Mechanical Engineering Exam > Mechanical Engineering Questions > Two parallel shafts whose axes are separated ...

Start Learning for Free

Two parallel shafts whose axes are separated by a distance of 75 mm are to be connected a spur gear set so that the output shaft rotates at 50% of the speed of the input shaft which of the following could be the possible pitch circle diameters of the gears.

- a)25 mm and 50 mm

- b)30 mm and 60 mm

- c)50 mm and 100 mm

- d)60 mm and 120 mm

Correct answer is option 'C'. Can you explain this answer?

Verified Answer

Two parallel shafts whose axes are separated by a distance of 75 mm ar...

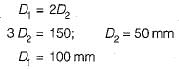

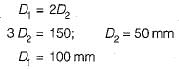

Centre distance between the shaft = 75 mm

Hence

Also,

Hence

Also,

Most Upvoted Answer

Two parallel shafts whose axes are separated by a distance of 75 mm ar...

To determine the possible pitch circle diameters of the gears, we need to consider the given conditions and formulas related to gear ratios and pitch circle diameters.

Given:

Distance between the axes of the parallel shafts (center-to-center distance) = 75 mm

Output shaft speed = 50% of the input shaft speed

We know that the gear ratio is given by:

Gear Ratio = (Number of Teeth on Output Gear) / (Number of Teeth on Input Gear)

Let's assume the number of teeth on the input gear as 'N1' and the number of teeth on the output gear as 'N2'. Since the gears are spur gears, the pitch circle diameter (D) is related to the number of teeth (N) by the formula:

D = (N * Module) / π

where Module is the pitch circle module.

We can also relate the gear ratio and pitch circle diameters by the following equation:

Gear Ratio = (D2 / D1) = (N2 / N1)

Now, let's analyze the given options:

a) 25 mm and 50 mm:

If we consider D1 = 25 mm and D2 = 50 mm, then the gear ratio is (50 / 25) = 2, which means the output shaft will rotate twice as fast as the input shaft. This contradicts the given condition that the output shaft should rotate at 50% of the speed of the input shaft. Therefore, option 'a' is not valid.

b) 30 mm and 60 mm:

If we consider D1 = 30 mm and D2 = 60 mm, then the gear ratio is (60 / 30) = 2, which again contradicts the given condition. Therefore, option 'b' is not valid.

c) 50 mm and 100 mm:

If we consider D1 = 50 mm and D2 = 100 mm, then the gear ratio is (100 / 50) = 2, which satisfies the given condition that the output shaft should rotate at 50% of the speed of the input shaft. Therefore, option 'c' is valid.

d) 60 mm and 120 mm:

If we consider D1 = 60 mm and D2 = 120 mm, then the gear ratio is (120 / 60) = 2, which again satisfies the given condition. Therefore, option 'd' is also valid.

Hence, the possible pitch circle diameters of the gears could be 50 mm and 100 mm (option 'c') or 60 mm and 120 mm (option 'd').

Given:

Distance between the axes of the parallel shafts (center-to-center distance) = 75 mm

Output shaft speed = 50% of the input shaft speed

We know that the gear ratio is given by:

Gear Ratio = (Number of Teeth on Output Gear) / (Number of Teeth on Input Gear)

Let's assume the number of teeth on the input gear as 'N1' and the number of teeth on the output gear as 'N2'. Since the gears are spur gears, the pitch circle diameter (D) is related to the number of teeth (N) by the formula:

D = (N * Module) / π

where Module is the pitch circle module.

We can also relate the gear ratio and pitch circle diameters by the following equation:

Gear Ratio = (D2 / D1) = (N2 / N1)

Now, let's analyze the given options:

a) 25 mm and 50 mm:

If we consider D1 = 25 mm and D2 = 50 mm, then the gear ratio is (50 / 25) = 2, which means the output shaft will rotate twice as fast as the input shaft. This contradicts the given condition that the output shaft should rotate at 50% of the speed of the input shaft. Therefore, option 'a' is not valid.

b) 30 mm and 60 mm:

If we consider D1 = 30 mm and D2 = 60 mm, then the gear ratio is (60 / 30) = 2, which again contradicts the given condition. Therefore, option 'b' is not valid.

c) 50 mm and 100 mm:

If we consider D1 = 50 mm and D2 = 100 mm, then the gear ratio is (100 / 50) = 2, which satisfies the given condition that the output shaft should rotate at 50% of the speed of the input shaft. Therefore, option 'c' is valid.

d) 60 mm and 120 mm:

If we consider D1 = 60 mm and D2 = 120 mm, then the gear ratio is (120 / 60) = 2, which again satisfies the given condition. Therefore, option 'd' is also valid.

