Class 9 Exam > Class 9 Questions > What is difference between thermoplastic and ...

Start Learning for Free

What is difference between thermoplastic and thermosetting?

Most Upvoted Answer

What is difference between thermoplastic and thermosetting?

Community Answer

What is difference between thermoplastic and thermosetting?

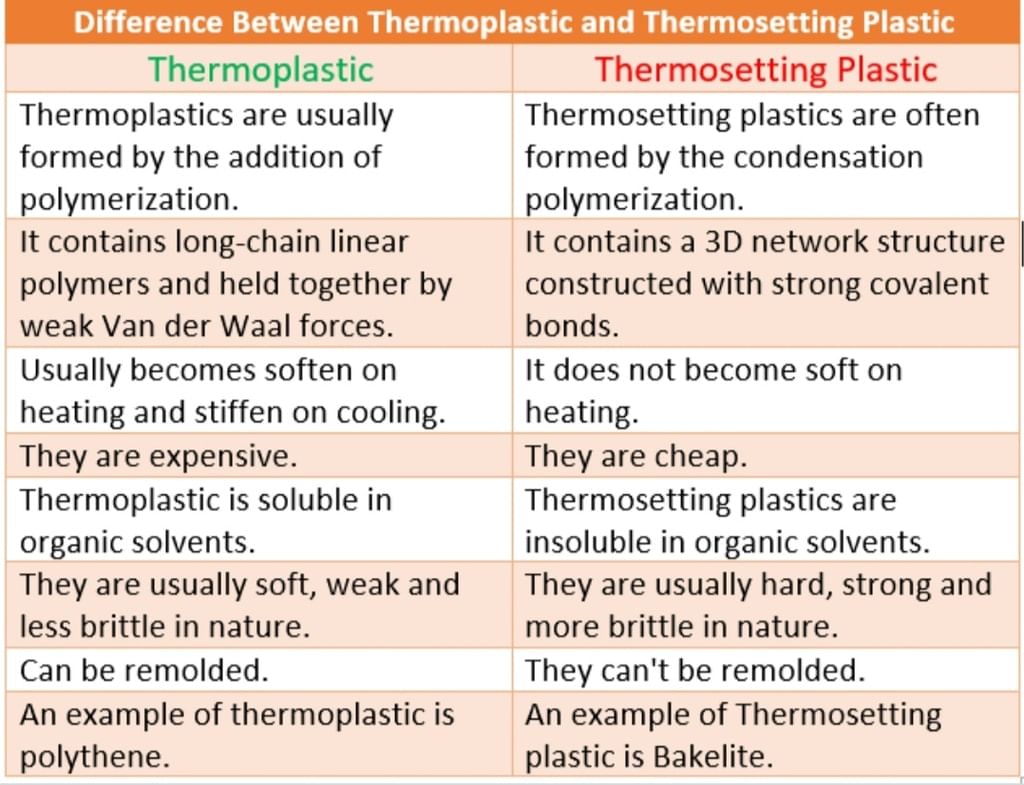

Thermoplastic and thermosetting are two different types of polymers that are used extensively in various industries. The primary difference between the two is their response to heat.

Thermoplastic

Thermoplastics are polymers that can be melted and re-molded multiple times without undergoing any significant chemical change. This means that they can be heated and molded into different shapes, and then cooled and hardened to retain the new shape. Some of the key features of thermoplastics include:

• Can be easily melted and re-molded

• Soften when heated and harden when cooled

• Examples include PVC, Nylon, and Polyethylene

• Used in a wide range of industries such as packaging, automotive, and construction

Thermosetting

Thermosetting polymers are different from thermoplastics in that they undergo a chemical change when they are heated. Once they are set, they cannot be re-molded or softened by heat. Some of the key features of thermosetting polymers include:

• Cannot be re-molded once set

• Hard and rigid

• Examples include Bakelite and epoxy resin

• Used in a wide range of industries such as electronics, aerospace, and automotive

Key Differences

1. Response to heat: Thermoplastics can be melted and re-molded multiple times without undergoing any significant chemical change, whereas thermosetting polymers undergo a chemical change when heated and cannot be re-molded.

