Mechanical Engineering Exam > Mechanical Engineering Questions > In orthogonal turning of a cylindrical tube o...

Start Learning for Free

In orthogonal turning of a cylindrical tube of wall thickness 5 mm, the axial and the tangential cutting forces were measured at 1259 N and 1601 N, respectively. The measured chip thickness after machining was found to be 0.3 mm. The rake angle was 10° and the axial feed was 100 mm/min. The rotational speed of the spindle was 1000 rpm. Assuming the material to be perfectly plastic and merchant’s first solution, the shear strength of the martial is closest to

[ME 2019,Set-1]

- a)875 M Pa

- b)200 M Pa

- c)722 M Pa

- d)920 M Pa

Correct answer is option 'C'. Can you explain this answer?

| FREE This question is part of | Download PDF Attempt this Test |

Verified Answer

In orthogonal turning of a cylindrical tube of wall thickness 5 mm, th...

For, orthogonal turning,

λ = 90°, Fc = 1601 N

Chip thickness 'tc' = 0.3,

Ft = 1259 N.

N = 1000 r pm , α = 10 m

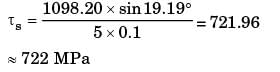

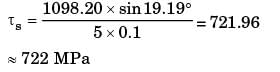

= 1601 x cos19.19° - 1259 sin 19.19

= 1098.20 N

λ = 90°, Fc = 1601 N

Chip thickness 'tc' = 0.3,

Ft = 1259 N.

N = 1000 r pm , α = 10 m

= 1601 x cos19.19° - 1259 sin 19.19

= 1098.20 N

Most Upvoted Answer

In orthogonal turning of a cylindrical tube of wall thickness 5 mm, th...

The rake angle is given as 10 degrees.

Attention Mechanical Engineering Students!

To make sure you are not studying endlessly, EduRev has designed Mechanical Engineering study material, with Structured Courses, Videos, & Test Series. Plus get personalized analysis, doubt solving and improvement plans to achieve a great score in Mechanical Engineering.

|

Explore Courses for Mechanical Engineering exam

|

|

Similar Mechanical Engineering Doubts

In orthogonal turning of a cylindrical tube of wall thickness 5 mm, the axial and the tangential cutting forces were measured at 1259 N and 1601 N, respectively. The measured chip thickness after machining was found to be 0.3 mm. The rake angle was 10° and the axial feed was 100 mm/min. The rotational speed of the spindle was 1000 rpm. Assuming the material to be perfectly plastic and merchant’s first solution, the shear strength of the martial is closest to[ME 2019,Set-1]a)875 M Pab)200 M Pac)722 M Pad)920 M PaCorrect answer is option 'C'. Can you explain this answer?

Question Description

In orthogonal turning of a cylindrical tube of wall thickness 5 mm, the axial and the tangential cutting forces were measured at 1259 N and 1601 N, respectively. The measured chip thickness after machining was found to be 0.3 mm. The rake angle was 10° and the axial feed was 100 mm/min. The rotational speed of the spindle was 1000 rpm. Assuming the material to be perfectly plastic and merchant’s first solution, the shear strength of the martial is closest to[ME 2019,Set-1]a)875 M Pab)200 M Pac)722 M Pad)920 M PaCorrect answer is option 'C'. Can you explain this answer? for Mechanical Engineering 2024 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about In orthogonal turning of a cylindrical tube of wall thickness 5 mm, the axial and the tangential cutting forces were measured at 1259 N and 1601 N, respectively. The measured chip thickness after machining was found to be 0.3 mm. The rake angle was 10° and the axial feed was 100 mm/min. The rotational speed of the spindle was 1000 rpm. Assuming the material to be perfectly plastic and merchant’s first solution, the shear strength of the martial is closest to[ME 2019,Set-1]a)875 M Pab)200 M Pac)722 M Pad)920 M PaCorrect answer is option 'C'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for In orthogonal turning of a cylindrical tube of wall thickness 5 mm, the axial and the tangential cutting forces were measured at 1259 N and 1601 N, respectively. The measured chip thickness after machining was found to be 0.3 mm. The rake angle was 10° and the axial feed was 100 mm/min. The rotational speed of the spindle was 1000 rpm. Assuming the material to be perfectly plastic and merchant’s first solution, the shear strength of the martial is closest to[ME 2019,Set-1]a)875 M Pab)200 M Pac)722 M Pad)920 M PaCorrect answer is option 'C'. Can you explain this answer?.

