Mechanical Engineering Exam > Mechanical Engineering Questions > Stress concentration factor for welded joints...

Start Learning for Free

Stress concentration factor for welded joints subjected to fatigue loading is highest in

- a)Reinforced buttwelds

- b)Toe of transverse fillet weld

- c)End of parallel fillet weld

- d)T-butt joint with sharp corner

Correct answer is option 'C'. Can you explain this answer?

Verified Answer

Stress concentration factor for welded joints subjected to fatigue loa...

Most Upvoted Answer

Stress concentration factor for welded joints subjected to fatigue loa...

Stress Concentration Factor in Welded Joints

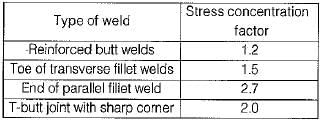

Stress concentration factor (Kt) is defined as the ratio of maximum stress to the nominal stress. In welded joints, Kt is used to evaluate the effect of the weld geometry on the stress distribution and the fatigue life of the joint.

Factors affecting the Kt value in welded joints are:

1. Weld Geometry

2. Material properties

3. Loading conditions

Among these factors, weld geometry has a significant effect on the Kt value.

Effect of Weld Geometry on Kt Value

Weld geometry refers to the shape and size of the weld. The weld geometry affects the stress distribution in the joint and hence the Kt value.

The following are the weld geometries that affect the Kt value:

1. Reinforced butt welds

2. Toe of transverse fillet welds

3. End of parallel fillet welds

4. T-butt joint with sharp corner

Among these, the end of parallel fillet welds and T-butt joint with sharp corner have the highest Kt value.

Explanation of the Correct Answer

Option C is the correct answer, which states that the stress concentration factor is highest at the end of parallel fillet welds. The following are the reasons why the Kt value is highest at the end of parallel fillet welds:

1. Stress concentration at the end of the weld: At the end of the parallel fillet weld, the stress concentration is high due to the sudden change in geometry. The stress concentration causes a high Kt value.

2. High bending stress: The end of the parallel fillet weld is subjected to high bending stress due to the applied load. The bending stress causes a high Kt value.

3. Fatigue crack initiation: The high Kt value at the end of the parallel fillet weld promotes the initiation of fatigue cracks. The cracks propagate due to cyclic loading, leading to failure of the joint.

Conclusion

The stress concentration factor (Kt) is used to evaluate the effect of weld geometry on the stress distribution in the joint. Among the weld geometries, the end of parallel fillet welds has the highest Kt value due to stress concentration, high bending stress, and fatigue crack initiation. Therefore, it is necessary to consider the weld geometry while designing the joint to ensure a longer fatigue life.

Stress concentration factor (Kt) is defined as the ratio of maximum stress to the nominal stress. In welded joints, Kt is used to evaluate the effect of the weld geometry on the stress distribution and the fatigue life of the joint.

Factors affecting the Kt value in welded joints are:

1. Weld Geometry

2. Material properties

3. Loading conditions

Among these factors, weld geometry has a significant effect on the Kt value.

Effect of Weld Geometry on Kt Value

Weld geometry refers to the shape and size of the weld. The weld geometry affects the stress distribution in the joint and hence the Kt value.

The following are the weld geometries that affect the Kt value:

1. Reinforced butt welds

2. Toe of transverse fillet welds

3. End of parallel fillet welds

4. T-butt joint with sharp corner

Among these, the end of parallel fillet welds and T-butt joint with sharp corner have the highest Kt value.

Explanation of the Correct Answer

Option C is the correct answer, which states that the stress concentration factor is highest at the end of parallel fillet welds. The following are the reasons why the Kt value is highest at the end of parallel fillet welds:

1. Stress concentration at the end of the weld: At the end of the parallel fillet weld, the stress concentration is high due to the sudden change in geometry. The stress concentration causes a high Kt value.

2. High bending stress: The end of the parallel fillet weld is subjected to high bending stress due to the applied load. The bending stress causes a high Kt value.

3. Fatigue crack initiation: The high Kt value at the end of the parallel fillet weld promotes the initiation of fatigue cracks. The cracks propagate due to cyclic loading, leading to failure of the joint.

