Class 11 Exam > Class 11 Questions > Explain Solvay process with reactions.?

Start Learning for Free

Explain Solvay process with reactions.?

Most Upvoted Answer

Explain Solvay process with reactions.?

Community Answer

Explain Solvay process with reactions.?

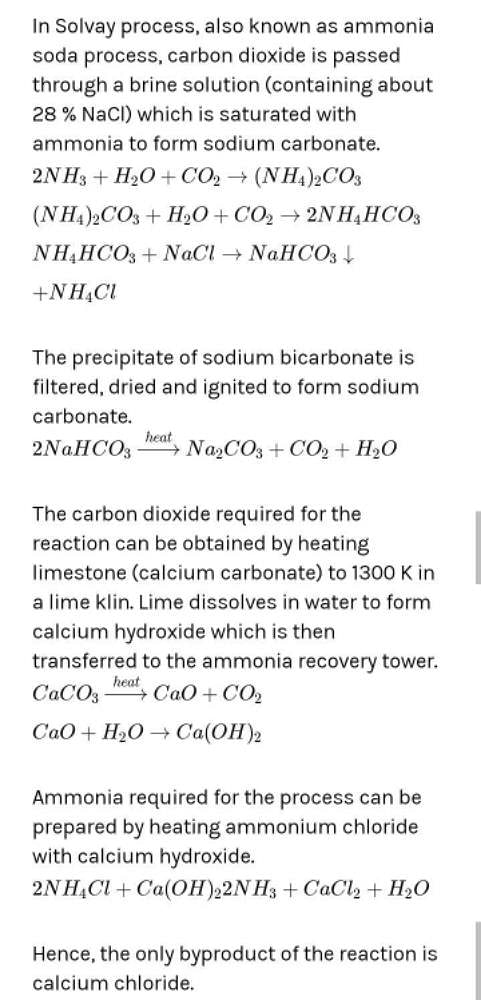

Solvay Process

The Solvay process is a method used to produce soda ash (sodium carbonate) from salt (sodium chloride) and limestone (calcium carbonate). It was developed by Ernest Solvay in the 1860s and is still widely used today. The process involves several chemical reactions and steps, which are as follows:

1. Brine Purification:

- Brine, which is a concentrated solution of salt (sodium chloride), is first purified to remove impurities such as calcium and magnesium ions.

- This is done by treating the brine with lime (calcium hydroxide) to form insoluble precipitates of calcium and magnesium hydroxides.

- The precipitates are then filtered out, leaving behind purified brine.

2. Carbonation of Ammoniated Brine:

- Purified brine is then treated with ammonia (NH3) gas to form ammoniated brine (sodium hydroxide and ammonium chloride).

- The reaction between brine and ammonia can be written as:

NaCl + NH3 + H2O → NH4Cl + NaOH

3. Carbon Dioxide Absorption:

- The ammoniated brine is then passed through towers where it comes into contact with carbon dioxide (CO2) gas.

- The carbon dioxide reacts with the ammonium chloride in the brine to form sodium bicarbonate (NaHCO3) and ammonium hydroxide (NH4OH):

2NH4Cl + CO2 + H2O → 2NH4OH + NaHCO3

4. Sodium Bicarbonate Precipitation:

- The sodium bicarbonate precipitates out of the solution and is collected.

- This is achieved by reducing the temperature of the solution, which increases the solubility of sodium bicarbonate and causes it to crystallize.

- The reaction is reversible, and by maintaining the right conditions, a continuous precipitation of sodium bicarbonate can be achieved.

5. Sodium Carbonate Formation:

- The sodium bicarbonate obtained from the previous step is then heated to decompose it into sodium carbonate (Na2CO3), water (H2O), and carbon dioxide:

2NaHCO3 → Na2CO3 + H2O + CO2

- The carbon dioxide released in this reaction is recycled back to the carbon dioxide absorption step.

6. Sodium Carbonate Recovery:

- The sodium carbonate produced is further purified by recrystallization or by converting it to a more pure form, such as soda ash dense or light.

- The recovered sodium carbonate can be used in various industrial applications, including glass manufacturing, detergent production, and water treatment.

