Mechanical Engineering Exam > Mechanical Engineering Questions > Trepanning operation is performed fora)finish...

Start Learning for Free

Trepanning operation is performed for

- a)finishing a drilled hole

- b)trueing a hole for alignment

- c)producing large hole

- d)sizing a small hole

Correct answer is option 'C'. Can you explain this answer?

Verified Answer

Trepanning operation is performed fora)finishing a drilled holeb)truei...

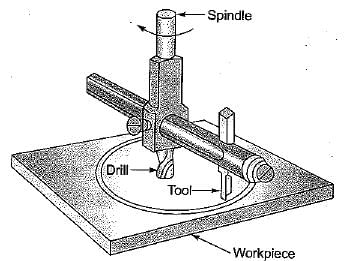

Trepanning is used to produce large size hole by removing a disk-shaped piece (core) usually from a flat plate. A hole is produced without reducing all the material removed to chip as is the case in drilling.

Most Upvoted Answer

Trepanning operation is performed fora)finishing a drilled holeb)truei...

Explanation:

Trepanning operation for producing large holes:

- Trepanning is a machining process used to produce large holes in a workpiece.

- It involves cutting out a disk-shaped piece of material to create the hole rather than drilling all the material out.

- This method is more efficient and faster than traditional drilling for large hole sizes.

Finishing a drilled hole:

- Once a hole is drilled, additional operations such as reaming or boring may be used to finish and size the hole to the required dimensions.

- These operations ensure that the hole is smooth, accurate, and meets the necessary tolerances.

Trueing a hole for alignment:

- Trueing a hole refers to aligning or straightening a hole that may have been drilled off-center or at an angle.

- This process is important in applications where precise alignment is critical, such as in the assembly of machine components.

Sizing a small hole:

- Sizing a small hole involves adjusting the diameter of the hole to meet specific requirements.

- This can be done using techniques such as reaming, honing, or grinding to achieve the desired hole size and surface finish.

In conclusion, trepanning operation is primarily used for producing large holes in a workpiece. While other operations like finishing, trueing, and sizing are also important in hole-making processes, trepanning specifically focuses on creating large holes efficiently and accurately.

Trepanning operation for producing large holes:

- Trepanning is a machining process used to produce large holes in a workpiece.

- It involves cutting out a disk-shaped piece of material to create the hole rather than drilling all the material out.

- This method is more efficient and faster than traditional drilling for large hole sizes.

Finishing a drilled hole:

- Once a hole is drilled, additional operations such as reaming or boring may be used to finish and size the hole to the required dimensions.

- These operations ensure that the hole is smooth, accurate, and meets the necessary tolerances.

Trueing a hole for alignment:

- Trueing a hole refers to aligning or straightening a hole that may have been drilled off-center or at an angle.

- This process is important in applications where precise alignment is critical, such as in the assembly of machine components.

Sizing a small hole:

- Sizing a small hole involves adjusting the diameter of the hole to meet specific requirements.

- This can be done using techniques such as reaming, honing, or grinding to achieve the desired hole size and surface finish.

In conclusion, trepanning operation is primarily used for producing large holes in a workpiece. While other operations like finishing, trueing, and sizing are also important in hole-making processes, trepanning specifically focuses on creating large holes efficiently and accurately.

|

Explore Courses for Mechanical Engineering exam

|

|

Question Description

Trepanning operation is performed fora)finishing a drilled holeb)trueing a hole for alignmentc)producing large holed)sizing a small holeCorrect answer is option 'C'. Can you explain this answer? for Mechanical Engineering 2025 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about Trepanning operation is performed fora)finishing a drilled holeb)trueing a hole for alignmentc)producing large holed)sizing a small holeCorrect answer is option 'C'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2025 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for Trepanning operation is performed fora)finishing a drilled holeb)trueing a hole for alignmentc)producing large holed)sizing a small holeCorrect answer is option 'C'. Can you explain this answer?.

Trepanning operation is performed fora)finishing a drilled holeb)trueing a hole for alignmentc)producing large holed)sizing a small holeCorrect answer is option 'C'. Can you explain this answer? for Mechanical Engineering 2025 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about Trepanning operation is performed fora)finishing a drilled holeb)trueing a hole for alignmentc)producing large holed)sizing a small holeCorrect answer is option 'C'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2025 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for Trepanning operation is performed fora)finishing a drilled holeb)trueing a hole for alignmentc)producing large holed)sizing a small holeCorrect answer is option 'C'. Can you explain this answer?.

Solutions for Trepanning operation is performed fora)finishing a drilled holeb)trueing a hole for alignmentc)producing large holed)sizing a small holeCorrect answer is option 'C'. Can you explain this answer? in English & in Hindi are available as part of our courses for Mechanical Engineering.

Download more important topics, notes, lectures and mock test series for Mechanical Engineering Exam by signing up for free.

Here you can find the meaning of Trepanning operation is performed fora)finishing a drilled holeb)trueing a hole for alignmentc)producing large holed)sizing a small holeCorrect answer is option 'C'. Can you explain this answer? defined & explained in the simplest way possible. Besides giving the explanation of

Trepanning operation is performed fora)finishing a drilled holeb)trueing a hole for alignmentc)producing large holed)sizing a small holeCorrect answer is option 'C'. Can you explain this answer?, a detailed solution for Trepanning operation is performed fora)finishing a drilled holeb)trueing a hole for alignmentc)producing large holed)sizing a small holeCorrect answer is option 'C'. Can you explain this answer? has been provided alongside types of Trepanning operation is performed fora)finishing a drilled holeb)trueing a hole for alignmentc)producing large holed)sizing a small holeCorrect answer is option 'C'. Can you explain this answer? theory, EduRev gives you an

ample number of questions to practice Trepanning operation is performed fora)finishing a drilled holeb)trueing a hole for alignmentc)producing large holed)sizing a small holeCorrect answer is option 'C'. Can you explain this answer? tests, examples and also practice Mechanical Engineering tests.

|

Explore Courses for Mechanical Engineering exam

|

|

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.