Mechanical Engineering Exam > Mechanical Engineering Questions > In centre-less grinding, the work piece centr...

Start Learning for Free

In centre-less grinding, the work piece centre be

- a)above the line joining the two wheel centres

- b)below the line joining the two wheel centres

- c)on the line joining the two wheel centres

- d)at the intersection of the line joining the wheel centre with workpiece plane

Correct answer is option 'A'. Can you explain this answer?

Verified Answer

In centre-less grinding, the work piece centre bea)above the line join...

Centre-less grinding is used for grinding cylindrical workpieces without actual fixing the workpiece.

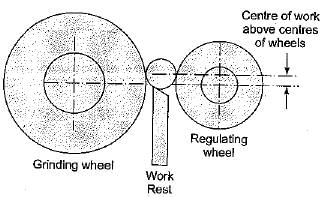

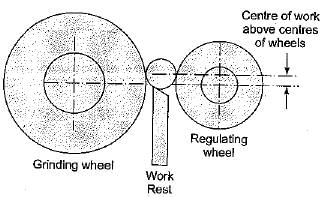

From the figure, the workpiece centre is above the centre of grinding and regulating wheel.

From the figure, the workpiece centre is above the centre of grinding and regulating wheel.

Most Upvoted Answer

In centre-less grinding, the work piece centre bea)above the line join...

In centreless grinding, the workpiece centre is located above the line joining the two wheel centres. This positioning is crucial for the effective functioning of the centreless grinding process. Let's understand why this is the case.

The Basics of Centreless Grinding:

Centreless grinding is a machining process used to remove material from a workpiece. It does not require a central axis, unlike traditional grinding methods. In this process, the workpiece is supported by a workblade and is positioned between two grinding wheels: the regulating wheel and the grinding wheel.

The Role of the Regulating Wheel:

The regulating wheel plays a critical role in centreless grinding. It controls the rotational speed and feed rate of the workpiece. The workpiece is fed between the grinding wheel and the regulating wheel, and the regulating wheel applies pressure to the workpiece, causing it to rotate. This rotation, combined with the grinding action of the grinding wheel, removes material from the workpiece.

The Importance of Workpiece Centre Position:

The position of the workpiece centre is crucial in centreless grinding because it determines the stability and accuracy of the process. The workpiece centre should be located above the line joining the two wheel centres for the following reasons:

1. Stability: Placing the workpiece centre above the line ensures that the workpiece is properly supported by the workblade and the regulating wheel. This positioning prevents any tilting or instability during the grinding process, resulting in a more stable and controlled grinding operation.

2. Accuracy: The workpiece centre needs to be accurately positioned to achieve precise grinding results. Placing it above the line allows for better control of the workpiece rotation and feed rate, leading to accurate material removal and consistent grinding results.

3. Uniform Grinding: When the workpiece centre is above the line, it ensures that the grinding action is evenly distributed across the workpiece surface. This helps in achieving uniform material removal and prevents uneven grinding or surface irregularities.

4. Wheel Wear: Positioning the workpiece centre above the line also helps in minimizing wheel wear. It allows for better contact between the grinding wheel and the workpiece, reducing the chances of wheel glazing or uneven wear.

In conclusion, in centreless grinding, the workpiece centre should be positioned above the line joining the two wheel centres for stability, accuracy, uniform grinding, and to minimize wheel wear. This positioning ensures optimal performance and better control over the grinding process, resulting in high-quality finished products.

The Basics of Centreless Grinding:

Centreless grinding is a machining process used to remove material from a workpiece. It does not require a central axis, unlike traditional grinding methods. In this process, the workpiece is supported by a workblade and is positioned between two grinding wheels: the regulating wheel and the grinding wheel.

The Role of the Regulating Wheel:

The regulating wheel plays a critical role in centreless grinding. It controls the rotational speed and feed rate of the workpiece. The workpiece is fed between the grinding wheel and the regulating wheel, and the regulating wheel applies pressure to the workpiece, causing it to rotate. This rotation, combined with the grinding action of the grinding wheel, removes material from the workpiece.

The Importance of Workpiece Centre Position:

The position of the workpiece centre is crucial in centreless grinding because it determines the stability and accuracy of the process. The workpiece centre should be located above the line joining the two wheel centres for the following reasons:

1. Stability: Placing the workpiece centre above the line ensures that the workpiece is properly supported by the workblade and the regulating wheel. This positioning prevents any tilting or instability during the grinding process, resulting in a more stable and controlled grinding operation.