Overall, the Solvay process is a highly efficient and sustainable method for the production of soda ash from readily available raw materials. It has significantly contributed to the development of the chemical industry and has remained a key process in the production of sodium carbonate.

The Solvay process is a method used to produce soda ash (sodium carbonate) from salt (sodium chloride) and limestone (calcium carbonate). It was developed by Ernest Solvay in the 1860s and is still widely used today. The process involves several chemical reactions and steps, which are as follows:

1. Brine Purification:

- Brine, which is a concentrated solution of salt (sodium chloride), is first purified to remove impurities such as calcium and magnesium ions.

- This is done by treating the brine with lime (calcium hydroxide) to form insoluble precipitates of calcium and magnesium hydroxides.

- The precipitates are then filtered out, leaving behind purified brine.

2. Carbonation of Ammoniated Brine:

- Purified brine is then treated with ammonia (NH3) gas to form ammoniated brine (sodium hydroxide and ammonium chloride).

- The reaction between brine and ammonia can be written as:

NaCl + NH3 + H2O → NH4Cl + NaOH

3. Carbon Dioxide Absorption:

- The ammoniated brine is then passed through towers where it comes into contact with carbon dioxide (CO2) gas.

- The carbon dioxide reacts with the ammonium chloride in the brine to form sodium bicarbonate (NaHCO3) and ammonium hydroxide (NH4OH):

2NH4Cl + CO2 + H2O → 2NH4OH + NaHCO3

4. Sodium Bicarbonate Precipitation:

- The sodium bicarbonate precipitates out of the solution and is collected.

- This is achieved by reducing the temperature of the solution, which increases the solubility of sodium bicarbonate and causes it to crystallize.

- The reaction is reversible, and by maintaining the right conditions, a continuous precipitation of sodium bicarbonate can be achieved.

5. Sodium Carbonate Formation:

- The sodium bicarbonate obtained from the previous step is then heated to decompose it into sodium carbonate (Na2CO3), water (H2O), and carbon dioxide:

2NaHCO3 → Na2CO3 + H2O + CO2

- The carbon dioxide released in this reaction is recycled back to the carbon dioxide absorption step.

6. Sodium Carbonate Recovery:

- The sodium carbonate produced is further purified by recrystallization or by converting it to a more pure form, such as soda ash dense or light.

- The recovered sodium carbonate can be used in various industrial applications, including glass manufacturing, detergent production, and water treatment.

Overall, the Solvay process is a highly efficient and sustainable method for the production of soda ash from readily available raw materials. It has significantly contributed to the development of the chemical industry and has remained a key process in the production of sodium carbonate.

Attention Class 11 Students!

To make sure you are not studying endlessly, EduRev has designed Class 11 study material, with Structured Courses, Videos, & Test Series. Plus get personalized analysis, doubt solving and improvement plans to achieve a great score in Class 11.

|

Explore Courses for Class 11 exam

|

|

Similar Class 11 Doubts

Explain Solvay process with reactions.?

Question Description

Explain Solvay process with reactions.? for Class 11 2024 is part of Class 11 preparation. The Question and answers have been prepared according to the Class 11 exam syllabus. Information about Explain Solvay process with reactions.? covers all topics & solutions for Class 11 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for Explain Solvay process with reactions.?.

Explain Solvay process with reactions.? for Class 11 2024 is part of Class 11 preparation. The Question and answers have been prepared according to the Class 11 exam syllabus. Information about Explain Solvay process with reactions.? covers all topics & solutions for Class 11 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for Explain Solvay process with reactions.?.

Solutions for Explain Solvay process with reactions.? in English & in Hindi are available as part of our courses for Class 11.

Download more important topics, notes, lectures and mock test series for Class 11 Exam by signing up for free.

Here you can find the meaning of Explain Solvay process with reactions.? defined & explained in the simplest way possible. Besides giving the explanation of

Explain Solvay process with reactions.?, a detailed solution for Explain Solvay process with reactions.? has been provided alongside types of Explain Solvay process with reactions.? theory, EduRev gives you an

ample number of questions to practice Explain Solvay process with reactions.? tests, examples and also practice Class 11 tests.

|

Explore Courses for Class 11 exam

|

|

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.