303c)Stainless 304d)AISI 1045Correct answer is option 'B'. Can you explain this answer? tests, examples and also practice Mechanical Engineering tests.

|

Explore Courses for Mechanical Engineering exam

|

|

Suggested Free Tests

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.