2. Accuracy: The workpiece centre needs to be accurately positioned to achieve precise grinding results. Placing it above the line allows for better control of the workpiece rotation and feed rate, leading to accurate material removal and consistent grinding results.

3. Uniform Grinding: When the workpiece centre is above the line, it ensures that the grinding action is evenly distributed across the workpiece surface. This helps in achieving uniform material removal and prevents uneven grinding or surface irregularities.

4. Wheel Wear: Positioning the workpiece centre above the line also helps in minimizing wheel wear. It allows for better contact between the grinding wheel and the workpiece, reducing the chances of wheel glazing or uneven wear.

In conclusion, in centreless grinding, the workpiece centre should be positioned above the line joining the two wheel centres for stability, accuracy, uniform grinding, and to minimize wheel wear. This positioning ensures optimal performance and better control over the grinding process, resulting in high-quality finished products.

|

Explore Courses for Mechanical Engineering exam

|

|

Question Description

In centre-less grinding, the work piece centre bea)above the line joining the two wheel centresb)below the line joining the two wheel centresc)on the line joining the two wheel centresd)at the intersection of the line joining the wheel centre with workpiece planeCorrect answer is option 'A'. Can you explain this answer? for Mechanical Engineering 2025 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about In centre-less grinding, the work piece centre bea)above the line joining the two wheel centresb)below the line joining the two wheel centresc)on the line joining the two wheel centresd)at the intersection of the line joining the wheel centre with workpiece planeCorrect answer is option 'A'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2025 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for In centre-less grinding, the work piece centre bea)above the line joining the two wheel centresb)below the line joining the two wheel centresc)on the line joining the two wheel centresd)at the intersection of the line joining the wheel centre with workpiece planeCorrect answer is option 'A'. Can you explain this answer?.

In centre-less grinding, the work piece centre bea)above the line joining the two wheel centresb)below the line joining the two wheel centresc)on the line joining the two wheel centresd)at the intersection of the line joining the wheel centre with workpiece planeCorrect answer is option 'A'. Can you explain this answer? for Mechanical Engineering 2025 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about In centre-less grinding, the work piece centre bea)above the line joining the two wheel centresb)below the line joining the two wheel centresc)on the line joining the two wheel centresd)at the intersection of the line joining the wheel centre with workpiece planeCorrect answer is option 'A'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2025 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for In centre-less grinding, the work piece centre bea)above the line joining the two wheel centresb)below the line joining the two wheel centresc)on the line joining the two wheel centresd)at the intersection of the line joining the wheel centre with workpiece planeCorrect answer is option 'A'. Can you explain this answer?.

Solutions for In centre-less grinding, the work piece centre bea)above the line joining the two wheel centresb)below the line joining the two wheel centresc)on the line joining the two wheel centresd)at the intersection of the line joining the wheel centre with workpiece planeCorrect answer is option 'A'. Can you explain this answer? in English & in Hindi are available as part of our courses for Mechanical Engineering.

Download more important topics, notes, lectures and mock test series for Mechanical Engineering Exam by signing up for free.

Here you can find the meaning of In centre-less grinding, the work piece centre bea)above the line joining the two wheel centresb)below the line joining the two wheel centresc)on the line joining the two wheel centresd)at the intersection of the line joining the wheel centre with workpiece planeCorrect answer is option 'A'. Can you explain this answer? defined & explained in the simplest way possible. Besides giving the explanation of

In centre-less grinding, the work piece centre bea)above the line joining the two wheel centresb)below the line joining the two wheel centresc)on the line joining the two wheel centresd)at the intersection of the line joining the wheel centre with workpiece planeCorrect answer is option 'A'. Can you explain this answer?, a detailed solution for In centre-less grinding, the work piece centre bea)above the line joining the two wheel centresb)below the line joining the two wheel centresc)on the line joining the two wheel centresd)at the intersection of the line joining the wheel centre with workpiece planeCorrect answer is option 'A'. Can you explain this answer? has been provided alongside types of In centre-less grinding, the work piece centre bea)above the line joining the two wheel centresb)below the line joining the two wheel centresc)on the line joining the two wheel centresd)at the intersection of the line joining the wheel centre with workpiece planeCorrect answer is option 'A'. Can you explain this answer? theory, EduRev gives you an

ample number of questions to practice In centre-less grinding, the work piece centre bea)above the line joining the two wheel centresb)below the line joining the two wheel centresc)on the line joining the two wheel centresd)at the intersection of the line joining the wheel centre with workpiece planeCorrect answer is option 'A'. Can you explain this answer? tests, examples and also practice Mechanical Engineering tests.

|

Explore Courses for Mechanical Engineering exam

|

|

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.