In orthogonal turning of a cylindrical tube of wall thickness 5 mm, the axial and the tangential cutting forces were measured at 1259 N and 1601 N, respectively. The measured chip thickness after machining was found to be 0.3 mm. The rake angle was 10° and the axial feed was 100 mm/min. The rotational speed of the spindle was 1000 rpm. Assuming the material to be perfectly plastic and merchant’s first solution, the shear strength of the martial is closest to[ME 2019,Set-1]a)875 M Pab)200 M Pac)722 M Pad)920 M PaCorrect answer is option 'C'. Can you explain this answer? for Mechanical Engineering 2024 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about In orthogonal turning of a cylindrical tube of wall thickness 5 mm, the axial and the tangential cutting forces were measured at 1259 N and 1601 N, respectively. The measured chip thickness after machining was found to be 0.3 mm. The rake angle was 10° and the axial feed was 100 mm/min. The rotational speed of the spindle was 1000 rpm. Assuming the material to be perfectly plastic and merchant’s first solution, the shear strength of the martial is closest to[ME 2019,Set-1]a)875 M Pab)200 M Pac)722 M Pad)920 M PaCorrect answer is option 'C'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for In orthogonal turning of a cylindrical tube of wall thickness 5 mm, the axial and the tangential cutting forces were measured at 1259 N and 1601 N, respectively. The measured chip thickness after machining was found to be 0.3 mm. The rake angle was 10° and the axial feed was 100 mm/min. The rotational speed of the spindle was 1000 rpm. Assuming the material to be perfectly plastic and merchant’s first solution, the shear strength of the martial is closest to[ME 2019,Set-1]a)875 M Pab)200 M Pac)722 M Pad)920 M PaCorrect answer is option 'C'. Can you explain this answer?.

Solutions for In orthogonal turning of a cylindrical tube of wall thickness 5 mm, the axial and the tangential cutting forces were measured at 1259 N and 1601 N, respectively. The measured chip thickness after machining was found to be 0.3 mm. The rake angle was 10° and the axial feed was 100 mm/min. The rotational speed of the spindle was 1000 rpm. Assuming the material to be perfectly plastic and merchant’s first solution, the shear strength of the martial is closest to[ME 2019,Set-1]a)875 M Pab)200 M Pac)722 M Pad)920 M PaCorrect answer is option 'C'. Can you explain this answer? in English & in Hindi are available as part of our courses for Mechanical Engineering.

Download more important topics, notes, lectures and mock test series for Mechanical Engineering Exam by signing up for free.

Here you can find the meaning of In orthogonal turning of a cylindrical tube of wall thickness 5 mm, the axial and the tangential cutting forces were measured at 1259 N and 1601 N, respectively. The measured chip thickness after machining was found to be 0.3 mm. The rake angle was 10° and the axial feed was 100 mm/min. The rotational speed of the spindle was 1000 rpm. Assuming the material to be perfectly plastic and merchant’s first solution, the shear strength of the martial is closest to[ME 2019,Set-1]a)875 M Pab)200 M Pac)722 M Pad)920 M PaCorrect answer is option 'C'. Can you explain this answer? defined & explained in the simplest way possible. Besides giving the explanation of

In orthogonal turning of a cylindrical tube of wall thickness 5 mm, the axial and the tangential cutting forces were measured at 1259 N and 1601 N, respectively. The measured chip thickness after machining was found to be 0.3 mm. The rake angle was 10° and the axial feed was 100 mm/min. The rotational speed of the spindle was 1000 rpm. Assuming the material to be perfectly plastic and merchant’s first solution, the shear strength of the martial is closest to[ME 2019,Set-1]a)875 M Pab)200 M Pac)722 M Pad)920 M PaCorrect answer is option 'C'. Can you explain this answer?, a detailed solution for In orthogonal turning of a cylindrical tube of wall thickness 5 mm, the axial and the tangential cutting forces were measured at 1259 N and 1601 N, respectively. The measured chip thickness after machining was found to be 0.3 mm. The rake angle was 10° and the axial feed was 100 mm/min. The rotational speed of the spindle was 1000 rpm. Assuming the material to be perfectly plastic and merchant’s first solution, the shear strength of the martial is closest to[ME 2019,Set-1]a)875 M Pab)200 M Pac)722 M Pad)920 M PaCorrect answer is option 'C'. Can you explain this answer? has been provided alongside types of In orthogonal turning of a cylindrical tube of wall thickness 5 mm, the axial and the tangential cutting forces were measured at 1259 N and 1601 N, respectively. The measured chip thickness after machining was found to be 0.3 mm. The rake angle was 10° and the axial feed was 100 mm/min. The rotational speed of the spindle was 1000 rpm. Assuming the material to be perfectly plastic and merchant’s first solution, the shear strength of the martial is closest to[ME 2019,Set-1]a)875 M Pab)200 M Pac)722 M Pad)920 M PaCorrect answer is option 'C'. Can you explain this answer? theory, EduRev gives you an

ample number of questions to practice In orthogonal turning of a cylindrical tube of wall thickness 5 mm, the axial and the tangential cutting forces were measured at 1259 N and 1601 N, respectively. The measured chip thickness after machining was found to be 0.3 mm. The rake angle was 10° and the axial feed was 100 mm/min. The rotational speed of the spindle was 1000 rpm. Assuming the material to be perfectly plastic and merchant’s first solution, the shear strength of the martial is closest to[ME 2019,Set-1]a)875 M Pab)200 M Pac)722 M Pad)920 M PaCorrect answer is option 'C'. Can you explain this answer? tests, examples and also practice Mechanical Engineering tests.

|

Explore Courses for Mechanical Engineering exam

|

|

Suggested Free Tests

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.