Mechanical Engineering Exam > Mechanical Engineering Questions > The process of reheating the martensitic stee...

Start Learning for Free

The process of reheating the martensitic steel to reduce its brittleness without any significant loss in its hardness is

[ME 2014, Set-1]

- a)normalising

- b)annealing

- c)quenching

- d)tempering

Correct answer is option 'D'. Can you explain this answer?

| FREE This question is part of | Download PDF Attempt this Test |

Verified Answer

The process of reheating the martensitic steel to reduce its brittlene...

Most Upvoted Answer

The process of reheating the martensitic steel to reduce its brittlene...

The Process of Reheating Martensitic Steel to Reduce Brittleness without Significant Loss in Hardness: Tempering

Introduction

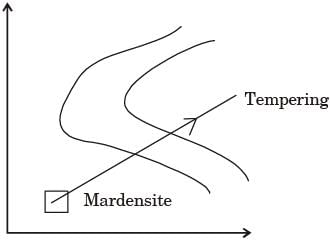

Martensitic steel is a type of steel that has been hardened through a process called quenching, which involves rapid cooling from a high temperature. This results in a steel with high hardness but also brittleness. To reduce the brittleness and improve its toughness while maintaining a certain level of hardness, the martensitic steel is reheated in a process called tempering.

Explanation

Tempering is a heat treatment process that involves reheating the hardened martensitic steel to a temperature below its lower critical point. This temperature is typically between 200-600°C, depending on the desired properties and the specific composition of the steel. The steel is held at this temperature for a specific period of time, typically ranging from a few minutes to a few hours, and then cooled down slowly.

Key Points

The process of reheating the martensitic steel to reduce its brittleness without any significant loss in its hardness is called tempering. Here are some key points to understand this process:

1. Purpose: The primary purpose of tempering is to reduce the brittleness of the martensitic steel while maintaining its hardness. This is achieved by relieving the internal stresses generated during quenching and by allowing the microstructure to undergo controlled changes.

2. Reduction in brittleness: During quenching, the martensitic steel undergoes a rapid transformation from austenite to a hard and brittle martensite phase. This high hardness makes the steel prone to cracking and failure under impact or sudden loads. Tempering helps to reduce this brittleness by allowing the transformation of some of the martensite into a more ductile structure, such as tempered martensite or troostite.

3. Controlled microstructural changes: The reheating during tempering causes the diffusion of carbon atoms within the steel, which leads to the precipitation of fine carbides. These carbides act as obstacles to dislocation movement, making the steel tougher and less prone to brittle fracture. The exact microstructural changes depend on the tempering temperature and time.

4. Hardness retention: While tempering reduces brittleness, it is important to note that it also causes a slight reduction in hardness. However, the aim of tempering is to balance the hardness and toughness of the steel, so the loss in hardness is minimal and acceptable. The specific tempering temperature and time are chosen to achieve the desired balance between hardness and toughness.

5. Applications: Tempering is commonly used in the heat treatment of various steels, including tool steels, high-strength steels, and some types of stainless steels. It is an essential step in achieving the desired mechanical properties for these materials.

Conclusion

In conclusion, the process of reheating martensitic steel to reduce its brittleness without significant loss in hardness is called tempering. This heat treatment process helps to improve the toughness and ductility of the steel while maintaining a certain level of hardness. Tempering is a critical step in achieving the desired mechanical properties for martensitic steel and is widely applied in various industries.

Introduction

Martensitic steel is a type of steel that has been hardened through a process called quenching, which involves rapid cooling from a high temperature. This results in a steel with high hardness but also brittleness. To reduce the brittleness and improve its toughness while maintaining a certain level of hardness, the martensitic steel is reheated in a process called tempering.

Explanation

Tempering is a heat treatment process that involves reheating the hardened martensitic steel to a temperature below its lower critical point. This temperature is typically between 200-600°C, depending on the desired properties and the specific composition of the steel. The steel is held at this temperature for a specific period of time, typically ranging from a few minutes to a few hours, and then cooled down slowly.

Key Points

The process of reheating the martensitic steel to reduce its brittleness without any significant loss in its hardness is called tempering. Here are some key points to understand this process:

1. Purpose: The primary purpose of tempering is to reduce the brittleness of the martensitic steel while maintaining its hardness. This is achieved by relieving the internal stresses generated during quenching and by allowing the microstructure to undergo controlled changes.

2. Reduction in brittleness: During quenching, the martensitic steel undergoes a rapid transformation from austenite to a hard and brittle martensite phase. This high hardness makes the steel prone to cracking and failure under impact or sudden loads. Tempering helps to reduce this brittleness by allowing the transformation of some of the martensite into a more ductile structure, such as tempered martensite or troostite.

3. Controlled microstructural changes: The reheating during tempering causes the diffusion of carbon atoms within the steel, which leads to the precipitation of fine carbides. These carbides act as obstacles to dislocation movement, making the steel tougher and less prone to brittle fracture. The exact microstructural changes depend on the tempering temperature and time.

