Mechanical Engineering Exam > Mechanical Engineering Questions > In which of the following milling operation c...

Start Learning for Free

In which of the following milling operation cutter is rotated in the same direction of travel of work piece

- a)Up milling

- b)Down milling

- c)Face milling

- d)End millingin

Correct answer is option 'B'. Can you explain this answer?

Verified Answer

In which of the following milling operation cutter is rotated in the s...

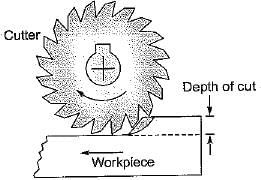

In down milling, also called climb milling, the feed direction of the workpiece is same as that of the cutter rotation.

Most Upvoted Answer

In which of the following milling operation cutter is rotated in the s...

Down Milling:

Down milling is the milling operation in which the cutter rotates in the same direction as the travel of the workpiece. This type of milling is also known as climb milling. Let's understand why down milling is carried out in this manner.

Advantages of Down Milling:

- In down milling, the cutting forces tend to push the workpiece towards the table, resulting in a better surface finish.

- It reduces the risk of workpiece lifting off the table, ensuring better stability during the machining process.

- Down milling also helps in reducing tool wear and prolonging tool life.

- It is suitable for cutting materials that are prone to work hardening.

Comparison with Up Milling:

In up milling, the cutter rotates in the opposite direction to the travel of the workpiece. This type of milling is also known as conventional milling. Up milling has the following disadvantages compared to down milling:

- Up milling tends to create a rougher surface finish due to the cutting forces pulling the workpiece away from the table.

- It can cause workpiece chatter and vibration, leading to poor machining accuracy.

- Up milling is more likely to cause tool chipping and premature tool wear.

Conclusion:

In conclusion, down milling is preferred over up milling in most cases due to its advantages in terms of surface finish, stability, and tool life. It is important to consider the specific requirements of the machining operation and choose the appropriate milling technique accordingly.

|

Explore Courses for Mechanical Engineering exam

|

|

Question Description

In which of the following milling operation cutter is rotated in the same direction of travel of work piecea)Up millingb)Down millingc)Face millingd)End millinginCorrect answer is option 'B'. Can you explain this answer? for Mechanical Engineering 2025 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about In which of the following milling operation cutter is rotated in the same direction of travel of work piecea)Up millingb)Down millingc)Face millingd)End millinginCorrect answer is option 'B'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2025 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for In which of the following milling operation cutter is rotated in the same direction of travel of work piecea)Up millingb)Down millingc)Face millingd)End millinginCorrect answer is option 'B'. Can you explain this answer?.

In which of the following milling operation cutter is rotated in the same direction of travel of work piecea)Up millingb)Down millingc)Face millingd)End millinginCorrect answer is option 'B'. Can you explain this answer? for Mechanical Engineering 2025 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about In which of the following milling operation cutter is rotated in the same direction of travel of work piecea)Up millingb)Down millingc)Face millingd)End millinginCorrect answer is option 'B'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2025 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for In which of the following milling operation cutter is rotated in the same direction of travel of work piecea)Up millingb)Down millingc)Face millingd)End millinginCorrect answer is option 'B'. Can you explain this answer?.

Solutions for In which of the following milling operation cutter is rotated in the same direction of travel of work piecea)Up millingb)Down millingc)Face millingd)End millinginCorrect answer is option 'B'. Can you explain this answer? in English & in Hindi are available as part of our courses for Mechanical Engineering.

Download more important topics, notes, lectures and mock test series for Mechanical Engineering Exam by signing up for free.

Here you can find the meaning of In which of the following milling operation cutter is rotated in the same direction of travel of work piecea)Up millingb)Down millingc)Face millingd)End millinginCorrect answer is option 'B'. Can you explain this answer? defined & explained in the simplest way possible. Besides giving the explanation of

In which of the following milling operation cutter is rotated in the same direction of travel of work piecea)Up millingb)Down millingc)Face millingd)End millinginCorrect answer is option 'B'. Can you explain this answer?, a detailed solution for In which of the following milling operation cutter is rotated in the same direction of travel of work piecea)Up millingb)Down millingc)Face millingd)End millinginCorrect answer is option 'B'. Can you explain this answer? has been provided alongside types of In which of the following milling operation cutter is rotated in the same direction of travel of work piecea)Up millingb)Down millingc)Face millingd)End millinginCorrect answer is option 'B'. Can you explain this answer? theory, EduRev gives you an

ample number of questions to practice In which of the following milling operation cutter is rotated in the same direction of travel of work piecea)Up millingb)Down millingc)Face millingd)End millinginCorrect answer is option 'B'. Can you explain this answer? tests, examples and also practice Mechanical Engineering tests.

|

Explore Courses for Mechanical Engineering exam

|

|

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.