Conclusion

The stress concentration factor (Kt) is used to evaluate the effect of weld geometry on the stress distribution in the joint. Among the weld geometries, the end of parallel fillet welds has the highest Kt value due to stress concentration, high bending stress, and fatigue crack initiation. Therefore, it is necessary to consider the weld geometry while designing the joint to ensure a longer fatigue life.

|

Explore Courses for Mechanical Engineering exam

|

|

Question Description

Stress concentration factor for welded joints subjected to fatigue loading is highest ina)Reinforced buttweldsb)Toe of transverse fillet weldc)End of parallel fillet weldd)T-butt joint with sharp cornerCorrect answer is option 'C'. Can you explain this answer? for Mechanical Engineering 2025 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about Stress concentration factor for welded joints subjected to fatigue loading is highest ina)Reinforced buttweldsb)Toe of transverse fillet weldc)End of parallel fillet weldd)T-butt joint with sharp cornerCorrect answer is option 'C'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2025 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for Stress concentration factor for welded joints subjected to fatigue loading is highest ina)Reinforced buttweldsb)Toe of transverse fillet weldc)End of parallel fillet weldd)T-butt joint with sharp cornerCorrect answer is option 'C'. Can you explain this answer?.

Stress concentration factor for welded joints subjected to fatigue loading is highest ina)Reinforced buttweldsb)Toe of transverse fillet weldc)End of parallel fillet weldd)T-butt joint with sharp cornerCorrect answer is option 'C'. Can you explain this answer? for Mechanical Engineering 2025 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about Stress concentration factor for welded joints subjected to fatigue loading is highest ina)Reinforced buttweldsb)Toe of transverse fillet weldc)End of parallel fillet weldd)T-butt joint with sharp cornerCorrect answer is option 'C'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2025 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for Stress concentration factor for welded joints subjected to fatigue loading is highest ina)Reinforced buttweldsb)Toe of transverse fillet weldc)End of parallel fillet weldd)T-butt joint with sharp cornerCorrect answer is option 'C'. Can you explain this answer?.

Solutions for Stress concentration factor for welded joints subjected to fatigue loading is highest ina)Reinforced buttweldsb)Toe of transverse fillet weldc)End of parallel fillet weldd)T-butt joint with sharp cornerCorrect answer is option 'C'. Can you explain this answer? in English & in Hindi are available as part of our courses for Mechanical Engineering.

Download more important topics, notes, lectures and mock test series for Mechanical Engineering Exam by signing up for free.

Here you can find the meaning of Stress concentration factor for welded joints subjected to fatigue loading is highest ina)Reinforced buttweldsb)Toe of transverse fillet weldc)End of parallel fillet weldd)T-butt joint with sharp cornerCorrect answer is option 'C'. Can you explain this answer? defined & explained in the simplest way possible. Besides giving the explanation of

Stress concentration factor for welded joints subjected to fatigue loading is highest ina)Reinforced buttweldsb)Toe of transverse fillet weldc)End of parallel fillet weldd)T-butt joint with sharp cornerCorrect answer is option 'C'. Can you explain this answer?, a detailed solution for Stress concentration factor for welded joints subjected to fatigue loading is highest ina)Reinforced buttweldsb)Toe of transverse fillet weldc)End of parallel fillet weldd)T-butt joint with sharp cornerCorrect answer is option 'C'. Can you explain this answer? has been provided alongside types of Stress concentration factor for welded joints subjected to fatigue loading is highest ina)Reinforced buttweldsb)Toe of transverse fillet weldc)End of parallel fillet weldd)T-butt joint with sharp cornerCorrect answer is option 'C'. Can you explain this answer? theory, EduRev gives you an

ample number of questions to practice Stress concentration factor for welded joints subjected to fatigue loading is highest ina)Reinforced buttweldsb)Toe of transverse fillet weldc)End of parallel fillet weldd)T-butt joint with sharp cornerCorrect answer is option 'C'. Can you explain this answer? tests, examples and also practice Mechanical Engineering tests.

|

Explore Courses for Mechanical Engineering exam

|

|

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.