4. Hardness retention: While tempering reduces brittleness, it is important to note that it also causes a slight reduction in hardness. However, the aim of tempering is to balance the hardness and toughness of the steel, so the loss in hardness is minimal and acceptable. The specific tempering temperature and time are chosen to achieve the desired balance between hardness and toughness.

5. Applications: Tempering is commonly used in the heat treatment of various steels, including tool steels, high-strength steels, and some types of stainless steels. It is an essential step in achieving the desired mechanical properties for these materials.

Conclusion

In conclusion, the process of reheating martensitic steel to reduce its brittleness without significant loss in hardness is called tempering. This heat treatment process helps to improve the toughness and ductility of the steel while maintaining a certain level of hardness. Tempering is a critical step in achieving the desired mechanical properties for martensitic steel and is widely applied in various industries.

Attention Mechanical Engineering Students!

To make sure you are not studying endlessly, EduRev has designed Mechanical Engineering study material, with Structured Courses, Videos, & Test Series. Plus get personalized analysis, doubt solving and improvement plans to achieve a great score in Mechanical Engineering.

|

Explore Courses for Mechanical Engineering exam

|

|

Similar Mechanical Engineering Doubts

The process of reheating the martensitic steel to reduce its brittleness without any significant loss in its hardness is[ME 2014, Set-1]a)normalisingb)annealingc)quenchingd)temperingCorrect answer is option 'D'. Can you explain this answer?

Question Description

The process of reheating the martensitic steel to reduce its brittleness without any significant loss in its hardness is[ME 2014, Set-1]a)normalisingb)annealingc)quenchingd)temperingCorrect answer is option 'D'. Can you explain this answer? for Mechanical Engineering 2024 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about The process of reheating the martensitic steel to reduce its brittleness without any significant loss in its hardness is[ME 2014, Set-1]a)normalisingb)annealingc)quenchingd)temperingCorrect answer is option 'D'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for The process of reheating the martensitic steel to reduce its brittleness without any significant loss in its hardness is[ME 2014, Set-1]a)normalisingb)annealingc)quenchingd)temperingCorrect answer is option 'D'. Can you explain this answer?.

The process of reheating the martensitic steel to reduce its brittleness without any significant loss in its hardness is[ME 2014, Set-1]a)normalisingb)annealingc)quenchingd)temperingCorrect answer is option 'D'. Can you explain this answer? for Mechanical Engineering 2024 is part of Mechanical Engineering preparation. The Question and answers have been prepared according to the Mechanical Engineering exam syllabus. Information about The process of reheating the martensitic steel to reduce its brittleness without any significant loss in its hardness is[ME 2014, Set-1]a)normalisingb)annealingc)quenchingd)temperingCorrect answer is option 'D'. Can you explain this answer? covers all topics & solutions for Mechanical Engineering 2024 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for The process of reheating the martensitic steel to reduce its brittleness without any significant loss in its hardness is[ME 2014, Set-1]a)normalisingb)annealingc)quenchingd)temperingCorrect answer is option 'D'. Can you explain this answer?.

Solutions for The process of reheating the martensitic steel to reduce its brittleness without any significant loss in its hardness is[ME 2014, Set-1]a)normalisingb)annealingc)quenchingd)temperingCorrect answer is option 'D'. Can you explain this answer? in English & in Hindi are available as part of our courses for Mechanical Engineering.

Download more important topics, notes, lectures and mock test series for Mechanical Engineering Exam by signing up for free.

Here you can find the meaning of The process of reheating the martensitic steel to reduce its brittleness without any significant loss in its hardness is[ME 2014, Set-1]a)normalisingb)annealingc)quenchingd)temperingCorrect answer is option 'D'. Can you explain this answer? defined & explained in the simplest way possible. Besides giving the explanation of

The process of reheating the martensitic steel to reduce its brittleness without any significant loss in its hardness is[ME 2014, Set-1]a)normalisingb)annealingc)quenchingd)temperingCorrect answer is option 'D'. Can you explain this answer?, a detailed solution for The process of reheating the martensitic steel to reduce its brittleness without any significant loss in its hardness is[ME 2014, Set-1]a)normalisingb)annealingc)quenchingd)temperingCorrect answer is option 'D'. Can you explain this answer? has been provided alongside types of The process of reheating the martensitic steel to reduce its brittleness without any significant loss in its hardness is[ME 2014, Set-1]a)normalisingb)annealingc)quenchingd)temperingCorrect answer is option 'D'. Can you explain this answer? theory, EduRev gives you an

ample number of questions to practice The process of reheating the martensitic steel to reduce its brittleness without any significant loss in its hardness is[ME 2014, Set-1]a)normalisingb)annealingc)quenchingd)temperingCorrect answer is option 'D'. Can you explain this answer? tests, examples and also practice Mechanical Engineering tests.

|

Explore Courses for Mechanical Engineering exam

|

|

Suggested Free Tests

Signup for Free!

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.