Hence, the possible pitch circle diameters of the gears could be 50 mm and 100 mm (option 'c') or 60 mm and 120 mm (option 'd').

|

Explore Courses for Mechanical Engineering exam

|

|

Question Description

Two parallel shafts whose axes are separated by a distance of 75 mm are to be connected a spur gear set so that the output shaft rotates at 50% of the speed of the input shaft which of the following could be the possible pitch circle diameters of the gears.a)25 mm and 50 mmb)30 mm and 60 mmc)50 mm and 100 mmd)60 mm and 120 mmCorrect answer is option 'C'. Can you explain this answer? for Mechanical Engineering 2025 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about Two parallel shafts whose axes are separated by a distance of 75 mm are to be connected a spur gear set so that the output shaft rotates at 50% of the speed of the input shaft which of the following could be the possible pitch circle diameters of the gears.a)25 mm and 50 mmb)30 mm and 60 mmc)50 mm and 100 mmd)60 mm and 120 mmCorrect answer is option 'C'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2025 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for Two parallel shafts whose axes are separated by a distance of 75 mm are to be connected a spur gear set so that the output shaft rotates at 50% of the speed of the input shaft which of the following could be the possible pitch circle diameters of the gears.a)25 mm and 50 mmb)30 mm and 60 mmc)50 mm and 100 mmd)60 mm and 120 mmCorrect answer is option 'C'. Can you explain this answer?.

Two parallel shafts whose axes are separated by a distance of 75 mm are to be connected a spur gear set so that the output shaft rotates at 50% of the speed of the input shaft which of the following could be the possible pitch circle diameters of the gears.a)25 mm and 50 mmb)30 mm and 60 mmc)50 mm and 100 mmd)60 mm and 120 mmCorrect answer is option 'C'. Can you explain this answer? for Mechanical Engineering 2025 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about Two parallel shafts whose axes are separated by a distance of 75 mm are to be connected a spur gear set so that the output shaft rotates at 50% of the speed of the input shaft which of the following could be the possible pitch circle diameters of the gears.a)25 mm and 50 mmb)30 mm and 60 mmc)50 mm and 100 mmd)60 mm and 120 mmCorrect answer is option 'C'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2025 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for Two parallel shafts whose axes are separated by a distance of 75 mm are to be connected a spur gear set so that the output shaft rotates at 50% of the speed of the input shaft which of the following could be the possible pitch circle diameters of the gears.a)25 mm and 50 mmb)30 mm and 60 mmc)50 mm and 100 mmd)60 mm and 120 mmCorrect answer is option 'C'. Can you explain this answer?.

Solutions for Two parallel shafts whose axes are separated by a distance of 75 mm are to be connected a spur gear set so that the output shaft rotates at 50% of the speed of the input shaft which of the following could be the possible pitch circle diameters of the gears.a)25 mm and 50 mmb)30 mm and 60 mmc)50 mm and 100 mmd)60 mm and 120 mmCorrect answer is option 'C'. Can you explain this answer? in English & in Hindi are available as part of our courses for Mechanical Engineering.

Download more important topics, notes, lectures and mock test series for Mechanical Engineering Exam by signing up for free.

Here you can find the meaning of Two parallel shafts whose axes are separated by a distance of 75 mm are to be connected a spur gear set so that the output shaft rotates at 50% of the speed of the input shaft which of the following could be the possible pitch circle diameters of the gears.a)25 mm and 50 mmb)30 mm and 60 mmc)50 mm and 100 mmd)60 mm and 120 mmCorrect answer is option 'C'. Can you explain this answer? defined & explained in the simplest way possible. Besides giving the explanation of

Two parallel shafts whose axes are separated by a distance of 75 mm are to be connected a spur gear set so that the output shaft rotates at 50% of the speed of the input shaft which of the following could be the possible pitch circle diameters of the gears.a)25 mm and 50 mmb)30 mm and 60 mmc)50 mm and 100 mmd)60 mm and 120 mmCorrect answer is option 'C'. Can you explain this answer?, a detailed solution for Two parallel shafts whose axes are separated by a distance of 75 mm are to be connected a spur gear set so that the output shaft rotates at 50% of the speed of the input shaft which of the following could be the possible pitch circle diameters of the gears.a)25 mm and 50 mmb)30 mm and 60 mmc)50 mm and 100 mmd)60 mm and 120 mmCorrect answer is option 'C'. Can you explain this answer? has been provided alongside types of Two parallel shafts whose axes are separated by a distance of 75 mm are to be connected a spur gear set so that the output shaft rotates at 50% of the speed of the input shaft which of the following could be the possible pitch circle diameters of the gears.a)25 mm and 50 mmb)30 mm and 60 mmc)50 mm and 100 mmd)60 mm and 120 mmCorrect answer is option 'C'. Can you explain this answer? theory, EduRev gives you an

ample number of questions to practice Two parallel shafts whose axes are separated by a distance of 75 mm are to be connected a spur gear set so that the output shaft rotates at 50% of the speed of the input shaft which of the following could be the possible pitch circle diameters of the gears.a)25 mm and 50 mmb)30 mm and 60 mmc)50 mm and 100 mmd)60 mm and 120 mmCorrect answer is option 'C'. Can you explain this answer? tests, examples and also practice Mechanical Engineering tests.

|

Explore Courses for Mechanical Engineering exam

|

|

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.