Mechanical Engineering Exam > Mechanical Engineering Questions > Which of the following welding process is als...

Start Learning for Free

Which of the following welding process is also known as upset welding?

- a)Flash welding

- b)Resistance projection welding

- c)Resistance seam welding

- d)Resistance spot welding

Correct answer is option 'A'. Can you explain this answer?

Verified Answer

Which of the following welding process is also known as upset welding?...

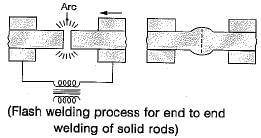

End to end welding pressure is applied axially for hot upsetting process.

Most Upvoted Answer

Which of the following welding process is also known as upset welding?...

Understanding Upset Welding

Upset welding is a specific type of welding process that primarily utilizes heat generated by electrical resistance to join two metal pieces together. It is often referred to as "flash welding," but let’s delve deeper into its mechanics and characteristics.

What is Flash Welding?

- Flash welding, or upset welding, involves the following key steps:

- Preparation: The two metal surfaces are brought into contact.

- Heating: An electric current is passed through the joint, creating heat due to resistance.

- Upset Action: Once the material reaches a specific temperature, the pieces are forced together (or "upset"), allowing the molten edges to fuse.

Characteristics of Upset Welding

- Applications: Commonly used in joining structural components and in manufacturing parts like railway tracks, pipes, and automotive components.

- Advantages:

- Strong Joints: Produces high-strength welds suitable for load-bearing applications.

- Efficiency: Quick process with minimal distortion of the base materials.

- Limitations:

- Material Compatibility: Best suited for similar materials; dissimilar metal welding can be challenging.

Comparison with Other Resistance Welding Processes

- Resistance Projection Welding: Involves using projections on one of the workpieces; not classified as upset welding.

- Resistance Seam and Spot Welding: Focus on joining surfaces at specific points or along seams; again, these do not fit the upset welding definition.

In conclusion, the correct answer to the question regarding which welding process is known as upset welding is indeed a) Flash welding. Understanding the unique characteristics of this process helps distinguish it from other welding techniques in mechanical engineering.

Upset welding is a specific type of welding process that primarily utilizes heat generated by electrical resistance to join two metal pieces together. It is often referred to as "flash welding," but let’s delve deeper into its mechanics and characteristics.

What is Flash Welding?

- Flash welding, or upset welding, involves the following key steps:

- Preparation: The two metal surfaces are brought into contact.

- Heating: An electric current is passed through the joint, creating heat due to resistance.

- Upset Action: Once the material reaches a specific temperature, the pieces are forced together (or "upset"), allowing the molten edges to fuse.

Characteristics of Upset Welding

- Applications: Commonly used in joining structural components and in manufacturing parts like railway tracks, pipes, and automotive components.

- Advantages:

- Strong Joints: Produces high-strength welds suitable for load-bearing applications.

- Efficiency: Quick process with minimal distortion of the base materials.

- Limitations:

- Material Compatibility: Best suited for similar materials; dissimilar metal welding can be challenging.

Comparison with Other Resistance Welding Processes

- Resistance Projection Welding: Involves using projections on one of the workpieces; not classified as upset welding.

- Resistance Seam and Spot Welding: Focus on joining surfaces at specific points or along seams; again, these do not fit the upset welding definition.

In conclusion, the correct answer to the question regarding which welding process is known as upset welding is indeed a) Flash welding. Understanding the unique characteristics of this process helps distinguish it from other welding techniques in mechanical engineering.

|

Explore Courses for Mechanical Engineering exam

|

|

Question Description

Which of the following welding process is also known as upset welding?a)Flash weldingb)Resistance projection weldingc)Resistance seam weldingd)Resistance spot weldingCorrect answer is option 'A'. Can you explain this answer? for Mechanical Engineering 2025 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about Which of the following welding process is also known as upset welding?a)Flash weldingb)Resistance projection weldingc)Resistance seam weldingd)Resistance spot weldingCorrect answer is option 'A'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2025 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for Which of the following welding process is also known as upset welding?a)Flash weldingb)Resistance projection weldingc)Resistance seam weldingd)Resistance spot weldingCorrect answer is option 'A'. Can you explain this answer?.

Which of the following welding process is also known as upset welding?a)Flash weldingb)Resistance projection weldingc)Resistance seam weldingd)Resistance spot weldingCorrect answer is option 'A'. Can you explain this answer? for Mechanical Engineering 2025 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about Which of the following welding process is also known as upset welding?a)Flash weldingb)Resistance projection weldingc)Resistance seam weldingd)Resistance spot weldingCorrect answer is option 'A'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2025 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for Which of the following welding process is also known as upset welding?a)Flash weldingb)Resistance projection weldingc)Resistance seam weldingd)Resistance spot weldingCorrect answer is option 'A'. Can you explain this answer?.

Solutions for Which of the following welding process is also known as upset welding?a)Flash weldingb)Resistance projection weldingc)Resistance seam weldingd)Resistance spot weldingCorrect answer is option 'A'. Can you explain this answer? in English & in Hindi are available as part of our courses for Mechanical Engineering.

Download more important topics, notes, lectures and mock test series for Mechanical Engineering Exam by signing up for free.

Here you can find the meaning of Which of the following welding process is also known as upset welding?a)Flash weldingb)Resistance projection weldingc)Resistance seam weldingd)Resistance spot weldingCorrect answer is option 'A'. Can you explain this answer? defined & explained in the simplest way possible. Besides giving the explanation of

Which of the following welding process is also known as upset welding?a)Flash weldingb)Resistance projection weldingc)Resistance seam weldingd)Resistance spot weldingCorrect answer is option 'A'. Can you explain this answer?, a detailed solution for Which of the following welding process is also known as upset welding?a)Flash weldingb)Resistance projection weldingc)Resistance seam weldingd)Resistance spot weldingCorrect answer is option 'A'. Can you explain this answer? has been provided alongside types of Which of the following welding process is also known as upset welding?a)Flash weldingb)Resistance projection weldingc)Resistance seam weldingd)Resistance spot weldingCorrect answer is option 'A'. Can you explain this answer? theory, EduRev gives you an

ample number of questions to practice Which of the following welding process is also known as upset welding?a)Flash weldingb)Resistance projection weldingc)Resistance seam weldingd)Resistance spot weldingCorrect answer is option 'A'. Can you explain this answer? tests, examples and also practice Mechanical Engineering tests.

|

Explore Courses for Mechanical Engineering exam

|

|

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.