2. Chemical structure: Thermoplastics have a linear or branched structure, while thermosetting polymers have a cross-linked structure.

3. Hardness: Thermoplastics are generally softer and more flexible, whereas thermosetting polymers are hard and rigid.

4. Applications: Thermoplastics are used in a wide range of industries such as packaging, automotive, and construction, while thermosetting polymers are used in industries such as electronics, aerospace, and automotive.

In conclusion, understanding the difference between thermoplastic and thermosetting polymers can help in choosing the right material for a specific application. While thermoplastics are more versatile and can be re-molded multiple times, thermosetting polymers provide superior hardness and rigidity.

Thermoplastic

Thermoplastics are polymers that can be melted and re-molded multiple times without undergoing any significant chemical change. This means that they can be heated and molded into different shapes, and then cooled and hardened to retain the new shape. Some of the key features of thermoplastics include:

• Can be easily melted and re-molded

• Soften when heated and harden when cooled

• Examples include PVC, Nylon, and Polyethylene

• Used in a wide range of industries such as packaging, automotive, and construction

Thermosetting

Thermosetting polymers are different from thermoplastics in that they undergo a chemical change when they are heated. Once they are set, they cannot be re-molded or softened by heat. Some of the key features of thermosetting polymers include:

• Cannot be re-molded once set

• Hard and rigid

• Examples include Bakelite and epoxy resin

• Used in a wide range of industries such as electronics, aerospace, and automotive

Key Differences

1. Response to heat: Thermoplastics can be melted and re-molded multiple times without undergoing any significant chemical change, whereas thermosetting polymers undergo a chemical change when heated and cannot be re-molded.

2. Chemical structure: Thermoplastics have a linear or branched structure, while thermosetting polymers have a cross-linked structure.

3. Hardness: Thermoplastics are generally softer and more flexible, whereas thermosetting polymers are hard and rigid.

4. Applications: Thermoplastics are used in a wide range of industries such as packaging, automotive, and construction, while thermosetting polymers are used in industries such as electronics, aerospace, and automotive.

In conclusion, understanding the difference between thermoplastic and thermosetting polymers can help in choosing the right material for a specific application. While thermoplastics are more versatile and can be re-molded multiple times, thermosetting polymers provide superior hardness and rigidity.

|

Explore Courses for Class 9 exam

|

|

Similar Class 9 Doubts

What is difference between thermoplastic and thermosetting?

Question Description

What is difference between thermoplastic and thermosetting? for Class 9 2025 is part of Class 9 preparation. The Question and answers have been prepared according to the Class 9 exam syllabus. Information about What is difference between thermoplastic and thermosetting? covers all topics & solutions for Class 9 2025 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for What is difference between thermoplastic and thermosetting?.

What is difference between thermoplastic and thermosetting? for Class 9 2025 is part of Class 9 preparation. The Question and answers have been prepared according to the Class 9 exam syllabus. Information about What is difference between thermoplastic and thermosetting? covers all topics & solutions for Class 9 2025 Exam. Find important definitions, questions, meanings, examples, exercises and tests below for What is difference between thermoplastic and thermosetting?.

Solutions for What is difference between thermoplastic and thermosetting? in English & in Hindi are available as part of our courses for Class 9.

Download more important topics, notes, lectures and mock test series for Class 9 Exam by signing up for free.

Here you can find the meaning of What is difference between thermoplastic and thermosetting? defined & explained in the simplest way possible. Besides giving the explanation of

What is difference between thermoplastic and thermosetting?, a detailed solution for What is difference between thermoplastic and thermosetting? has been provided alongside types of What is difference between thermoplastic and thermosetting? theory, EduRev gives you an

ample number of questions to practice What is difference between thermoplastic and thermosetting? tests, examples and also practice Class 9 tests.

|

Explore Courses for Class 9 exam

|

|

Signup to solve all Doubts

Signup to see your scores go up within 7 days! Learn & Practice with 1000+ FREE Notes, Videos & Tests.